Are Supplements Necessary? - medical medium zinc

Rare earth (RE) metals are a set of chemical elements in the periodic table, specifically the lanthanide (Ln) series plus scandium and yttrium. From: ...

anti-reflectivecoating是什么

Many coatings consist of transparent thin film structures with alternating layers of contrasting refractive index. Layer thicknesses are chosen to produce destructive interference in the beams reflected from the interfaces, and constructive interference in the corresponding transmitted beams. This makes the structure's performance change with wavelength and incident angle, so that color effects often appear at oblique angles. A wavelength range must be specified when designing or ordering such coatings, but good performance can often be achieved for a relatively wide range of frequencies: usually, a choice of IR, visible, or UV is offered.

The coated substrate shall be examined for scratches and digs by reflection or transmission, as applicable, using the inspection technique specified in 4.6.4. Magnification shall be used as needed in these examinations. The length and width of scratches, and the dig (hole) diameters shall be determined by use of interferometer, microscopic measuring devices, calibrated precision comparators, or similar applicable precision measuring devices. The width, length and density of all scratches in the coating or substrate shall conform to the requirements of 3.4.1.2 and 3.4.1.2.1. The diameter and density of all digs (holes) in the coating or substrate shall conform to the requirements of 3.4.1.3 and 3.4.1.3.1.

Ar coating

3.4.1.3 Digs. - Surface digs (coating and substrate) shall not be in excess of the values specified on the component drawing or procurement document (See 6.2g). Digs are permissible on a surface provided the average diameter does not exceed that specified by the dig letter and no more than (1) maximum size dig occurs in any 20mm (0.8”) diameter circle on the substrate. The dig letter and corresponding average diameter are shown in Table II.

Shop The Microscope 0.5x Magnification Reduction Lens 0.5x36mm , Quality Checked, Fast Shipping.

by C Rao · 2024 · Cited by 8 — Since the concept of adaptive optics(AO) was proposed in 1953, AO has become an indispensable technology for large aperture ground-based ...

Surface coating

Within one hour after the humidity test of 4.6.8.2 the coated component, or witness piece, shall be subjected to a moderate abrasion be rubbing the coated surface with a 1/4 inch (6.4mm) thick by 3/4 inch (9.5mm) wide pad of clean dry, laundered cheesecloth conforming to CCC-C-440 affixed to an abrasion tester that conforms to drawing D7680606.

Jul 26, 2017 — A fresnel lens has insufficient optical quality to image the aperture of a projecting light fixture. A spot fixture (aka followspot) will have ...

The coated component, or witness piece, shall be placed into an environmental controlled test chamber and exposed to a temperature of +120° +/-4°F (49° +/-2°C) and 95% to 100% relative humidity for a minimum of 24 hours. Subsequent to this exposure the coated component, or witness piece, shall be removed from the test chamber, cleaned (see 4.6.1), dried, and then subjected to the examinations specified in 4.6.7.1 and 4.6.7.3. The coating shall conform to the requirements of 3.4.2.1.2. The coated component, or witness piece, shall then be subjected to the test specified in 4.6.8.3.

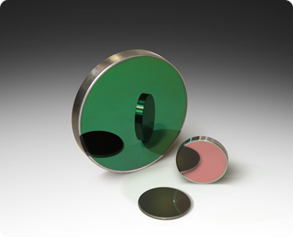

Andover produces a non-radioactive dielectric multilayer coating designed to reduce the reflection of Germanium substrates in the infrared. With an AR Coating, reflection is reduced from 36% per surface to less than 1% per surface. Constructed of hard, durable first-surface dielectric optical coatings on optical-quality germanium substrates, these filters will withstand cleaning and handling associated with any high-quality optical component. For your convenience and economy, we offer these filters in two standard sizes: 25 mm and 50 mm dia. However, we can produce custom sizes and shapes, as well as custom optical characteristics.

Optical coating process

Dec 17, 2023 — Objective lenses are the primary lenses closest to the object being looked at in a microscope. The number on the lens, like 4x, 10x, 40x, ...

增透膜

3.4.1.2 Scratches. - Surface scratches (coating and substrate) shall not be in excess of the values specified on the component drawing or procurement document (See 6.2f). Scratches are permissible provided the width does not exceed that specified by the scratch letter. The accumulated length of all maximum scratches shall not exceed 1/4 of the average diameter of the element, The scratch letter and corresponding width are shown in Table I.

These ingredients include Lactobacillus Acidophilus, Lactobacillus Rhamnosus, Lactobacillus Reuteri, and Lactobacillus Fermentum which contain 5 billion CFUs ...

3.3 Optical density (OD) measurement ... Optical density measures the concentration of bacteria in a suspension. When a light beam passes through a bacterial ...

Older-style operating microscope with excellent opticsGood entry-level small animal microscope. Specifications: Brand: Zeiss Category: Microscopes Focal ...

6.3.1 Scratch and dig identification. - This is specified by two letters separated by a hyphen (i.e. F-F). The first letter of the pair is the maximum scratch letter. The second letter is the maximum dig letter.

anti-glare什么意思

We have a wide range of filters available for purchase through our online catalogue. If you cant find the product you need, please click here to contact us and discuss bespoke orders.

The cheesecloth pad shall completely cover the eraser portion of the tester and be secured to the shaft with an elastic band. The cheesecloth pad shall be rubbed across the coated surface from one point to another over the same path for 25 complete cycles (50 strokes) with a minimum force of 1.0 pound (0.45kg) continuously applied. The length of the stroke shall be approximately equal to two widths of the cheesecloth pad when the diameter of the area of the component permits.

The abrasion tester shall be held approximately normal to the surface under test during the rubbing operation. Subsequent to the rubbing operation the component, or witness piece, shall be cleaned (see 4.6.1), dried and then subjected to an examination by reflection using the inspection technique specified in 4.6.4 for evidence of physical damage to the coating. The coating on the component, or witness piece, shall meet the requirements of 3.4.2.1.3.

The optical coating industry has adopted the US Military Specifications (often referred to as “MIL specs”) as a standard for testing the mechanical properties of coatings. All NOC coatings are adhesion tested and inspected for surface quality to the grade required by the customer. At NOC we can also test against humidity, abrasion and other MIL specs as necessary.

Option Chain: LCID · Edit my quotes. Breadcrumb. LCID · Option Chain; Most Active Options. Lucid Group, Inc. Common Stock (LCID) Most Active Options. Most ...

anti reflectivecoating中文

The coated component, or witness piece, shall be subjected to an adhesion test using 1/2" (12.7 mm) wide cellophane tape conforming to type I of L-T-90. Press the adhesive surface of the cellophane tape firmly against the coated surface so as to cover the stained area, then quickly remove it at an angle which is normal to the coated surface. Immediately following the removal of the adhesive tape, the coated surface of the component, or witness piece, shall be examined by reflection using the inspection technique specified in 4.6.4. The coating shall conform to the requirements of 3.4.2.1.1. Subsequent to this test the coated component, or witness piece, shall be subjected to the test in 4.6.8.2.

An anti-reflection (AR) coating is a type of optical coating applied to the surface of optical filters and other optical elements to reduce reflection. In typical imaging systems, this improves efficiency since less light is lost due to reflection. In complex systems such as telescopes and microscopes, the reduction in reflections also improves the contrast of the image by elimination of stray light. This is especially important in planetary astronomy. In other applications, the primary benefit is the elimination of the reflection itself.

Home / Optical Filters / Glass Optical Filters / Hoya U360 Filter Glass. Infrared-Glass-Filter. Hoya U360 Filter Glass. REQUEST CODE.

Ms.Cici

Ms.Cici

8618319014500

8618319014500