Beam Splitters - polarization beam splitter

Glass Design - The quality of glass formulations has been paramount in the evolution of modern microscope optics, and there are currently several hundred of optical glasses available for the design of microscope objectives. The suitability of glass for the demanding optical performance of a microscope objective is a function of its physical properties such as refractive index, dispersion, light transmission, contaminant concentrations, residual autofluorescence, and overall homogeneity throughout the mixture. Care must be taken by optical designers to ensure that glass utilized in high-performance objectives has a high transmission in the near-ultraviolet region and also produces high extinction factors for applications such as polarized light or differential interference contrast.

From the discussion above it is apparent that objectives are the most important optical element of a compound microscope. It is for this reason that so much effort is invested in making sure that they are well-labeled and suited for the task at hand. We will explore other properties and aspects of microscope objectives in other sections of this tutorial.

In refractors, the objective lens is designed to focus different wavelengths of light onto the same plane. While this design leads to chromatic aberrations, where colors don’t converge at the same point, the lens’s precise curvature effectively reduces coma.

Although not common today, other types of adjustable objectives have been manufactured in the past. Perhaps the most interesting example is the compound "zoom" objective that has a variable magnification, usually from about 4x to 15x. These objectives have a short barrel with poorly designed optics that have significant aberration problems and are not very practical for photomicrography or serious quantitative microscopy.

Microscope manufacturers offer a wide range of objective designs to meet the performance needs of specialized imaging methods, to compensate for cover glass thickness variations, and to increase the effective working distance of the objective. Often, the function of a particular objective is not obvious simply by looking at the construction of the objective. Finite microscope objectives are designed to project a diffraction-limited image at a fixed plane (the intermediate image plane), which is dictated by the microscope tube length and located at a pre-specified distance from the rear focal plane of the objective. Microscope objectives are usually designed to be used with a specific group of oculars and/or tube lenses strategically placed to assist in the removal of residual optical errors. As an example, older Nikon and Olympus compensating eyepieces were used with high numerical aperture fluorite and apochromatic objectives to eliminate lateral chromatic aberration and improve flatness of field. Newer microscopes (from Nikon and Olympus) have objectives that are fully corrected and do not require additional corrections from the eyepieces or tube lenses.

Nikon objectives microscopemanual

Extra Low Dispersion (ED) glass was introduced as a major advancement in lens design with optical qualities similar to the mineral fluorite but without its mechanical and optical demerits. This glass has allowed manufacturers to create higher quality objectives with lens elements that have superior optical corrections and performance. Because the chemical and optical properties of many glasses are of a proprietary nature, documentation is difficult or impossible to obtain. For this reason the literature is often vague about the specific properties of glasses utilized in the construction of microscope objectives.

The objective depicted on the left in Figure 3 has a parfocal distance of 45mm and is labeled with an immersion medium color code in addition to the magnification color code. Parfocal distance is measured from the nosepiece objective mounting hole to the point of focus on the specimen as illustrated in the figure. The objective on the right in Figure 3 has a longer parfocal distance of 60 millimeters, which is the result of its being produced to the Nikon CFI60 200/60/25 Specification, again deviating from the practice of other manufacturers such as Olympus and Zeiss, who still produce objectives with a 45mm parfocal distance. Most manufacturers also make their objective nosepieces parcentric, meaning that when a specimen is centered in the field of view for one objective, it remains centered when the nosepiece is rotated to bring another objective into use.

Parfocal Distance - This is another specification that can often vary by manufacturer. Most companies produce objectives that have a 45 millimeter parfocal distance, which is designed to minimize refocusing when magnifications are changed.

Some telescopes incorporate multiple lenses in their design, with each lens serving to correct aberrations or enhance the image quality. The choice and combination of lenses influences various factors, including the telescope’s focal length, magnification, and overall performance.

Cements employed in building multiple lens elements usually have a thickness around 5-10 microns, which can be a source of artifacts in groups that have three or more lens elements cemented together. Doublets, triplets, and other multiple lens arrangements can display spurious absorption, transmission, and fluorescence characteristics that will disqualify the lenses for certain applications.

There is a wealth of information inscribed on the barrel of each objective, which can be broken down into several categories. These include the linear magnification, numerical aperture value, optical corrections, microscope body tube length, the type of medium the objective is designed for, and other critical factors in deciding if the objective will perform as needed. A more detailed discussion of these properties is provided below and in links to other pages dealing with specific issues.

Motorized rotation stages are a set of precision positioning products designed and built over many decades of experience in providing solutions to research ...

Chromatic aberration occurs because objective lenses refract different wavelengths of light at varying angles. This results in a failure to focus all colors to the same convergence point, leading to color fringing around observed objects.

To prolong the life of an objective lens, it’s crucial to maintain it properly by protecting it from scratches and pollutants, like dust. Dust accumulation not only compromises image clarity but also leads to optical aberrations if not addressed.

Nikon microscope

Finding a good color scheme for presenting data can be challenging. This color cheatsheet will help! R uses hexadecimal to represent colors. Hexadecimal is a ...

Nikon60X objective

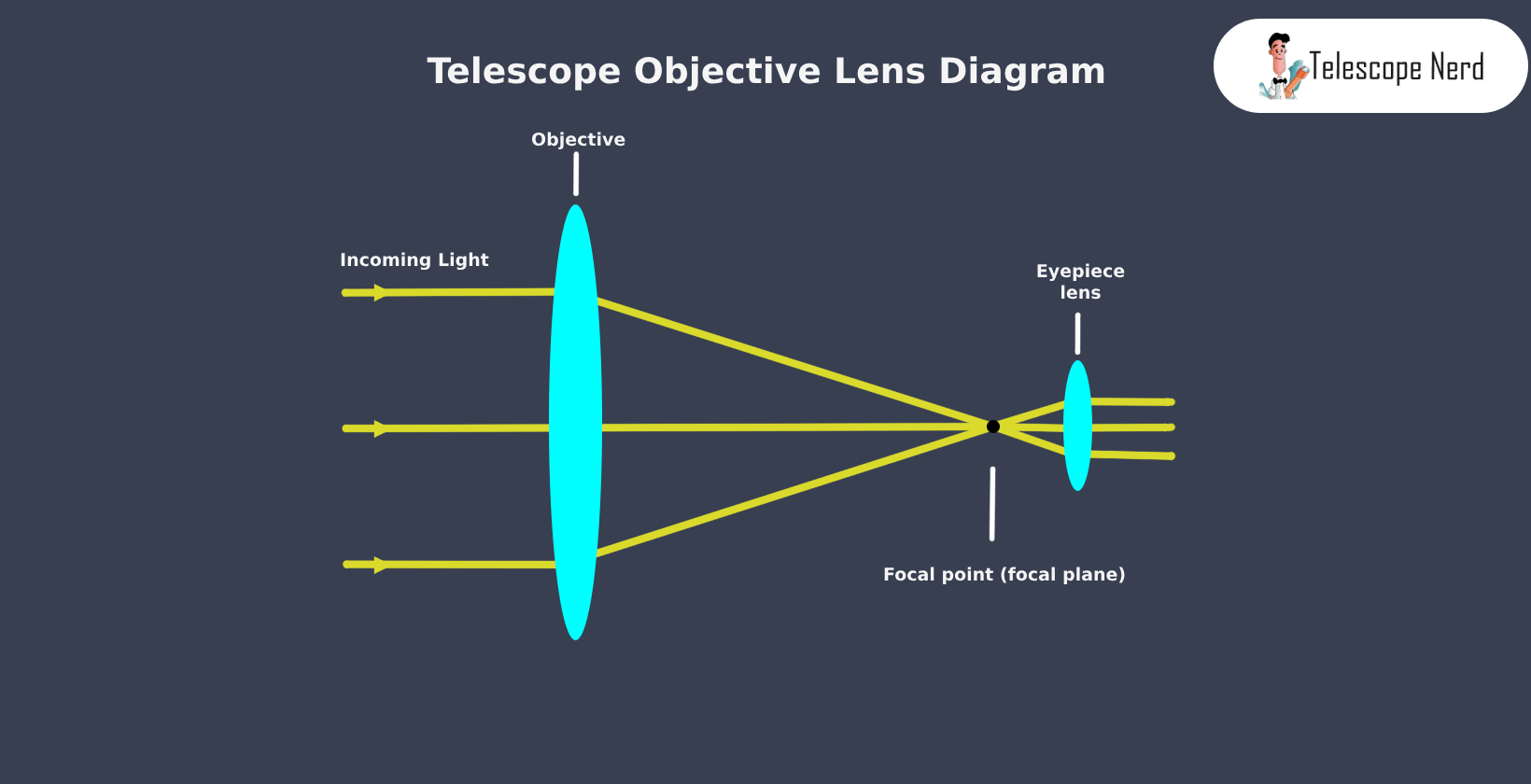

The objective lens refracts light into the focal point because the lens is thinner at the edges than in the middle. When light passes through the thinner parts, it is refracted at a higher angle than in the middle. This causes light to converge into focus at the same point where it is magnified and observed.

Illustrated in Figure 4 is a schematic drawing of light waves reflecting and/or passing through a lens element coated with two antireflection layers. The incident wave strikes the first layer (Layer A in Figure 4) at an angle, resulting in part of the light being reflected (R(o)) and part being transmitted through the first layer. Upon encountering the second antireflection layer (Layer B), another portion of the light is reflected at the same angle and interferes with light reflected from the first layer. Some of the remaining light waves continue on to the glass surface where they are again both reflected and transmitted. Light reflected from the glass surface interferes (both constructively and destructively) with light reflected from the antireflection layers. The refractive indices of the antireflection layers vary from that of the glass and the surrounding medium (air). As the light waves pass through the antireflection layers and glass surface, a majority of the light (depending upon the incident angle--usual normal to the lens in optical microscopy) is ultimately transmitted through the glass and focused to form an image.

Due to diffraction of light, conventional microscopy has a practical resolution limit of ∼ λ / ( 2 N A ) , called the Abbe diffraction limit, where λ is the ...

It’s also important to monitor other components such as the lens mount, where the objective lens is attached to the telescope. The lens mount should be periodically inspected for debris to ensure the telescope focuses optimally. Additionally, the storage environment of the telescope plays a pivotal role in its longevity. A dry environment is paramount to prevent the onset of fungus or moisture damage to the objective lens.

Annealing of optical glass for the manufacture of objectives is critical in order to remove stress, improve transmission, and reduce the level of other internal imperfections. Some of the glass formulations intended for apochromat lens construction are slow-cooled and annealed for extended periods, often exceeding six months. True apochromat objectives are manufactured with a combination of natural fluorite and other glasses that have reduced transmission in the near-ultraviolet region.

The objective lens is a part of a refracting telescope that collects and focuses light from distant objects. Knowing the design and material of an objective lens is crucial as it influences the telescope’s field of view, magnification, and overall performance.

The objective lens of a telescope, integral to the viewing experience, is constructed using a combination of materials. The lens is typically crafted from crown or flint glass, each known for its unique refractive properties. The objective lens is secured within the telescope’s optical tube assembly (OTA). To enhance performance, the surface of the objective lens should be treated with anti-reflective coatings, commonly derived from materials such as magnesium fluoride, to maximize light transmission and minimize unwanted reflections. Each material, combined with its quality and any applied coatings, plays a pivotal role in determining the clarity, brightness, and color accuracy of the images produced by the telescope.

Calculate FOV. Focal Length (mm)*. Pixel Size (μm)*. Detector Horizontal Pixels*. Detector Vertical Pixels*. Horizontal FOV (°). Vertical FOV ...

The shape of the objective lens is convex, meaning it bulges outward. This design allows it to act as a converging lens, focusing parallel rays of light to converge at a focal point. The distance from the focal point to the objective lens is called the focal length.

Special Features - Objectives often have additional special features that are specific to a particular manufacturer and type of objective. The plan apochromat objective illustrated in Figure 1 has a spring-loaded front lens to prevent damage when the objective is accidentally driven onto the surface of a microscope slide.

It also allows a laser beam to stay narrow over great distances (collimation), a feature used in applications such as laser pointers, lidar, and free-space ...

NikonE Planobjectives

Multilayer Antireflection Coatings - One of the most significant advances in objective design during recent years is the improvement in antireflection coating technology, which helps to reduce unwanted reflections (flare and ghosts) that occur when light passes through a lens system, and ensure high-contrast images. Each uncoated air-glass interface can reflect between four and five percent of an incident light beam normal to the surface, resulting in a transmission value of 95-96 percent at normal incidence. Application of a quarter-wavelength thick antireflection coating having the appropriate refractive index can increase this value by three to four percent. As objectives become more sophisticated with an ever-increasing number of lens elements, the need to eliminate internal reflections grows correspondingly. Some modern objective lenses with a high degree of correction can contain as many as 15 lens elements having many air-glass interfaces. If the lenses were uncoated, the reflection losses of axial rays alone would drop transmittance values to around 50 percent. The single-layer lens coatings once utilized to reduce glare and improve transmission have now been supplanted by multilayer coatings that produce transmission values exceeding 99.9 percent in the visible spectral range. These specialized coatings are also used on the phase plates in phase contrast objectives to maximize contrast.

Investigate how the size of the light cone entering the objective front lens changes with the objective numerical aperture value.

Discover how internal lens elements in a high numerical aperture dry objective may be adjusted to correct for fluctuations in cover glass thickness.

To maintain the condition of the lens, use a lens cap consistently when the telescope is not in active use. To clean an objective lens, begin with a soft brush or compressed air to delicately remove any loose dust particles. If the lens has more stubborn marks or smudges, use a lens cleaning solution with a microfiber cloth. It’s crucial to remember to apply the solution to the cloth and not directly onto the lens, using gentle, circular motions to avoid potential damage. Excessive or incorrect cleaning methods will inadvertently scratch the lens or harm its protective coating.

Although these aberrations negatively impact the telescope’s performance, proper maintenance of the objective lens can mitigate their effects. Dust, smudges, or scratches will degrade the image quality. Regular maintenance along with careful handling will prolong the lens’s life and maintain its performance.

Fresnel lenses consist of a flat surface with interspaced, concentric steps whereby each step corresponds to the surface of a conventional ...

Refracting telescopes use an objective lens as their primary optical component. A refracting telescope, or refractor, operates on the principle of refraction, using an objective lens to gather and bend incoming light. At the front of a reflector, this lens refracts and concentrates the light rays to a focal point inside the telescope.

Nikon100x Objective

Nikon objectives microscopeprice

For many years, natural fluorite was commonly used in the manufacture of fluorite (semi-apochromat) and apochromat objectives. Unfortunately, many newly developed fluorescence techniques often rely on ultraviolet excitation at wavelengths significantly below 400 nanometers, which is severely compromised by autofluorescence that occurs from natural organic constituents present in this mineral. Also, the tendency of natural fluorite to exhibit widespread localized regions of crystallinity can seriously degrade performance in polarized light microscopy. Many of these problems are circumvented with new, more advanced materials, such as fluorocrown glass.

Other features found on specialized objectives are variable working distance (LWD) and numerical aperture settings that are adjustable by turning the correction collar on the body of the objective as illustrated in Figure 2. The plan fluor objective on the left has a variable immersion medium/numerical aperture setting that allows the objective to be used with both air and an alternative liquid immersion medium, glycerin. The plan apo objective on the right has an adjustable working distance control (termed a "correction collar") that allows the objective to image specimens through glass coverslips of variable thickness. This is especially important in dry objectives with high numerical aperture that are particularly susceptible to spherical and other aberrations that can impair resolution and contrast when used with a cover glass whose thickness differs from the specified design value.

Michael W. Davidson - National High Magnetic Field Laboratory, 1800 East Paul Dirac Dr., The Florida State University, Tallahassee, Florida, 32310.

Nikonobjective thread

Most manufacturers have now transitioned to infinity-corrected objectives that project emerging rays in parallel bundles from every azimuth to infinity. These objectives require a tube lens in the light path to bring the image into focus at the intermediate image plane. Infinity-corrected and finite-tube length microscope objectives are not interchangeable and must be matched not only to a specific type of microscope, but often to a particular microscope from a single manufacturer. For example, Nikon infinity-corrected objectives are not interchangeable with Olympus infinity-corrected objectives, not only because of tube length differences, but also because the mounting threads are not the same pitch or diameter. Objectives usually contain an inscription denoting the tube focal length as will be discussed.

In refracting telescopes, the entire volume of objective lenses must be free from imperfections, as any flaws will lead to image distortion. This is because light must pass through the entire lens uninterrupted, while in reflecting telescopes, only the surface quality is critical for accurate image representation.

The maintenance of an objective lens in a refractor is easier than a primary mirror in a reflector, due to the delicate nature of mirrors. However, both types of telescopes provide both upsides and downsides.

In the fine arts, to exhibit the differences or dissimilitude of; heighten the effect of, or show to advantage, by opposition of position, attitude, form, or ...

Explore how variations in the refractive index of the imaging medium effect the ability of an objective to capture light rays emanating from the specimen.

Optical density is a measure of how much a material resists and slows the transmission of light. ... Optical density and refractive index are related properties.

Identification of the properties of individual objectives is usually very easy because important parameters are often inscribed on the outer housing (or barrel) of the objective itself as illustrated in Figure 1. This figure depicts a typical 60x plan apochromat objective, including common engravings that contain all of the specifications necessary to determine what the objective is designed for and the conditions necessary for proper use.

The objective lens directly affects telescope’s performance, including the magnification, light-gathering power and resolution. The curvature of this lens plays a pivotal role in determining the telescope’s focal length. A stronger curvature bends light at a higher angle, causing it to focus at a shorter distance. This results in a shorter focal length because focal length describes the distance from the objective lens to the focal point.

Will Kalif is an amateur astronomer at TelescopeNerd.com. Will is an author of the book "See It With A Small Telescope". Will Kalif has been passionate about telescopes and the wonders of the night sky ever since he received his first telescope as a teenager. And for several decades now he has been making and using his own telescopes and helping other people to also enjoy the various things that can be seen on a dark and starry night.

Nikonobjective selector

Magnesium fluoride is one of many materials utilized in thin-layer optical antireflection coatings, but most microscope manufacturers now produce their own proprietary formulations. The general result is a dramatic improvement in contrast and transmission of visible wavelengths with a concurrent destructive interference in harmonically-related frequencies lying outside the transmission band. These specialized coatings can be easily damaged by mis-handling and the microscopist should be aware of this vulnerability. Multilayer antireflection coatings have a slightly greenish tint, as opposed to the purplish tint of single-layer coatings, an observation that can be employed to distinguish between coatings. The surface layer of antireflection coatings used on internal lenses is often much softer than corresponding coatings designed to protect external lens surfaces. Great care should be taken when cleaning optical surfaces that have been coated with thin films, especially if the microscope has been disassembled and the internal lens elements are subject to scrutiny.

A smaller curvature will cause light to focus further from the objective, increasing the focal length. The increase in focal length will provide more detailed images of distant objects, but it also narrows the field of view. Decreasing the curvature, thus increasing the focal length, will also result in higher magnification.

POLARIZATION meaning: 1. the act of dividing something, especially something that contains different people or opinions…. Learn more.

The objective lens also affects the brightness and clarity of the image. A lens with a larger diameter collects more light, resulting in brighter and more detailed images. The quality of the lens material and its coatings also influences the clarity and color accuracy by reducing aberrations.

The downsides of using an objective lens are primarily chromatic aberration, weight and size constraints, and potential lens imperfections.

Weight and size constraints arise because crafting large, high-quality lenses is both challenging and heavy, limiting the practical size of refracting telescopes. The process involves shaping and polishing thick glass or other transparent materials to exact specifications, ensuring that the entire lens is free from imperfections. As the diameter of the lens increases, the challenges in manufacturing become exponentially more complex.

Nov 14, 2024 — ... optic. Vortex ... The eye box is relatively strict compared to traditional scopes, but this is typical for prism optics.

Ms.Cici

Ms.Cici

8618319014500

8618319014500