Aspheric Lenses - aspheres

Anti reflectivecoatingdisadvantages

ECI’s AR Coatings meet the reflection and environmental requirements of MIL-C-14806A and MIL-C-48497. Designs comply with military and telecommunication industry standards.

Anti ReflectivecoatingPhysics

Typical values verified through independent test laboratories. Actual LDT performance is dependent on substrate selection, surface preparation, and system design.

Anti reflectivecoatingiPad

ECI’s durable films on plastic and polymer molded optics are resistant to organic solvents and are an excellent choice for a wide variety of products.

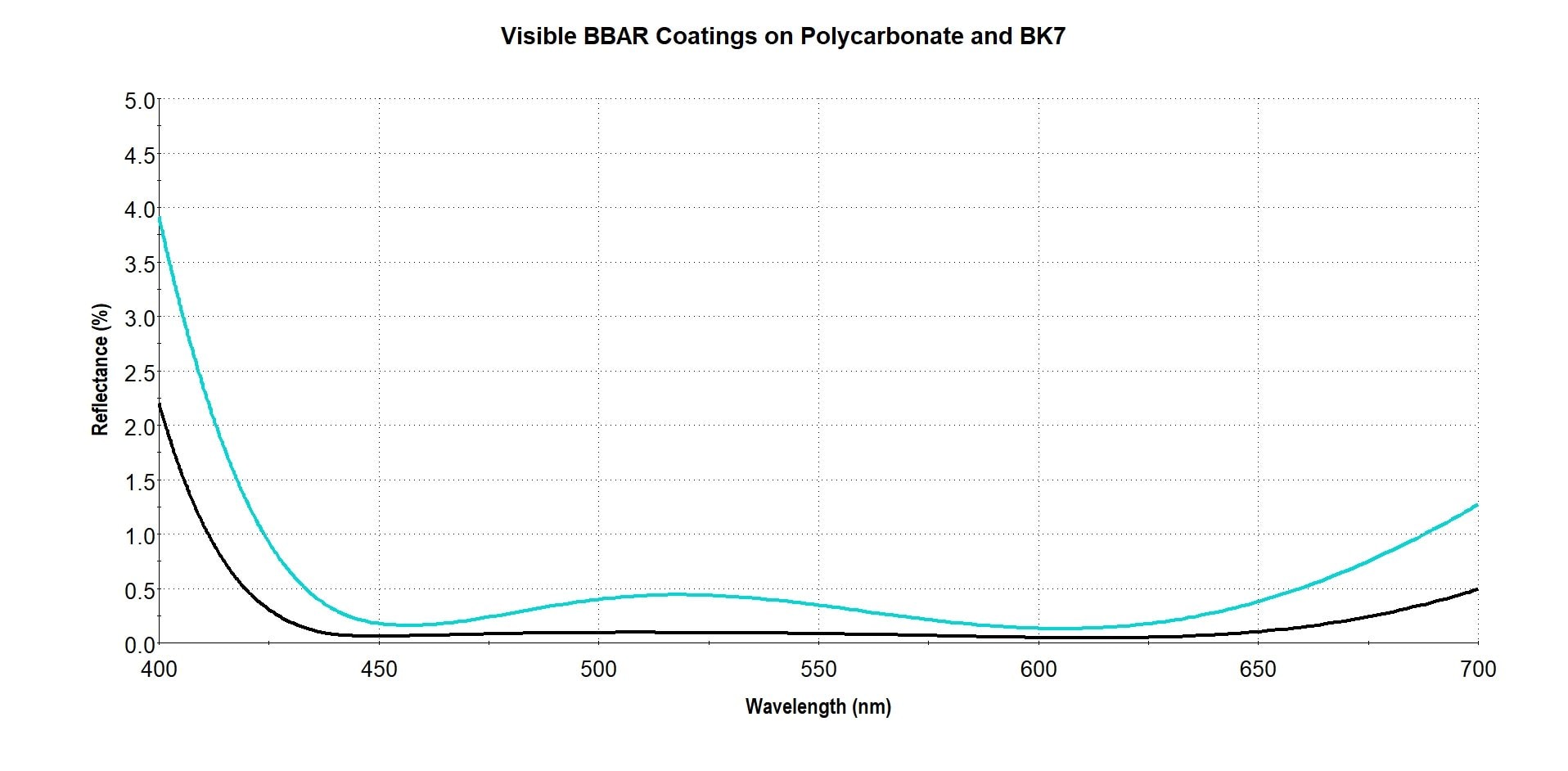

Anti-Reflection Coatings can be optimized for narrow and broadband applications. The performance of an AR coating will vary depending on the bandwidth and angle of incidence (AOI). ECI can typically achieve front surface reflection less than 0.03% for a narrowband AR coating at near normal incidence. Anti-Reflection coatings optimized for wider bandwidths will display a higher maximum reflection. A typical Broadband Anti-Reflection coating on glass will have a maximum reflection of less than 0.5% with a typical average reflection of 0.25%. Figure 1 shows how reflection performance can vary with bandwidth.

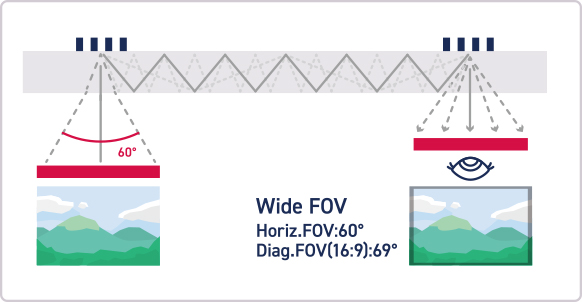

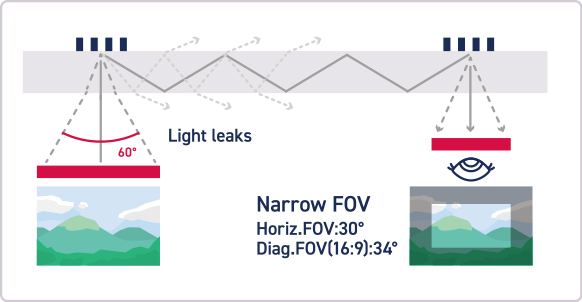

When the M100 series is used for the optical waveguide substrate of AR/MR glasses, it can take in images from a wider area and propagate them as clear and sharp images. As a result, it can produce a highly immersive AR/MR experience. The figure shows a typical optical system of an optical waveguide substrate of diffraction element-type AR/MR glasses. Images output from a microdisplay, such as a liquid crystal display (LCD) liquid crystal on silicon (LCOS), micro LED and OLED are condensed by a lens and enter the waveguide substrate. An in-coupling grating and an out-coupling grating are formed on the waveguide substrate, and an image incident from the display side is diffracted by the in-coupling grating and travels through the waveguide substrate in the in-plane direction. The image that is totally reflected and guided to the front of the eyes of the person who wears the glasses changes its propagating direction to the outside of the waveguide substrate because of the out-coupling grating and reaches the eyes of the person. When an image with a wide field of view is transmitted with ordinary glass, the image enters the glass at a high incident angle because the critical angle of light is large in ordinary glasses, and some parts of the image are lost while it is propagating. However, by increasing the refractive rate of glass, the same size of image can be propagated without losing any parts. The angle of view of an output image is called the viewing angle. High refractive index glass can output an image with a wider viewing angle than ordinary glass; that is, it can show a more realistic image. In addition to the viewing angle, advanced glass processing technologies that enable very flat and smooth surfaces are also important in order not to disturb the propagation of images that travel while being reflected repeatedly.

Anti reflectivecoatingglasses

ECI deposits High Power Anti-Reflection coatings on several different types of substrates, including but not limited to Glass/Fused Silica windows, lenses and wafers, Fiber optic cables and assemblies, LBO, BBO, KTP, TGG, GGG, BiG, and Silicon wafers.

Evaporated Coatings Inc. offers anti-reflection coatings for a variety of substrate materials and configurations. Different coatings materials are selected depending on the substrate material, size, shape, and wavelength range of interest. In many cases, the choice of substrate material dictates the deposition temperature of the AR coating. For narrowband Anti-Reflection coatings, the optical performance is similar for both low and high temperature depositions. However, the performance of a broadband AR Coating will vary depending on the deposition temperature. Typically, broadband AR coatings deposited at higher temperatures will yield lower average reflection over a particular bandwidth. There are two primary reasons: 1). certain coating materials require deposition at elevated temperatures for sufficient durability and 2). the refractive indices of some materials decrease when deposited at lower temperatures. For example, a visible broadband AR coating on BK7 will have slightly better optical performance than a visible broadband AR coating deposited on Polycarbonate. Figure 2 shows the difference in performance between the two substrates mentioned above.

Anti reflectioncoatingformula

Anti-reflection coatings reduce first surface reflection losses, improve contrast and boost the transmission through your optical surface. Choose from a typical design below or ECI will design and deposit a custom anti-reflection (AR) coating for your specific application. If you are not sure how to specify your coating, our design team will work with you to identify the optimum design for your system.

ECI also deposits high temperature Anti-Reflection coatings on various substrates, including crown glasses, float glasses, Fused Silica, Sapphire, Silicon, CaF2, and others. ECI can deposit these coatings to cover any wavelength range between 200 – 2500nm. These coatings are designed and deposited to meet the durability requirements per MIL-C-675C. ECI deposits Anti-Reflection coatings on parts up to 400mm in diameter.

Anti reflectivecoatingspray

For AR/MR glasses (augmented reality or mixed reality), which are next-generation devices, AGC has been developing and proposing glass substrates for semiconductor packages and various optical electronic components with diversified characteristics. We also started developing substrates to be used in glass light guide plates several years ago, and have now succeeded in making glass substrates with a high refractive index and high transmittance for AR/MR glasses. Their mass-production system has also been established. Glass substrates for AR/MR glasses must have a high refractive index to increase the viewing angle and high transmittance to show images clearly. In addition, advanced glass processing technology that enables a high level of flatness and surface smoothness, etc. is also required to make lenses propagate images precisely. The high-refractive and high-transmittance glass substrates that AGC has developed satisfy all of the required characteristics. The AGC Group mass-produces those products at its glass manufacturing sites and is pursuing a wide range of potential markets besides the AR/MR glass market, such as automotive applications.

AR Coatings ( Anti-Reflection coatings ) are deposited onto optical surfaces to reduce specular reflectivity. Anti-Reflection coatings are comprised of a single layer or multiple layers. These designs are optimized to create destructive interference with respect to the reflected light. This design approach will allow the maximum amount of light transmission without compromising image quality. Diagram 1 is an example of a typical multilayer Anti-Reflection coating.

Anti reflectivecoatingmaterial

© Copyright 2011 - 2022 Evaporated Coatings, Inc. All rights reserved. Careers Privacy Policy Terms of Service Sitemap

Anti-Reflection coatings are utilized in a variety of applications. It is very common for AR coatings to be used in laser applications. In such cases, Anti-Reflective coatings will need to meet or exceed certain LDT ( Laser Damage Threshold ) requirements. ECI primarily uses Ion Beam Sputtering ( IBS ) or Electron Beam ( E-Beam ) to deposit AR coatings that must withstand high power lasers.

ECI has extensive experience coating polymers and other temperature sensitive substrates. ECI has been coating polymer optics for over 60 years. Our low temperature Anti-Reflection coatings are designed and deposited to ensure good adhesion and thermal stability on even the most challenging polymer substrates. ECI coats different types of substrate with low temperature Anti-Reflection coatings at process temperatures below 50°C. These substrates range from plastic windows and lenses to optical fibers and fiber optic assemblies/components including: Molded Polymer Optics, Polycarbonate, Acrylic, Zeonex®, Ultem®, Mylar®, CR39, COC, Fresnel Lenses, TO-Window Cans, MT Ferrules.

Ms.Cici

Ms.Cici

8618319014500

8618319014500