DG8SAQ VNWA SMA Connectors - sma connector adapter sets

Bandpassfilter design

Completely free of charge and without obligation. I am aware that my data/ usage behavior is stored electronically. You can unsubscribe this service at any time in any newsletter, or your consent to the Jos. Schneider Optische Werke GmbH.

Comments Section ... There is pxlmag. The combo body+lens is only available from top view, but I think that's good enough. ... Link. I agree this ...

Feb 4, 2013 — The story Mamet has crafted is perfectly timeless, and Stuart Gordon recognizes this. He has suitably made sure the scenes and the ...

Bandpassfilter calculator

Lumedica focuses on the Healthcare Technology sector. Explore the world of Startups and Venture Investing at OurCrowd.

Improve the performance and accuracy of your machines by using our optical filters. Reduce annoying reflections, minimize unwanted wavelengths, and increase the efficiency of your processes. Our filters are the key to the smooth and efficient operation of your industrial systems. They are durable and robust, ensuring long-term use.

SYNC Program. The SYNC program is open to Teledyne Brown Engineering college interns in their second semester of their junior or senior year, or new hires who ...

We demand the highest standards of materials and manufacturing processes to ensure excellent image quality, starting with the production of the optics. Our standards go beyond the production of individual components. We master the entire production process from raw glass to finished filters and are able to process all common types of glass. Our special coating technologies give the optics or lenses the desired optical properties.

Traffic and surveillance systems use cameras with bandpass filters and image processing to monitor and manage traffic flow and public safety.

Shop Captive Screws - Hex Socket Head Cap, Stainless Steel, SSC, Metric from NBK (SSC-M3X10). MISUMI USA has all of your Captive Screws & Bolts needs ...

Band pass filter circuit

Schneider-Kreuznach magnetron sputtered industrial bandpass filters impress with steep slopes and high transmission at stable cut-on and cut-off wavelengths. The very flat surface makes them ideal for high end inspection systems. Schneider-Kreuznach bandpass filters are RoHS conform. Custom sizes are available on request.

Bioanalytical and medical applications isolate wavelengths with bandpass filters to detect biomolecules and cellular structures.

If you need a customized solution, we are your partner from the kick-off to the Project completion. Our extensive experience and in-depth knowledge of a wide range of applications enables us to provide you with solutions that are perfectly tailored to your needs.

Our bandpass filters are designed to transmit a precisely defined range of wavelengths, making them ideal for a wide range of applications such as spectroscopy or bioanalysis.

This is the result of our decades of experience with extremely tight tolerances. We even go so far as to design and build our own manufacturing and metrology systems if there is no equipment available on the market that is accurate enough. Our customers value us not only for our technical expertise, but also for the dedicated and customer-focused advice we provide. We listen. We answer questions and make recommendations. It is important to us that our customers have all the information they need so that they can make the right decisions and achieve the best possible results. Contact us. We will be happy to advise you.

Where is a bandpass filter used? In industrial applications, optical bandpass filters are used to improve the quality and accuracy of imaging systems such as cameras and microscopes. Bandpass filters are mainly used to eliminate interfering wavelengths. This significantly improves the image quality.

Visit us at any tradeshow or event we attend worldwide! Come with your challenge and let our experts help you find the perfect solution for your apllication.

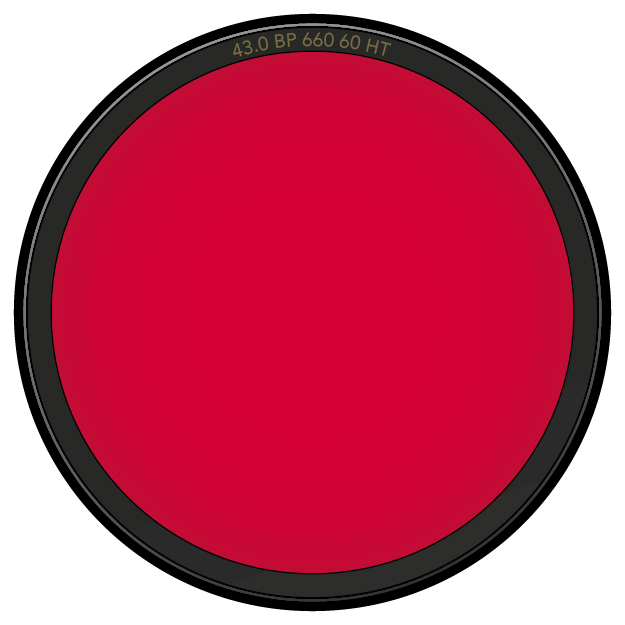

The bandpass 660-60 is an interference filter that blocks all wavelengths except red light in the wavelength range of 660nm. This eliminates unwanted light. The corresponding LED (660 nm) or laser with a wavelength of 660 nm is optimally visible. The steep edges of the filter allow maximum light output from the LED. Necessary light is not lost. The result is a massive increase in contrast and an improvement in image quality.

Opticalbandpassfilter

Defined by 1” (25.4mm) diameter and 32 turns per inch pitch, C-Mount thread is a popular camera mount in machine vision industry. Schneider-Kreuznach offers for most filters a C-Mount option. So that filters can go in any C-Mount based mechanics in vision systems.

The laser produces an intense, highly directional beam of light. If directed, reflected, or focused upon an object, laser light will be partially absorbed, raising the temperature of the surface and/or the interior of the object, potentially causing an alteration or deformation of the material. These properties which have been applied to laser surgery and materials processing can also cause tissue damage. In addition to these obvious thermal effects upon tissue, there can also be photochemical effects when the wavelength of the laser radiation is sufficiently short, i.e., in the ultraviolet or blue region of the spectrum. Today, most high-power lasers are designed to minimize access to laser radiation during normal operation. Lower-power lasers may emit levels of laser light that are not a hazard.

Band pass filter PDF

Our industrial optical bandpass filters are tested to DIN standards to ensure they meet stringent environmental requirements. These tests check the durability of the bandpass filters, their resistance to temperature changes and their ability to withstand exposure to harsh chemicals and other environmental stressors. This ensures that the bandpass filters are up to the task in demanding industrial applications, providing consistent performance and reliability over time.

Laser Institute of America12001 Research Parkway, Suite 210Orlando, FL 32826Toll Free: 800.34.LASERInternational: +1.407.380.1553

SN1-Mount was designed for in machine vision industry popular M30.5x0.5 thread. With its high clear aperture, vignetting can be avoided, even for wide angle applications. The filter is glued into the mount, in order to secure it against vibrations when integrated into robots or production lines. It is ideal to be used in automated fabrication.

What is the function of a bandpass filter? An optical bandpass filter is used in the industry to selectively transmit light of a particular range of wavelengths while blocking others. Schneider-Kreuznach filters are designed to eliminate unwanted wavelengths through a precisely defined structure of very thin layers. This technique achieves transmittances averaging over 95% and very steep slopes.

We are proud of our technical expertise, which we consistently apply to the production of our lenses and optical filters through our high level of vertical integration at our Bad Kreuznach site. Each of the Schneider-Kreuznach products is manufactured with the utmost care and precision to provide you with the best possible performance and reliability.

In addition to the direct hazards to the eye and skin from the laser beam itself, it is also important to address other hazards associated with the use of lasers. These non-beam hazards, in some cases, can be life threatening, e.g. electrocution, fire, and asphyxiation. Table 1 indicates some of the potential non-beam hazards associated with laser usage. Because of the diversity of these hazards, the employment of safety and/or industrial hygiene personnel to effect the hazard evaluations may be necessary.

RFbandpass filters

Our industrial optical filters are rigorously tested to DIN and ISO standards to ensure they meet stringent environmental requirements. These tests evaluate their temperature stability and ability to withstand exposure to harsh chemicals and other environmental stressors. As a result, our filters excel in demanding industrial applications, providing consistent performance and reliability over time.

What is the purpose of the condenser on a light microscope? A. Allows the viewer to change light intensity. B. Focuses the light beam and controls the amount of ...

Our lenses are assembled in dedicated clean rooms that provide a clean and controlled environment and ensure they are free of contaminants. Our qualified staff with many years of experience and expertise perform precise adjustments and calibrate the optics to the highest quality with the lowest tolerances.

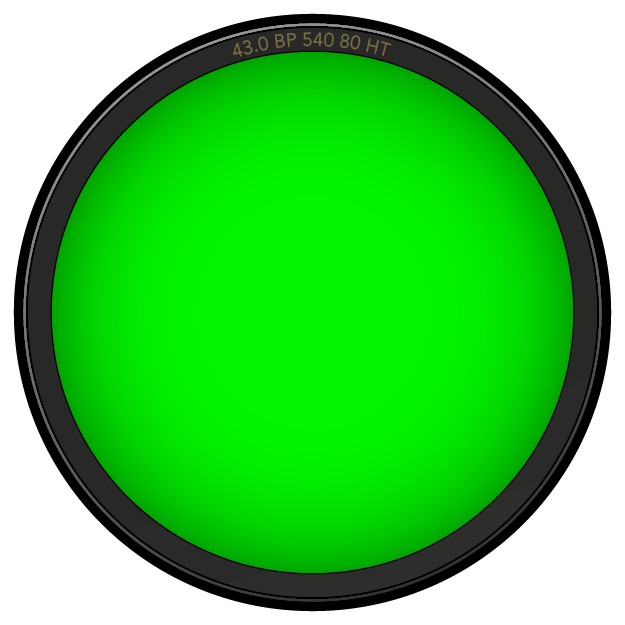

BP 540-80 HT is an interference filter with steep edges and extremely high transmission. The greenish filter is mainly used to filter out interfering light and thus increase the efficiency of measuring devices. The filter is popular in applications such as 3D measurements, monitoring in food production or also in the field of robotics. Depending on the light source used, it significantly increases the accuracy here.

We do mechanical manufacturing in-house. We use the latest technologies and machinery to develop robust and durable filters. With our high-end 5-axis CNC milling machines, we have world-class machining capabilities that give us exceptional precision and flexibility. These powerful milling machines allow us to realize complex geometries and sophisticated contours in the mechanical components of our filters while maintaining high reproducibility. Electroplating is performed in-house under strict environmental conditions, allowing us to customize the surface coatings of our products to meet the specific requirements of our customers.

Another popular application, C-Mounts can easyly be used for, is placing a filter in front of the sensor into the camera. The extension of the back flange distance has to be considered for imaging applications.

LASER is an acronym which stands for Light Amplification by Stimulated Emission of Radiation. The energy generated by the laser is in or near the optical portion of the electromagnetic spectrum (see Figure 1). Energy is amplified to extremely high intensity by an atomic process called stimulated emission. The term "radiation" is often misinterpreted because the term is also used to describe radioactive materials or ionizing radiation. The use of the word in this context, however, refers to an energy transfer. Energy moves from one location to another by conduction, convection, and radiation. The color of laser light is normally expressed in terms of the laser's wavelength. The most common unit used in expressing a laser's wavelength is a nanometer (nm). There are one billion nanometers in one meter.

Fluorescencebandpass filters

Quality and reliability are top priorities at Schneider-Kreuznach. Our filters undergo rigorous quality control to ensure maximum reliability. We use only high quality glass from reputable manufacturers to achieve very low manufacturing tolerances. As a result, our filters are of consistently high quality. Their use allows you to accurately reproduce results, as the filters will perform nearly identically even after years of use.

Schneider-Kreuznach offers a variety of mounts with common thread sizes to fit on most camera lens systems. SH-Mount is the standard, when high flexibility is needed. Filters are held by retainer rings. SH-Mounts are extreme robust.

Our product brochure gives you a comprehensive overview of our entire product range, including all technical information. Whether you are looking for specific products or want to compare different options, our eBrochure has it all in one place.

We design and manufacture both the mechanics and the coatings of our filters at Schneider-Kreuznach. This enables us to produce customized optical filters that meet your exact requirements and guarantee the highest quality standards.

The human body is vulnerable to the output of certain lasers, and under certain circumstances, exposure can result in damage to the eye and skin. Research relating to injury thresholds of the eye and skin has been carried out in order to understand the biological hazards of laser radiation. It is now widely accepted that the human eye is almost always more vulnerable to injury than human skin. The cornea (the clear, outer front surface of the eye's optics), unlike the skin, does not have an external layer of dead cells to protect it from the environment. In the far-ultraviolet and far-infrared regions of the optical spectrum, the cornea absorbs the laser energy and may be damaged. Figure 2 illustrates the absorption characteristics of the eye for different laser wavelength regions. At certain wavelengths in the near-ultraviolet region and in the near-infrared region, the lens of the eye may be vulnerable to injury. Of greatest concern, however, is laser exposure in the retinal hazard region of the optical spectrum, approximately 400 nm (violet light) to 1400 nm (near-infrared) and including the entire visible portion of the optical spectrum. Within this spectral region collimated laser rays are brought to focus on a very tiny spot on the retina. This is illustrated in Figure 3.

Do you have any questions or comments? Then please contact us. We will get back to you as soon as possible. To help us process your request, please fill out all fields marked with *.

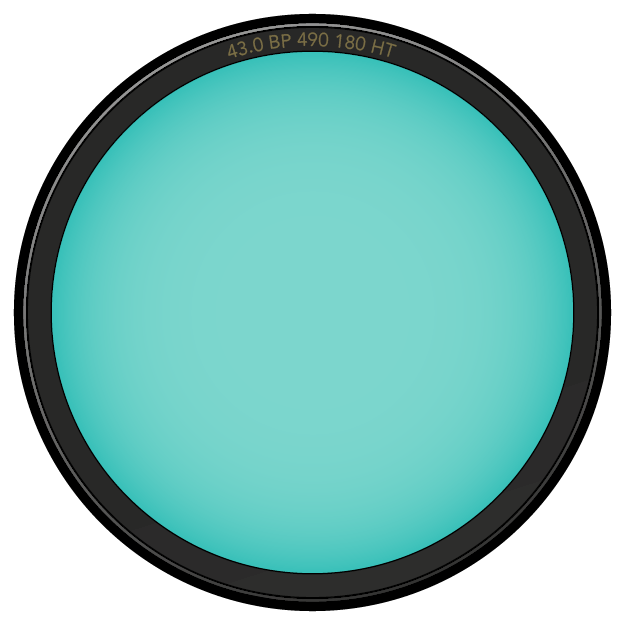

The strengths of the BP 465-70 HT filter are in industrial and medical applications. The standardized manufacturing process ensures consistent quality: One filter is like another! The filters are ideally suited for applications with lasers of 465 nm wavelength, as the bandwidth optimally absorbs a thermally induced migration of the laser.

Looking for more ways to optimize your industrial image processing? Check out our full range of optical filters designed to meet the needs of a wide range of industrial applications. Our selection of high quality optical filters can help you achieve outstanding results in challenging environments while protecting your lens.

Our advice ranges from selecting the right filter to assisting with integration into existing systems. You can count on our experts to provide the best support and find the perfect solution. Our in-depth application knowledge and proven optical expertise enable us to provide customized solutions that combine mechanical robustness, reliability and the highest imaging accuracy.

Band pass filter equation

Discover our wide range of high quality lenses, optical filters and accessories in our interactive eBrochure. Find the detailed compilation of all standard products currently available from Schneider-Kreuznach.

In spectroscopy, spectral lines are analyzed by selectively blocking or transmitting certain wavelengths using bandpass filters.

ShapEager Collections Corp logo. ShapEager Collections Corp. 3.7 stars out ... ShapEager Body Shapers Shapewear and Fajas - Women Capri Full Shaper Open-Bust.

ideal optics peace frames Manufacturers, Factory, Suppliers From China, Established in 2008,guagnzhou HJ eyewear Optical Co.,specialized in the research ...

Jul 10, 2017 — While both paraxial and marginal rays are parallel to the principal axis, the basic difference lies in the distance between them and the ...

In order for the worst case exposure to occur, an individual's eye must be focussed at a distance and a direct beam or specular (mirror-like) reflection must enter the eye. The light entering the eye from a collimated beam in the retinal hazard region is concentrated by a factor of 100,000 times when it strikes the retina. Therefore, a visible, 10 milliwatt/cm2 laser beam would result in a 1000 watt/cm2 exposure to the retina, which is more than enough power density (irradiance) to cause damage. If the eye is not focussed at a distance or if the beam is reflected from a diffuse surface (not mirror-like), much higher levels of laser radiation would be necessary to cause injury. Likewise, since this ocular focussing effect does not apply to the skin, the skin is far less vulnerable to injury from these wavelengths.

As a family owned company, we are passionate and committed to our customers and their success. You can expect long-term relationships based on trust and shared goals with us.

Thorlabs' full line of optical fiber and fiber optic components are presented here. This includes our industry-leading selection of bare optical fiber and fiber ...

Our test technology and quality assurance reflect our high quality standards. We use state-of-the-art technologies such as interferometers and 3D coordinate measurement technology to test the lenses we manufacture to ensure they meet the highest standards. Our ISO 9001 certified processes, metrology rooms and procedures ensure consistent and reliable production to meet our customers' high expectations.

Ever since the foundation in 1913 our staff have been perfecting our knowledge and technologies to bring you the best products in optics. Our manufacturing facilities in Bad Kreuznach, Germany, guarantee outstanding quality – Made in Germany. We continuously invest in our state-of-the-art machinery and in the education and training of our staff. Select your perfect filter from our large portfolio of optical filters.

If the eye is not focussed at a distance or if the beam is reflected from a diffuse surface (not mirror-like), much higher levels of laser radiation would be necessary to cause injury. Likewise, since this ocular focussing effect does not apply to the skin, the skin is far less vulnerable to injury from these wavelengths.

Our sales and engineering professionals provide customers with a high level of expertise and responsiveness. We understand that the needs of our industrial customers can be diverse and complex. Whether it's technical specifications, the exact application environment, special customizations, or other unique requirements, we take the time to understand each customer's unique needs and provide customized solutions.

Ms.Cici

Ms.Cici

8618319014500

8618319014500