Anti-Reflective Coating - ar coated lens

Micro Lens arrayheadlamp

AR Coating OptionsWhile our uncoated PMMA microlens arrays offer excellent performance, improved transmission can be gained by choosing a lens with an antireflective coating on both sides to reduce the surface reflections. Our broadband antireflection (BBAR) coatings provide <0.8% average reflectance over one of the following wavelength ranges: 420 - 700 nm or 650 - 1050 nm.

Micro Lens ArrayTV

Use Microlens Arrays to transform a round collimated beam into a rectangular homogeneous spot.See the Application tab for details.

For microlens arrays that are ideal for use in custom-built Shack-Hartmann wavefront sensors, please visit the Fused Silica Microlens Arrays page.

Please note that the output rectangle is only sharply defined at a specific distance from the focusing lens. The actual size of the rectangle can be adjusted by changing the distance between the two MLAs. Decreasing the distance will increase the size of the rectangle and increasing the distance will make the rectangle smaller. Smaller rectangle sizes can also be produced by using lenses with shorter focal lengths. A simplified diagram of the setup is shown on the bottom right.

Micro Lens ArrayOLED

These PMMA Microlens Arrays (MLAs) are available mounted or unmounted. MLAs are excellent for homogenizing and shaping light, yielding a flat top profile output or square spot patterns. PMMA has excellent UV resistance, filtering out UV light less than 300 nm. The microlenses have a plano-convex shape and are arranged in a 10.0 mm by 9.8 mm rectangular grid with a lens pitch of 1.0 mm by 1.4 mm. These can be used in fly's eye homogenizer configurations, where a round beam is transformed into a rectangular spot (see the Application tab for details). Alternatively, Thorlabs offers a line of Fly's Eye Homogenizer devices using these MLAs with 40 mm or 95 mm working distances.

There are multiple ways to homogenize the output of a light source. Microlens arrays (MLAs) used in a fly's eye homogenizer configuration transform a round collimated beam with a Gaussian profile into a rectangular homogeneous area. The size of the rectangle is defined by the size and pitch of the microlenses.

For the mounted versions, the MLA is glued into a Ø1", 4.0 mm thick mount that is externally SM1-threaded (1.035"-40). The aperture of the lens window is 9.0 mm by 9.0 mm. The plate has slots that are compatible with a SPW602, SPW606, SPW801, or SPW909 spanner wrench. Their unmounted counterparts are most easily held using one of our cylindrical lens mounts, which are specifically designed to hold square or rectangular optics.

Micro lens arrayvs microlensarray

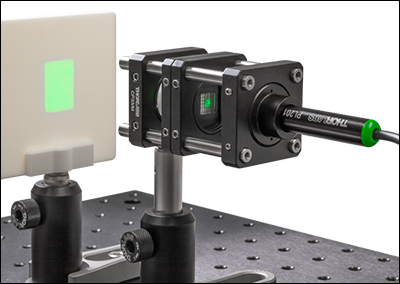

In this example, the setup was mounted using Ø1/2" posts and post holders that were secured to an MB3045(/M) breadboard using clamping forks.

Sphere (Sph) : Sphere sph is the measurement of how much your eye needs to be corrected to see clearly. Sphere (Sph) is often referred to as “power” or “minus cylinder.” If the number appearing under this heading has a minus sign (–), you are nearsighted; if the number has a plus sign (+) or is not preceded by a plus sign or a minus sign, you are farsighted.

Please note that the Zemax file provided below is not the common sequential (SC) raytracing file which we typically provide, but the non-sequential (NSC) raytracing file. Be aware that the standard version of Zemax OpticStudio® does not support the NSC mode.

The application photo to the right shows one possible fly's eye homogenizer configuration mounted in a 30 mm cage system. The light source is a PL201 compact laser module fixed in an AD11F SM1-threaded adapter held in a CP33(/M) cage plate. Alternatively, other light sources can be used such as a fiber-coupled LED connected to a collimator or mounted LED with a collimation adapter. The light passes through the first of two MLAs held in CP6T cage plates. These cage plates are thin enough to hold the mounted MLAs and secure them with a retaining ring while allowing the user to place the MLAs as close as possible to each other to maximize the rectangular output size. The lensed side of the first MLA should face the source. It is key to accurately align the rotation of the MLAs relative to each other; there will be artifacts on screen otherwise. The light then passes through an LB1471 N-BK7 bi-convex lens to produce a rectangular 9 mm x 12 mm area on an EDU-VS2(/M) screen, as seen in the photo to the right. A similar setup can be produced using our Fly's Eye Homogenizer devices as seen here.

Not all eyeglass prescriptions are the same. In order to be interpreted worldwide, eyeglass prescriptions are writtenin a standardized format with common notations. Notable terms include:

Ms.Cici

Ms.Cici

8618319014500

8618319014500