Cock ring - vibro testis

The PT3(/M) translation stage is fitted with standard 1" 150-811ST micrometer drives, each of which is engraved every 0.001", while its metric counterpart (PT3/M) comes with 150-801ME micrometers, which offer 25 mm of travel and are engraved every 10 µm. Each stage offers sixteen 1/4"-20 (M6) tapped mounting holes that are 0.22" (5.8 mm) deep.

If the fine adjustment knob on the DM12 is accidentally removed, it can be reattached. Please refer to the DM12 Knob Attachment tab on our DM12 differential drive page for details.

Any of the translation stages featured here can be purchased as a special order without an actuator, thereby allowing the user to choose from our large selection of manual and motorized actuators. We also offer screw adjusters that have Ø3/8" barrel adapters for 1/4"-80, 1/4"-100, or M6 x 0.25 threads, making them compatible with the stages below. When choosing a custom actuator, please be aware of the barrel size of the actuator. Please contact Tech Support to discuss the various micrometer options and to get quotes for custom configurations with or without alternative actuator options.

Another solution is to purchase the Mitutoyo® 05CZA662 SPC cable and IT-016U USB input tool that provide a push button and USB interfacing cable. With this device the user can open any text entry software package, press the single push button, and the device acts like a keyboard to enter the number into the software.

The PT3A(/M) translation stage is offered with differential micrometers for applications requiring increased resolution. The coarse adjustment, which can be locked using a thumbscrew on the mounting collar, provides 0.5 mm of translation per revolution over a range of 1" (25.4 mm).

These linear translation stages feature crossed-roller bearing travel mechanisms for precision motion, high load capacity, and low angular deviation. The LNR Series stages feature all-steel body construction, while the LX, XRN, and XR Series stage bodies are constructed of cast tool and jig aluminum. We also offer several vertical crossed-roller bearing stages (see below).

Digital micrometers, such as the DM713, are handy for moving a piece of optomech a specific distance. For example, a user might want to increment a translation stage holding a sample in front of an objective lens in order to focus the light to equally spaced points within the sample.

Ocularmicrometer

Buy Metric Short Arm Allen Keys / Hex Wrench / Hexagon Sizes 0.9mm-10mm SALE S6I5 H8 L3Q1 from Walmart Canada. Shop for more Hex Keys available online at ...

The objective is parfocalized by translating the entire lens cluster upward or downward within the sleeve with locking nuts so that objectives housed on a ...

The differential adjustment knob provides 25 µm of translation per revolution over a 250 µm range and features graduations every 0.5 µm. Two oversized 1/4" (M6) counterbores allow the stage to be directly attached to a mounting adapter (sold below) or a metric or imperial breadboard with user-supplied cap screws. Each stage includes two alignment dowel pins and contains sixteen 1/4"-20 (M6) tapped mounting holes that are 0.22" (5.8 mm) deep.

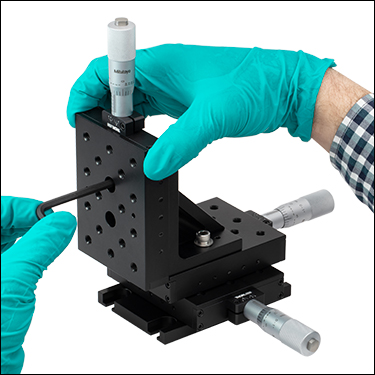

The PT102(/M) is an angle bracket with four 1/4"-20 (M6) mounting holes that allows a PT Series stage to be mounted vertically. This is necessary in all XZ and XYZ configurations. The adapter plate includes four 1/4"-20 (M6) cap screws. It is also compatible with our manual and motorized MT Series translation stages that offer 1/2" (12.7 mm) of travel. This allows stages with different travel ranges to be easily connected within the same mechanical system.

Micrometer stagechart

PT102(/M) Angle BracketThe PT102(/M) Angle Bracket allows for a PT series stage to be oriented vertically, making left- or right-handed XYZ, XZ, and XY configurations possible. For information on constructing an XYZ configuration from individual components, see the XYZ Assembly tab.

Attach the second, orthogonal PT series translation stage, as shown above, using two 1/4"-20 (M6) cap screws. Then insert the two 1/8" alignment pins into the provided holes for aligning the angle bracket.

Micrometer stagemeasurement

Screw the PT102(/M) Angle Bracket to the PT series translation stage, as shown above, using two 1/4"-20 (M6) cap screws. Then insert the two 1/8" alignment pins into the provided holes on the front face of the angle brakcet for aligning the third and final stage.

May 8, 2015 — To measure flatness (for this type of application at least) the proper way to get an accurate measurement is to undermount the probe so the ...

The PT1B(/M) translation stage is configured with a 1/4"-170 TPI adjuster, which has a 1.00" (25.4 mm) travel range. The adjuster can either be actuated by hand or by the 5/64" (2.0 mm) hex located on the end. Each stage includes two alignment dowel pins and contains sixteen 1/4"-20 (M6) tapped mounting holes that are 0.22" (5.8 mm) deep. Two oversized 1/4" (M6) counterbores allow the stage to be directly attached to a mounting adapter (sold below) or a metric or imperial breadboard with user-supplied cap screws.

Eyepiece graticule andstage micrometer

Each stage comes with two precision dowel pins that allow the PT series of translation stages to be stacked in right- or left-handed XY configurations with excellent orthogonality of <5 mrad. The right-handed XYZ configuration, with either the standard manual micrometer or the differential micrometer, is available fully assembled below.

Please contact technical support if your application would benefit from a stage that is equipped with imperial taps and metric micrometer drives or vice versa.

Microscopemicrometerruler

Programming references that provide introductions to communicating with the DM713 Digital Micrometer (Figure 3) are available. One reference has been developed for LabVIEW, and the other for Visual C#. Each reference includes a step-by-step discussion for writing the program, as well as a section that concisely provide the full program text without explanation.

Thorlabs' Smart Pack Initiative is aimed at waste minimization while still maintaining adequate protection for our products. By eliminating any unnecessary packaging, implementing packaging design changes, and utilizing eco-friendly packaging materials for our customers when possible, this initiative seeks to improve the environmental impact of our product packaging. Products listed above are now shipped in re-engineered packaging that minimizes the weight and the use of non-recyclable materials. b

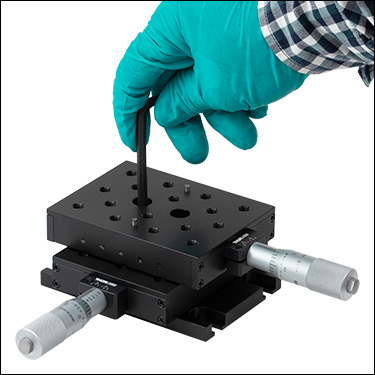

The PT Series of translation stages can be purchased individually (PT1 Series above) or as fully assembled, 3-axis, XYZ translators (PT3 Series). Therefore, the PT3 stage can be disassembled using a 3/16" (5 mm) hex key to customize the positions of the micrometers or to use three PT1 stages separately, see the XYZ Assembly tab for details.

The actuators above are compatible with all of the stages offered on this page, with the exception of PT1/M and PT3/M stages sold before December 30, 2015. Please refer to the footnotes above for more information.

However, there are also times where the user might want to record the position of an event. One example could be making a distance measurement where the micrometer is set to a starting position, zeroed, and then translated the desired amount to display the distance.

3 — Thomas Lilti, son créateur, a longtemps hésité avant de donner une suite à ce récit captivant, puissant reflet de la crise du monde médical ...

XYZ AssemblyThe modular design of the PT series translation stages allows the assembly of 2- or 3-axis stages within minutes. Each stage comes with two precision dowel pins that allow for right- or left-handed XY configurations with excellent orthogonality. Follow the steps in the animation to the left or the photos below to build a 3-axis XYZ translator (PT3) from individual components.

MicroscopeStage Micrometer

In multiphoton microscopy, also known as non linear or two-photon microscopy, a sample is illuminated at twice its normal excitation wavelength.

If the fine adjustment knob on the DM12 is accidentally removed, it can reattached. Please refer to our DM12 Knob Attachment tab on our DM12 differential drive page for details.

Stage micrometercalibration

The Mr. Magnifier 5 Handheld Magnifier is a convenient aid for anyone with low vision. It's small and compact enough to take anywhere.

Custom OptionsAny PT series translation stage can be purchased as a special order without a micrometer, thereby allowing the user to choose from our large selection of manual and motorized actuators. We also offer screw adjusters that have Ø3/8" barrel adapters for 1/4"-80, 1/4"-100, or M6 x 0.25 threads, making them compatible with the stages below. Please see the selection guide in the Actuators tab for a list of compatible actuators. Please contact Tech Support to discuss the various micrometer options and to get quotes for custom configurations with or without alternative actuator options.

As a calibration standard, that disc would cost me about $300-500 when mounted. ... What we use instead is barium sulfate mixed with white paint ...

These compact stages incorporate dovetails and a leadscrew for the translation mechanism. They are suitable in general purpose motion control applications.

Thorlabs' Nanoflex™ translation stages feature frictionless flexure mechanisms for improved positioning and resolution when compared to similar stages made using bearings. The translation of the stage is accomplished by the elastic deformation (flexing) of a linkage attached to the mounting platform. Most models also include piezo actuators for small position adjustments.

Using the DM713 alone creates an extra step where the user has to read and record the display, which can be tedious in a dark lab where the display is not visible. One solution is to use Thorlabs' SBC-COMM, which includes an RS-232 interfacing cable. Thorlabs has created software application notes that walk the user through creating Visual C#® and LabVIEW® programs to continuously measure distances with the DM713. The application notes can be downloaded from links in the following section.

by N Klemke · 2019 · Cited by 101 — The carrier dynamics can produce high-order harmonics of the driving field extending up into the extreme-ultraviolet region. Here, we introduce ...

2024724 — BEAMS CALCULATION Complete instructions at: https://carreteras-laser-escaner.blogspot.com/2015/09/calculo-de-momentos-flectores-cortantes.

Thorlabs' manual translation stages are offered in a range of maximum travel distances, from less than 1/4" (6 mm) to 2" (50 mm) and longer for our long travel, large area platforms. Many of these stages can be ordered in multi-axis configurations, providing XY or XYZ translation. For fiber coupling applications, please see our Multi-Axis Stages, which offer finer adjustment than our standard manual translation stages. In addition to linear translation stages, we offer rotation stages, pitch and yaw platforms, and goniometers. We also offer motorized translation stages that are powered by DC Servo motors, stepper motors, or direct drive technology.

PT101(/M) Base PlateThe PT101(/M) Base Plate is ideal for XY or XYZ multi-axis configurations where the standard counterbores in the middle of the stages are obstructed. It has 1/4" (M6) counterbore slots for mounting to a breadboard or optical table and comes with the two 1/4"-20 (M6) cap screws that are needed to attach it to a PT series stage.

The PT3(/M) XYZ configured stages include both the PT101(/M) and PT102(/M) adapters. Please see the XYZ Assembly tab for more information on using these adapters to create a multi-axis configuration.

We offer vertical translation stages with crossed-roller bearings for precise motion as well as long travel vertical stages for heavy-duty applications.

For applications that require increased resolution, the PT1A(/M) translation stage is configured with the DM12 differential adjuster. The coarse adjustment, which can be locked using a thumbscrew on the mounting collar, provides 0.5 mm of translation per revolution over a range of 1.00" (25.4 mm).

The PT101(/M) and PT102(/M) are adapter plates designed for the PT Series translation stages. The PT101(/M) has four 1/4"-20 (M6) mounting slots on the side that enable obstruction-free mounting onto an optical breadboard. It is ideal for XY configurations or already assembled XYZ multi-axis configurations where the standard counterbores in the middle of the stages are obstructed. This base plate includes two alignment dowel pins and two 1/4"-20 (M6) cap screws.

Stage micrometerlength

If you can get away without the waterproofing, The Insta 360 One RS 1 Inch is by far the best quality camera in the price range. While it has a few drawbacks - ...

Insert the two 1/8" alignment pins into the PT101(/M) Base and then screw it onto a PT series translation stage using the two included 1/4"-20 (M6) cap screws. Then insert the two 1/8" alignment pins into the provided holes to ensure orthogonality of the second stage.

The differential adjustment provides 25 µm of translation per revolution over a 250 µm range. The dfferential adjustment knob features graduations every 0.5 µm. Two 1/4"-20 (M6) counterbores allow the stage to be directly attached to a breadboard or mounting adapter (sold below) with user-supplied cap screws. Each stage contains sixteen 1/4"-20 (M6) tapped mounting holes that are 0.22" (5.8 mm) deep.

Thorlabs' PT Translation Stages have a 1.00" (25.0 mm) translation range and feature hardened steel linear bearings for precise motion and long life. These translation stages are available preconfigured with an adjuster screw, standard manual micrometer, or differential adjuster. The actuator on the translation stage can be removed by loosening the screw on the barrel clamp with a 3/32" (2.5 mm) hex key.

The PT Series translation stages can be purchased individually (PT1 Series) or as fully assembled, 3-axis, XYZ translators (PT3 Series). Therefore, the PT3A stage can be disassembled using a 3/16" (5 mm) hex key to customize the positions of the micrometers or to use three PT1 stages separately, see the XYZ Assembly tab for details.

The PT1(/M) translation stage is configured with the 150-811ST micrometer drive, which has a 1.00" travel range and engraved graduations every 0.001". The PT1/M is fitted with the metric 150-801ME micrometer, which has a 25.0 mm travel range and engraved graduations every 10 µm. Each stage includes two alignment dowel pins and contains sixteen 1/4"-20 (M6) tapped mounting holes that are 0.22" (5.8 mm) deep. Two oversized 1/4" (M6) counterbores allow the stage to be directly attached to a mounting adapter (sold below) or a metric or imperial breadboard with user-supplied cap screws.

These translation stages feature hardened steel linear bearings for precise motion and long life. They are available with a variety of actuators and in single-axis or preassembled multi-axis configurations.

Ms.Cici

Ms.Cici

8618319014500

8618319014500