Contrast - definition of contrast by The Free Dictionary - contrast define

Fresnel diffraction

CCD sensors remained the natural choice for many product developers for a very long time when it came to building camera-based devices that need to operate under low lighting conditions or an IR/NIR light source. This was true especially in higher temperature ranges where CMOS sensors needed an additional cooler to maintain the required level of QE (Quantum Efficiency – a measure that indicates the sensitivity of a sensor). This was also owing to the fact that CCD sensors offered the flexibility of having a thicker substrate layer for the absorption of photons in the NIR spectrum. But recent developments in the CMOS sensor technology have given birth to sensors that offer better sensitivity than traditional CCD sensors. For instance, the STARVIS series from Sony includes a wide variety of sensors with superior low light performance and NIR sensitivity.

As discussed before, CMOS cameras are catching up on CCD cameras when it comes to most of the imaging parameters. Reduced costs with matching performance are encouraging more and more product developers to pick CMOS sensors over CCD sensors. Also, for the same reason, sensor manufacturers are also gradually moving away from developing new CCD sensors. Hence not much research or advancement is happening in the space. This is resulting in a cascade effect that is reducing the popularity of CCD sensors over time.

The invention of image sensors dates back to the 1960s. A journey that started with designing the MOS (Metal Oxide Semiconductor) sensor architecture in the early 1960s and developing the first digital camera in 1969 to the latest SPAD (Single Photon Avalanche Diode) technique from Canon, sensor technology has come a long way. Despite these developments, CCD and CMOS sensors have remained two of the most popular sensor technologies in the imaging space for decades.

Figure 3. A graph of single slit diffraction intensity showing the central maximum to be wider and much more intense than those to the sides. In fact the central maximum is six times higher than shown here.

We see that the slit is narrow (it is only a few times greater than the wavelength of light). This is consistent with the fact that light must interact with an object comparable in size to its wavelength in order to exhibit significant wave effects such as this single slit diffraction pattern. We also see that the central maximum extends 20.7º on either side of the original beam, for a width of about 41º. The angle between the first and second minima is only about 24º(45.0º − 20.7º). Thus the second maximum is only about half as wide as the central maximum.

Here you’ll find a wealth of practical technical insights and expert advice to help you bring AI and visual intelligence into your products without flying blind.

Fraunhofer diffraction

With further developments stalled, we are soon likely to see the death of CCD sensors. In fact, many sensor manufacturers had already stopped producing CCD sensors years back, but are merely continuing to support their existing customers using them.

Both CCD and CMOS technologies use the photoelectric effect to convert packets of light (or photons) into electric signals. Also, these two sensors are made up of pixel wells that collect these incoming photons. The fundamental difference between the two lies in recreating an image from electric signals.

Moreover, many imaging applications like medical microscopy that stayed with CCD for much longer compared to other embedded vision applications have also joined the ‘CMOS wave’. Further, in addition to power consumption advantages, CMOS sensors also tend to offer higher frame rates and better dynamic range. This has also led embedded camera companies to come up with cutting-edge camera solutions using CMOS sensors. For instance, e-con Systems’ wide portfolio of CMOS cameras includes a 16MP autofocus USB camera, 4K HDR camera, global shutter camera module, IP67 rated Full HD GMSL2 HDR camera module, IP66 rated AI smart camera, and much more (To get a complete view of e-con Systems’ CMOS camera portfolio, please visit our Camera Selector).

Diffraction

From the given information, and assuming the screen is far away from the slit, we can use the equation D sin θ = mλ first to find D, and again to find the angle for the first minimum θ1.

Hope you were able to develop a good understanding of CMOS and CCD technologies and the key differences between the two types of sensors. If you have any further queries on the topic or are looking for help in integrating a CMOS camera for your vision-based application, please write to us at [email protected].

In Figure 2 we see that light passing through a single slit is diffracted in all directions and may interfere constructively or destructively, depending on the angle. The difference in path length for rays from either side of the slit is seen to be D sin θ.

9. (a) 0.0150º; (b) 0.262 mm; (c) This distance is not easily measured by human eye, but under a microscope or magnifying glass it is quite easily measurable.

At the larger angle shown in Figure 2c, the path lengths differ by 3λ/2 for rays from the top and bottom of the slit. One ray travels a distance λ different from the ray from the bottom and arrives in phase, interfering constructively. Two rays, each from slightly above those two, will also add constructively. Most rays from the slit will have another to interfere with constructively, and a maximum in intensity will occur at this angle. However, all rays do not interfere constructively for this situation, and so the maximum is not as intense as the central maximum. Finally, in Figure 2d, the angle shown is large enough to produce a second minimum. As seen in the figure, the difference in path length for rays from either side of the slit is D sin θ, and we see that a destructive minimum is obtained when this distance is an integral multiple of the wavelength.

diffraction翻译

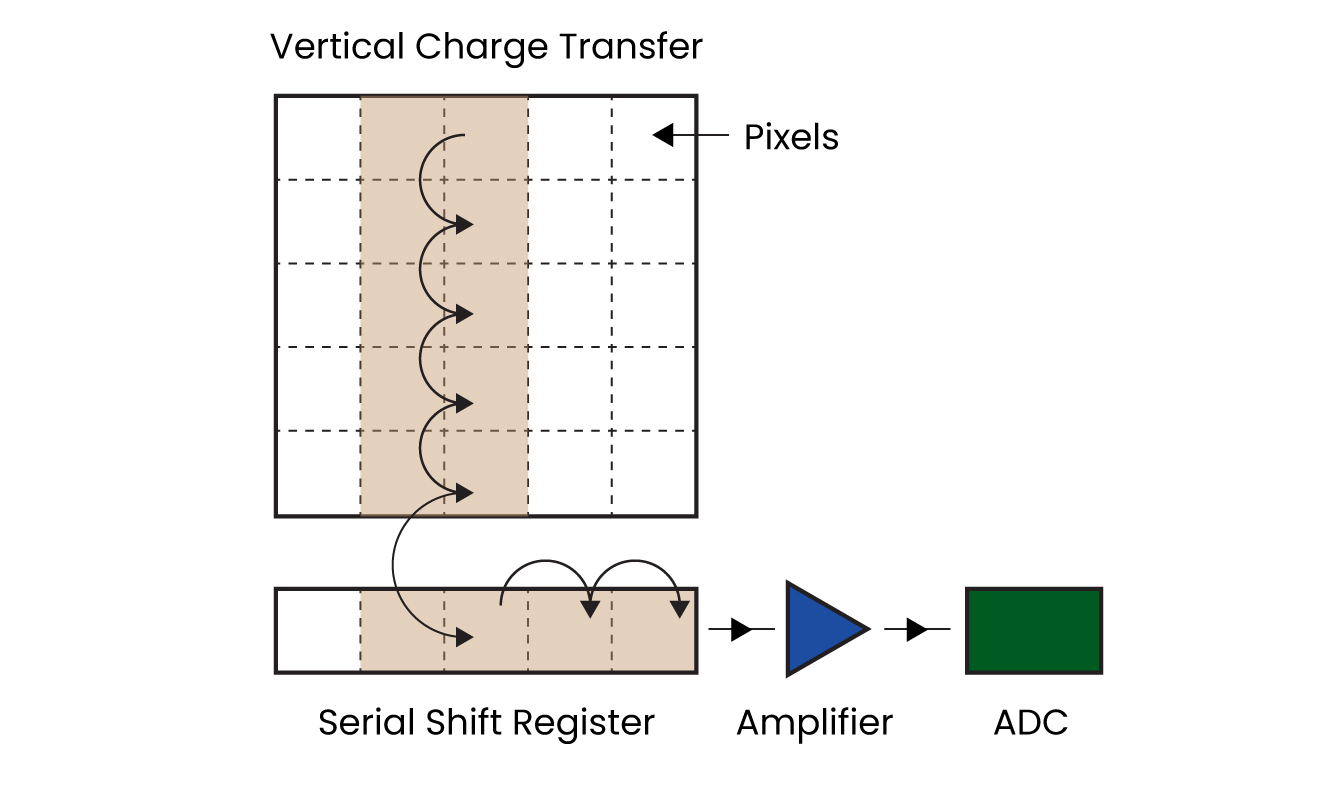

A CCD sensor is an analog device. Below the CCD layer lies the SSR (Serial Shift Register) which is connected to an amplifier on one end and an ADC (Analog to Digital Converter) on the other. The charge in the CCD layer is transferred to the SSR, and then to the amplifier and the ADC. This charge is read from each pixel site to recreate the image. Have a look at the below diagram to understand how the whole process works:

[latex]\displaystyle\sin\theta_1=\frac{m\lambda}{D}=\frac{1\left(550\times10^{-9}\text{ m}\right)}{1.56\times10^{-6}\text{ m}}\\[/latex]

This blog post was originally published at e-con Systems’ website. It is reprinted here with the permission of e-con Systems.

Electron diffraction

[latex]\begin{array}{lll}D&=&\frac{m\lambda}{\sin\theta_2}=\frac{2\left(550\text{ nm}\right)}{\sin45.0^{\circ}}\\\text{ }&=&\frac{1100\times10^{-9}}{0.707}\\\text{ }&=&1.56\times10^{-6}\end{array}\\[/latex]

Light passing through a single slit forms a diffraction pattern somewhat different from those formed by double slits or diffraction gratings. Figure 1 shows a single slit diffraction pattern. Note that the central maximum is larger than those on either side, and that the intensity decreases rapidly on either side. In contrast, a diffraction grating produces evenly spaced lines that dim slowly on either side of center.

Single slit diffraction

While things are dark on the CCD side, the future looks shiny for CMOS sensors. From global shutter to extreme low light cameras to high-resolution cameras, advancements are moving fast in CMOS technology. With leading sensor manufacturers such as Sony, Onsemi, Omnivision etc putting more focus on enhancing the sensitivity, resolution, dynamic range, power efficiency, etc of CMOS sensors, innovations in the space are happening with lightning speed.

When both types of sensors come with their own set of advantages, CMOS sensors have started becoming more popular in recent years, especially in the embedded vision space. While a vast majority of the discussions around the comparison of these two technologies have revolved around mobile phone cameras and machine vision systems, not much has been spoken about the topic in light of embedded vision.

Reflection, refraction diffraction

In this article, we briefly look at some of the key differences between CMOS and CCD sensors, why CMOS is gaining on – or is already beating– CCD in embedded vision, and what the future holds for both in the imaging world.

Diffraction pattern

Visible light of wavelength 550 nm falls on a single slit and produces its second diffraction minimum at an angle of 45.0º relative to the incident direction of the light.

Thus, to obtain destructive interference for a single slit, D sin θ = mλ, for m = 1,−1,2,−2,3, . . . (destructive), where D is the slit width, λ is the light’s wavelength, θ is the angle relative to the original direction of the light, and m is the order of the minimum. Figure 3 shows a graph of intensity for single slit interference, and it is apparent that the maxima on either side of the central maximum are much less intense and not as wide. This is consistent with the illustration in Figure 1b.

The analysis of single slit diffraction is illustrated in Figure 2. Here we consider light coming from different parts of the same slit. According to Huygens’s principle, every part of the wavefront in the slit emits wavelets. These are like rays that start out in phase and head in all directions. (Each ray is perpendicular to the wavefront of a wavelet.) Assuming the screen is very far away compared with the size of the slit, rays heading toward a common destination are nearly parallel. When they travel straight ahead, as in Figure 2a, they remain in phase, and a central maximum is obtained. However, when rays travel at an angle θ relative to the original direction of the beam, each travels a different distance to a common location, and they can arrive in or out of phase. In Figure 2b, the ray from the bottom travels a distance of one wavelength λ farther than the ray from the top. Thus a ray from the center travels a distance λ/2 farther than the one on the left, arrives out of phase, and interferes destructively. A ray from slightly above the center and one from slightly above the bottom will also cancel one another. In fact, each ray from the slit will have another to interfere destructively, and a minimum in intensity will occur at this angle. There will be another minimum at the same angle to the right of the incident direction of the light.

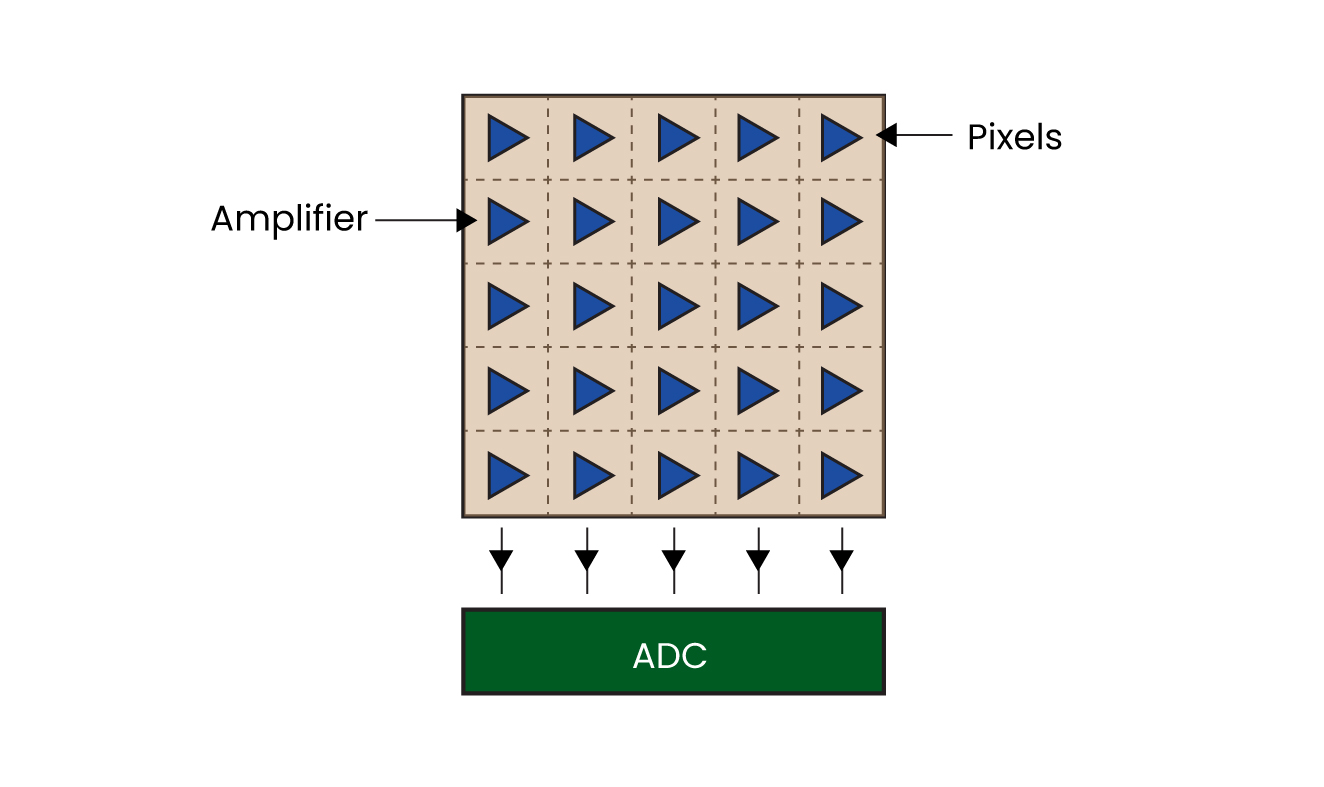

CMOS stands for ‘Complementary Metal Oxide Semiconductor’. The major difference between a CMOS and a CCD sensor is that the former has an amplifier in every pixel. In some CMOS sensor configurations, each pixel has an ADC as well. This results in higher noise compared to a CCD sensor. However, this setup makes it possible to read several sensor pixels simultaneously. In a later section, we will also see how CMOS sensors are matching CCD’s performance despite having this disadvantage.

destructive interference for a single slit: occurs when D sin θ = mλ, (form=1,–1,2,–2,3, . . .), where D is the slit width, λ is the light’s wavelength, θ is the angle relative to the original direction of the light, and m is the order of the minimum

Figure 1. (a) Single slit diffraction pattern. Monochromatic light passing through a single slit has a central maximum and many smaller and dimmer maxima on either side. The central maximum is six times higher than shown. (b) The drawing shows the bright central maximum and dimmer and thinner maxima on either side.

In a CCD sensor, when photons get converted into electric signals, the charge to be converted into voltage is transferred through a limited number of nodes. This would mean that only a few amplifiers and ADCs are in action, which in turn results in less noise in the output image.

Ms.Cici

Ms.Cici

8618319014500

8618319014500