Diffraction Grating - Definition, Formula and Solved Examples - refraction grating

The diffraction limit is essentially the resolution limit that is imposed on an optical system by the wave nature of light and the process of diffraction. To understand this, let’s look at what diffraction does when light shines through an opening.

Diffraction-limited spot size

This article— part two of our series on “Avoid Optical Pitfalls”— will look at what the diffraction limited is, how to calculate it, and how it can affect the resolution of high performance optics.

Abbediffractionlimit

Apollo Optical Systems is a leader in optical surface finishes and performance with both plastic and metals using single-point diamond turning. The process can fabricate small quantities of custom optical prototypes before mass production.

There’s a mistake people often make when assessing the performance of a microscope or telescope— forgetting the diffraction limit. It is a theoretical limiting factor governing the maximum obtainable resolution of an optical system. When we leave it out of our calculations we may end up with very unrealistic expectations.

Diffractionlimit formula

How does this relate to the limited diffraction? Imagine a perfect lens with no aberrations, not limited by design or manufacturing flaw. Each point light source will create an airy disk, and when an image is properly resolved the airy disks do not overlap. When the outer rings merge, the sensor will be diffraction limited. The only way to improve resolution will be to increase the numerical aperture. But when the center of each airy disk merges, we’ve reached the limit of resolution; the diffraction cutoff frequency. When you’ve reached the limit of resolution you’ll not be able to resolve further even by increasing aperture.

These surfaces have at least one optical surface of non-constant radius of curvature. These parameters can be set, and the machine can generate the coordinates according to the radius of the diamond tool to allow an aspherical surface to be cut. This is one of the most common surface types for single-point diamond turning.

Dr. Dale Buralli has served as the Chief Scientist for Apollo Optical Systems since 2003. In this role, Dr. Buralli is responsible for the design and optical modeling of various optical systems. These systems include virtual or augmented reality, ophthalmic and other imaging or illumination systems. Additionally, he provides support for optical tooling of lens molds and prototypes, including the development of custom software for both production and metrology. Dr. Buralli got his Ph.D. in optics from the University of Rochester in 1991. Now he is an Adjunct Professor of Optics at the University of Rochester’s Institute of Optics.

Once the process is complete, and the surface has been fabricated, the workpiece is removed from the spindle to be measured. The surface is measured by both a standard interferometer to determine the surface shape and an interferometric microscope to test the roughness of the surface.

Diffraction limitedmeaning

No; the passage of light through the atmosphere introduces significant distortions that limit performance to a lower resolution than provided by diffraction limited observation.

For visible light microscopy, the diffraction limit— the smallest detail that can be resolved— is about 200-250 nanometers.

VIETNAM:Alpha Industrial Park, Tu ThonVillage, Yen My District, HungYen Province 17721+84 221-730-8668sales-vn@avantierinc.com

These optical shapes or surfaces are designed with little to no symmetry. Manufacturing freeform is similar to manufacturing a complex aspherical surface.

diffraction-limited spot size formula

Optical elements created by single-point diamond turning are often used for optical assemblies in video projectors, missile guidance systems, telescopes, lasers, and other systems and devices. Most single-point diamond turning is done with the aid of computer numerical control (CNC) machine tools.

There are 12 screws on the side of the spindle. Adjusting the position of the screws changes the spindle’s balance, ensuring it’s moving smoothly during the cutting process.

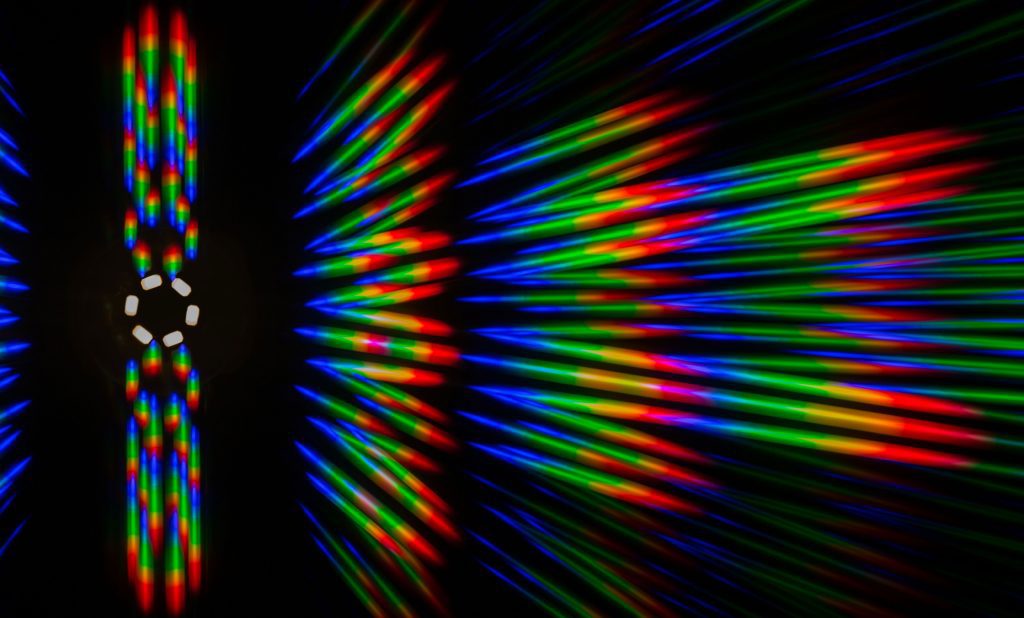

Any lens has a finite aperture, and when light passes through an aperture— no matter its size— diffraction will occur. We call a diffraction pattern an Airy disk, and it is disk shaped. There is a bright area in the center surrounded by concentric rings, and each ring decreases in brightness as you move out. This Airy disk is the key to the diffraction limit, as it is the Airy disk which is the smallest point to which you can focus a beam of light. We sometimes call this the ‘minimum spot size’ of an optical system.

Apollo Optical Systems combines knowledge and experience with optical design and metrology to ensure a successful final optical element. Contact us today to discuss your custom optics project!

Single-point diamond turning is a process of mechanical machining of precision elements equipped with diamond-tipped tool bits. The process used for single-point diamond turned optics may be applied to the manufacturing of high-quality aspheric optical elements from acrylic, metals, crystals, and other materials.

A nozzle is placed next to the diamond tool. A cooling liquid is needed to cool the contact point when cutting metal. With plastic, air is used to avoid damaging the material.

The radius of the Airy disk depends on two important factors: the wavelength of light and the size of the aperture, and we can estimate it with the equation: Ra = 1.22λ/2Na. In this equation Ra is the airy radius, λ is the wavelength of illuminating light, and Na the numerical aperture.

Diffraction-limited resolution

Also, because of the high accuracy and precision of turning equipment, the surface finishes and errors in form that may be created in the process are tightly controlled and therefore minimized. Single-point diamond turning can also create complex surface geometries, such as off-axis aspheric and freeform surfaces.

As the numerical aperture increases, the radius of the airy disk decreases. In modern optics, the numerical aperture can be as high as 1.4-1.6. The table below shows the diameter of an airy disk for lenses of different apertures when the lens is illuminated with light at 520 nm.

Abbediffractionlimit derivation

Diffraction limitedtelescope

The diffraction limit tells us that there is a limit to the resolution of images we can obtain, no matter how much we improve our optical system. Although this limit is not important for everyday photography or situations in which resolution is already limited by other significant optical aberrations, it is important to microscopy, telescopic, and high resolution photography.

This can be fabricated after extensive design. Lens arrays are difficult to cut and may require special tools or a unique cutting procedure.

We currently have three single-point diamond turning lathes: Two Precitech Optimum 2400 two-axis lathes and one three-axis Precitech Nanoform 200 lathe.

Before cutting, the workpiece must be placed at the center of the spindle to ensure that the rotation axis is the same as the spindle. A gauge is used to detect the centering, then a hammer is used to move the workpiece.

Single-point diamond turning is a manufacturing process that’s used to produce low to moderate volumes of accurate and precise optics, typically for research and development or prototyping.

What is the cutoff frequency of the lens, the diffraction limit? We can calculate it using the same two parameters we used to calculate the radius of our airy disks. The equation is:

This manufacturing method offers several key advantages over other methods. It offers speed of delivery, reduced tooling costs, high accuracy, and sophisticated surface profiles. As a result, the overall manufacturing lead times are much lower.

The tool position must also be aligned before the cutting can begin. The Y axis is aligned using a microscope. If it’s misaligned, the center will leave materials behind. The X axis must be aligned using an interferometer to ensure the correct shape of the workpiece.

Ms.Cici

Ms.Cici

8618319014500

8618319014500