Anti-Reflective Coating - anti reflection coating lens

In Young’s double-slit experiment, an interference pattern comprising alternate dark and bright fringes on-screen was observed. However, in that experiment, we have assumed each slit as behaving like a point source thus we did not consider the width of the slit, as a result, no diffraction pattern was observed due to either slit.

AsphericLenses price

We are a comprehensive manufacturer of Opto-mechatronic systems that conceptualize customer needs from design to development.

In this section, we will explain the features, advantages / disadvantages, and manufacturing methods of aspheric lenses.

where, λ is the wavelength of light (or other electromagnetic radiation) and D is the diameter of the aperture, lens, mirror, etc., with which the two objects are observed

Rayleigh scattering can be considered to be elastic scattering since the photon energies of the scattered photons are not changed.

Asphericlenses advantages disadvantages

A spherical glass lens is processed by grinding one surface at a time, but grinding and polishing an aspherical lens one surface at a time would be very expensive. For this reason, aspheric shapes are generally processed into molds, which are then transferred and molded onto glass or plastic.

Asphericallensphotography

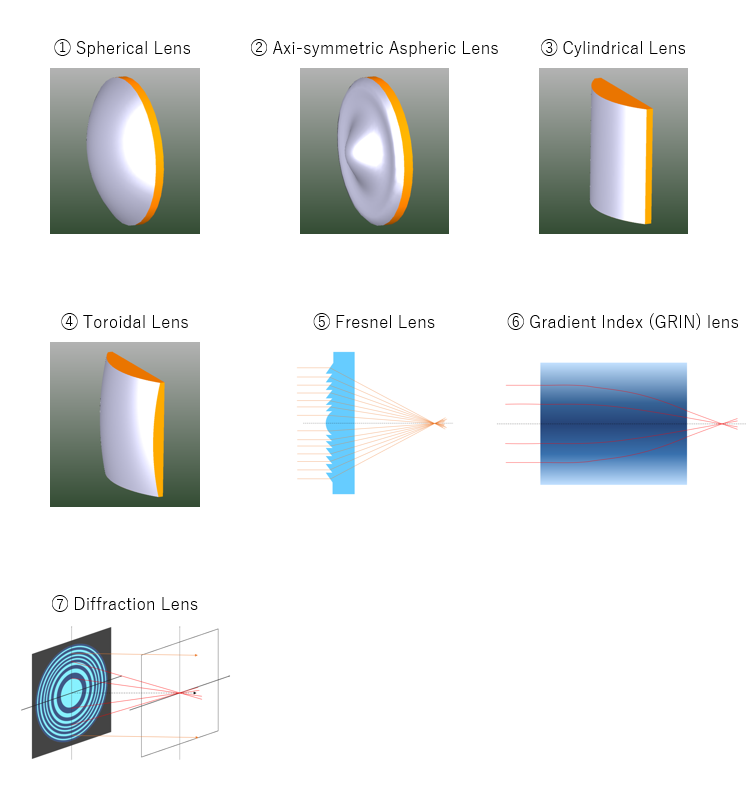

Lenses ① to ⑤ are lenses that have a focusing and diverging effect solely due to refraction on the lens surface. Of these, lenses ① to ④ have a continuous smooth surface, while lens ⑤ has a lens surface that is divided into discontinuous zones.

In addition, when axi-symmetric aspheres are used in illumination and focusing optics, it is possible to achieve uniform illumination distribution and increase the degree of freedom in ray control.

An aspherical lens is a lens whose lens surface is not spherical. By using lenses with aspherical surfaces, which offer a high degree of freedom in design, it becomes possible to reduce aberrations that could not be fully corrected with spherical lenses alone.

Asphericmeaning

What is an aspheric lensmade of

Now if d is the separation between two slits, N is the number of diffractions grating and θ is some angle for the first maxima then the angular width can be expressed as

TOYOTEC, operator of the Optical Design Technology Navigator, is an all-around optical manufacturer with proficiency in optical, mechanical, and electronical technology. We can design and develop products from scratch based on our customers’ needs, and provides integrated support from design to productization. In addition to manufacturing aspheric lenses, we offer one-stop manufacturing services from ultra-precision machining of lens cores to the design and assembly of lens units, including systems and peripheral components.

With fewer lenses, it is possible to reduce lens materials, processing costs, and assembly man-hours, leading to overall cost reductions.

A diffraction grating is an extremely useful device, and one of it consists of a large number of narrow slits side by side.

Based on Rayleigh scattering, the Rayleigh criterion for the diffraction limit is used to define the resolution. It states that two images which are just resolvable when the centre of the diffraction pattern of one is directly over the first minimum of the diffraction pattern of the other.

Atmosphere consists of many different particles and molecules of gases and dirt, suspended or in relative motion. When sunlight passes through the atmosphere, it hits these particles and gets diffracted. This diffraction also scatters light. For example, Light can enter the room through a small hole, get diffracted and fill the room.

Lenses ② to ④ are lenses with continuous, smooth, non-spherical lens surfaces and are called aspherical lenses in a broad sense. ② is a lens with an aspheric surface that is axi-symmetric (rotationally symmetric) with respect to the optical axis of the lens, and is often used in imaging optical systems. Lenses ③ to ④ are aspheric lenses that do not have axisymmetry (rotational symmetry) with respect to the optical axis of the lens, and are mainly used in lighting and focusing optical systems.

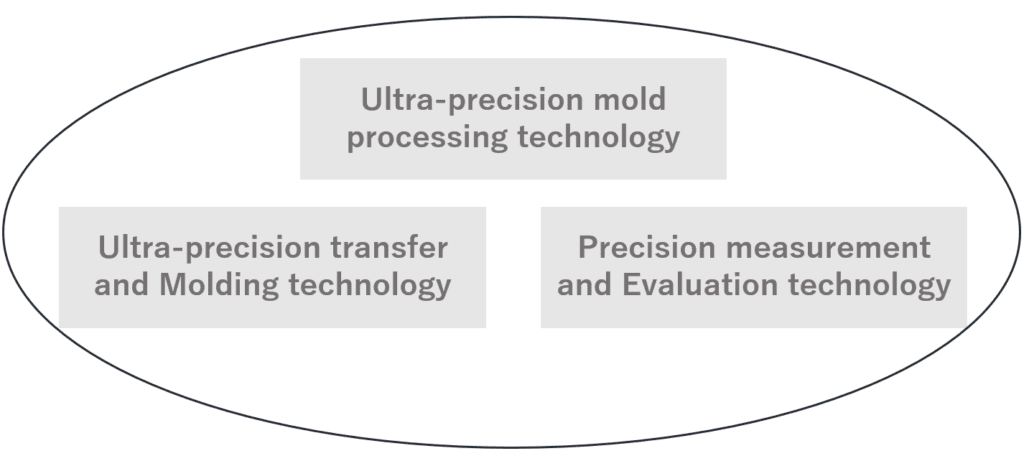

The method of manufacturing aspherical lenses by transferring and molding the aspherical shape of the mold onto the lens requires three technologies: ultra-precision mold processing technology, ultra-precision transfer and molding technology, and precision measurement and evaluation technology for these surface shapes.

In this way, aspherical lenses make it possible to reduce the size and weight of products, and even to cut costs. However, the production of aspherical lenses requires a very high level of manufacturing technology.

As explained above Diffraction of light is the phenomenon of bending light from the sharp corners of a slit or obstacle and spreading into the region of the geometrical shadow.

Aspheres that are not axi-symmetrical (rotationally symmetrical) can be used to change the magnification of vertical and horizontal images in imaging optics. Also, in illumination and focusing optics, light emitted from a point light source can be projected in the form of a line. In this way, aspheres that are not axisymmetric (rotationally symmetric) can achieve new functions that cannot be achieved with spherical lenses alone.

Spherical surfaces are characterized by the fact that the radius of curvature is the same at all positions on the sphere, and this leads to the fact that they are easy to polish and high precision can be obtained. On the other hand, aspheric lenses require the radius of curvature to be made different depending on the position, which requires precision mold processing and technology to precisely transfer and mold the aspheric shape.

Diffraction can occur only when the wavelength of light is comparable to the size of the obstacle or the width of the slit.

The slits are separated by opaque spaces. When a wavefront is an incident on a grating surface, light is transmitted through the slits and obstructed by the opaque portions. Such a grating is called transmission grating.

We hope that the above Physics Optics detailed notes helped you to understand the importance of the Diffraction of Light. Do practice it now on the Testbook App through the free mock tests.

At Optical Design Technology Navigator, we use state-of -the-art ultra-precision processing machines to process aspheric surfaces on a sub-micron order, transfer these aspheric surfaces using molding technology that incorporates a high level of know-how, and then transfer these aspheric surfaces into an ultra-precision 3D mold.

Diffraction is the slight bending of light as it passes around the edge of an object. The amount of bending depends on the relative size of the wavelength of light to the size of the opening.

Although light is typically thought to move in straight lines, when it comes close to a barrier, it tends to bend around the barrier and disperse out. The dispersion of waves as they go through or around a barrier is referred to as diffraction. Diffraction of light, more precisely, happens when a light wave passes by a corner or through an opening or slit that is physically as tiny as, or even smaller than, that light’s wavelength.

What is an aspheric lensused for

On the other hand, in the case of ⑥, the refractive index inside the lens is not homogeneous but distributed, and in the case of ⑦, light is focused and diverged by using the diffraction effect on the surface instead of refraction.

The capacity of an optical instrument to show separate images of very closely placed two objects is called resolving power.

A distinctive element of the diffraction pattern is the centre maxima, also referred to as the central fringe. A distinctive element of the diffraction pattern is the centre maxima, also referred to as the central fringe. The secondary minima and maxima, which encircle the centre maxima, are made up of dark and bright lines.

The Rayleigh criterion specifies the minimum separation between two light sources that may be resolved into distinct objects.

Now at any point on the screen, the rays reaching from the first and second slit will have a path difference, where ‘b’ is the separation between the center of two slits.

Aspheric lensglasses

Now if the width of each slit is finite, we shall observe a combined effect of diffraction (through each slit) as well as interference pattern as we can see in the figure below.

Francesco Grimaldi made the first observation of diffraction in 1665. When light waves were forced to pass through a slit, he observed that they dispersed. Later, it was discovered that diffraction happens everywhere light waves bend around a corner, not just in tiny slits or holes.

The resolving power of a diffraction grating is defined as its ability to form separate diffraction maxima of two closely separated wavelengths.

Although the time required for transfer and molding is shorter than for the spherical polishing process, manufacturing of precision aspheric molds (which incurs cost) in advance are necessary. For this reason, consideration of whether or not to use aspheric lens prior to production, based on the estimated total cost of the production volume is necessary.

There are many different types of lenses. They can be broadly classified as the following according to the principle of light focusing and divergence and the type of surface.

If you are thinking about something like, “If only there was a product like this…”, or, “Is it possible to do these kind of things with lenses?”, Optical Design Technology Navigator, a website operated by a group of optical design professionals, is the place to go. If you have any questions about optical design, please feel free to contact us at Optical Design Technology Navigator.

What is an aspheric lensvs asphericallens

Axi-symmetric aspheres include rotational parabolas, rotational hyperbolic surfaces, rotational elliptic surfaces, and rotational quadric surfaces. In imaging optics, the use of such axisymmetric aspheres increases the degree of freedom in shape and makes it possible to suppress aberrations that would be difficult with spherical lenses alone.

Aspherical surfaces are classified into two categories: axi-symmetric aspherical surfaces, which have axial symmetry (rotational symmetry) with respect to the lens optical axis, and aspherical surfaces, which do not have axial symmetry. Each type of aspheric surface has its own characteristics.

Where λ is the wavelength of the light, n is an integer value, a is slit width and D is the distance of the screen from the slit.

In imaging optics, multiple spherical lenses are used in combination to reduce aberrations such as image blur and distortion. By using aspherical lenses, it is possible to reduce the number of lenses while maintaining the same performance. For example, you can achieve the same performance of an 5-spherical-lens optical system with a total of 4 lenses using 2 spherical lenses and 2 aspherical lenses.

In this section, we will introduce the advantages and disadvantages of axi-symmetric (rotationally symmetric) aspheres in imaging optics. There are three major advantages.

The most common example of diffraction occurs with water waves that bend around a fixed object. Light bends similarly around the edge of an object.

The reciprocal of the smallest angle subtended at the objective lens of a telescope by two-point objects which can be just distinguished as separate is called the resolving power of a telescope.

The resolving power of a microscope is the ability of the microscope to show as separate images of two-point objects lying close to each other.

Ms.Cici

Ms.Cici

8618319014500

8618319014500