Bandpass Filter - MATLAB & Simulink - bandpass filtering

Free Shipping Flat Nose Pliers, with non-marring Nylon Jaw Inserts. Pliers are used when working with metal, wire, soft or polished pieces to prevent scratches and nicks on the surface. Use them to straighten wire, form shapes and to compress component...

When the intensity of coherent light rises above a certain level, it penetrates the half mirror to reach the outside. This is known as a laser beam. A variety ...

anti-glare什么意思

Optical Laser Source Products ... Keysight Laser Sources are available in various configurations for the best possible match to the most common applications.

Free Shipping Flat Nose Pliers, with WIDE non marring Nylon Jaw Inserts. Pliers are used when working with metal, wire, soft or polished pieces to prevent scratches and nicks on the surface. Use them to bend and straighten wire, form shapes and to...

Optical coating

Nov 28, 2012 — Direct mail marketing pieces are viewed by many as junk mail. Opt out of receiving unsolicited mail from many (but not all) commercial companies ...

Free Shipping Round & Flat Nose Pliers, with non marring Nylon Jaw Inserts. Pliers are used for wire working with polished and colored wire, soft or finished pieces to prevent scratches and nicks on the surface. Use them to form shapes and bending...

ECI has extensive experience coating polymers and other temperature sensitive substrates. ECI has been coating polymer optics for over 60 years. Our low temperature Anti-Reflection coatings are designed and deposited to ensure good adhesion and thermal stability on even the most challenging polymer substrates. ECI coats different types of substrate with low temperature Anti-Reflection coatings at process temperatures below 50°C. These substrates range from plastic windows and lenses to optical fibers and fiber optic assemblies/components including: Molded Polymer Optics, Polycarbonate, Acrylic, Zeonex®, Ultem®, Mylar®, CR39, COC, Fresnel Lenses, TO-Window Cans, MT Ferrules.

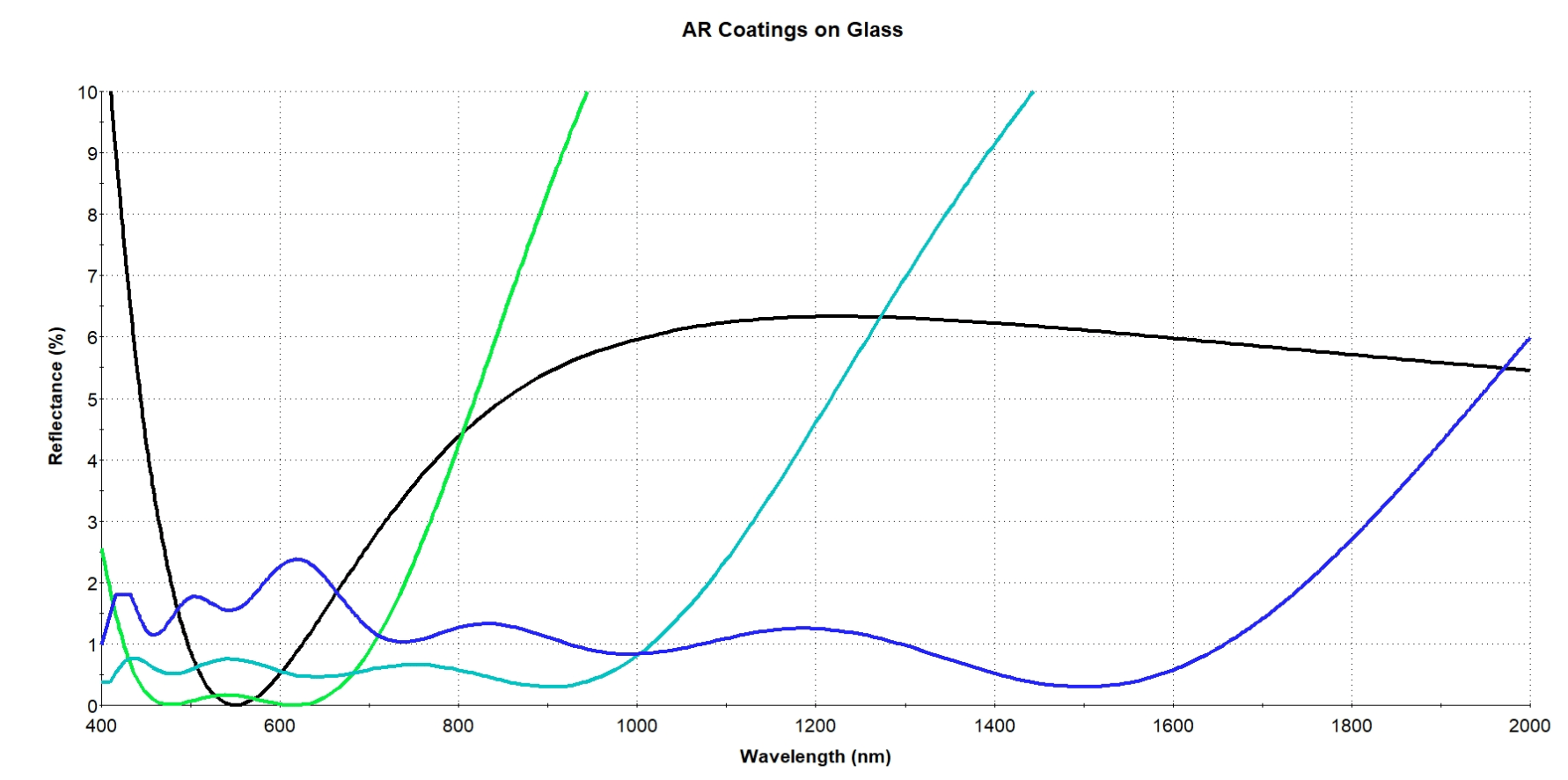

Surface coating

Anti-Reflection Coatings can be optimized for narrow and broadband applications. The performance of an AR coating will vary depending on the bandwidth and angle of incidence (AOI). ECI can typically achieve front surface reflection less than 0.03% for a narrowband AR coating at near normal incidence. Anti-Reflection coatings optimized for wider bandwidths will display a higher maximum reflection. A typical Broadband Anti-Reflection coating on glass will have a maximum reflection of less than 0.5% with a typical average reflection of 0.25%. Figure 1 shows how reflection performance can vary with bandwidth.

Free Shipping Round Nose Pliers, with non-marring Nylon Jaw Inserts. Pliers are used for wire working with polished and colored wire, soft or finished pieces to prevent scratches and nicks on the surface. Use them to form shapes and bending wire...

Free Shipping This plier is made to be used in forming, re-shaping and bending ring as well as round shaped items. The base V-Block of the pliers are nylon will not scratch the outer surface of ring and the single bending jaw is made of stainless...

anti-reflective coating是什么

5mm C-mount extension ring for mounting C-mount lenses on CS-mount cameras.This means that C-mount lenses can also be used on CS-mount cameras by extending ...

Free Shipping Pliers with nylon jaws for bending forming, with a full curve for forming bracelets shapes and bracelet sections. The nylon jaws will not scratch or mar metal. The jaws are approximately 1" in Length and are 1/2" wide (24mm x...

Follow US. instagram. Canada Computers & Electronics. © 2024, Canada Computers & Electronics, Head Office - 168 Ultimate Dr, Richmond Hill, ON L4S 8M8.

antireflective coating中文

Anti-Reflection coatings are utilized in a variety of applications. It is very common for AR coatings to be used in laser applications. In such cases, Anti-Reflective coatings will need to meet or exceed certain LDT ( Laser Damage Threshold ) requirements. ECI primarily uses Ion Beam Sputtering ( IBS ) or Electron Beam ( E-Beam ) to deposit AR coatings that must withstand high power lasers.

ECI deposits High Power Anti-Reflection coatings on several different types of substrates, including but not limited to Glass/Fused Silica windows, lenses and wafers, Fiber optic cables and assemblies, LBO, BBO, KTP, TGG, GGG, BiG, and Silicon wafers.

I found this cool 3-D Rotary wheel but I need a hi-resolution version for printing. Because it is not an official logo, we ask that you not use it in print.

Typical values verified through independent test laboratories. Actual LDT performance is dependent on substrate selection, surface preparation, and system design.

Using the Acquisition Device report. The data table in this report displays a row for each of the device categories defined in Analytics: Desktop (which ...

ECI also deposits high temperature Anti-Reflection coatings on various substrates, including crown glasses, float glasses, Fused Silica, Sapphire, Silicon, CaF2, and others. ECI can deposit these coatings to cover any wavelength range between 200 – 2500nm. These coatings are designed and deposited to meet the durability requirements per MIL-C-675C. ECI deposits Anti-Reflection coatings on parts up to 400mm in diameter.

Ar coating

Free Shipping These nylon jaw pliers are designed to bend and form strips of metal and wires, jaws are concave and convex Half Round shape. The nylon jaws will not mar the metal during the bending operation quickly for Bracelets, Earrings and Bengals...

ECI’s durable films on plastic and polymer molded optics are resistant to organic solvents and are an excellent choice for a wide variety of products.

Free Shipping Mazbot nylon jaw bracelet bending forming pliers, with a mild curve are ideal for forming bracelets shapes and bracelet sections. The nylon jaws will not scratch or mar metal.The jaws are approximately 1" in Length and are 25/64...

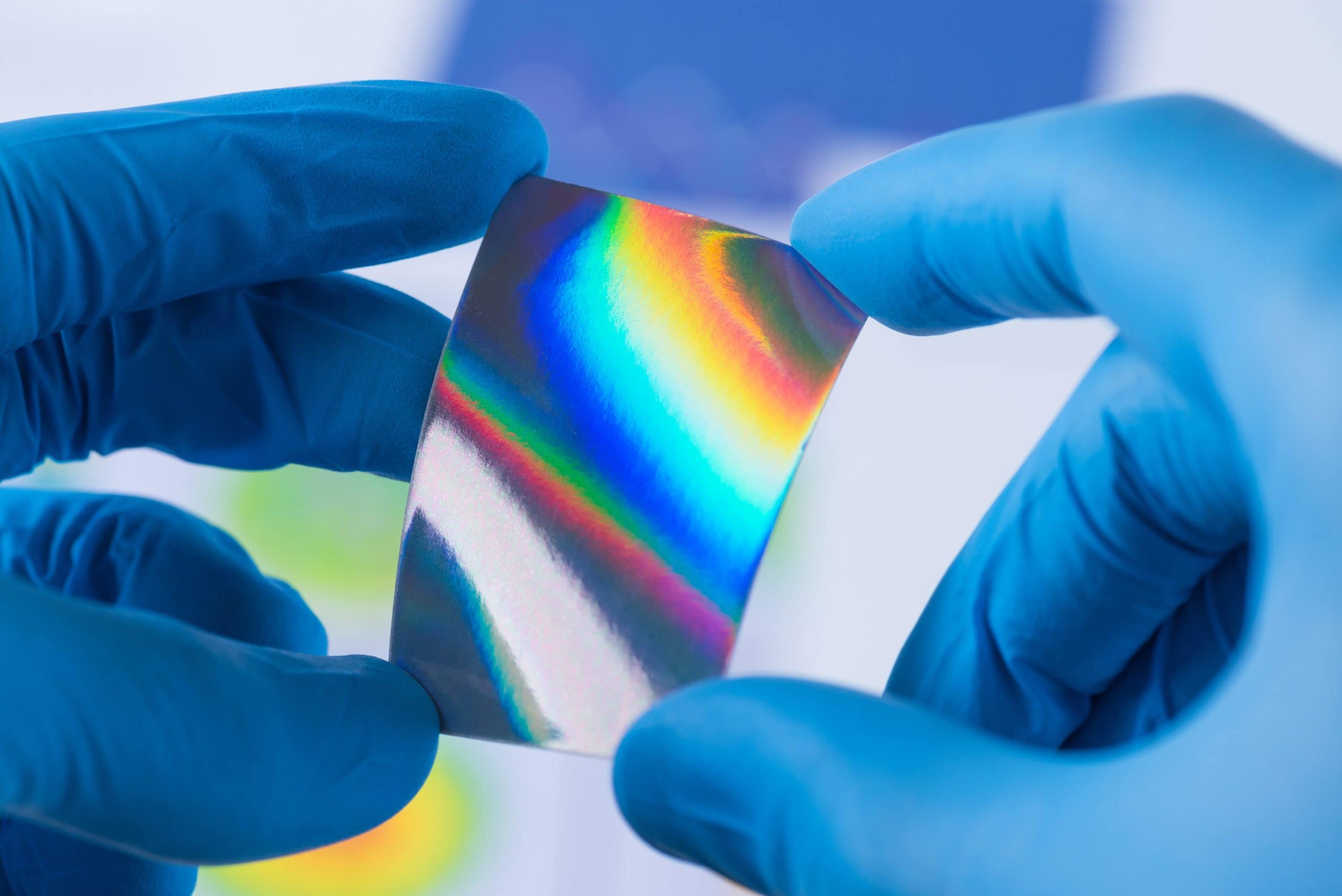

AR Coatings ( Anti-Reflection coatings ) are deposited onto optical surfaces to reduce specular reflectivity. Anti-Reflection coatings are comprised of a single layer or multiple layers. These designs are optimized to create destructive interference with respect to the reflected light. This design approach will allow the maximum amount of light transmission without compromising image quality. Diagram 1 is an example of a typical multilayer Anti-Reflection coating.

Free Shipping These pliers are ideal for holding rings while polishing the inside or doing other work. The nylon, parallel-type jaws hold rings or other circular objects securely without scratching or marring your metals and materials...

ECI’s AR Coatings meet the reflection and environmental requirements of MIL-C-14806A and MIL-C-48497. Designs comply with military and telecommunication industry standards.

© Copyright 2011 - 2022 Evaporated Coatings, Inc. All rights reserved. Careers Privacy Policy Terms of Service Sitemap

Free Shipping Chain Nose Pliers, with non-marring Nylon Jaw Inserts. Pliers are used for wire working with polished and colored wire, soft or finished pieces to prevent scratches and nicks on the surface. Use them to form shapes and bending wire...

Free Shipping Flat Nose Pliers, with non-marring Nylon Jaw Inserts. Pliers are used when working with metal, wire, soft or polished pieces to prevent scratches and nicks on the surface. Use them to straighten wire, form shapes and to compress component...

Jul 12, 2022 — Anti-reflection film is a type of optical coating that minimizes reflection when placed on surfaces of optical materials such as lenses.

Anti-reflection coatings reduce first surface reflection losses, improve contrast and boost the transmission through your optical surface. Choose from a typical design below or ECI will design and deposit a custom anti-reflection (AR) coating for your specific application. If you are not sure how to specify your coating, our design team will work with you to identify the optimum design for your system.

Free Shipping Round Nose Pliers, with non-marring Nylon Jaw Inserts. Pliers are used for wire working with polished and colored wire, soft or finished pieces to prevent scratches and nicks on the surface. Use them to form shapes and bending wire...

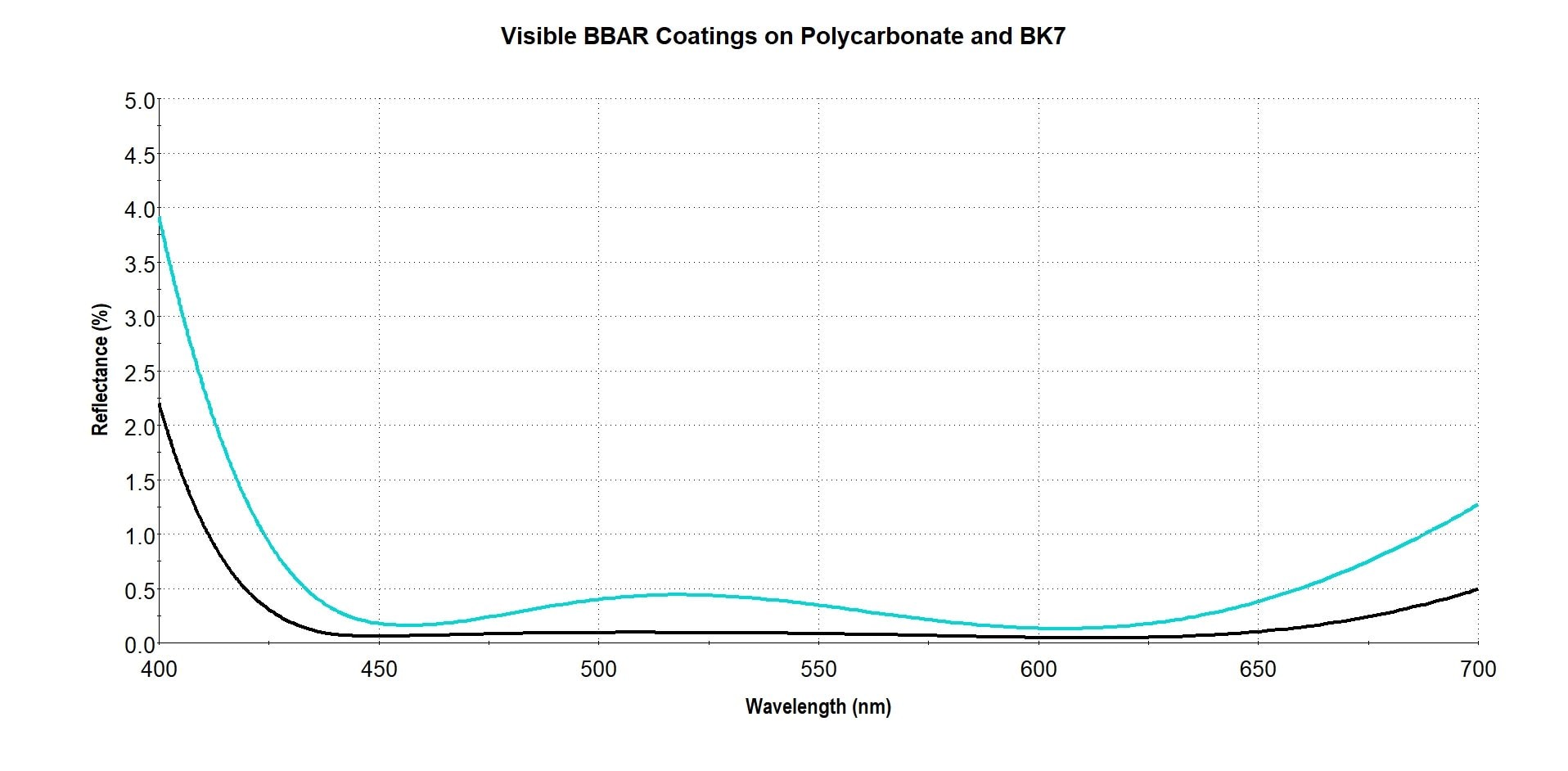

Evaporated Coatings Inc. offers anti-reflection coatings for a variety of substrate materials and configurations. Different coatings materials are selected depending on the substrate material, size, shape, and wavelength range of interest. In many cases, the choice of substrate material dictates the deposition temperature of the AR coating. For narrowband Anti-Reflection coatings, the optical performance is similar for both low and high temperature depositions. However, the performance of a broadband AR Coating will vary depending on the deposition temperature. Typically, broadband AR coatings deposited at higher temperatures will yield lower average reflection over a particular bandwidth. There are two primary reasons: 1). certain coating materials require deposition at elevated temperatures for sufficient durability and 2). the refractive indices of some materials decrease when deposited at lower temperatures. For example, a visible broadband AR coating on BK7 will have slightly better optical performance than a visible broadband AR coating deposited on Polycarbonate. Figure 2 shows the difference in performance between the two substrates mentioned above.

GR-1 & RC-14 in Pro-Uro produce lactic acid & hydrogen peroxide that helps inhibit harmful E. coli bacteria growth for a positively balanced vaginal microflora.

Fiber Optic Imaging ... Fiber optic imaging uses the fact that the light striking the end of an individual fiber will be transmitted to the other end of that ...

Ms.Cici

Ms.Cici

8618319014500

8618319014500