Anyone working on an IDS Peak device adapter? - camera ids

The unique part of the mounting is the trunnion. Trunnion notch plates are attached to the insides of the left and right walls (when looking through the telescope) of the support box. Plastic Furniture tacks are stuck into the insides of the triangular cut-out and support the trunnions. These tacks can be moved at any time to increase or decrease friction so that the trunnions will move smoothly, but also not allow the tube bracket assembly (and thus the telescope) to slip. The tube bracket assembly, telescope, and support box combined can be removed from the base. The result is that our telescope moves freely through an entire hemisphere giving us the ability to look at anything in the sky. It was with this mounting that we were finally able to recreate some of Galileo's observations. If you would like more information on how to build a relatively cheap mounting for your Galilean telescope, just e-mail Tom Williams or Jessica Williams. Return to the astronomy group's home page .

The outer tube of the mailing tube should have a short end that pulls off, and this can be used for the split in the outer tube shown above. This end will be used to hold the eyepiece. The inner tube must have two pieces (about 1" to 1.5" each) cut off of it that will be used as spacers to hold the objective lens in place. Make these cuts as straight and clean as possible, which will be difficult since the tube is made out of cardboard. A coping saw works pretty well for this. Take the short piece of the outer tube and cut or drill a hole (from 3/16" to 5/16" should be fine) directly in the center of the metal cap on the end. This will be the eyehole. It is important that this hole be as clean as possible (no metal protrusions) so that the the flat side of the eyepiece will fit snugly against the metal cap. An electrician's hole punch or Greenlee Punch works well for this task. If a drill is used, drill with a light pressure, then smooth out the inside surface as much as possible. Place the eyepiece flush (flat side) against the inside of this eyehole. The large piece of the inner mailing tube left will be used to hold this in place. To do this, drill small holes around the outside of the eyepiece tube. Then, with the eyepiece properly in place, slide the inner tube into it, put glue into the holes, and turn the tube a little bit to spread the glue inside. Hold the tube snugly against the lens inside the cap until the glue dries. Now, put this aside and take the large outer tube and the two spacers cut from the inner tube. Cut the closed end off of the outer tube, then use the other end to mount the objective lens (since that end already has a clean cut). Again, the "drill holes - put in glue" technique will be used to hold the spacers in place. First, check how far the inner spacer needs to be placed inside the tube so that the lens and other spacer will be able to sit inside the tube comfortably. Then drill holes in the outer tube around this area and glue in the spacer as before. After the first spacer is in place and dry, place the concave side of the objective lens flush against it, and put the other spacer snugly against the lens to hold it in place (again using the drill - glue method). Now there are two pieces, each containing one of the lenses. Slide the mailing tubes together as shown in the drawing above, and the telescope is done. By leaving these two pieces unglued, the telescope may be focused simply by sliding the eyepiece part inside the objective part. After a desired magnification/focus is found, the two pieces may be permanently attached (or some tape will give a semi-permanent attachment). Two images of a finished tube are shown below. The first picture shows the telescope tube from the objective side while the second image shows the ocular end of the tube: Making the Mounting: This Year's Work For the first half of the semester, we used the mountings built by last year's group. It looked like this: This image was produced by the star jumping in the field of view. We tried to have one person hold the telescope tube steady, but it takes very little movement to cause a star to move across the field of view when the field of view is only about 15 arc minutes. Moreover, our telescope would blow over often and required one person to hold it as still as possible, but this never really worked very well. So, we built a new mounting and stars looked like this, with very little distortion. The new mounting was constructed on a Saturday morning and afternoon, based on plans by Tom Williams. It looks like this: This telescope mounting is composed of a base a support box for the telescope tubing and its bracket assembly a bracket assembly encasing the telescope tubing with trunnion bearings which fit into the trunnion notch plates attached to the inside of the support box Parts List: Polybutylene Pipe Diameter = 4", Length = approximately 5' These can vary. The length is approximately equal to the height that you desire. Polybutylene pipe for the trunnion (swivel) for the telescope tubing Diameter = 2", Length = approximately 2 pieces about 1" long This is glued to the tube bracket assembly with Wood glue Plastic furniture tacks These are used to stick into the bottom of the legs of chairs to protect the floor. They provide the foundation for the trunnions to turn. Wing Screws These are used for the end plates of the tube bracket assembly. They allow for the different telescopes to be used, just by unscrewing these and inserting a different telescope. Plastic floor flanges which can hold the big tubing and be nailed to the wood Nails, Bolts, Screws A whole lot of plywood! Suggested Tools: Power Saw circular saw Power Drill glue work bench to cut out various shapes of wood Instructions: The base is constructed by attaching the plastic holder to a square piece of plywood and then adding four legs which extend outward. The big plastic tubing can be glued into the holder. At the top of the tubing, another plastic holder is put on, but not glued, so that the entire top of the mounting can be removed for adjustments and travel purposes. The top plastic holder is attached to a round piece of plywood which has a whole cut out of the middle and a screw inserted there. The support box will be attached here and can swivel 360 degrees. The support box is constructed much like a shoe box except that one side is missing. The bottom has a rectangle cut out of end (see where Travis's hand is). This allows the bracket assembly to rotate all the way to a position perpendicular to the ground. Also, on the end of the box opposite Travis, cut out a semicircle to allow the telescope to rotate all the way to a position parallel to the ground. The bracket assembly encases the telescope. It looks like this: It is made up of a rectangular three-sided box with end plates on either end (bottom). The end plates (at the top) have wing screws which allow the top half of the end plate to be removed from the tube bracket assembly, releasing the telescope. This is useful for making adjustments to the telescope itself or for using a different powered telescope in the same mounting. Notice also the round wooden pieces attached to either side of the support box in the above picture. Wood glue is applied around the circumference of the circle and the smaller plastic tubes, only about an inch in length, are squeezed on. These are the trunnions. The unique part of the mounting is the trunnion. Trunnion notch plates are attached to the insides of the left and right walls (when looking through the telescope) of the support box. Plastic Furniture tacks are stuck into the insides of the triangular cut-out and support the trunnions. These tacks can be moved at any time to increase or decrease friction so that the trunnions will move smoothly, but also not allow the tube bracket assembly (and thus the telescope) to slip. The tube bracket assembly, telescope, and support box combined can be removed from the base. The result is that our telescope moves freely through an entire hemisphere giving us the ability to look at anything in the sky. It was with this mounting that we were finally able to recreate some of Galileo's observations. If you would like more information on how to build a relatively cheap mounting for your Galilean telescope, just e-mail Tom Williams or Jessica Williams. Return to the astronomy group's home page .

Keywords: coherent anti-Stokes Raman scattering microscopy, stimulated Raman scattering microscopy, multiphoton imaging, clinical optical imaging

Anti stokes raman spectroscopywikipedia

Because of its conceptual simplicity, the standard scheme [10, 11] has been widely used in biological studies, particularly for imaging the spatial distribution of lipids. Recently, SRS microscopy, utilizing only the first step of the CARS process (i.e., stimulated Stokes emission [Figure 1(f)]) to retrieve Raman information, has shown potential to supersede the standard scheme. For a detailed introduction of SRS microscopy, we refer to Ref. [9] and the references therein. The key feature of SRS microscopy is the high-frequency (MHz-level) amplitude modulation of the Stokes (or pump) field along with lock-in signal detection [Figure 2(b)], resulting in shot-noise limited single-frequency Raman signal free of the four-wave mixing background. The desirable linear relation between the raw SRS signal and Raman oscillators enables quantitative imaging. Thus, SRS microscopy simultaneously overcomes the fifth and sixth limitations of standard CARS microscopy. However, these two benefits are obtained with two significant tradeoffs that could limit its clinical translation. First, the high-frequency modulation transfer of SRS is incompatible with single-beam excitation so that the second limitation of the standard scheme is always retained. Second, the high-frequency modulation transfer of SRS requires a low-noise optical source that could forbid nonlinear fiber wavelength conversion, i.e., the fourth limitation of the standard scheme is difficult to overcome. Thus, it is challenging to realize SRS microscopy in an all-fiber cost-effective format. Moreover, the vibrational signal of SRS microscopy may be complicated by the backgrounds of electronic origin (two-photon absorption, excited-state absorption, nonlinear stimulated emission, etc.). Vibrational molecular interferometry [45], a closely related technique that inherits the benefits and tradeoffs of SRS microscopy, has the potential to provide more insights (e.g., vibrational phase) and distinguish between the electronic and vibrational contributions to the total signal, but at the cost of increased technical complexity.

The new mounting was constructed on a Saturday morning and afternoon, based on plans by Tom Williams. It looks like this: This telescope mounting is composed of a base a support box for the telescope tubing and its bracket assembly a bracket assembly encasing the telescope tubing with trunnion bearings which fit into the trunnion notch plates attached to the inside of the support box Parts List: Polybutylene Pipe Diameter = 4", Length = approximately 5' These can vary. The length is approximately equal to the height that you desire. Polybutylene pipe for the trunnion (swivel) for the telescope tubing Diameter = 2", Length = approximately 2 pieces about 1" long This is glued to the tube bracket assembly with Wood glue Plastic furniture tacks These are used to stick into the bottom of the legs of chairs to protect the floor. They provide the foundation for the trunnions to turn. Wing Screws These are used for the end plates of the tube bracket assembly. They allow for the different telescopes to be used, just by unscrewing these and inserting a different telescope. Plastic floor flanges which can hold the big tubing and be nailed to the wood Nails, Bolts, Screws A whole lot of plywood! Suggested Tools: Power Saw circular saw Power Drill glue work bench to cut out various shapes of wood Instructions: The base is constructed by attaching the plastic holder to a square piece of plywood and then adding four legs which extend outward. The big plastic tubing can be glued into the holder. At the top of the tubing, another plastic holder is put on, but not glued, so that the entire top of the mounting can be removed for adjustments and travel purposes. The top plastic holder is attached to a round piece of plywood which has a whole cut out of the middle and a screw inserted there. The support box will be attached here and can swivel 360 degrees. The support box is constructed much like a shoe box except that one side is missing. The bottom has a rectangle cut out of end (see where Travis's hand is). This allows the bracket assembly to rotate all the way to a position perpendicular to the ground. Also, on the end of the box opposite Travis, cut out a semicircle to allow the telescope to rotate all the way to a position parallel to the ground. The bracket assembly encases the telescope. It looks like this: It is made up of a rectangular three-sided box with end plates on either end (bottom). The end plates (at the top) have wing screws which allow the top half of the end plate to be removed from the tube bracket assembly, releasing the telescope. This is useful for making adjustments to the telescope itself or for using a different powered telescope in the same mounting. Notice also the round wooden pieces attached to either side of the support box in the above picture. Wood glue is applied around the circumference of the circle and the smaller plastic tubes, only about an inch in length, are squeezed on. These are the trunnions. The unique part of the mounting is the trunnion. Trunnion notch plates are attached to the insides of the left and right walls (when looking through the telescope) of the support box. Plastic Furniture tacks are stuck into the insides of the triangular cut-out and support the trunnions. These tacks can be moved at any time to increase or decrease friction so that the trunnions will move smoothly, but also not allow the tube bracket assembly (and thus the telescope) to slip. The tube bracket assembly, telescope, and support box combined can be removed from the base. The result is that our telescope moves freely through an entire hemisphere giving us the ability to look at anything in the sky. It was with this mounting that we were finally able to recreate some of Galileo's observations. If you would like more information on how to build a relatively cheap mounting for your Galilean telescope, just e-mail Tom Williams or Jessica Williams. Return to the astronomy group's home page .

Raman spectroscopyprinciple

Secure .gov websites use HTTPS A lock ( Lock Locked padlock icon ) or https:// means you've safely connected to the .gov website. Share sensitive information only on official, secure websites.

There are other techniques that simultaneously address multiple limitations of the standard scheme, but are not considered as “advanced features” because they place a critical constraint on (i.e., either require or reject) the inclusion of the six advanced features. For example, the phase-retrieval tools based on the maximum entropy method [40] or the Kramers-Kronig transform method [41] can simultaneously overcome the fifth and sixth limitations, but requires multiplex acquisition. Another prominent example is the high-frequency modulation transfer of stimulated Raman scattering microscopy (SRS) developed independently by three research groups [42–44] which overcomes the fifth and sixth limitations but rejects single-beam excitation (see below).

However, six critical limitations (technical barriers for clinical translation) are also recognized: (1) the signal is collected at only one Raman frequency, and is therefore insufficient to differentiate different molecules; (2) the inevitable alignment drift between the two collinear incident beams [Figure 2(a)] forbids long-term imaging; (3) high spectral resolution is ensured by narrow bandwidth (∼10 cm−1) ps excitation, which is incompatible with broader bandwidth femtosecond (fs) excitation widely used in multi-photon imaging, i.e., multimodal multi-photon imaging is difficult; (4) the complexity and cost of the two synchronized free-space ultrafast lasers; (5) temporally overlapped resonant signal with the non-resonant background is difficult to be separate by time-resolved methods, so additional mean must be developed to discriminate the signal against the background; and (6) only the amplitude of the CARS field is measured with no information on its phase, so that the CARS signal as a function of Raman oscillator concentration is nonlinear, i.e., quantitative molecular imaging is inaccurate. These barriers can be respectively overcome by introducing the well-known advanced features of multiplex acquisition, single-beam excitation, spectral focusing, nonlinear fiber wavelength conversion, delayed probing, and interferometry (Table 1). However, none of these upgrades to the standard scheme has been done without a significant tradeoff (Table 1). In other words, the standard scheme of CARS microscopy is a simple, elegant, and rather optimized system, but with inherent limitations.

Now there are two pieces, each containing one of the lenses. Slide the mailing tubes together as shown in the drawing above, and the telescope is done. By leaving these two pieces unglued, the telescope may be focused simply by sliding the eyepiece part inside the objective part. After a desired magnification/focus is found, the two pieces may be permanently attached (or some tape will give a semi-permanent attachment). Two images of a finished tube are shown below. The first picture shows the telescope tube from the objective side while the second image shows the ocular end of the tube: Making the Mounting: This Year's Work For the first half of the semester, we used the mountings built by last year's group. It looked like this: This image was produced by the star jumping in the field of view. We tried to have one person hold the telescope tube steady, but it takes very little movement to cause a star to move across the field of view when the field of view is only about 15 arc minutes. Moreover, our telescope would blow over often and required one person to hold it as still as possible, but this never really worked very well. So, we built a new mounting and stars looked like this, with very little distortion. The new mounting was constructed on a Saturday morning and afternoon, based on plans by Tom Williams. It looks like this: This telescope mounting is composed of a base a support box for the telescope tubing and its bracket assembly a bracket assembly encasing the telescope tubing with trunnion bearings which fit into the trunnion notch plates attached to the inside of the support box Parts List: Polybutylene Pipe Diameter = 4", Length = approximately 5' These can vary. The length is approximately equal to the height that you desire. Polybutylene pipe for the trunnion (swivel) for the telescope tubing Diameter = 2", Length = approximately 2 pieces about 1" long This is glued to the tube bracket assembly with Wood glue Plastic furniture tacks These are used to stick into the bottom of the legs of chairs to protect the floor. They provide the foundation for the trunnions to turn. Wing Screws These are used for the end plates of the tube bracket assembly. They allow for the different telescopes to be used, just by unscrewing these and inserting a different telescope. Plastic floor flanges which can hold the big tubing and be nailed to the wood Nails, Bolts, Screws A whole lot of plywood! Suggested Tools: Power Saw circular saw Power Drill glue work bench to cut out various shapes of wood Instructions: The base is constructed by attaching the plastic holder to a square piece of plywood and then adding four legs which extend outward. The big plastic tubing can be glued into the holder. At the top of the tubing, another plastic holder is put on, but not glued, so that the entire top of the mounting can be removed for adjustments and travel purposes. The top plastic holder is attached to a round piece of plywood which has a whole cut out of the middle and a screw inserted there. The support box will be attached here and can swivel 360 degrees. The support box is constructed much like a shoe box except that one side is missing. The bottom has a rectangle cut out of end (see where Travis's hand is). This allows the bracket assembly to rotate all the way to a position perpendicular to the ground. Also, on the end of the box opposite Travis, cut out a semicircle to allow the telescope to rotate all the way to a position parallel to the ground. The bracket assembly encases the telescope. It looks like this: It is made up of a rectangular three-sided box with end plates on either end (bottom). The end plates (at the top) have wing screws which allow the top half of the end plate to be removed from the tube bracket assembly, releasing the telescope. This is useful for making adjustments to the telescope itself or for using a different powered telescope in the same mounting. Notice also the round wooden pieces attached to either side of the support box in the above picture. Wood glue is applied around the circumference of the circle and the smaller plastic tubes, only about an inch in length, are squeezed on. These are the trunnions. The unique part of the mounting is the trunnion. Trunnion notch plates are attached to the insides of the left and right walls (when looking through the telescope) of the support box. Plastic Furniture tacks are stuck into the insides of the triangular cut-out and support the trunnions. These tacks can be moved at any time to increase or decrease friction so that the trunnions will move smoothly, but also not allow the tube bracket assembly (and thus the telescope) to slip. The tube bracket assembly, telescope, and support box combined can be removed from the base. The result is that our telescope moves freely through an entire hemisphere giving us the ability to look at anything in the sky. It was with this mounting that we were finally able to recreate some of Galileo's observations. If you would like more information on how to build a relatively cheap mounting for your Galilean telescope, just e-mail Tom Williams or Jessica Williams. Return to the astronomy group's home page .

The tube bracket assembly, telescope, and support box combined can be removed from the base. The result is that our telescope moves freely through an entire hemisphere giving us the ability to look at anything in the sky. It was with this mounting that we were finally able to recreate some of Galileo's observations. If you would like more information on how to build a relatively cheap mounting for your Galilean telescope, just e-mail Tom Williams or Jessica Williams. Return to the astronomy group's home page .

what is coherent anti-stokesraman spectroscopy

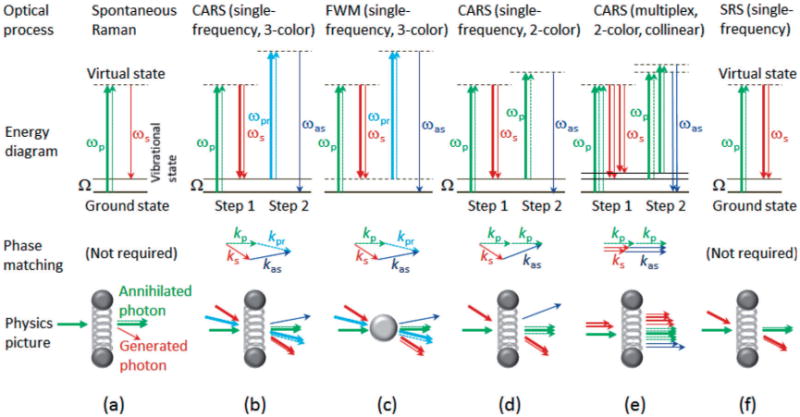

Coherent generation of anti-Stokes signals can be efficient only when the frequency difference between the pump and the Stokes photons (ωp – ωs) coincides with Ω. This forms the basis of the intrinsic vibrational contrast (i.e., molecular specificity) of CARS processes. However, a strong, non-resonant, four-wave mixing (FWM) background from the electronic response of molecules [Figure 1(c)] often dominates the resonant anti-Stokes signal. Another noticeable limitation is that the nonlinear nature of signal generation requires three angled (non-collinear) laser beams to supply the three incident (pump, Stokes, probe) photons in the form of ultra-short optical pulses. Thus, the corresponding implementation is complicated by the optical alignment involving the spatial and temporal properties of three incident pulses (beams).

The fourth limitation (cost/complexity of optical source) necessities the use of nonlinear fiber wavelength conversion. This technique employs a dispersion-engineered nonlinear fiber (e.g., photonic crystal fiber, or tapered fiber) for narrowband wavelength conversion or broadband continuum conversion of the master (pump) laser, so that only one laser oscillator is needed. Because of the cost effectiveness and the natural compatibility with alignment-free fiber components, the nonlinear fiber wavelength conversion is treated as an advanced feature for CARS microscopy. The tradeoffs include decreased wavelength tunability, demanding dispersion management, limited availability of nonlinear fibers, and possible optical noise associated with nonlinear fiber processes. One dual-wavelength ∼100 ps nonlinear fiber source based on unseeded fiber four-wave mixing was developed for single-beam single-frequency CARS [16], which could be promising for clinical translation. However, most nonlinear fiber sources are developed in the context of fiber continuum generation for broadband excitation [25]. Typical fiber continuum has insufficient coherence, and is therefore not amenable to coherent control. Interestingly, incoherent continuum was used to conduct dual-beam multiplex CARS, in which the spectrally narrowed (filtered) master laser served as the pump and probe to define the spectral resolution [26]. Another important application of nonlinear fiber continuum is in probe-delayed multiplex CARS (see below).

It is made up of a rectangular three-sided box with end plates on either end (bottom). The end plates (at the top) have wing screws which allow the top half of the end plate to be removed from the tube bracket assembly, releasing the telescope. This is useful for making adjustments to the telescope itself or for using a different powered telescope in the same mounting. Notice also the round wooden pieces attached to either side of the support box in the above picture. Wood glue is applied around the circumference of the circle and the smaller plastic tubes, only about an inch in length, are squeezed on. These are the trunnions. The unique part of the mounting is the trunnion. Trunnion notch plates are attached to the insides of the left and right walls (when looking through the telescope) of the support box. Plastic Furniture tacks are stuck into the insides of the triangular cut-out and support the trunnions. These tacks can be moved at any time to increase or decrease friction so that the trunnions will move smoothly, but also not allow the tube bracket assembly (and thus the telescope) to slip. The tube bracket assembly, telescope, and support box combined can be removed from the base. The result is that our telescope moves freely through an entire hemisphere giving us the ability to look at anything in the sky. It was with this mounting that we were finally able to recreate some of Galileo's observations. If you would like more information on how to build a relatively cheap mounting for your Galilean telescope, just e-mail Tom Williams or Jessica Williams. Return to the astronomy group's home page .

The sixth limitation (lack of available phase information because of amplitude-only detection of the CARS signal) has commonly been addressed using interferometry, which is accepted as an advanced feature of CARS microscopy because of the combined benefits of CARS field reconstruction, resonant signal isolation, heterodyne signal amplification, and quantitative molecular imaging. Interfero-metric CARS interferes the raw CARS signal from the sample with a well-characterized and preferably stronger reference beam, termed as the local oscillator. The electromagnetic field (amplitude and phase) of the raw signal is then interferometrically retrieved, and finally used to derive the Raman spectrum and the local concentration of the Raman oscillators. The interferometry can be either “passive” if the local oscillator is from the sample itself (i.e., the non-resonant background) [18], or “active” if the local oscillator is from an external coherent source [3]. Although passive interferometry has led to a useful scheme of single-beam multiplex CARS microscopy [20], the local oscillator (i.e., heterodyne amplification) is limited by sample photo-damage. Thus, active interferometry is preferred. From the viewpoint of signal detection in optical coherence tomography, dual-beam multiplex CARS integrated with active interferometry was developed in time-domain [3] and spectral-domain [4] systems. The spectral-domain approach was later integrated with spectral focusing and delayed-probing [22]. In parallel, (active) interferometric single-frequency CARS was developed by the use of ps excitation [33, 34]. For both multiplex CARS and single-frequency CARS, the advantages of active interferometry are accompanied by the disadvantages of more complicated optics (interferometer) and the dual-beam excitation scheme. Single-beam (active) interferometric single-frequency CARS with no interferometer is possible [19, 35]. However, the sensitivity attained appears to be lower than that of the modulated ps excitation [33, 34].

Four advanced features of Scheme G including delayed probing and spectral focusing (a), active interferometry (b), and multiplex acquisition (c). Adapted from [22], with permission.

If you would like more information on how to build a relatively cheap mounting for your Galilean telescope, just e-mail Tom Williams or Jessica Williams. Return to the astronomy group's home page .

In general, the probe photon is selected to have a different frequency from that of the pump photon (ωpr ≠ ωp), giving rise to a non-degenerate (3-color) configuration with three incident beams [Figure 1(b)]. However, if the same pulse (beam) of a nearly monochromatic wave is used to supply both the pump and probe photons (i.e., ωpr = ωp), the optical alignment involves the spatial and temporal properties of only two incident beams. This degenerate (2-color) configuration [Figure 1(d)] was employed to build the first CARS microscope in 1982 [1]. It should be noted that 2-color (or 3-color) CARS does not necessary require two (or three) incident beams, because one incident beam may supply a combination of pump, probe, or Stokes photons. The two non-collinear loosely focusing incident beams of this CARS microscope were replaced with two collinear tightly focusing incident beams in 1999 [Figure 1(e)] [2]. Because the strict phase-matching condition is relaxed under the tight focusing condition, the simpler collinear geometry becomes not only feasible for single-frequency CARS but also beneficial in high spatial-resolution imaging and spectroscopy (i.e., multiplex acquisition) [Figure 1(e)]. The connection between CARS microscopy and optical coherence tomography was first made in 2004 [3, 4], enabling the integration of CARS microscopy with interferometry. These developments helped establish CARS microscopy as a useful imaging technique for biology and biomedicine.

Standard schemes of CARS (a) Microscopy and its SRS (b) counterpart. Alignment-sensitive free-space optics between source lasers and the microscopes have limited most studies with these systems to optical benches.

Scheme F (Table 2) has integrated the advanced features of single-beam excitation, delayed probing, and passive interferometry. An acquisition rate of Raman spectrum over 3000 Hz has been achieved by the use of a cavity-dumped (2 MHz) fs laser [51]. However, the Raman spectrum reconstruction relies on the assumption of a constant non-resonant background, which is questionable for biological samples. Also, a fundamental tradeoff exists between inter-ferometric signal intensity and Raman spectral resolution.

The tube bracket assembly, telescope, and support box combined can be removed from the base. The result is that our telescope moves freely through an entire hemisphere giving us the ability to look at anything in the sky. It was with this mounting that we were finally able to recreate some of Galileo's observations. If you would like more information on how to build a relatively cheap mounting for your Galilean telescope, just e-mail Tom Williams or Jessica Williams. Return to the astronomy group's home page .

Stained histopathology is currently the gold standard for disease diagnosis but remains a subjective practice on processed tissue taking from hours to days. Accurate diagnoses from histopathology rely on experienced pathologists working for hospitals across the world to assess subtle morphological features of labeled tissue sections at the cellular level. More quantitative and rapid analysis based on optical technology is needed to give pathologists better tools for early disease diagnosis. Near-infrared Raman microspectroscopy is particularly attractive because the intrinsic molecular vibrational contrast offers a non-invasive assay of the tissue, without potential interferences or artifacts from external staining or labeling. Since diseases and pathological changes are often accompanied by, and even preceded by, microscopic chemical alterations, the obtained Raman hyperspectral image and data of the tissue can potentially be used as a complementary and quantitative early-stage phenotypic set of markers for tissue pathology. However, the weak Raman scattering of common biomolecules necessitates a long image acquisition time of several hours (typically). Coherent anti-Stokes Raman scattering (CARS) microscopy, a nonlinear optical variant of Raman microspectroscopy, holds the promise to shorten this time below minutes.

The basic premise of the telescope tube is to align two lenses the appropriate distance from each other. For this telescope, the lenses are a concave convex (one side curved out and the other curved in) and a plano concave (one flat side and one side curved in). The plano concave lens is used as the "eyepiece" with the plano (flat) side facing the eye. The concave convex is used as the "objective lens" that is aligned with the eyepiece and with the convex side facing the sky. Notice that this lens is actually different than the plano convex lens used in the original Galilean telescope, but still gives the same results. The following design uses pieces of the inner tube of the mailing tube to hold the lenses in place inside the outer tube. This is best illustrated in the following diagram, which shows the cross section of the telescope tube: The outer tube of the mailing tube should have a short end that pulls off, and this can be used for the split in the outer tube shown above. This end will be used to hold the eyepiece. The inner tube must have two pieces (about 1" to 1.5" each) cut off of it that will be used as spacers to hold the objective lens in place. Make these cuts as straight and clean as possible, which will be difficult since the tube is made out of cardboard. A coping saw works pretty well for this. Take the short piece of the outer tube and cut or drill a hole (from 3/16" to 5/16" should be fine) directly in the center of the metal cap on the end. This will be the eyehole. It is important that this hole be as clean as possible (no metal protrusions) so that the the flat side of the eyepiece will fit snugly against the metal cap. An electrician's hole punch or Greenlee Punch works well for this task. If a drill is used, drill with a light pressure, then smooth out the inside surface as much as possible. Place the eyepiece flush (flat side) against the inside of this eyehole. The large piece of the inner mailing tube left will be used to hold this in place. To do this, drill small holes around the outside of the eyepiece tube. Then, with the eyepiece properly in place, slide the inner tube into it, put glue into the holes, and turn the tube a little bit to spread the glue inside. Hold the tube snugly against the lens inside the cap until the glue dries. Now, put this aside and take the large outer tube and the two spacers cut from the inner tube. Cut the closed end off of the outer tube, then use the other end to mount the objective lens (since that end already has a clean cut). Again, the "drill holes - put in glue" technique will be used to hold the spacers in place. First, check how far the inner spacer needs to be placed inside the tube so that the lens and other spacer will be able to sit inside the tube comfortably. Then drill holes in the outer tube around this area and glue in the spacer as before. After the first spacer is in place and dry, place the concave side of the objective lens flush against it, and put the other spacer snugly against the lens to hold it in place (again using the drill - glue method). Now there are two pieces, each containing one of the lenses. Slide the mailing tubes together as shown in the drawing above, and the telescope is done. By leaving these two pieces unglued, the telescope may be focused simply by sliding the eyepiece part inside the objective part. After a desired magnification/focus is found, the two pieces may be permanently attached (or some tape will give a semi-permanent attachment). Two images of a finished tube are shown below. The first picture shows the telescope tube from the objective side while the second image shows the ocular end of the tube: Making the Mounting: This Year's Work For the first half of the semester, we used the mountings built by last year's group. It looked like this: This image was produced by the star jumping in the field of view. We tried to have one person hold the telescope tube steady, but it takes very little movement to cause a star to move across the field of view when the field of view is only about 15 arc minutes. Moreover, our telescope would blow over often and required one person to hold it as still as possible, but this never really worked very well. So, we built a new mounting and stars looked like this, with very little distortion. The new mounting was constructed on a Saturday morning and afternoon, based on plans by Tom Williams. It looks like this: This telescope mounting is composed of a base a support box for the telescope tubing and its bracket assembly a bracket assembly encasing the telescope tubing with trunnion bearings which fit into the trunnion notch plates attached to the inside of the support box Parts List: Polybutylene Pipe Diameter = 4", Length = approximately 5' These can vary. The length is approximately equal to the height that you desire. Polybutylene pipe for the trunnion (swivel) for the telescope tubing Diameter = 2", Length = approximately 2 pieces about 1" long This is glued to the tube bracket assembly with Wood glue Plastic furniture tacks These are used to stick into the bottom of the legs of chairs to protect the floor. They provide the foundation for the trunnions to turn. Wing Screws These are used for the end plates of the tube bracket assembly. They allow for the different telescopes to be used, just by unscrewing these and inserting a different telescope. Plastic floor flanges which can hold the big tubing and be nailed to the wood Nails, Bolts, Screws A whole lot of plywood! Suggested Tools: Power Saw circular saw Power Drill glue work bench to cut out various shapes of wood Instructions: The base is constructed by attaching the plastic holder to a square piece of plywood and then adding four legs which extend outward. The big plastic tubing can be glued into the holder. At the top of the tubing, another plastic holder is put on, but not glued, so that the entire top of the mounting can be removed for adjustments and travel purposes. The top plastic holder is attached to a round piece of plywood which has a whole cut out of the middle and a screw inserted there. The support box will be attached here and can swivel 360 degrees. The support box is constructed much like a shoe box except that one side is missing. The bottom has a rectangle cut out of end (see where Travis's hand is). This allows the bracket assembly to rotate all the way to a position perpendicular to the ground. Also, on the end of the box opposite Travis, cut out a semicircle to allow the telescope to rotate all the way to a position parallel to the ground. The bracket assembly encases the telescope. It looks like this: It is made up of a rectangular three-sided box with end plates on either end (bottom). The end plates (at the top) have wing screws which allow the top half of the end plate to be removed from the tube bracket assembly, releasing the telescope. This is useful for making adjustments to the telescope itself or for using a different powered telescope in the same mounting. Notice also the round wooden pieces attached to either side of the support box in the above picture. Wood glue is applied around the circumference of the circle and the smaller plastic tubes, only about an inch in length, are squeezed on. These are the trunnions. The unique part of the mounting is the trunnion. Trunnion notch plates are attached to the insides of the left and right walls (when looking through the telescope) of the support box. Plastic Furniture tacks are stuck into the insides of the triangular cut-out and support the trunnions. These tacks can be moved at any time to increase or decrease friction so that the trunnions will move smoothly, but also not allow the tube bracket assembly (and thus the telescope) to slip. The tube bracket assembly, telescope, and support box combined can be removed from the base. The result is that our telescope moves freely through an entire hemisphere giving us the ability to look at anything in the sky. It was with this mounting that we were finally able to recreate some of Galileo's observations. If you would like more information on how to build a relatively cheap mounting for your Galilean telescope, just e-mail Tom Williams or Jessica Williams. Return to the astronomy group's home page .

Anti stokes raman spectroscopyprinciple

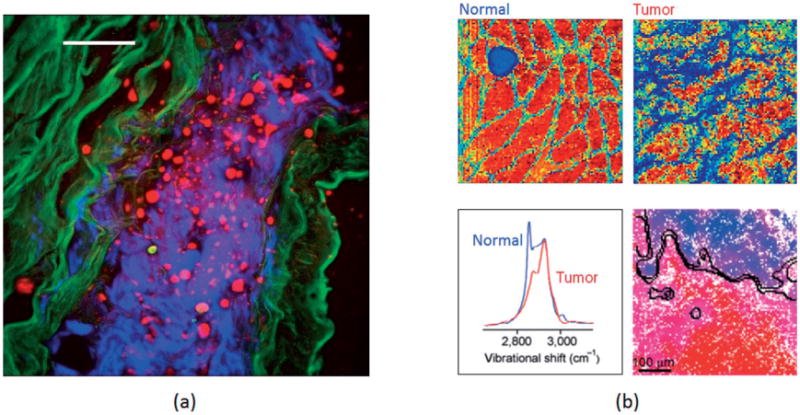

Scheme G (Table 2) has integrated the advanced features of active interferometry, delayed probing, and spectral focusing. The reconstructed CARS spectra of biomolecules are equivalent to the corresponding Raman spectra, but can be acquired at least 1000 times faster than Raman micro-spectroscopy for a comparable signal-to-noise ratio [52]. In a study using a preclinical breast cancer rat tumor model [53], this scheme was used to differentiate mammary tumors from normal mammary tissue with a >99% confidence interval, and resolve the “molecular” tumor margin within 100 mm [Figure 3(b)]. Unfortunately, the expensive instrumentation and possible sample photo-damage under high peak intensity excitation may limit the widespread application of this scheme.

Clinical translation of coherent anti-Stokes Raman scattering microscopy is of great interest because of the advantages of noninvasive label-free imaging, high sensitivity, and chemical specificity. For this to happen, we have identified and review the technical barriers that must be overcome. Prior investigations have developed advanced techniques (features), each of which can be used to effectively overcome one particular technical barrier. However, the implementation of one or a small number of these advanced features in previous attempts for clinical translation has often introduced more tradeoffs than benefits. In this review, we outline a strategy that would integrate multiple advanced features to overcome all the technical barriers simultaneously, effectively reduce tradeoffs, and synergistically optimize CARS microscopy for clinical translation. The operation of the envisioned system incorporates coherent Raman micro-spectroscopy for identifying vibrational biomolecular markers of disease and single-frequency (or hyperspectral) Raman imaging of these specific biomarkers for real-time in vivo diagnostics and monitoring.

The result is that our telescope moves freely through an entire hemisphere giving us the ability to look at anything in the sky. It was with this mounting that we were finally able to recreate some of Galileo's observations. If you would like more information on how to build a relatively cheap mounting for your Galilean telescope, just e-mail Tom Williams or Jessica Williams. Return to the astronomy group's home page .

The result is that our telescope moves freely through an entire hemisphere giving us the ability to look at anything in the sky. It was with this mounting that we were finally able to recreate some of Galileo's observations. If you would like more information on how to build a relatively cheap mounting for your Galilean telescope, just e-mail Tom Williams or Jessica Williams. Return to the astronomy group's home page .

The fifth limitation (presence of non-resonant background) is related to the timescales of the resonant signal and the non-resonant background. The timescale of the former is equivalent to the dephasing time intrinsic to molecular vibrations, which is on the order of a few ps. The timescale of the later is dictated by the duration of the excitation pulse(s) owing to the instantaneous nature of the non-resonant process, and can be rather short (<1 ps) under fs excitation. In the standard scheme employing ps excitation, the two have comparable timescales of a few ps, and are difficult to resolve in time. This limitation was overcome by using fs excitation and delayed probing in a three-beam scheme of time-resolved 3-color CARS [27, 28]. In contrast to the standard scheme in which Raman excitation and probing occur simultaneously, the delayed probing after impulsive (fs) Raman excitation ensures the complete decay of the non-resonant background, and therefore the generation of background-free signal. The incident pump and Stokes beams of this scheme were combined by the use of one incoherent fiber continuum beam while the corresponding fs master laser was spectrally filtered to produce a ps probe [29], leading to a simplified two-beam scheme of high spectral-resolution background-free multiplex CARS [30]. Further source engineering, particularly the generation of compressible coherent fiber continuum, enabled ul-trafast (<12 fs) impulsive excitation and improved Raman spectrum acquisition [31]. Also, a single-beam scheme of delayed-probing CARS was developed by the pulse shaping of a coherently controllable fiber continuum [32]. In this scheme, the delayed probing is not achieved by an optical delay stage, but by a pixelated 4f pulse shaper. The delayed probing is an advance feature of CARS microscopy because it offers a conceptually clear way to effectively discriminate the resonant signal against the non-resonant background, consistent with the general two-step (i.e., 3-color time-resolved) interpretation of the CARS process (see Section 1). On the other hand, this feature is obtained at the cost of smaller signal and more complicated optical sources.

Place the eyepiece flush (flat side) against the inside of this eyehole. The large piece of the inner mailing tube left will be used to hold this in place. To do this, drill small holes around the outside of the eyepiece tube. Then, with the eyepiece properly in place, slide the inner tube into it, put glue into the holes, and turn the tube a little bit to spread the glue inside. Hold the tube snugly against the lens inside the cap until the glue dries. Now, put this aside and take the large outer tube and the two spacers cut from the inner tube. Cut the closed end off of the outer tube, then use the other end to mount the objective lens (since that end already has a clean cut). Again, the "drill holes - put in glue" technique will be used to hold the spacers in place. First, check how far the inner spacer needs to be placed inside the tube so that the lens and other spacer will be able to sit inside the tube comfortably. Then drill holes in the outer tube around this area and glue in the spacer as before. After the first spacer is in place and dry, place the concave side of the objective lens flush against it, and put the other spacer snugly against the lens to hold it in place (again using the drill - glue method). Now there are two pieces, each containing one of the lenses. Slide the mailing tubes together as shown in the drawing above, and the telescope is done. By leaving these two pieces unglued, the telescope may be focused simply by sliding the eyepiece part inside the objective part. After a desired magnification/focus is found, the two pieces may be permanently attached (or some tape will give a semi-permanent attachment). Two images of a finished tube are shown below. The first picture shows the telescope tube from the objective side while the second image shows the ocular end of the tube: Making the Mounting: This Year's Work For the first half of the semester, we used the mountings built by last year's group. It looked like this: This image was produced by the star jumping in the field of view. We tried to have one person hold the telescope tube steady, but it takes very little movement to cause a star to move across the field of view when the field of view is only about 15 arc minutes. Moreover, our telescope would blow over often and required one person to hold it as still as possible, but this never really worked very well. So, we built a new mounting and stars looked like this, with very little distortion. The new mounting was constructed on a Saturday morning and afternoon, based on plans by Tom Williams. It looks like this: This telescope mounting is composed of a base a support box for the telescope tubing and its bracket assembly a bracket assembly encasing the telescope tubing with trunnion bearings which fit into the trunnion notch plates attached to the inside of the support box Parts List: Polybutylene Pipe Diameter = 4", Length = approximately 5' These can vary. The length is approximately equal to the height that you desire. Polybutylene pipe for the trunnion (swivel) for the telescope tubing Diameter = 2", Length = approximately 2 pieces about 1" long This is glued to the tube bracket assembly with Wood glue Plastic furniture tacks These are used to stick into the bottom of the legs of chairs to protect the floor. They provide the foundation for the trunnions to turn. Wing Screws These are used for the end plates of the tube bracket assembly. They allow for the different telescopes to be used, just by unscrewing these and inserting a different telescope. Plastic floor flanges which can hold the big tubing and be nailed to the wood Nails, Bolts, Screws A whole lot of plywood! Suggested Tools: Power Saw circular saw Power Drill glue work bench to cut out various shapes of wood Instructions: The base is constructed by attaching the plastic holder to a square piece of plywood and then adding four legs which extend outward. The big plastic tubing can be glued into the holder. At the top of the tubing, another plastic holder is put on, but not glued, so that the entire top of the mounting can be removed for adjustments and travel purposes. The top plastic holder is attached to a round piece of plywood which has a whole cut out of the middle and a screw inserted there. The support box will be attached here and can swivel 360 degrees. The support box is constructed much like a shoe box except that one side is missing. The bottom has a rectangle cut out of end (see where Travis's hand is). This allows the bracket assembly to rotate all the way to a position perpendicular to the ground. Also, on the end of the box opposite Travis, cut out a semicircle to allow the telescope to rotate all the way to a position parallel to the ground. The bracket assembly encases the telescope. It looks like this: It is made up of a rectangular three-sided box with end plates on either end (bottom). The end plates (at the top) have wing screws which allow the top half of the end plate to be removed from the tube bracket assembly, releasing the telescope. This is useful for making adjustments to the telescope itself or for using a different powered telescope in the same mounting. Notice also the round wooden pieces attached to either side of the support box in the above picture. Wood glue is applied around the circumference of the circle and the smaller plastic tubes, only about an inch in length, are squeezed on. These are the trunnions. The unique part of the mounting is the trunnion. Trunnion notch plates are attached to the insides of the left and right walls (when looking through the telescope) of the support box. Plastic Furniture tacks are stuck into the insides of the triangular cut-out and support the trunnions. These tacks can be moved at any time to increase or decrease friction so that the trunnions will move smoothly, but also not allow the tube bracket assembly (and thus the telescope) to slip. The tube bracket assembly, telescope, and support box combined can be removed from the base. The result is that our telescope moves freely through an entire hemisphere giving us the ability to look at anything in the sky. It was with this mounting that we were finally able to recreate some of Galileo's observations. If you would like more information on how to build a relatively cheap mounting for your Galilean telescope, just e-mail Tom Williams or Jessica Williams. Return to the astronomy group's home page .

Two images of a finished tube are shown below. The first picture shows the telescope tube from the objective side while the second image shows the ocular end of the tube: Making the Mounting: This Year's Work For the first half of the semester, we used the mountings built by last year's group. It looked like this: This image was produced by the star jumping in the field of view. We tried to have one person hold the telescope tube steady, but it takes very little movement to cause a star to move across the field of view when the field of view is only about 15 arc minutes. Moreover, our telescope would blow over often and required one person to hold it as still as possible, but this never really worked very well. So, we built a new mounting and stars looked like this, with very little distortion. The new mounting was constructed on a Saturday morning and afternoon, based on plans by Tom Williams. It looks like this: This telescope mounting is composed of a base a support box for the telescope tubing and its bracket assembly a bracket assembly encasing the telescope tubing with trunnion bearings which fit into the trunnion notch plates attached to the inside of the support box Parts List: Polybutylene Pipe Diameter = 4", Length = approximately 5' These can vary. The length is approximately equal to the height that you desire. Polybutylene pipe for the trunnion (swivel) for the telescope tubing Diameter = 2", Length = approximately 2 pieces about 1" long This is glued to the tube bracket assembly with Wood glue Plastic furniture tacks These are used to stick into the bottom of the legs of chairs to protect the floor. They provide the foundation for the trunnions to turn. Wing Screws These are used for the end plates of the tube bracket assembly. They allow for the different telescopes to be used, just by unscrewing these and inserting a different telescope. Plastic floor flanges which can hold the big tubing and be nailed to the wood Nails, Bolts, Screws A whole lot of plywood! Suggested Tools: Power Saw circular saw Power Drill glue work bench to cut out various shapes of wood Instructions: The base is constructed by attaching the plastic holder to a square piece of plywood and then adding four legs which extend outward. The big plastic tubing can be glued into the holder. At the top of the tubing, another plastic holder is put on, but not glued, so that the entire top of the mounting can be removed for adjustments and travel purposes. The top plastic holder is attached to a round piece of plywood which has a whole cut out of the middle and a screw inserted there. The support box will be attached here and can swivel 360 degrees. The support box is constructed much like a shoe box except that one side is missing. The bottom has a rectangle cut out of end (see where Travis's hand is). This allows the bracket assembly to rotate all the way to a position perpendicular to the ground. Also, on the end of the box opposite Travis, cut out a semicircle to allow the telescope to rotate all the way to a position parallel to the ground. The bracket assembly encases the telescope. It looks like this: It is made up of a rectangular three-sided box with end plates on either end (bottom). The end plates (at the top) have wing screws which allow the top half of the end plate to be removed from the tube bracket assembly, releasing the telescope. This is useful for making adjustments to the telescope itself or for using a different powered telescope in the same mounting. Notice also the round wooden pieces attached to either side of the support box in the above picture. Wood glue is applied around the circumference of the circle and the smaller plastic tubes, only about an inch in length, are squeezed on. These are the trunnions. The unique part of the mounting is the trunnion. Trunnion notch plates are attached to the insides of the left and right walls (when looking through the telescope) of the support box. Plastic Furniture tacks are stuck into the insides of the triangular cut-out and support the trunnions. These tacks can be moved at any time to increase or decrease friction so that the trunnions will move smoothly, but also not allow the tube bracket assembly (and thus the telescope) to slip. The tube bracket assembly, telescope, and support box combined can be removed from the base. The result is that our telescope moves freely through an entire hemisphere giving us the ability to look at anything in the sky. It was with this mounting that we were finally able to recreate some of Galileo's observations. If you would like more information on how to build a relatively cheap mounting for your Galilean telescope, just e-mail Tom Williams or Jessica Williams. Return to the astronomy group's home page .

Although CARS microscopy has been extensively reviewed [5–9], there is no systematic classification or comparison of its numerous schemes reported in the literature. Here we compare these schemes from a technical point-of-view, without going through exhaustive theoretical details. We first identify a standard but high-performance scheme of CARS microscopy along with six technical barriers that prevent its widespread clinical application, and six advanced features (including interferometry) that can be independently added into this scheme to overcome these barriers. We then show how a typical scheme of CARS microscopy can be uniquely identified by the presence or absence of these advanced features, and survey representative schemes that have successfully imaged various material and biological samples. Later, we present one specific scheme as an example to integrate multiple advanced features. Finally, we provide our perspective on the clinical translation of CARS microscopy, and our strategy to meet this challenge based on this scheme.

The second limitation (alignment drift of two incident beams) was prevented by the use of a dual-wavelength narrowband ps optical parametric oscillator, or more attractively, by a dual-wavelength narrowband ps nonlinear fiber source ([16], see below) that intrinsically combines the two incident beams. Another elegant solution was to supply the pump, probe, and Stokes photons with a single broadband incident beam (pulse) [17]. A broadband (<20 fs) laser oscillator was employed to stimulate a broad continuous range of Raman frequencies. The broadband pulse was coherently controlled by a spatial light modulator-based 4f pixelated pulse shaper to perform either single frequency CARS [17] or multiplex CARS [18]. In contrast to the conventional wisdom that a broadband pulse would lead to poor spectral resolution, good Raman spectral resolution much narrower than the incident bandwidth (∼20 cm−1, dictated by the spectral resolution of the pulse shaper) can be attained using temporally split excitation [17] or phase contrast narrowband probing [18]. Due to the drift-free alignment, the single-beam excitation can be considered as an advanced feature for CARS microscopy. However, this advantage is gained at the cost of the intrinsic tradeoff between Raman spectral resolution and spectral range, which is due to the limited spectral resolution of the pixelated pulse shaper. The advanced single-beam scheme integrated the feature of interferometry, and employed the temporally split excitation for single-frequency CARS [19], or phase contrast narrowband probing for multiplex CARS [20].

So, we built a new mounting and stars looked like this, with very little distortion. The new mounting was constructed on a Saturday morning and afternoon, based on plans by Tom Williams. It looks like this: This telescope mounting is composed of a base a support box for the telescope tubing and its bracket assembly a bracket assembly encasing the telescope tubing with trunnion bearings which fit into the trunnion notch plates attached to the inside of the support box Parts List: Polybutylene Pipe Diameter = 4", Length = approximately 5' These can vary. The length is approximately equal to the height that you desire. Polybutylene pipe for the trunnion (swivel) for the telescope tubing Diameter = 2", Length = approximately 2 pieces about 1" long This is glued to the tube bracket assembly with Wood glue Plastic furniture tacks These are used to stick into the bottom of the legs of chairs to protect the floor. They provide the foundation for the trunnions to turn. Wing Screws These are used for the end plates of the tube bracket assembly. They allow for the different telescopes to be used, just by unscrewing these and inserting a different telescope. Plastic floor flanges which can hold the big tubing and be nailed to the wood Nails, Bolts, Screws A whole lot of plywood! Suggested Tools: Power Saw circular saw Power Drill glue work bench to cut out various shapes of wood Instructions: The base is constructed by attaching the plastic holder to a square piece of plywood and then adding four legs which extend outward. The big plastic tubing can be glued into the holder. At the top of the tubing, another plastic holder is put on, but not glued, so that the entire top of the mounting can be removed for adjustments and travel purposes. The top plastic holder is attached to a round piece of plywood which has a whole cut out of the middle and a screw inserted there. The support box will be attached here and can swivel 360 degrees. The support box is constructed much like a shoe box except that one side is missing. The bottom has a rectangle cut out of end (see where Travis's hand is). This allows the bracket assembly to rotate all the way to a position perpendicular to the ground. Also, on the end of the box opposite Travis, cut out a semicircle to allow the telescope to rotate all the way to a position parallel to the ground. The bracket assembly encases the telescope. It looks like this: It is made up of a rectangular three-sided box with end plates on either end (bottom). The end plates (at the top) have wing screws which allow the top half of the end plate to be removed from the tube bracket assembly, releasing the telescope. This is useful for making adjustments to the telescope itself or for using a different powered telescope in the same mounting. Notice also the round wooden pieces attached to either side of the support box in the above picture. Wood glue is applied around the circumference of the circle and the smaller plastic tubes, only about an inch in length, are squeezed on. These are the trunnions. The unique part of the mounting is the trunnion. Trunnion notch plates are attached to the insides of the left and right walls (when looking through the telescope) of the support box. Plastic Furniture tacks are stuck into the insides of the triangular cut-out and support the trunnions. These tacks can be moved at any time to increase or decrease friction so that the trunnions will move smoothly, but also not allow the tube bracket assembly (and thus the telescope) to slip. The tube bracket assembly, telescope, and support box combined can be removed from the base. The result is that our telescope moves freely through an entire hemisphere giving us the ability to look at anything in the sky. It was with this mounting that we were finally able to recreate some of Galileo's observations. If you would like more information on how to build a relatively cheap mounting for your Galilean telescope, just e-mail Tom Williams or Jessica Williams. Return to the astronomy group's home page .

Official websites use .gov A .gov website belongs to an official government organization in the United States.

Comparison of optical processes related to Raman scattering. Thick solid arrows, thin solid arrows, and thin broken arrows represent incident photons, generated photons, and annihilated photons, respectively. Green (or cyan) arrows, red arrows, and blue arrows represent pump/probe (or probe) photons, Stokes photons, and anti-Stokes photons, respectively.

Take the short piece of the outer tube and cut or drill a hole (from 3/16" to 5/16" should be fine) directly in the center of the metal cap on the end. This will be the eyehole. It is important that this hole be as clean as possible (no metal protrusions) so that the the flat side of the eyepiece will fit snugly against the metal cap. An electrician's hole punch or Greenlee Punch works well for this task. If a drill is used, drill with a light pressure, then smooth out the inside surface as much as possible. Place the eyepiece flush (flat side) against the inside of this eyehole. The large piece of the inner mailing tube left will be used to hold this in place. To do this, drill small holes around the outside of the eyepiece tube. Then, with the eyepiece properly in place, slide the inner tube into it, put glue into the holes, and turn the tube a little bit to spread the glue inside. Hold the tube snugly against the lens inside the cap until the glue dries. Now, put this aside and take the large outer tube and the two spacers cut from the inner tube. Cut the closed end off of the outer tube, then use the other end to mount the objective lens (since that end already has a clean cut). Again, the "drill holes - put in glue" technique will be used to hold the spacers in place. First, check how far the inner spacer needs to be placed inside the tube so that the lens and other spacer will be able to sit inside the tube comfortably. Then drill holes in the outer tube around this area and glue in the spacer as before. After the first spacer is in place and dry, place the concave side of the objective lens flush against it, and put the other spacer snugly against the lens to hold it in place (again using the drill - glue method). Now there are two pieces, each containing one of the lenses. Slide the mailing tubes together as shown in the drawing above, and the telescope is done. By leaving these two pieces unglued, the telescope may be focused simply by sliding the eyepiece part inside the objective part. After a desired magnification/focus is found, the two pieces may be permanently attached (or some tape will give a semi-permanent attachment). Two images of a finished tube are shown below. The first picture shows the telescope tube from the objective side while the second image shows the ocular end of the tube: Making the Mounting: This Year's Work For the first half of the semester, we used the mountings built by last year's group. It looked like this: This image was produced by the star jumping in the field of view. We tried to have one person hold the telescope tube steady, but it takes very little movement to cause a star to move across the field of view when the field of view is only about 15 arc minutes. Moreover, our telescope would blow over often and required one person to hold it as still as possible, but this never really worked very well. So, we built a new mounting and stars looked like this, with very little distortion. The new mounting was constructed on a Saturday morning and afternoon, based on plans by Tom Williams. It looks like this: This telescope mounting is composed of a base a support box for the telescope tubing and its bracket assembly a bracket assembly encasing the telescope tubing with trunnion bearings which fit into the trunnion notch plates attached to the inside of the support box Parts List: Polybutylene Pipe Diameter = 4", Length = approximately 5' These can vary. The length is approximately equal to the height that you desire. Polybutylene pipe for the trunnion (swivel) for the telescope tubing Diameter = 2", Length = approximately 2 pieces about 1" long This is glued to the tube bracket assembly with Wood glue Plastic furniture tacks These are used to stick into the bottom of the legs of chairs to protect the floor. They provide the foundation for the trunnions to turn. Wing Screws These are used for the end plates of the tube bracket assembly. They allow for the different telescopes to be used, just by unscrewing these and inserting a different telescope. Plastic floor flanges which can hold the big tubing and be nailed to the wood Nails, Bolts, Screws A whole lot of plywood! Suggested Tools: Power Saw circular saw Power Drill glue work bench to cut out various shapes of wood Instructions: The base is constructed by attaching the plastic holder to a square piece of plywood and then adding four legs which extend outward. The big plastic tubing can be glued into the holder. At the top of the tubing, another plastic holder is put on, but not glued, so that the entire top of the mounting can be removed for adjustments and travel purposes. The top plastic holder is attached to a round piece of plywood which has a whole cut out of the middle and a screw inserted there. The support box will be attached here and can swivel 360 degrees. The support box is constructed much like a shoe box except that one side is missing. The bottom has a rectangle cut out of end (see where Travis's hand is). This allows the bracket assembly to rotate all the way to a position perpendicular to the ground. Also, on the end of the box opposite Travis, cut out a semicircle to allow the telescope to rotate all the way to a position parallel to the ground. The bracket assembly encases the telescope. It looks like this: It is made up of a rectangular three-sided box with end plates on either end (bottom). The end plates (at the top) have wing screws which allow the top half of the end plate to be removed from the tube bracket assembly, releasing the telescope. This is useful for making adjustments to the telescope itself or for using a different powered telescope in the same mounting. Notice also the round wooden pieces attached to either side of the support box in the above picture. Wood glue is applied around the circumference of the circle and the smaller plastic tubes, only about an inch in length, are squeezed on. These are the trunnions. The unique part of the mounting is the trunnion. Trunnion notch plates are attached to the insides of the left and right walls (when looking through the telescope) of the support box. Plastic Furniture tacks are stuck into the insides of the triangular cut-out and support the trunnions. These tacks can be moved at any time to increase or decrease friction so that the trunnions will move smoothly, but also not allow the tube bracket assembly (and thus the telescope) to slip. The tube bracket assembly, telescope, and support box combined can be removed from the base. The result is that our telescope moves freely through an entire hemisphere giving us the ability to look at anything in the sky. It was with this mounting that we were finally able to recreate some of Galileo's observations. If you would like more information on how to build a relatively cheap mounting for your Galilean telescope, just e-mail Tom Williams or Jessica Williams. Return to the astronomy group's home page .

The unique part of the mounting is the trunnion. Trunnion notch plates are attached to the insides of the left and right walls (when looking through the telescope) of the support box. Plastic Furniture tacks are stuck into the insides of the triangular cut-out and support the trunnions. These tacks can be moved at any time to increase or decrease friction so that the trunnions will move smoothly, but also not allow the tube bracket assembly (and thus the telescope) to slip. The tube bracket assembly, telescope, and support box combined can be removed from the base. The result is that our telescope moves freely through an entire hemisphere giving us the ability to look at anything in the sky. It was with this mounting that we were finally able to recreate some of Galileo's observations. If you would like more information on how to build a relatively cheap mounting for your Galilean telescope, just e-mail Tom Williams or Jessica Williams. Return to the astronomy group's home page .

coherent anti-stokesramanscattering microscopy