Collimate Definitions for Land Surveyors - collimated meaning

The plot below shows reflectance data from four -P01 coatings produced by Thorlabs. While all four meet the average reflectance specification from 450 - 2000 nm, their reflectances differ at specific wavelengths. The variation is largest below 850 nm, where all four coatings have reflectances lower than 96.5%. This kind of behavior is typical of coatings specified by Ravg. Outside of the specified range, the variation can be more pronounced, because the reflectance at those wavelengths is not controlled.

Thorlabs expresses LIDT for CW lasers as a linear power density measured in W/cm. In this regime, the LIDT given as a linear power density can be applied to any beam diameter; one does not need to compute an adjusted LIDT to adjust for changes in spot size, as demonstrated by the graph to the right. Average linear power density can be calculated using the equation below.

Microscope Objectives or Objective lenses are in many ways the heart of the microscope, and are typically mounted on a rotating nosepiece or turret to enable easy selection. Many microscopes will be equipped with a scanning objective (4x), a low power objective (10x), a high power objective (40x), and perhaps even an oil immersion objective lens.

Objectives are complex multi-element lenses. For any given application, careful consideration of the optical parameters and specifications is necessary. In many cases, custom-designed objective assemblies provide the best-fit solution for meeting all the requirements of a specialized application. Custom parameters may include antireflection coatings, chromatic focus shift, working distance, image quality (MTF and spot size), lens mount, glass window thickness, and field of view, among others.

Objective lenses can be classified based on the objective construction, field of use, microscopy method, performance (optical aberration corrections), and magnification. Many microscope objective manufacturers offer a wide range of objective designs, which provide various degrees of optical aberration corrections for supporting different needs. Mirrors or reflective elements are used in objective lenses for the applications that requires chromatic aberration over board spectral ranges. Most traditional microscopy systems use refractive objectives such as achromatic objectives (the cheaper objectives) for laboratory microscope applications and plan apochromats (expensive objectives) for biological and science research microscope applications.

Magnification is one important parameter. Magnification is usually denoted by an X next to a numeric value. Objectives are available in a range of magnifications from 2X to 200X.

Beam diameter is also important to know when comparing damage thresholds. While the LIDT, when expressed in units of J/cm², scales independently of spot size; large beam sizes are more likely to illuminate a larger number of defects which can lead to greater variances in the LIDT [4]. For data presented here, a <1 mm beam size was used to measure the LIDT. For beams sizes greater than 5 mm, the LIDT (J/cm2) will not scale independently of beam diameter due to the larger size beam exposing more defects.

The first and one of the most critical steps of our process is cleaning uncoated substrates with an automated ultrasonic clean line. Using a series of ultrasonic solvent and detergent baths, each step of the cleaning process removes different types of contamination from the surfaces of the substrate. This ensures surface contamination does not interfere with adhesion of coatings to the substrate.

The AR Coating Range graph below shows the specified wavelength range of Thorlabs' in-house AR coatings. Click on the bars in the graph below to view the performance plot for each coating.

Laser Line and Bandpass filters transmit light in a narrow, well-defined spectral region while rejecting other unwanted radiation. This type of filter displays very high transmission in the bandpass region and blocks a limited spectral range of light on either side of the bandpass region. To compensate for this deficiency, an additional blocking component is added, which is either an all-dielectric or a metal-dielectric depending on the requirements of the filter. Although this additional blocking component eliminates any unwanted out-of-band radiation, it also reduces the filter's overall transmission throughput.

The dielectric coating on dichroic beamsplitters is the source of their functionality. The alternating layers in the coating are designed to cause constructive interference for those wavelengths to be transmitted and destructive interference for those wavelengths to be reflected. The thickness of the coating and the refractive index of the materials in the layers determine the design wavelength for a given beamsplitter.

Since the objective is closest to the specimen being examined, it will relay a real image to the ocular lens. While doing so, it contributes a base magnification of anywhere from 4x (for a scanning objective lens, typically used to provide an overview of a sample) to 100x (for oil immersion objectives).

V-coatings are multilayer, dielectric, thin-film, AR coatings that are designed to minimize reflectance over a short wavelength range. Surface reflectance rises rapidly on either side of this minimum, which gives the reflectance curve a "V" shape. Compared to the broadband AR coatings, V-coatings achieve lower reflectance over a narrower bandwidth when used within their design AOI range. See the graph to the right for an example of the reflectance of a 633 nm V-coat designed for 0° AOI at various angles. We offer a variety of different V-coatings; see the table below for more information.

Two major lens components—the objective lens and the ocular lens, or eyepiece—work together to project the image of the specimen onto a sensor. This may be the human eye or a digital sensor, depending on the microscope setup.

Thorlabs' textured AR surfaces are created by removing material from the bulk optic substrate using our proprietary process, which has been optimized to fabricate subwavelength structures. The surface that remains consists of roughly conical nanostructures, with irregular spacing and varied height. These nanostructures produce a smooth gradient of the effective refractive index.

Anti Reflective film

The other type of reflectance specification is Average Reflectance (Ravg), which is always quoted over a wavelength range. Ravg is found by measuring the reflectance at wavelengths across the specified range and then averaging the reflectance over wavelength. This specification is insensitive to certain variations between individual coating runs that may not be of interest for broadband applications. If a guarantee of performance at a particular wavelength is needed, then a coating specified by Rabs will be preferable.

A simple magnifier (magnifying glass), works when the object to be examined is situated within focal length of the magnifier lens, enabling larger virtual image is produced. This type of magnifier is very limited in both resolution and magnification. A compound microscope, on the other hand, uses a relay lens system instead of the single lens, and since each lens component can contribute magnifying power, the result is greatly increased capability.

These coatings are formed by vacuum deposition coating techniques and consist of two reflecting stacks, separated by an even-order spacer layer. These reflecting stacks are constructed from alternating layers of high and low refractive index materials, which can have a reflectance in excess of 99.99%. By varying the thickness of the spacer layer and/or the number of reflecting layers, the central wavelength and bandwidth of the filter can be altered.

Please note that we have a buffer built in between the specified damage thresholds online and the tests which we have done, which accommodates variation between batches. Upon request, we can provide individual test information and a testing certificate. The damage analysis will be carried out on a similar optic (customer's optic will not be damaged). Testing may result in additional costs or lead times. Contact Tech Support for more information.

The energy density of your beam should be calculated in terms of J/cm2. The graph to the right shows why expressing the LIDT as an energy density provides the best metric for short pulse sources. In this regime, the LIDT given as an energy density can be applied to any beam diameter; one does not need to compute an adjusted LIDT to adjust for changes in spot size. This calculation assumes a uniform beam intensity profile. You must now adjust this energy density to account for hotspots or other nonuniform intensity profiles and roughly calculate a maximum energy density. For reference a Gaussian beam typically has a maximum energy density that is twice that of the 1/e2 beam.

Thorlabs offers dielectric and metallic broadband coatings, dielectric narrowband coatings for laser line applications, and high-performance crystalline mirror coatings. We also offer a selection of ultrafast mirrors optimized for femtosecond laser pulse applications.

Anti reflectivecoatingiPad

Thorlabs' dielectric HR coatings, available in broadband and narrowband designs, are hard, refractory, oxide coatings that maximize surface reflections within specified wavelength ranges and at specified angles of incidence. These coatings consist of alternating layers of high- and low-index materials. Using computer models, the thickness of each layer is optimized to produce constructive interference for reflected waves and destructive interference for transmitted waves.

The E01, E02, E03, and E04 dielectric HR coatings offer high reflectance over broad wavelength ranges. Our UV-Enhanced Aluminum coating has an overcoat of MgF2 to increase its average reflectance in the UV portion of the spectrum. The Protected Aluminum coating is an inexpensive solution and has an overcoat of SiO2 to make the aluminum coating suitable for laboratory and industrial use. The Protected Silver coating has the highest reflectance in the visible spectrum and is protected with an SiO2 overcoat to prevent oxidation. The Ultrafast-Enhanced Silver coating is manufactured such that it exhibits a low group delay dispersion. Three gold coating options are offered: protected, MIR enhanced, and unprotected. The Protected Gold coating retains a high reflectance down to 800 nm, while the MIR enhanced gold coating is optimized to reduce losses in the MIR that are commonly found in gold mirrors. Each of these gold coatings is protected by an overcoat that also makes the mirrors easy to clean. The Unprotected Gold coating offers higher reflectance than the protected gold coating, but is slightly more delicate.

When pulse lengths are between 1 ns and 1 µs, laser-induced damage can occur either because of absorption or a dielectric breakdown (therefore, a user must check both CW and pulsed LIDT). Absorption is either due to an intrinsic property of the optic or due to surface irregularities; thus LIDT values are only valid for optics meeting or exceeding the surface quality specifications given by a manufacturer. While many optics can handle high power CW lasers, cemented (e.g., achromatic doublets) or highly absorptive (e.g., ND filters) optics tend to have lower CW damage thresholds. These lower thresholds are due to absorption or scattering in the cement or metal coating.

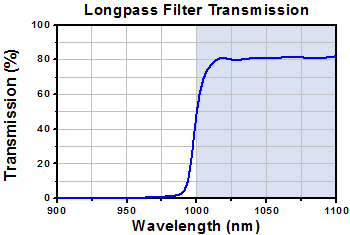

Edgepass filters are very useful for isolating specific spectral regions. Longpass filters transmit wavelengths longer than the cutoff wavelenght and block wavelengths shorter than the cutoff wavelength. Shortpass filters block wavelengths longer than the cutoff wavelength and transmit those shorter than the cutoff wavelength.

Anti reflectivecoatingmaterial

Now compare the maximum energy density to that which is specified as the LIDT for the optic. If the optic was tested at a wavelength other than your operating wavelength, the damage threshold must be scaled appropriately [3]. A good rule of thumb is that the damage threshold has an inverse square root relationship with wavelength such that as you move to shorter wavelengths, the damage threshold decreases (i.e., a LIDT of 1 J/cm2 at 1064 nm scales to 0.7 J/cm2 at 532 nm):

Anti reflectivecoatingdisadvantages

The following is a general overview of how laser induced damage thresholds are measured and how the values may be utilized in determining the appropriateness of an optic for a given application. When choosing optics, it is important to understand the Laser Induced Damage Threshold (LIDT) of the optics being used. The LIDT for an optic greatly depends on the type of laser you are using. Continuous wave (CW) lasers typically cause damage from thermal effects (absorption either in the coating or in the substrate). Pulsed lasers, on the other hand, often strip electrons from the lattice structure of an optic before causing thermal damage. Note that the guideline presented here assumes room temperature operation and optics in new condition (i.e., within scratch-dig spec, surface free of contamination, etc.). Because dust or other particles on the surface of an optic can cause damage at lower thresholds, we recommend keeping surfaces clean and free of debris. For more information on cleaning optics, please see our Optics Cleaning tutorial.

When properly handled, textured surfaces can exhibit greater durability than BBAR coatings. Their single-material construction means that they do not suffer from mismatched coefficients of thermal expansion (CTE) under temperature cycling and avoid issues with thin-film adhesion that can occur in some AR coatings.

The spectral performance and other key characteristics of optical thin films are determined by the structure and number of layers in the coating, the refractive indices of the materials used, and the optical properties of the substrate.

According to the test, the damage threshold of the mirror was 2.00 J/cm2 (532 nm, 10 ns pulse, 10 Hz, Ø0.803 mm). Please keep in mind that these tests are performed on clean optics, as dirt and contamination can significantly lower the damage threshold of a component. While the test results are only representative of one coating run, Thorlabs specifies damage threshold values that account for coating variances.

The parfocal length is the distance between the objective mounting plane and the specimen / object. This is another specification that can often vary by manufacturer.

The structure of most coatings resembles a series of discrete alternating layers of high index and low index materials. Different arrangements of stack structure result in different types of coatings (e.g., Bandpass vs. Edgepass vs. BBAR). Fine tuning of layer thicknesses and refractive indices is done to optimize performance characteristics in the wavelength range of interest. Thorlabs has a selection of thin film modeling tools to design, characterize, and optimize many aspects of an individual coating's performance.

Thorlabs' coating facility currently operates four fully automated Electron Beam (E-Beam) deposition systems. These systems use an electron beam source to evaporate a selection of materials such as transition metal oxides (e.g., TiO2, Ta2O5, HfO2, Nb2O5, ZrO2), metal halides (MgF2, YF3), or SiO2. This type of process must be done at elevated temperatures (200 - 250 °C) to achieve good adhesion to the substrate and acceptable material properties in the final coating.

The calculation above assumes a uniform beam intensity profile. You must now consider hotspots in the beam or other non-uniform intensity profiles and roughly calculate a maximum power density. For reference, a Gaussian beam typically has a maximum power density that is twice that of the uniform beam (see lower right).

Thorlabs uses a selection of research-grade spectroscopy instruments to characterize coating performance from the UV to the Far Infrared. In addition to spectroscopy tools, we employ a variety of laser and laser diode sources, power meters, detectors, and polarimeters to test the performance of our optics. Specific metrology systems include Cary 660 FTIR, Cary 5000, PE Lambda 950, and Olis PE 983 IR spectrophotometers, a KLA Tencor surface profilometer, a J.A. Woollam RC2 ellipsometer, Zygo monochromatic interferometers, an Optoflat broadband interferometer for single surface and multi-surface interferometric measurements, a surface scatter instrument, and a custom-built cavity ring down system. All of these tools help us understand our coatings and materials at a molecular level. We build custom setups to test both catalog and OEM parts to ensure every optic we offer performs within the specified range. All metrology instruments are calibrated regularly per the ISO 9001:2015 standard.

At Shanghai Optics, we design and manufacture custom objectives and imaging systems to support our customers’ needs in many industries, including medical, biomedical, machine version, scientific research, and metrology, etc. Taking the client’s budget and precision requirements into consideration, our experienced engineering team ensure that each design can be manufactured at a reasonable cost and the optical performance is being met based on fabrication, assembly, and alignment tolerance analysis.

Ion-Beam Assisted Deposition (IAD) uses the same E-beam method to evaporate coating materials but with the addition of an ion source to promote nucleation and growth of materials at lower temperatures (20 - 100 °C). The ion source allows temperature-sensitive substrates to be coated. This process also results in a denser coating that is less sensitive to spectral shifting in both humid and dry environmental conditions.

Notch filters, also commonly referred to as band-stop or band-rejection filters, are designed to transmit most wavelengths but attenuate light within a specific wavelength range (the stop band) to a very low level. They are functionally the inverse of bandpass filters and are made in the same way.

Broadband antireflective (BBAR) coatings consist of multiple layers, alternating between a high index material and a low index material. The layers are deposited on the substrate via electron-beam deposition. The thickness of the layers is optimized, using modeling software, to produce destructive interference between reflected waves and constructive interference between transmitted waves. This results in an optic that has enhanced performance within a specified wavelength band as well as minimal internal reflections (ghosting). Thorlabs' BBAR coatings provide good performance for angles of incidence between 0° and 30° and a numerical aperture (NA) of 0.5. Thorlabs currently offers BBAR coatings designed to maximize performance within 8 different wavelength ranges.

Anti reflectioncoatingformula

Several coating chambers are outfitted with optical thickness monitoring and crystal thickness monitoring which enable our coatings to meet the stringent specifications required for sensitive applications.

Dichroic Beamsplitters are used as beam directors at 45° and are either longpass or shortpass. The longpass variety reflects >90% of the incident light below the design wavelength and transmits >90% of the incident light above the design wavelength. The shortpass variety transmits below the design wavelength, and reflects above the design wavelength. Dichroic beamsplitters are used in many applications, the most common one being fluorescence microscopy.

Most objectives are designed to image specimens with air as the medium between the objective and the cover glass. However, for achieving higher working numerical apertures, some objectives are designed to image the specimen through another medium such as special oil with a refractive index of 1.51.

The reflectance of surfaces can be greatly improved by the addition of an HR coating; however, performance will depend on both the wavelength and the angle of incidence (AOI). At high AOIs, the performance will also depend on the polarization of the incident light. Information about the reflectance of each HR coating can be found in the tables below.

The ocular lens, located at the top of a standard microscope and close to the sensor (receiving eye) receives the real image from the ocular lens, magnifies the image received and relays a virtual image to the sensor. While most eyepieces magnify 10x, there are some which provide no magnification and others which magnify as much as 30x. The magnification power of the microscope can be calculated by multiplying the magnification power of the eyepiece, or ocular lens, by the magnification power of the objective lens. For example, an objective lens with a magnification of 10x used in combination with a standard eyepiece (magnification 10x) would project an image of the specimen magnified 100x.

In contrast, the effective index gradient of our textured surfaces is less sensitive to the wavelength and AOI than thin-film interference, allowing for very low reflectance over a broad range of both. See the graphs below for an illustration of this difference.

Crystalline Mirror CoatingsThorlabs Crystalline Solutions currently offers three different GaAs/AlGaAs crystalline coatings optimized for superior mid-IR performance, as well as the ability to create custom crystalline coatings. These high-reflectance mirror coatings are ideal for high-finesse laser cavities, precision interferometry, and high-power laser systems. The specifications below are typical values. Thorlabs offers a selection of concave and plano xtal stable™-coated mirrors from stock. Mirrors with xtal mir™ or xtal therm™ coatings, as well as custom mirrors with xtal stable™ coatings, are made to order by request through Tech Support.

While this rule of thumb provides a general trend, it is not a quantitative analysis of LIDT vs wavelength. In CW applications, for instance, damage scales more strongly with absorption in the coating and substrate, which does not necessarily scale well with wavelength. While the above procedure provides a good rule of thumb for LIDT values, please contact Tech Support if your wavelength is different from the specified LIDT wavelength. If your power density is less than the adjusted LIDT of the optic, then the optic should work for your application.

LIDT in linear power density vs. pulse length and spot size. For long pulses to CW, linear power density becomes a constant with spot size. This graph was obtained from [1].

LIDT in energy density vs. pulse length and spot size. For short pulses, energy density becomes a constant with spot size. This graph was obtained from [1].

Antireflection Performance Compared to our traditional thin-film broadband antireflective (BBAR) coatings, our textured surfaces exhibit lower reflectance over a broad wavelength range and lower angular sensitivity. The anti-reflection mechanism used in dielectric AR coatings is based on the interference between reflections from subsequent thin film dielectric layers. This behavior is highly dependent on the wavelength of the light, as the refractive indices and thicknesses of each layer are designed to provide the desired phase relationship between reflecting waves. Moreover, the angle of incidence (AOI) affects the effective thickness of each layer that the light interacts with, which leads to a strong dependence on the AOI. As a result, there are limitations on the performance that a BBAR coating can achieve over a broad range of wavelengths and AOIs.

The optical aberration correction determines the optical performance of an objective lens and plays a central role in the image quality and measurement accuracy of imaging or microscopy systems. According to the degrees of the aberration corrections, objective lenses are generally classified into five basic types: Achromat, Plan Achromat, Plan Fluorite (Plan Semi-Apochromat), Plan Apochromat, and Super Apochromat.

Since indirect backlight illumination is generally more effective than direct illumination, most microscopes do not include an internal light source. Instead, they rely on daylight or on background illumination such as a lightbulb. In brightfield illumination, also known as Koehler illumination, two convex lenses saturate the specimen with external light admitted from behind. These two lenses, the collector lens and condenser lens, work together to provide a bright, even, and constant light throughout the system: on the image plane as well as on the object plane. This system of illumination is used in many compound microscopes, including student microscopes and those found in many research labs.

Room 609, 6/F, Global Gateway Tower, No.63 Wing Hong Street, Cheung Sha Wan, Kowloon, Hong Kong +852-54993705 info@shanghai-optics.com

Our Ion Beam Sputtering (IBS) deposition chamber is the most recent addition to our line-up of coating tools. This process uses a high energy, radio frequency, plasma source to sputter coating materials and deposit them on substrates while another RF ion source (Assist source) provides IAD function during deposition. The sputtering mechanism can be characterized as momentum transfer between ionized gas molecules from the ion source and the atoms of the target material. This is analogous to a cue ball breaking a rack of billiard balls, only on a molecular scale and with several more balls in play.

As previously stated, pulsed lasers typically induce a different type of damage to the optic than CW lasers. Pulsed lasers often do not heat the optic enough to damage it; instead, pulsed lasers produce strong electric fields capable of inducing dielectric breakdown in the material. Unfortunately, it can be very difficult to compare the LIDT specification of an optic to your laser. There are multiple regimes in which a pulsed laser can damage an optic and this is based on the laser's pulse length. The highlighted columns in the table below outline the relevant pulse lengths for our specified LIDT values.

All Thorlabs edgepass filters are constructed of durable dielectric coatings and will withstand the normal cleaning and handling associated with any high-quality optical component. Their film construction is essentially a modified quarter-wave stack, using interference effects rather than absorption to isolate their spectral bands.

Neutral Density (ND) filters attenuate all wavelengths within a range by a certain factor to prevent damage to detecting equipment. Fixed ND filters attenuate the spectra by a fixed amount. Variable ND filters have stepped films at discrete locations to allow for various attenuation depending on the application. Continuous ND filters have a film gradient across the entire filter, which allows for a continuous range of attenuation. Thorlabs offers a selection of both linear and circular variable and continuous ND filters.

Thorlabs quotes two types of reflectance values for our optical coatings. Absolute Reflectance (Rabs, or simply R) indicates the maximum or minimum reflectance at a specific wavelength or wavelengths. When specified over a wavelength range, it indicates the maximum or minimum reflectance for each wavelength within the range. The reflectance may increase or decrease sharply near the specified wavelengths or wavelength range, as in our V-coatings.

Pulses shorter than 10-9 s cannot be compared to our specified LIDT values with much reliability. In this ultra-short-pulse regime various mechanics, such as multiphoton-avalanche ionization, take over as the predominate damage mechanism [2]. In contrast, pulses between 10-7 s and 10-4 s may cause damage to an optic either because of dielectric breakdown or thermal effects. This means that both CW and pulsed damage thresholds must be compared to the laser beam to determine whether the optic is suitable for your application.

Important specifications are marked on the barrel of the objective, so students or researchers can easily identify the properties of an objective and determine the optical performance and working conditions for proper use. Figure 1 shows a diagram of an objective lens. A detailed discussion of the objection specifications is provided below.

When an optic is damaged by a continuous wave (CW) laser, it is usually due to the melting of the surface as a result of absorbing the laser's energy or damage to the optical coating (antireflection) [1]. Pulsed lasers with pulse lengths longer than 1 µs can be treated as CW lasers for LIDT discussions.

Use this formula to calculate the Adjusted LIDT for an optic based on your pulse length. If your maximum energy density is less than this adjusted LIDT maximum energy density, then the optic should be suitable for your application. Keep in mind that this calculation is only used for pulses between 10-9 s and 10-7 s. For pulses between 10-7 s and 10-4 s, the CW LIDT must also be checked before deeming the optic appropriate for your application.

A microscope is a special optical device designed to magnify the image of an object. Depending on the type of microscope, it may project the image either onto a human eye or onto a recording or video device. As an example, consider the photographs of cells that can be found in a science textbook. These photographs have all been taken by a specialized microscope, and may be called micrographs.

Thorlabs' LIDT testing is done in compliance with ISO/DIS 11254 and ISO 21254 specifications.First, a low-power/energy beam is directed to the optic under test. The optic is exposed in 10 locations to this laser beam for 30 seconds (CW) or for a number of pulses (pulse repetition frequency specified). After exposure, the optic is examined by a microscope (~100X magnification) for any visible damage. The number of locations that are damaged at a particular power/energy level is recorded. Next, the power/energy is either increased or decreased and the optic is exposed at 10 new locations. This process is repeated until damage is observed. The damage threshold is then assigned to be the highest power/energy that the optic can withstand without causing damage. A histogram such as that below represents the testing of one BB1-E02 mirror.

The pulse length must now be compensated for. The longer the pulse duration, the more energy the optic can handle. For pulse widths between 1 - 100 ns, an approximation is as follows:

where θ is the maximum 1/2 acceptance ray angle of the objective, and n is the index of refraction of the immersion medium. Figure 2 shows the ray angle θ of an infinity-corrected objective.

A microscope objective is an important component of a microscopy or imaging system for a range of science research, biological, industrial, and general lab applications.. An objective lens determines the basic performance of an optical microscope or imaging systems and is designed for various performance needs and applications. It is located closest to the object and is an important component in imaging an object onto the human eye or an image sensor.

Broadband HR CoatingsThorlabs offers a number of broadband HR coatings optimized for various performance parameters. The graph below shows the specified wavelength range of Thorlabs' in-house broadband HR coatings. Click on the bars in the graph below to view the performance plot for each coating. Click here for a raw data file that compares all of our broadband HR Coatings.

Damage Threshold and DurabilityBecause the nanostructures comprising Thorlabs' textured surfaces are originally part of the bulk optic, they have substantially higher laser-induced damage thresholds than BBAR coatings. Laser-induced damage at moderate fluence typically originates from the interface between two materials, and the large number of thin-film layers in BBAR coatings increase the likelihood of damage. As our textured surfaces consist of the same material as the bulk, the damage threshold is higher.

Anti reflectivecoatingspray

Each microscope objective is itself a complex assembly of lenses, and besides contributing to the magnification, it is the objective lens which determines the resolution power of the microscope. An objective lens can also provide optical aberration corrections. A reflective objective, for instance, includes two mirrors within the assembly. These mirrors can focus laser light as well as provide chromatic corrections.

Anti reflective paint

Thorlabs' state-of-the-art, in-house, optical coating department provides us with coating capabilities ranging from metal coatings and antireflective coatings to cutting edge Ion Beam Sputtered (IBS), Radio Frequency (RF) Magnetron Sputtered, and Plasma Assisted coatings. This full-scale facility not only allows us to produce large numbers of our catalog optics in house but also expands our ability to manufacture custom-coated optics to suit a variety of customer needs.

Many objectives are designed to be used with a cover glass. Using an incorrect coverslip thickness can greatly reduce the optical performance of a microscopy system.

[1] R. M. Wood, Optics and Laser Tech. 29, 517 (1998).[2] Roger M. Wood, Laser-Induced Damage of Optical Materials (Institute of Physics Publishing, Philadelphia, PA, 2003).[3] C. W. Carr et al., Phys. Rev. Lett. 91, 127402 (2003).[4] N. Bloembergen, Appl. Opt. 12, 661 (1973).

While the simplest of microscopes is simply a magnifying glass with a single lens, compound microscopes used today are highly complex devices with a carefully designed series of lenses, filters, polarizers, beamsplitters, sensors, and perhaps even illumination sources. The exact combination of optical components used will depend on the application of the microscope; the wavelength of light with which it is intended to be used, and the resolution and magnification required in the final image.

The tables below give the specifications for Thorlabs' in-house antireflection coatings, which are deposited on the surfaces of many optics and fibers in our catalog. However, we also offer optics that are coated by external vendors. As such, the specifications for some of our antireflection coated optics may be slightly different than the specifications given on this page. The AR coating specifications for any individual item are always included in that item's web presentation.

Handling Precautions and Cleaning Thorlabs' Textured Windows could be contaminated or damaged by moisture, fingerprints, aerosols, or contact with any abrasive material. The windows should only be handled when necessary and always held by the sides using our TZ2 or TZ3 tweezers. Latex gloves or a similar protective covering should be worn to prevent oil from fingers from reaching the structured surface.

Since there are no step changes in the refractive index, the incident light is able to travel from the air to the bulk glass with virtually no Fresnel reflections. As a result, textured optics can achieve significantly higher transmission than un-textured optics. Thorlabs currently offers three surfaces for stock optics (see the table below for details).

Please note that we have a buffer built in between the specified damage thresholds online and the tests which we have done, which accommodates variation between batches. Upon request, we can provide individual test information and a testing certificate. Contact Tech Support for more information.

The ocular lens, or eyepiece, is also an optical assembly rather than a single lens, but it is typically more simple than the objective. Often it is composed of two lenses: a field lens and an eye lens. The design of the ocular lens determines the field of view of the microscope, as well as contributing to the total magnification of the system.

For keeping the objective at the proper position, there are mounting threads on almost all objectives. Commonly used mounting threads include RMS, M25 x 0.75, M26X 0.706, M32 x 0.75.

Narrowband Laser Line HR CoatingsThorlabs offers a number of laser line HR coatings optimized for various performance parameters. These dielectric HR coatings offer very high reflectance over specific laser line wavelength ranges.

Anti reflectioncoatingprinciple PDF

Alpha Industrial Park, Tu Thon Village, Ly Thuong Kiet Commune, Yen My District, Hung Yen Province Vietnam 17721 +84 221-730-8668 rfqvn@shanghai-optics.com

AR coatings are hard refractory-oxide coatings that minimize surface reflections within specified wavelength ranges when applied to the surface of optical components. Without AR coating, 4% of the light is lost at each optical surface due to reflections. For example, if three uncoated lenses are being used in series, this 4% loss occurs at each of the six optical surfaces. This results in a total loss of 21.7%. If three AR-coated lenses with a "B" coating (Ravg <0.5% per surface) are used instead, the total loss of incident light due to surface reflections is <3%. The use of AR-coated optics improves transmission from 78.3% to greater than 97% in this case. Please note that the 4% loss at the interfaces of uncoated optics is an approximate value that varies greatly with material and angle of incidence (AOI). Please note that the color of the lens does not correlate to the lens’ specifications. The color of each AR coating may vary from batch to batch and is not an indicator of performance.

Now compare the maximum power density to that which is specified as the LIDT for the optic. If the optic was tested at a wavelength other than your operating wavelength, the damage threshold must be scaled appropriately. A good rule of thumb is that the damage threshold has a linear relationship with wavelength such that as you move to shorter wavelengths, the damage threshold decreases (i.e., a LIDT of 10 W/cm at 1310 nm scales to 5 W/cm at 655 nm):

Field of View is the area of the object that can be imaged by a microscopy system. The size of the field of view is determined by the objective magnification or focal length of the tube lens for an infinite-corrected objective. In a camera system, the field of view of the objective is related to the sensor size.

Pulsed lasers with high pulse repetition frequencies (PRF) may behave similarly to CW beams. Unfortunately, this is highly dependent on factors such as absorption and thermal diffusivity, so there is no reliable method for determining when a high PRF laser will damage an optic due to thermal effects. For beams with a high PRF both the average and peak powers must be compared to the equivalent CW power. Additionally, for highly transparent materials, there is little to no drop in the LIDT with increasing PRF.

Ms.Cici

Ms.Cici

8618319014500

8618319014500