Color Blind Lenses | Pass a Color Blind Test | Color Blind ... - color correction glasses

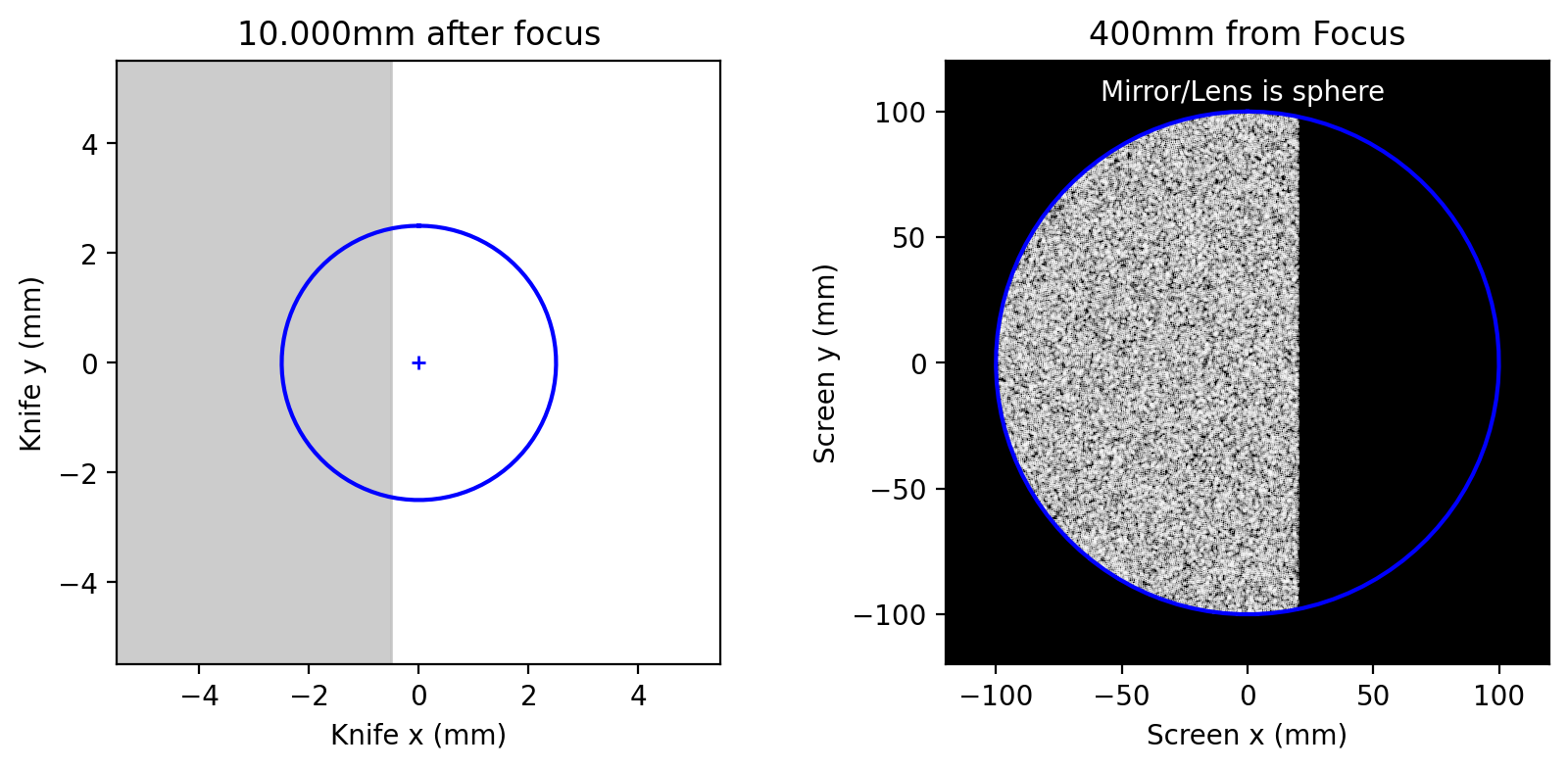

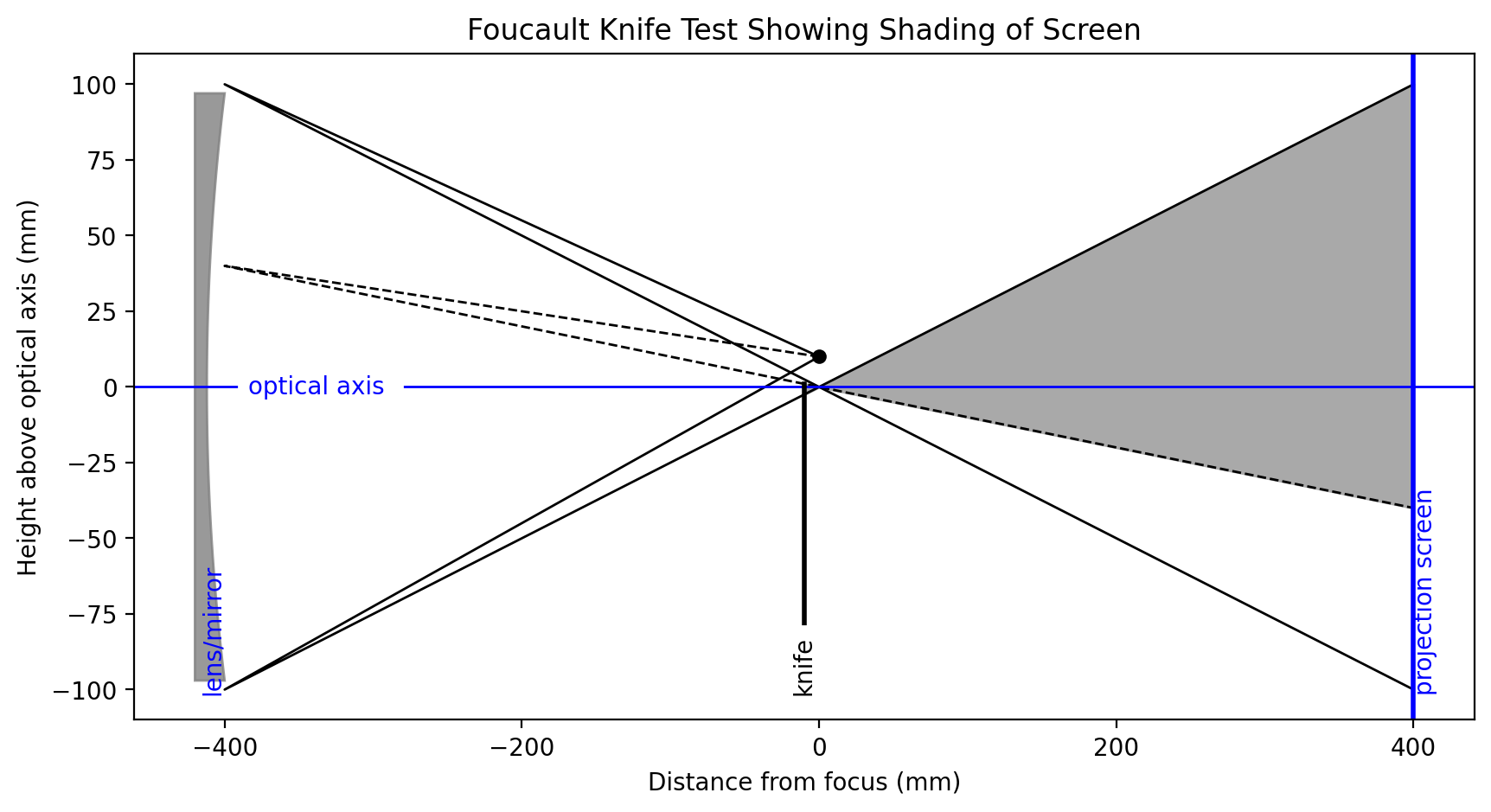

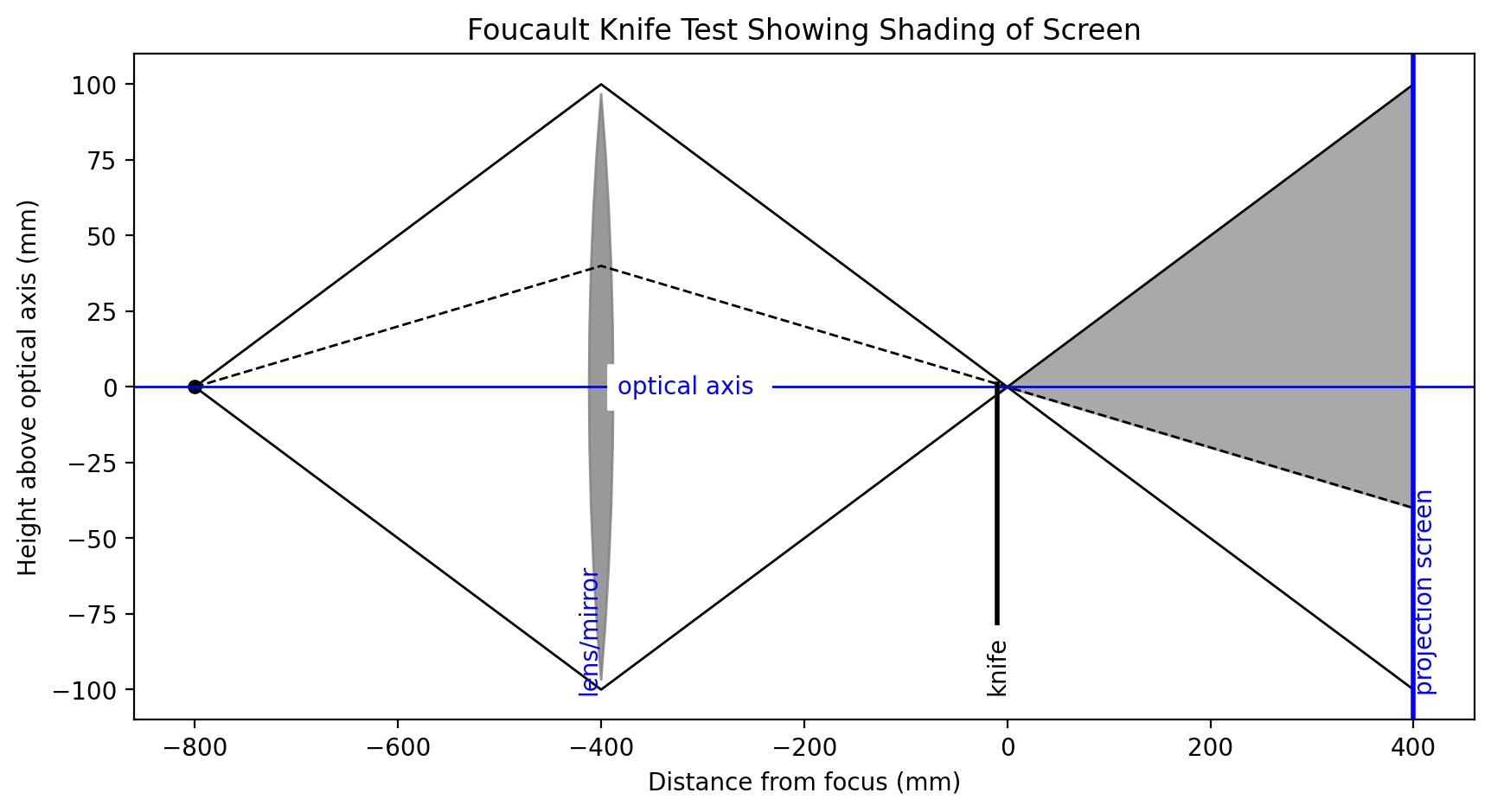

The basic setup for a Foucault knife edge test consists of and illuminated pinhole size source, a knife edge, and the mirror or lens being tested. The pinhole source is placed at one center of curvature of a mirror (or say twice the focal distance of a lens), and the knife edge is placed near the image of the pinhole.

Richardson gratingsfor sale

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.

NewportGratings

The knife edge is translated across the optical axis and the image of the light spot on a screen placed behind the lens or mirror is observed. As the knife edge is moved, the position of the light spot on the screen will change in a way that is related to the curvature of the lens or mirror. By measuring the position of the light spot on the screen as the knife edge is moved, it is possible to determine the curvature of the lens or mirror.

The peak unpolarized diffraction efficiency meets or exceeds 60% for diffracted orders peaking between 900 and 1650 nm. Spectral resolving power was measured to exceed 1,190,000 at 633 nm, and spatial resolution was measured to be better than two seconds of arc. The overall diffracted wavefront demonstrates irregularity less than 0.06 waves at 633 nm.

Newportrichardson gratings

A Foucault knife edge test is a method used to measure the curvature of a mirror or lens. It is named after the French physicist Léon Foucault, who developed the technique in the 19th century.

For further information on the HzPF, see Mahadeven et al., “The Habitable Zone Planet Finder: A Proposed High Resolution NIR Spectrograph for the Hobby Eberly Telescope to Discover Low Mass Exoplanets around M Dwarfs,” Proc. SPIE 7735 (2010) (http://arxiv.org/ftp/arxiv/papers/1007/1007.3235.pdf).

Richardson gratingswebsite

Rochester, NY--A large mosaic echelle grating was manufactured and shipped by Richardson Gratings, a Newport Corporation business, for use in the Habitable Zone Planet Finder. Contracted by the Pennsylvania State University, this 214 x 840 x 125 mm grating has 31.6 grooves per millimeter and a nominal blaze angle of 75 degrees. The mosaic grating was fabricated as a monolithic gold-coated replica grating from two matched gratings from the same echelle master. The fifteenth mosaic echelle produced by Richardson Gratings, the company says it possesses excellent performance characteristics as measured by spectral resolution, efficiency, blaze angle, wavefront, and alignment between the two segments.

The Habitable Zone Planet Finder (HzPF) is a cooled, fiber-fed, high resolution near-infrared echelle spectrograph developed at the Pennsylvania State University for the Hobby-Eberly telescope, which is housed at the McDonald Observatory in Texas. HzPF will be capable of discovering low-mass planets around cool, nearby stars as well as determining if these planets are in orbits that allow liquid water to exist on their surfaces, the so-called “habitable zone” around stars. The spectrograph will cover the wavelength range from 900 to 1650 nm to enable precise radial velocities as low as one meter per second—the speed of a person walking.

Ms.Cici

Ms.Cici

8618319014500

8618319014500