Compound Microscope Parts - condenser lens function

High power objective lenses in microscopes typically have magnifications ranging from 40x to 100x. These lenses are used for detailed examination of specimens and provide high levels of magnification, allowing for close-up views of fine structures and cellular details. Keep in mind that the actual magnification will also depend on the eyepiece being used in conjunction with the high-power objective. For example, if you're using a 10x eyepiece with a 40x objective, the total magnification will be 400x.

Objectivelens microscope function

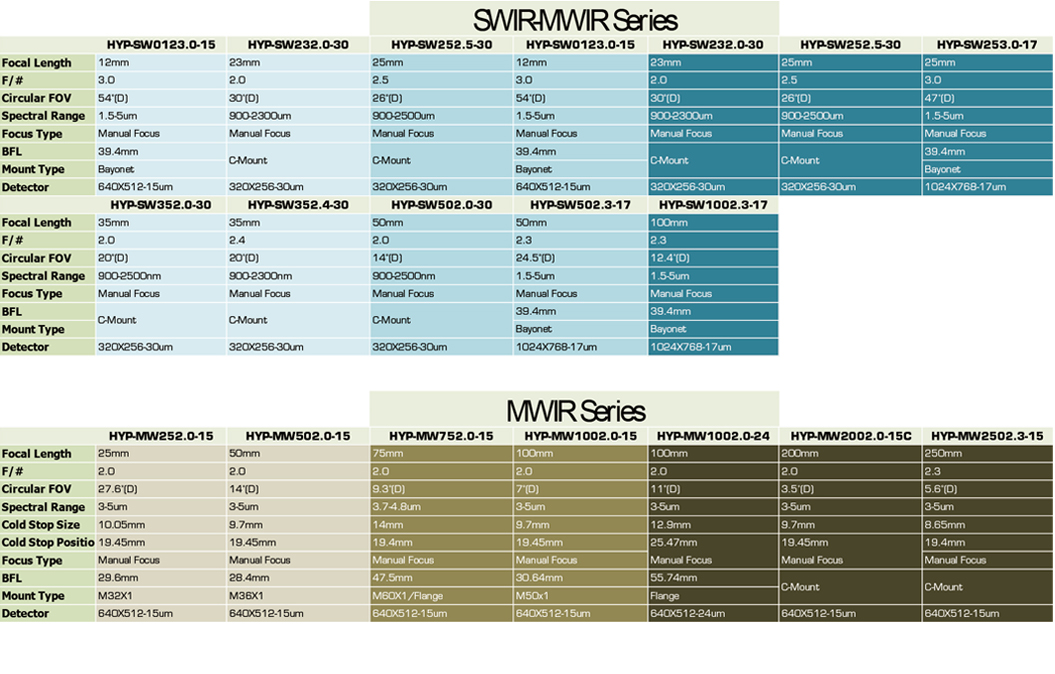

If you need further MWIR optics technical support please contact us. We also provide LWIR lens for thermal imaging surveillance applications.

Diopter adjustmentmicroscope function

11. Stereo Microscope Auxiliary Objectives: Stereo microscope auxiliary objectives are supplementary lenses used to alter the magnification and working distance of a stereo microscope. They are designed to be easily interchangeable, allowing users to adapt the microscope's capabilities for different tasks. These objectives can provide additional magnification for closer inspection of specimens or extend the working distance to accommodate larger objects. They play a crucial role in enhancing the versatility and functionality of stereo microscopes in various fields such as biology, electronics, and precision manufacturing.

By understanding these specifications, users can make informed decisions about which objective lens is best suited for their specific microscopy needs. This ensures that they can achieve the highest level of detail and clarity in their observations.

4. Field of View: This specification indicates the area of the specimen that can be observed at a specific level of magnification. It's crucial for understanding the scope of what can be viewed.

Objectivelensmagnification

9. Metallurgical Objectives: Unlike standard microscope lenses, it has a longer working distance, is designed for an inverted microscope configuration, and often boasts a high numerical aperture for better resolution. These features make it particularly effective for analyzing opaque, irregularly shaped metal specimens in fields like materials science and metallurgy.

3. Working Distance: This is the distance required between the objective lens and the specimen to create an in-focus image. It's an important consideration, especially in applications where space is limited, or when using specialized accessories.

14. Ultraviolet (UV) Radiation Objectives: Objective lenses tailored for the ultraviolet (UV) radiation range are crafted for brightfield microscopy and find applicability in laser-based tasks. These UV objectives boast features like infinity correction, long working distance, and a Plan Apochromat design. They excel in performance specifically within the ultraviolet spectrum (266nm) and also maintain high-quality imaging for visible wavelengths.

Ocular lensmagnification

3. Fluorescence Objectives: These specialized lenses are optimized for fluorescent microscopy. They enable the observation of specimens labeled with fluorescent markers, which emit light of a specific wavelength when illuminated.

Hyperion Optics off-the-shelf Mid-wave (MWIR) lenses feature cooled technology, which offers very high sensitivity and better transmission. We have our standard design but we also offer customized design to meet our customer needs. These lenses include EFL from 9.05mm to 100mm and function in the wavelengths of 2 - 5μm and 3 - 5μm. The F number is 2. The lenses also cover various detector sizes from 15.36x12.29 to 320x240 pixels. The front lens is coated with Hard Diamond coating and mounted with aluminum mounts.

Armmicroscope function

5. Oil Immersion Objectives: These objectives are designed to work with a layer of immersion oil between the lens and the specimen. This reduces refraction and increases numerical aperture, allowing for higher resolution images.

2. Numerical Aperture (NA): A higher NA indicates better resolution and light-gathering capabilities, which can result in clearer and more detailed images.

With the great assistance of our IR components manufacturing capability, we are confident to provide our customer the most affordable design solution without performance compromise. Please refer to our IR components fabrication capability (IR components link here) for further information. We provide 6 weeks typical prototyping lead time for custom MWIR lens design, including assembly and testing, Trioptics MTF chart provided. For complicated asphere/DOE involved system, please contact our optical engineer to discuss your specification for helpful and informative consultation section.

A microscope objective lens is a fundamental component of a microscope responsible for gathering and magnifying the image of a specimen. Positioned in close proximity to the specimen, it plays a crucial role in determining the quality and clarity of the final magnified image.

Objective lenses are typically labeled with two numbers, such as 10x/0.25. The first number represents the magnification, indicating that the lens magnifies the specimen by a factor of 10. The second number is the numerical aperture (NA), which signifies the lens's ability to gather light. This combination of magnification and numerical aperture is crucial in determining the level of detail and clarity that can be achieved when examining specimens under a microscope.

7. Phase Contrast Objectives: These are specially designed for phase contrast microscopy, a technique used to visualize transparent or low-contrast specimens without the need for staining.

4. High-Resolution Objectives: These offer exceptionally high levels of detail and are ideal for applications requiring precise imaging, such as in medical or scientific research.

Objectivelens function

8. Darkfield Objectives: These objectives are optimized for darkfield microscopy, a technique used to observe specimens against a dark background, enhancing contrast for certain types of samples.

A scanning objective in microscopy refers to a specific type of objective lens used to observe specimens. It is characterized by a low magnification level, typically between 2x and 4x, and is designed to provide a wide field of view. Scanning objectives are commonly used for initial specimen location and overview. They allow for quick scanning of a large area to locate regions of interest before switching to higher magnification objectives for detailed examination. This type of objective is particularly useful in tasks where a broad perspective is needed before zooming in for more precise observation.

Ocular lensand objectivelenstotal magnification

5. Correction Type: Depending on the type of microscope and the specific application, one may choose from achromatic, plan, or specialized objectives. Each type is optimized for different imaging conditions.

1. Magnification Range: This determines the range of magnification levels the lens can achieve, allowing for versatility in examining different types of specimens.

13. Near-Ultraviolet Radiation (NUV) Objectives: Objective lenses designed for the near-ultraviolet (NUV) radiation range are tailored for brightfield microscopy, making them well-suited for laser applications. These NUV objectives possess characteristics such as Plan Apochromat design, long working distance, and infinity correction. Specifically optimized for wavelengths from near-ultraviolet (355nm) to visible light, they offer high-performance imaging in this spectral range. Additionally, high-resolution NUV objectives are also available for specialized applications.

Ocular lensvs objectivelens

1. Achromatic Objectives: These are standard objectives that correct for chromatic aberration, enhancing color accuracy in the image.

6. Long Working Distance Objectives: These objectives have a greater distance between the lens and the specimen, making them suitable for applications where space is limited or for examining larger specimens.

10. Strain Free Polarizing Microscope Objectives: Strain-free polarizing microscope objectives are specialized lenses designed for use in polarizing microscopes. They are crafted to minimize birefringence, which is the distortion of light passing through a material under stress. These objectives allow for precise examination of transparent specimens, particularly those with mineral compositions, by reducing optical distortions related to internal strains. This makes them invaluable in geology, petrology, and materials science for studying crystalline structures and material properties.

Hyperion Optics hold sophisticated algorithm for optics design optimization process back-up by powerful workstations. The unique optimization allows reduced complexity in the optical element/system spec, which finally will insure the manufacturing feasibility. It also allows higher yields with almost no performance degradation. In addition, Hyperion Optics has extensive experience in mechanical and Opto-Mechanical design which includes tolerance, thermal and stray light analysis. With the great assistance of our IR components manufacturing capability, we are confident to provide our customer the most affordable design solution without performance compromise. Please refer to our IR components fabrication capability (IR components link here) for further information. We provide 6 weeks typical prototyping lead time for custom MWIR lens design, including assembly and testing, Trioptics MTF chart provided. For complicated asphere/DOE involved system, please contact our optical engineer to discuss your specification for helpful and informative consultation section. Hyperion Optics off-the-shelf Mid-wave (MWIR) lenses feature cooled technology, which offers very high sensitivity and better transmission. We have our standard design but we also offer customized design to meet our customer needs. These lenses include EFL from 9.05mm to 100mm and function in the wavelengths of 2 - 5μm and 3 - 5μm. The F number is 2. The lenses also cover various detector sizes from 15.36x12.29 to 320x240 pixels. The front lens is coated with Hard Diamond coating and mounted with aluminum mounts. Off-The-Shelf MWIR Lenses If you need further MWIR optics technical support please contact us. We also provide LWIR lens for thermal imaging surveillance applications.

IR lens has a wide range of applications, which can be used as infrared for a special purpose or as a normal lens. In other words, the MWIR lens can be used with the regular color camera, black and white camera and the day and night conversion camera. Black and white cameras have no infrared cut-off, but the spectrum of sunlight also contains infrared light, so even in daylight, the image of a black-and-white camera is subject to infra-red interference. Therefore, the MWIR lens can effectively improve the image quality.

Choosing the right type of objective lens depends on the specific requirements of the microscopy application, including the type of specimen, desired level of detail, and any specialized techniques being employed.

The IR lens adopted the advanced technologies such as the latest optical design methods, special optical glass materials and special ferry films and materials, eliminating the focal plane deviation of visible light and infrared light.

The MWIR lens uses special optical glass materials as well as special ferry films and materials. The special optical glass material solves the problem of infrared corresponding clear imaging so that the light from the visible region to the infrared region can be obtained in the same focal plane position to achieve a clear image. Special crossing technology allows the infrared light to penetrate as far as possible. The multi-layer coating can also minimize the occurrence of ghost and flash in the backlight condition, and the high contrast quality can be obtained even under the bad conditions such as backlighting.

The primary function of objective lenses in microscopy is to capture light emitted or reflected by the specimen. They then focus this light to form an enlarged image, which can be further magnified by the eyepiece lens. By adjusting the objective lens, users can achieve different levels of magnification, allowing for detailed examination of minute structures.

12. Near-Infrared Radiation (NIR) Objectives: Near-infrared (NIR) range objectives in brightfield microscopy are tailored for laser applications, enabling precise observation within the near-infrared radiation spectrum. These NIR objectives are characterized by their Plan Apochromat design, infinity correction, and long working distance, making them ideal for applications involving this specific wavelength range.

Hyperion Optics hold sophisticated algorithm for optics design optimization process back-up by powerful workstations. The unique optimization allows reduced complexity in the optical element/system spec, which finally will insure the manufacturing feasibility. It also allows higher yields with almost no performance degradation. In addition, Hyperion Optics has extensive experience in mechanical and Opto-Mechanical design which includes tolerance, thermal and stray light analysis.

2. Plan Objectives: Designed for flat-field microscopy, these objectives ensure a sharp focus across the entire visual field, reducing distortion at the edges.

Ms.Cici

Ms.Cici

8618319014500

8618319014500