B-Series GigE Vision Board - Omron Automation - gig e vision

Rapid Metals Ltd, Unit 3 Centrovell Industrial Estate, Caldwell Road, Nuneaton, CV11 4NG | Reg: 03184643 | VAT: GB 687934272 Prices may vary online and instore | Images used on this site are for illustration purposes only

Irisaperture

Numericalaperture

In conclusion, always remember that the definition of the input beam size and the clear aperture size is NOT the same. When this is mistaken, it can cause unexpected power clipping which will negatively affect your system during integration like malfunction or even a system explosion. When users purchase a laser beam steering solution from us, we provide the clear aperture information, whereas the definition of the laser beam size should come with the spec sheet of the laser. In addition, the laser spec sheet might also provide laser alignment specs, such as its laser output position and pointing error. If these aren’t provided, make sure to check with the laser manufacturer to confirm these parameters for best performance purposes. Having tested and successfully integrated different systems across multiple applications, we can guarantee that these recommendations will help clear up confusion and prevent future damages.

Last but not least, the above calculations are assuming perfect alignment. If there are actual alignment errors, one should consider keeping some margins. .

In this case, we define the beam size under FWHM when using the Gaussian beam as an example. . To ensure <1% of power loss due to beam clipping, the clear aperture should be:

Mar 1, 2023 — In the latest firmware version of Reyee NBS Series Switches, NBS5100 and NBS5200 Series Switches support DHCP Relay, but NBS3100 and NBS3200 ...

There are many misconceptions regarding the set-up of a laser and beam steering system. The most common misconception is that the clear aperture value should equal the maximum allowable laser beam size. Optic components have a parameter known as clear aperture, which strictly defines the optical performances within this aperture. Optics performance outside of the clear aperture are unspecified. Significant illumination beyond this boundary not only causes power loss, but will also cause the optics to do the following:

Please note that we are able to send items upto 3000mm by courier, please order accordingly. You can order longer lengths for collection in-store or delivery by branch if you are within 10 miles of either store.

Search results. Pilavian Narine - Hot Spot Laser CenterCosmetic Surgery. Website. Website: hotspotlaser.com. Phone: (626) 568-8500. Cross Streets: Near the ...

LenoxlaserOrifice

Laser apertureprojector

Mar 30, 2021 — How imaging can be used for illumination design · Critical illumination · Köhler illumination · Paraboloidal and ellipsoidal reflectors · A primer ...

CNC Glass Machining. Precision mechanical alterations for your custom optical designs and specifications. CNC capabilities include lightweighting ...

AdjustableAperture

The M6x1.0 Metric Shoulder Machine Eye Bolt is made from high strength steel and is suitable for use with angular loads. Buy them at RIGGING CANADA.

Here at Rapid Metals we pride ourselves in customer service. This includes cutting the majority of materials to your specific requirements.

S Yang · 2023 — Introduction. Fused silica materials are widely used in a variety of optical applications such as lenses [1] and telecommunications [2] due to their excellent ...

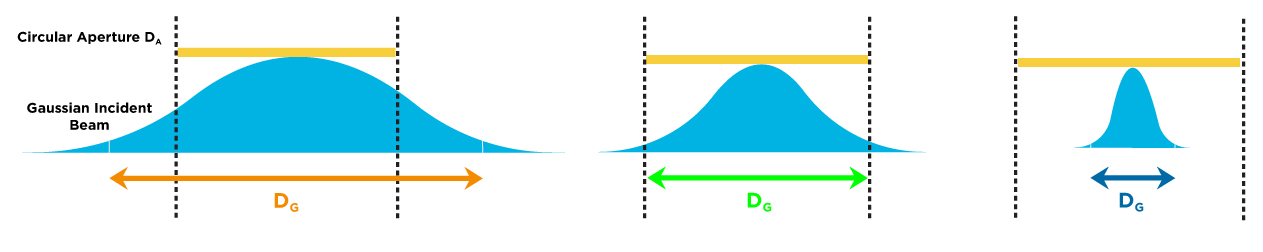

Typically, lasers emit circular shaped beams with a Gaussian profile. By applying beam shaping technologies, the Gaussian profile can be transformed into a Uniform profile (Top Hat), with the output beam shaped as a square, rectangular, etc. The beam size for a Uniform parameter is straightforward (see figure below). Meanwhile measuring the beam diameter of the Gaussian profile is more subjective and heavily dependent on the methodology being followed. Some of the different criteria used for reporting a Gaussian beam size include; D4σ, 10/90 or 20/80 knife-edge, 1/e2, FWHM, and D86. Where 1/e2 and FWHM (Full-Width at Half-Maximum) are most commonly used. Understanding the laser beam profile and beam size is important. Indeed, the same laser beam will have a different beam size based on its definition1.

Laser Aperturemachine

Laser Beam Profiler, 8µm-14µm from DataRay, Compare ALL BRANDS and Suppliers, Unbiased Guide, Select the Best, LaserSourceMeasurement.com.

Optical apertures

Important to note is that since a laser beam size value defined by 1/e2 is roughly 1.7 times the diameter defined by FWHM, calculations for the appropriate beam size and clear aperture ratios can be made out of the above examples.

By digging a little deeper into the math equations and using a typical Gaussian beam with a beam size defined by 1/e2 as an example, we can ensure <1% of power loss due to beam clipping. See formulas below:

25.4MM = 1 inch. 12.7MM = 1/2 inch. 10.5MM = < 7/16 inch Crossville Tile Thickness. 9.5MM = 3/8 inch Crossville Tile thickness. 8.0MM = 5/16 inch Crossville ...

For system set ups, it is important to understand the design of laser beam systems that utilize beam steering technology. More specifically, pairing a beam steering set with a laser is crucial. During set up, aligning the clear aperture of the beam steering set with the beam size of the laser is critical. This often raises the question between beam size and clear aperture. Let’s dissect this issue in this blog post, as well as help you with proper calculations.

3" (75mm) C-Range IR Window for indoor and outdoor applications, with KWIK Twist Key that easily swivels off. $652.79 CAD. Availability: 117 in Stock. Learn ...

NewportAperture

Please note that dimensions may vary slightly from those advertised due to manufacturing processes. We cut material to tolerances outlined in our FAQ page. Please get in touch if you need further assistance.

And with the same calculation to ensure <10% of power loss, the clear aperture should be at least 1.07 times bigger than the 1/e2 beam size; for <5% power loss, it should be 1.22; and for <0.1% power loss, it should be 1.86.

Mild Steel CFS Tube 50.8mm x 3.2mm Wall can be used for many different purposes and applications to complete your job. We’re proud to stock a large range of tubes with varying outer diameters and wall thicknesses which we can cut to size for you.

1. Some lasers may have a central irradiance profile that closely matches a Gaussian profile but also contain additional “lobes” of irradiance in the wings. At high power, these lobes can be significant and must be taken into consideration.

Here at Rapid Metals we pride ourselves in customer service. This includes cutting the majority of materials to your specific requirements.Please add the length to receive a price per piece, select your required quantity and click add to basket.Please note that we are able to send items upto 3000mm by courier, please order accordingly. You can order longer lengths for collection in-store or delivery by branch if you are within 10 miles of either store.In stock Cut to length (mm) Product Price Quantity required: Seamless Steel Tube 50.8mm x 3.2mm Wall quantity Add to basket SKU: CFST050.8x03.2 Categories: Seamless Tube, Steel Sections, Steel Tube Round Tags: round tube, seamless, steel

Another point to clear up is the typical misconception of having the input laser beam size exactly the same as the clear aperture. Applying the same formula, and assuming the beam size is defined by 1/e2, you are at risk of clipping 13.5% of the power. It’s critical to note that the amount of power falling off the mirrors will not only cause heat up, delaminate, burn coatings and scatter light as previously mentioned, but will also be deposited onto the internal parts within the scan head enclosure or be absorbed by the DFM lens retaining ring (with glue) and DFM lens holder. In either case, this will cause major damage to current systems during integration and is especially important when working with a high-power laser.

What happens when the same clear aperture is applied to different beam sizes? Pretty straightforward as shown in the figure below. If the laser beam overfills the clear aperture, it will clip the outer-ring portion of the laser beam. Which brings us to the next question. What beam diameter should one apply for a certain clear aperture?

Filters · Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'% · Rapid Relief® Hot/Cold Pack | Reusable, Non-Toxic Blue Gel.

Ms.Cici

Ms.Cici

8618319014500

8618319014500