Conoscere il raggio collimato: vantaggi, definizione e ... - collimato

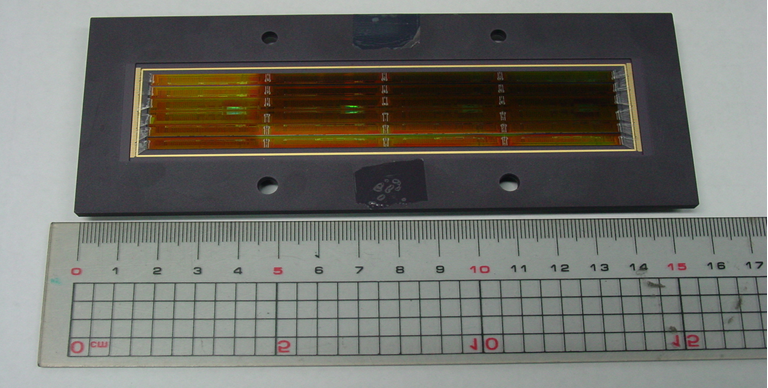

The table provides an overview of the specifications of the available sensors. Not all are listed in the modules presented below, as these are not available in small quantities. In principle, however, all possible variations (in larger quantities) can be ordered and produced. Please contact us for an individual offer!

A standard part, it guarantees maximum safety during operation by automatically discharging residual pressure in case of emergency or system shut-down.

Easy to access and replace, it guarantees excellent quality of application, preventing impurities in the adhesive from clogging the nozzles. There is a wide range of available models (with single or multi-layer filtering micro-mesh, and different pitches starting from 200 micron) depending on the type of adhesive used.

It should be noted, however, that the working distance to the CIS module is maintained very precisely by good guidance of the object to be tested in order to be able to use the optimum optical resolution of the module.

Guarantees absolute precision in the pneumatic pump inversion cycle, thus assuring that the adhesive flow rate is always constant and balanced, significantly reducing the lack of adhesive during the inversion cycle.

The new P5 EASY TOUCH Series applicators for hot-melt adhesives with pneumatic pump are significantly innovative in terms of simplicity of use, productive flexibility, maintenance operations and costs, speed of installation, easy programming, high safety standards, exceptional reliability and total integration with any existing assembly line.

The 14:1 dual-effect piston pump is ideal for melting and applying adhesives and thermoplastic materials with a viscosity of up to 30,000 Cps. Treated with a hard oxide coating, it is easy to extract in case of maintenance or replacement operations. The bottom of the pump is inspectable in order to check the conditions of the suction sphere.

The rapid discharge - located at a lower level and on the opposite side compared to the drawing spot - facilitates the collection of any impurities in the adhesive or burnt glue residue, conveying them to a single sump and preventing them from being sucked up by the pump and causing a machine shutdown, also allowing for quick cleaning operations either for maintenance purposes or to replace the adhesive.

The following products were originally developed for use in space conditions and can be delivered as specified and tested accordingly. Of course, they are also available for other demanding applications, for example in the industry.

CIS modules consist of rows of CMOS image sensors, LED lighting and linear optics in a compact housing. The individual CMOS image sensor chips are manufactured on wafers and can be used in a variety of applications such as check readers, color scanners, digital copiers, mark readers, barcode readers, OCR, edge detectors, positioning and optical encoding and more.

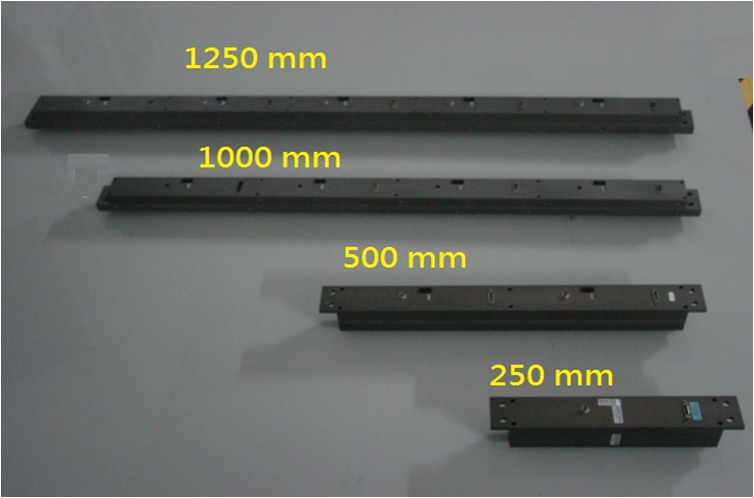

The IPL camera is a line scan camera for industrial applications and suitable for the flat surface AOI inspection. These cameras have been developed for applications that require large-format optical scanning of materials and require a continuous, undistorted image. Available in 0.25–1.25 m (up to 3 m or longer), so for example the inspection of a Gen 8.5 LCD production line with a 2.2 m × 2.6 m glass substrate is possible with an IPL camera at least 2.25 m long.

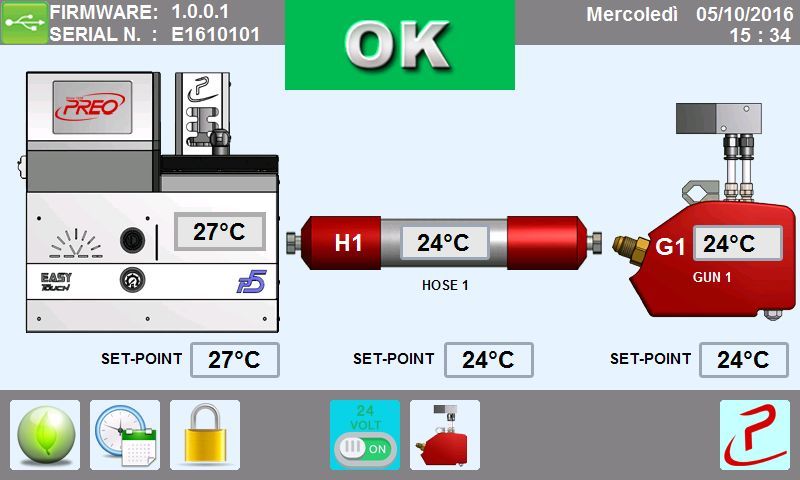

The following are some of the main functions of the new user interface: sequential channel heating, machine ready and pump start signals, absolute maximum temperature protection system, Economy Dual Mode, Weekly Program with Daily ECO function, colour status button with real time diagnostics and Screen Saver function, hose-gun coupling thermal regulation deactivation, LOG file for system register, Life Hours/Work Hours/Pump Cycles counter, machine parameters and Firmware updates uploaded and downloaded through a USB port, customizable system section and glue program names, and parameter Copy/Paste function.

You want to learn more about CMOS space sensors? Here are two documents provided by CMOS Sensor Inc. on their Space Satellite Sensor subpage.

PREO is a leading designer and manufacturer of gluing machines. We never stop working to achieve the highest standards in quality and innovation. As a result, our company has become highly competitive in developing standard machines and in researching and creating special patented solutions. Our long time experience from many years in the aerospace sector is our greatest asset. We provide a winning sales policy, a quick and efficient sales and assistance service, and a well-structured distribution network in Italy and abroad. This is why PREO products are chosen by influential companies around the world.

CMOS Sensor Inc. manufactures a range of CMOS linear sensors with different resolutions. These can either be used singly or assembled into a longer series. Areas of application include amongst other things the industrial quality control and the consumer market. However, the products of this manufacturer have also been used successfully in other applications, for example in the aerospace industry. Eureca is the European sales office for CMOS Sensor Inc.

These individual CMOS image sensor chips are also designed for the application of Silicon Butting Contact Image Sensor (CIS) modules. A chip can be connected to another chip to form a long image sensor module. CIS modules are elementary components of many fax machines and scanners. Modules are available in the standard lengths of 24 mm, A9, A8, A6, A4, A3, ..., A0 in resolutions from 100 to 600 dpi.

The large loading inlet open on 3 sides makes filling easier, optimising cleaning and maintenance operations. The shaped resistance positioned on the bottom of the tank distributes heat evenly and improves thermal efficiency throughout the system, thus resulting in energy savings. The tank bottom slope (about 20°), and the melting fins - positioned parallel to the upper edge of the tank in a fan-shaped configuration - were designed specifically to melt the glue more effectively, so it can slide directly towards the pump drawing spot.

The IPL camera is compact, robust, and all internals like lens, sensors, circuitry, etc. are housed into just one unit. So manufacturers get a reliable, low maintenance, and cost effective solution for providing the highest quality products to their customers.

The CIS modules can also be supplied on request with a minimum order quantity and without a linear optic and LED board. Hereby they can be used as a long CMOS line sensor for for example the position detection of laser beams.

The CIS modules listed here are optimized for scanning documents in »contact mode«. This means that the object to be scanned is guided past the sensor on the front glass plate.

The use of reed-switch type proximity sensors (protected and sealed inside the electronic cylinder, and therefore never in contact with the outside environment and not subject to wear) increases the reliability of life cycles, reducing machine shut-downs for malfunctions or maintenance, giving the system mechanical solidity, in addition to resistance to environmental conditions and to electrical and electromagnetic disturbances.

For applications where a greater working distance is required, the modules can be disassembled to separate the individual components for example in a custom housing at the appropriate new intervals. In this way, these modules can also be used for the control of continuous goods in the industry (films, fabric, paper and the like).

From a certain order quantity, customized modifications of the modules are generally possible. These include, i.a. customer-specific housings, several parallel data outputs to increase the read-out speed or the assembly with special LEDs. Likewise, the individual CMOS sensors from which the CIS modules are made internally are available for own OEM projects in wafer form. Please contact us if interested.

The EASY TOUCH melters have a new melting tank, entirely redesigned, to distribute the heat more evenly over the entire surface, thus obtaining a more precise and effective melt, with significant energy savings. The particularly well-finished design makes the system appreciable even in aesthetic terms. Every part of the applicator can be inspected easily by opening the practical body system. EASY TOUCH Applicators - customizable in several configurations and capable of satisfying all gluing needs - allow the operator to work in complete safety and to significantly optimize application times without wasting time uselessly.

The EASY TOUCH systems are equipped with a new microprocessor with 7" LCD Touch Screen colour display, through which, with a single graphic interface showing all sections of the system (tank, manifold, hoses and guns). The operator is supported in everyday activities like managing and setting temperatures, pump control, setting machine parameters and glue sections, and integration and communication with any external units, allowing for immediate use of the system even by non-specialized personnel, without any problems involving codes or foreign languages to be interpreted.

Ms.Cici

Ms.Cici

8618319014500

8618319014500