Binding of an acceptor substrate analog enhances the ... - substrate analog

However, you can (in some cases) get adapters that let you use a lens designed for a lens mount with a shorter flange distance than the mount your camera uses. There are two types of these adapters.

The "screw driver" is spring loaded, so you can mount lenses without it scratching the mount as you rotate the lens to lock it in place. On the lens you can see the corresponding "screw" that the "screw driver" slots into.

But if you have or are thinking of buying a camera with the Canon EF, Nikon F, Sony A, or Pentax K mount, then this section is worth a read.

Mixing ratios for both PU and acrylic catalytic curing materials will be calculated by weight and / or volume. The calculation of ratio values for 3-part acrylic materials will be different from that of PU based. Clearly single part ultra-violet curing acrylic LOCA materials do not require mixing.

Both curing mechanisms (the radical polymerisation of acrylic systems and the polyaddition of the PU systems) can be considered as exothermic.

Pentax's KAF2 mount provides a screw drive motor and works with K mount lenses that have a built in focus motor as well.

Room 201 - 401 , Building B1, Hengli Industrial Park, no. 168, Weikeng Road, Tongde Community, Baolong Street Longgang Qu Shenzhen Shi Guangdong Sheng, 518115 China

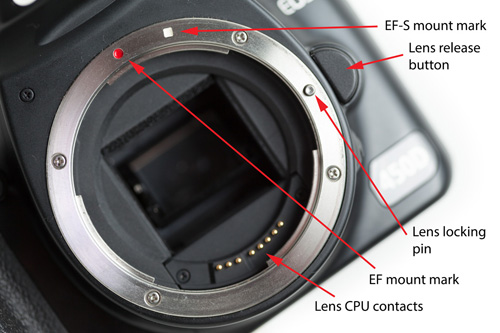

Some lens mounts use a purely electronic connection to the lens, while other mounts use a combination of electronic and mechanical connections. Below you can see a Canon EF mount lens, and the EF mount on the camera. The Canon EF mount is an electronic mount.

Calculation of the correct material volumes will be a function of the required interlayer thickness, area of the envelope and appropriate shrinkage values.

In some materials the polymeric chains are classified as fully crosslinked subsequently providing a viscoelastic behaviour that can demonstrate relatively low dependency when considered over temperature, time and under load duration.

After a few years, technology improved, and it became possible to produce full frame image sensors, the same size as a frame of 35mm film at a reasonable cost. And so we today have a situation where cameras with different sensor sizes both use the same lens mount, and lenses designed for different sensor sizes both use the same lens mount.

But, the sensor size used in the first DSLRs (and still used in many today) was smaller than a frame of 35mm film used in film SLRs. This was mostly due to the high costs of large sensor fabrication.

The lens mount a camera uses affects what lenses you can use with that camera. Most lens mounts have a wide range of different lenses available, and so consideration of the lens mount is not particularly important.

For cameras with APS-C sized sensors, they can accept both 'designed for APS-C' lenses, and lenses designed to cover the image circle covered by 35mm film (full frame).

Shrinkage values will change for different materials ranging from 2% up to 13% by volume with the shrinkage values for polyurethane materials generally being lower than those of the acrylics.

For example, a Canon 600D DSLR has an APS-C sized sensor and uses the Canon EF mount. It can accept lenses that use the EF mount and are designed for use with APS-C sized sensors (EF-S / Di II / DC / DX depending on the lens manufacturer). It can also accept lenses that use the EF mount and are designed for use with 35mm film cameras or full frame digital cameras.

It is also worth noting that manufacturers can license a lens mount. For example, Fuji produced several DSLR cameras that used the Nikon F mount. And Kodak produced a couple of cameras that were available in both Canon EF and Nikon F mount versions.

Any additional adhesion preparations e.g. primers will be applied to the glass surface at this point before finally rinsing with de-ionised water.

You can't use a lens designed for one lens mount on a different lens mount as the lens just won't fit. E.g. you can't use a Canon lens on a Nikon camera. Sometimes an a adapter can be used, but we'll look at this later.

With adhesions to pyrolytic coated glass surfaces, consideration should be given to the interlocking adhesion of the metallised coatings to themselves in addition to the adhesion to substrate surfaces. The characteristics of these surfaces should always be considered before commencing preparation or processing.

These sorts of adapters are only available for lens mounts where there is a small difference between the two flange distances. A common one is an adapter that lets you use Canon FD mount lenses on a Canon EF mount body. The FD mount has a flange distance of 42 mm, while the EF mount has a flange distance of 44 mm.

The number and placement of CPU contacts varies between each type of lens mount. Also, the signals sent through the contacts is different.

Another thing to note is that the camera manufacturers also produce different versions of their lenses and lens mounts that are not fully compatible with each other.

It won't work the other way round, of course. You can't have an adapter that removes 26.21 mm from the Pentax K mount to allow you to use micro four thirds lenses. The lenses would have to go inside the mount!

Nikon meanwhile uses a combination electronic and mechanical mount. Below you can see a Nikon F mount lens and the F mount on the camera.

So if you have a full frame camera, or might want to purchase one in the future, you need to consider this when looking at lenses.

c) Free formed edge sealing, free of a proprietary adhesive material, can be achieved by using specially designed mechanically applied systems.

Lamination of most standard substrates is possible, however changes in type and thickness may require a change of interlayer thickness. Certain non-glass substrates require particular chemical preparations or pre-treatments.

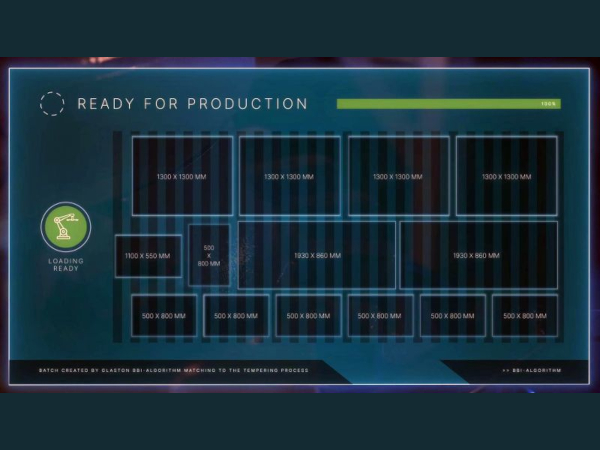

Catalytic curing interlayers are mixed and metered in specially design dispensing units which area essential to manage the differing material densities to achieve the correct final mixed liquid density and the final density of the fully cured material.

Most lens mounts use a pin on the camera body that inserts into a hole on the lens to lock the lens in place. To remove the lens, press the lens release button on the camera body. This retracts the locking pin. With the button held down, you can then rotate the lens back and remove it from the camera.

The main issue is the coverage of the lens. When digital cameras were first introduced, most of the manufacturers (with the exception of Olympus) carried on using the same lens mounts they had been using for their film cameras.

PU materials require the efficient degassing of both A and B components before mixing and metering this can also be applied to single part acrylic materials where evacuation of the oxygen from the pre-cured material increases the efficiency of the polymerisation reaction.

The pot life of different systems, although influenced by ambient temperatures can be adjusted for the catalytic systems.

Canon's EF mount uses a purely electronic linkage with the lens, so all lenses for the EF mount contain a built in focus motor.

LOCA glue remover

If you are considering purchasing a camera that accepts interchangeable lenses, you need to be aware of compatibility issues. Buying a camera and lens and then finding they don't work properly together could be quite annoying.

Curing profiles can be monitored by measuring temperature changes resulting from the exothermic reaction. Completion of the reaction can generally be expected from 6 to 20 minutes. Changes in the types and thickness of substrates used will directly impact the intensities of UV radiation absorbed by the liquid interlayer and this changes the duration of the cure required. Additional time (safety factor) is generally added to the time taken to reach the maximum temperature to ensure that all materials are full and equally cured. This ensures that reliance is not placed entirely, only the area of the envelope that is monitored, thus reducing the opportunity for excessive differential curing.

Interlayer dimensions are key to effecting full cross linking thus offsetting the changing surface tension conditions and stiffness characteristics of differing glass types. As an example, interlayer thickness for float glass may increase from the standard 1.0mm up to 1.5mm and the maximum 2.0mm once the thickness of the float glass increases up to 6.0mm and then 8.0mm. Where the surface tensions of tempered glass increase and then the minimum interlayer thickness will automatically start at 1.5mm and then 2.0mm for all substrates thicker than a nominal design thickness of 5.0mm. This increase in interlayer thickness will also be required to accommodate for the changing roller wave and edge dip characteristics of heat-treated glass.

Although these manufacturers produce lenses in multiple mounts, the mount on the lens is not interchangeable. So you can't buy a Sigma lens designed for use with Canon EF mount and then use it on a Nikon F mount camera. Instead you'd need to buy the Nikon F mount version of the lens.

Changes in ambient temperatures outside of those recommended for production 18 0 C – 23 0 C (dependant on the material type) can impact on the realisation of the correct mixing of the components. Controlling temperature in the production environment within the prescribed operating window is therefore important for achieving the optimum mixing of materials.

However, the lens mount does become more important if you are looking to use older (and cheaper) manual lenses. It is also important when buying a lens to check that it is compatible with your camera. For most people though, the type of lens mount a camera uses is worth considering, but probably quite far down on the list of important features.

On Canon EF-S lenses, they modified the mount on the lens slightly, so they cannot be mounted on a full frame camera with EF mount. For Sony and Nikon, their DT and DX lenses can be mounted on full frame cameras, and the camera will crop the images to the same size as an APS-C sensor.

The first thing to note is that each camera manufacturer typically has their own lens mount that they use on their cameras.

LOCA UV Glue

a) Single part acrylic-based materials are generally cured using UVA light radiated within a specific prescribed wavelength window. This activates the photo initiators embedded in the polymer, initiating the chemical reaction and forming the bonds and within the polymeric chains. UV light sources can be directed from above or both above and below.

The automatic cropping of lenses designed for use with APS-C sized sensors on a full frame camera can be disabled. This gives you a good idea of the reduced image circle that these lenses offer when cropping is disabled:

Ambient temperatures outside of the recommended operating windows may prevent, retard or accelerate the reaction resulting in incomplete or accelerated curing resulting in localised stresses being formed. Differential curing can also be caused by a differential thickness across the interlayer that exceeds the allowed tolerance generally expressed as +/-0.5mm /m. This may result from the substrates being out of flatness or uneven curing tables. Tolerances should be set to guide the levels of acceptable uniform intensity for the sources of UV radiation. These can be either conventional blacklight tubes or alternatively UV LED units. Unequal radiation intensity outside of set parameters from the UV light sources must be controlled if excessive levels of differential stress are to be avoided.

b) Preformed acrylic edge tapes at standard 1.0mm, 1.5mm and 1.8mm thickness. Full wetting of the adhesive faces can be improved using a primer and utilising a wetting out period of up to 24 hours ensuring that good adhesion is achieved. The recommendation to use tested, fully cured and approved materials will ensure that the:

For cameras with full frame sensors, they cannot properly use a lens designed for use with an APS-C sensored camera. The image circle produced by the lens is just not big enough to cover the full frame sensor.

Some lenses feature built in autofocus motors, while other lenses use what's known as a screw drive, which is driven by a motor in the camera body. Not all camera bodies feature screw drive motors.

b) With catalytic curing, materials curing is activated or accelerated by a chemical reaction between the catalyst component and the base material. Ambient temperatures will play an important part in the phasing of the reaction process. Measurement of the maximum temperatures and durations of the temperature cycle provides a quality management process for the effectiveness of the final cure.

The four thirds, micro four thirds, Nikon CX, Sony E, and Samsung NX mounts are all new 'designed for digital' mounts that have no hold-over from the days of film cameras. So if you have or are thinking buying a camera with one of these mounts, you can safely skip over this section.

The majority of links on this website are affiliate links. This means that I earn a commission if you purchase a product through one of these links. The product will still cost you the same as if you went direct, and the commission helps pay for running this site.

LOCA materials are designed to manufacture laminated glass composites for use in most standard applications, used in both building product and automotive applications where primary requirements are safety and structural stability. Increasing focus is now placed on the use of LOCA products to embed and encapsulate passive and dynamic functions whilst providing mechanical stability and protection against potentially damaging environmental conditions.

a) Isobutylene material formed on a roll, which can be manually or automatically pressed at around 1 bar to provide the correct envelope depth. Butyl materials are considered as having thermal expansion values more aligned to those of the interlayer LOCA materials. They are also generally considered to provide superior barriers to moisture transmission however they are generally not transparent.

The CPU contacts on the lens and lens mount connect together so that the camera can communicate information to the lens. In the examples above you can see Nikon uses spring loaded pins in the lens, while Canon uses spring loaded pins in the camera. When the lens is locked into position, the pins touch the contacts to allow electrical signals between the body and lens.

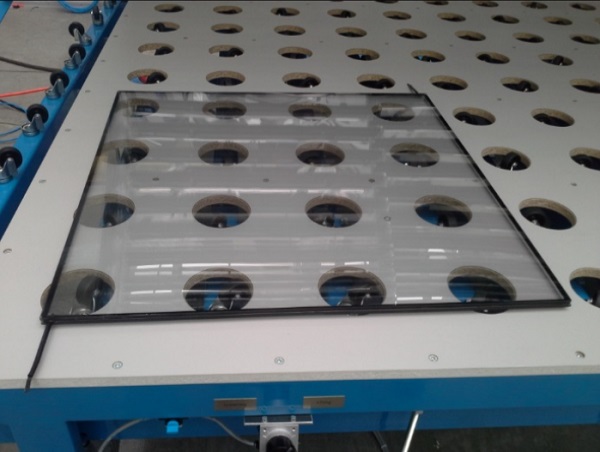

Liquid interlayers present an alternative thermoset solution to more conventional thermoplastic folio materials for bonding glass to itself or to alternative substrate types. The principle of liquid lamination generally requires the void between the substrates to be permanently or temporarily perimeter sealed before the introduction of the pre-cured liquid polymer. It generally requires only one significant phase change from liquid to a cured polymer through either catalyst or ultra-violet light activated photo initiator mechanisms.

Each camera manufacturer typically produces lenses designed only for their own lens mounts. There are also a number of third party manufacturers who produce lenses for a variety of mounts. The main lens manufacturers are Sigma, Tokina, and Tamron.

Processing cleaning with the use of a standardised 3 stage warm water clean station, de-mineralised rinse and final air drying. Excessive residual moisture content resulting from the cleaning process and incidental humidity should be avoided if possible. Non-compliant incidental surface contaminations such as oils are normally treated with an isopropanol / de-ionised water mixture in a secondary cleaning process.

After a while, the manufacturers started to produce lenses specially to fit the reduced sensor size of their digital cameras. This made the lenses smaller and cheaper to manufacture. These lenses covered the smaller size of the digital sensors, but did not produce an image circle large enough to cover a frame of 35mm film.

Processing is possible with all types of standard soda lime silicate float glass without the specific need to consider particular surface preparations for adhesion to the “tin” or “air” sides.

LOCA glue for Tempered glass

So it is best the check the specification of the lens if you want to be sure whether or not it includes a built in autofocus motor. All Canon and third party autofocus lenses for the Canon EF mount feature a built-in focus motor.

Free flowing liquids will more easily follow the shape, contour and surface textures of the envelopes they are injected into and can be considered as “passive” with processing generally carried out at room temperatures and without the need for excessive mechanical pressing or vacuum extraction.

There are a large number of old lenses designed for use with lens mounts that are no longer in common use. That means these lenses can often be picked up fairly cheap. When used on a different lens mount via an adapter, they will always be manual focus, and you will also need to control the aperture manually. (Old lenses have an aperture ring you use to set the aperture).

iii) Multi component catalytic curing acrylic materials are often in 3 components based on a base material, catalyst and then a separate adhesion promotor. The curing mechanism is generally by radical polymerization via a catalyst thus the reaction only starts when the components are mixed.

With Pentax cameras, you don't (currently) need to worry about whether a lens will be compatible with your camera or not. All Pentax DSLRs use an APS-C sized sensor, and so are compatible with lenses that use the K mount, whether they cover APS-C or full frame.

The first acts like an extension tube, so the lens can focus closer, but you lose infinity focus (can't focus on things further away).

In addition to glass substrates the bonding of glass to polycarbonate is enabled using specially developed PU based materials which have a naturalised chemical relationship to the surface of polycarbonate. The differential thermal expansion value of glass and polycarbonates, where the linear and / or volumetric expansion of polycarbonate is much greater than glass thus placing much greater tensions onto and into the interlayer material. Due to this differential expansion, it is important that the material bonding these two differing substrates combines a level of restraint or stiffness with creep and relaxation behaviour to compensate. Specially designed primers are used to enhance the adhesive properties of the glass surface to PUR.

Different lens mounts use a different flange distance. The flange distance, also known as the register distance, is the distance between the lens mount and the camera sensor (where the rays from the lens will be focused).

i) Polyurethane based catalytic curing ii) Acrylic based cured with ultraviolet light iii) Acrylic based catalytic curing materials

Both Nikon and Sony vary as to whether their camera bodies include a built in screw drive motor. Some do, some don't. Typically their cheapest models don't include a built in motor, and will only autofocus with lenses that have a built in motor.

As a note to the above table, Samsung produced a couple of K mount lenses for use with APS-C sized sensors, but their lenses are not specifically labeled as such. Samsung also licensed the Schneider-Kreuznach name for use on some re-badged Pentax K mount lenses, again these lenses are not labeled as to whether they are designed for use with APS-C cameras.

Note that Tokina do not have a special designation to show that the lens features a built in motor. Similarly, some Sigma and Tamron lenses may have a built in motor but not feature the HSM / PZD / USD designations. (The designations actually refer to the type of autofocus motor used in the lens).

Conditioning of both components requires de-gassing and adhesion is achieved via a reaction of the PU material with the glass surface and enhanced by adhesion promotors.

All current lens mounts use a bayonet type fitting. You line up a marking on the lens with a marking on the camera body, and the lens can then be slotted into the mount on the camera. Then the lens is rotated (whether left or right depends on the lens mount), until it locks into place.

ii) Single part ultraviolet curing acrylic-based materials include an embedded photo-initiator that starts the radical polymerization under UVA exposure thus resulting in formed polymeric chains. The inclusion of co-monomers can enhance or tune properties such as tensile strength for impact performance.

Of course, cropping the image means you loose image data compared to what you would capture with a lens designed for use with full frame cameras. A DT lens used on the 24.6MP Sony A900 will only produce an 11MP image. The rest of the image has to be cropped away to compensate for the lens' reduced image circle.

i) Polyurethane systems are generally designed with 2 parts formed by a base polyol material (component A) and corresponding isocyanate-based component (B component). The curing mechanism is often a catalytical poly-addition reaction with a function that may absorb small amounts of atmospheric moisture within the envelope and moisture captured on the surface of the substrate from the glass cleaning process. These materials can be considered as hydrophobic with low residual moisture contents. However excess moisture present during the curing phase should be avoided as it can create a side reaction within the isocyanate forming carbon dioxide that consequently forms a matrix with bubble inclusions.

Some mechanical mounts feature a screw drive motor used for autofocusing the lens. (See section below on Autofocus motors for more information). In the Nikon F mount photo, the camera was set to manual focus, and so the "screw driver" is recessed in the body, in autofocus mode it would pop out.

Tagged with Digital Single Lens Reflex cameras, DSLRS, Flange distance, Interchangeable Lenses, Lens mount adapters, Lens mounts, MILCs, Mirrorless cameras, Single Lens Translucent Cameras, SLTs, Using old manual lenses

Mechanical mounts like the Nikon F mount often have an aperture lever. This is to allow controlling the aperture of the lens from the camera. Electronic mounts still allow this, just the control is done via sending an electrical signal to the lens rather than mechanically.

It is also important to remember that when you buy into a camera that offers interchangeable lenses, you are buying into a system. So you need to consider carefully the range of lenses available in that system.

As a general rule, a lens mount with a smaller flange distance can use lenses designed for use with a mount with a larger flange distance, provided the correct adapter is used. The exception to this is with some lenses where the rear protrudes back inside the camera. These can cause a problem with DSLRs and SLTs as the rear of the lens might hit against the camera's mirror.

Mirrorless cameras tend to have quite a short flange distance because they don't need any room behind the lens mount for a mirror. This has made them quite popular for mounting old lenses on, and there are a wide range of adapters for using different mount lenses on the micro four thirds and Sony E mount (NEX) cameras.

So if you buy a lens that relies on the screw drive motor of the camera body, but the camera body doesn't have a motor, then you won't be able to autofocus with that lens.

In this article we'll look at the different compatibility issues you might come across, and also how some cameras can be used with a wider range of lenses via adapters.

So if you might be interested in using older manual lenses with your digital camera, it is a good idea to check the flange distance for the mount of the camera you are looking at. You can see a good list of different lens mounts and their flange distances at Wikipedia: Flange focal distance.

For example, the Micro four thirds lens mount has a flange distance of 19.25 mm, while the Pentax K mount has a flange distance of 45.46 mm. So, by using an adapter with a width of 26.21 mm (19.25 + 26.21 = 45.46), a Pentax K mount lens can be used on a micro four thirds lens mount.

The image sensors used in DSLRs were about the same size as a piece of APS-C film. So they are known as APS-C sized sensors.

With a temporary or permanent edge seal applied to the envelope the LOCA material can, where applicable, be mixed and subsequently metered into the envelope by way of an injection type process. Mixing is normally carried out at the point of delivery to avoid excessive purging post-application.

Optically Clear Adhesivefilm

A camera with a short flange distance can use lenses meant for a camera with a larger flange distance by use of an adapter. The adapter adds the extra distance needed so that the lens can focus correctly.

The other type of adapter includes corrective glass, so you retain infinity focus. This usually works like a teleconverter, so the image is magnified / cropped compared to what it should be. The extra glass in these adapters usually reduces image quality as well.

The method for curing the liquid material into the semi solid polymer changes dependant on the curing mechanisms as described above:

Ms.Cici

Ms.Cici

8618319014500

8618319014500