Angle of View Vs. Field of View. Is There Even a Difference?! - field of view definition

cr-30 print speed

This slicing software CrealityBelt is specially designed for 3DPrintMill. CrealityBelt is truly user-friendly ascribing to its simple operation

CR 305e

Olympus microscope objective lenses for industrial inspections offer outstanding optical performance from the visible light to near-infrared region. At Evident, we offer an extensive selection of Olympus objectives suited to specific inspection requirements and tasks. Our MXPLFLN-BD objective is designed for darkfield observation and examining scratches on polished surfaces, while our SLMPLN objective is ideal for electronic assembly inspection. Find your ideal microscope objective today for your inspection task. No matter your requirements, Olympus objective lenses have you covered.

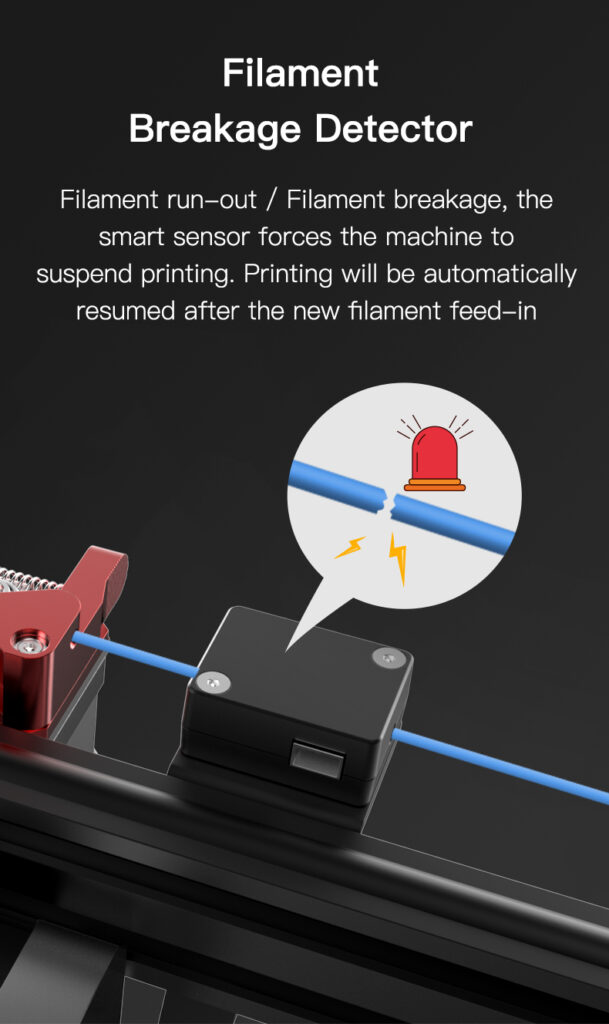

* Infinite-Z build volume* Stable Core-XY structure* Broadband power supply* Exclusive slice software* 45° angled hot-end* Nylon conveyor belt* Filament breakage detector* Ultra-silent motherboard

Terms Of Use | Privacy Notice | Cookies | Cookie Settings | About Us | Imprint | Careers | Careers | Sitemap

cr-30 slicer

creality cr-30 alternative

MXPLFLN objectives add depth to the MPLFLN series for epi-illumination imaging by offering a simultaneously improved numerical aperture and working distance.

We are closed until 3rd November. All orders will be dispatched after 4th November. We apologize for any inconvenience and appreciate your patience. Wishing you a Happy Diwali

The special infinite-Z belt is the first Creality 3D printer to realize infinite build volume in the world. Since 3DPrintMill is going to be released on Ceality’s sixth anniversary, it will make a stir in the whole 3D printing industry.

MicrometerThis product may not be available in your area.View ProductMPLAPON Our MPLAPON plan apochromat objective lens series provides our highest level of chromatic correction and resolution capability, along with a high level of wavefront aberration correction. View ProductMPLAPON-Oil Our MPLAPON-Oil objective is a plan apochromat and oil immersion lens that provides our highest level of chromatic correction and resolution capability. The numerical aperture of 1.45 offers outstanding image resolution. View ProductMXPLFLN MXPLFLN objectives add depth to the MPLFLN series for epi-illumination imaging by offering a simultaneously improved numerical aperture and working distance. View ProductMXPLFLN-BD MXPLFLN-BD objective lenses add depth to the MPLFLN series for epi-illumination imaging by offering simultaneously improved numerical aperture and working distance. View ProductMPLN Our MPLN plan achromat lens series is dedicated to brightfield observation and provides excellent contrast and optimal flatness throughout the field of view. View ProductMPLN-BD Our MPLN plan achromat lens series is designed for both brightfield and darkfield observation and provides excellent contrast and optimal flatness throughout the field of view. View ProductMPLFLN The MPLFLN objective lens has well-balanced performance with a semi-apochromat color correction, a fair working distance, and a high numerical aperture. It is suitable for a wide range of applications. View ProductMPLFLN-BD The MPLFLN-BD objective lens has semi-apochromat color correction and suits a wide range of industrial inspection applications. It is specially designed for darkfield observation and examining scratches or etchings on polished surfaces. View ProductLMPLFLN Our LMPLFLN lens is part of our plan semi-apochromat series, providing longer working distances for added sample safety and observation with increased contrast. View ProductLMPLFLN-BD Our LMPLFLN-BD brightfield/darkfield objective lens is part of our plan semi-apochromat series, providing longer working distances for added sample safety and observation with increased contrast. View ProductSLMPLN The SLMPLN plan achromat objective lens offers an exceptionally long working distance and the image clarity that you expect from the Olympus UIS2 optical system. It is ideal for electronic assembly inspection and other similar applications. View ProductLCPLFLN-LCD The LCPLFLN-LCD objective lenses are optimal for observing samples through glass substrates, such as LCD panels. The adoption of optical correction rings enables aberration correction according to glass thickness. View ProductLMPLN-IR/LCPLN-IR Our LMPLN-IR and LCPLN-IR plan achromat lenses have a long working distance and are specifically designed for optimal transmission in the near-infrared region (700–1300 nm wavelengths). View ProductWhite Light Interferometry Objective Lens This objective lens is designed for the Mirau style of white light interferometers and maintains a high level of temperature tolerance. The optimized numerical aperture of 0.8 provides improved light gathering, with a working distance of 0.7 mm. View Product

The stable and sturdy CoreXY precision structure with isosceles right triangle support gives you an extraordinary printing experience

To clean a microscope objective lens, first remove the objective lens and place it on a flat surface with the front lens facing up. Use a blower to remove any particles without touching the lens. Then fold a piece of lens paper into a narrow triangular shape. Moisten the pointed end of the paper with small amount of lens cleaner and place it on the lens. Wipe the lens in a spiral cleaning motion starting from the lens’ center to the edge. Check your work for any remaining residue with an eyepiece or loupe. If needed, repeat this wiping process with a new lens paper until the lens is clean. Important: never wipe a dry lens, and avoid using abrasive or lint cloths and facial or lab tissues. Doing so can scratch the lens surface. Find more tips on objective lens cleaning in our blog post, 6 Tips to Properly Clean Immersion Oil off Your Objectives.

creality cr-30 review

Objective lenses are responsible for primary image formation, determining the quality of the image produced and controlling the total magnification and resolution. They can vary greatly in design and quality.

CR-30 extruder

Many microscopes have several objective lenses that you can rotate to view the specimen at varying magnification powers. Usually, you will find multiple objective lenes on a microscope, consisting of 1.25X to 150X.

Molding technology: FDM Print dimension: 200 * 170 * ∞ mm Machine dimension: 535 * 656 * 410mm Slice software: Crealitybelt Print accuracy: ± 0.1mm Nozzle diameter: 0.4mm Number of nozzles: 1 Hotbed temperature: ≤ 100 ℃ Nozzle temperature: ≤ 240 ℃ Layer thickness: 0.1mm-0.4mm Rated Power: 350W Supported filaments: PLA / TPU / PETG

Made of wear-resistant Nylon, the conveyor belt features excellent adhesion to the model. The printed model can fall off automatically as the belt rolls to the end, thus free your hand

Molding technology: FDMPrint dimension: 200 * 170 * ∞ mmMachine dimension: 535 * 656 * 410mmPackage dimension: 685 * 565 * 302mmN.W.: 16.5kgG.W.: 20.5kgSlice software: CrealitybeltPrint accuracy: ± 0.1mmNozzle diameter: 0.4mmNumber of nozzles: 1Hotbed temperature: ≤ 100 ℃Nozzle temperature: ≤ 240 ℃Layer thickness: 0.1mm-0.4mmRated Power: 350WPower supply: AC 100-120v / 200-240v, DC 24VSupported filaments: PLA / TPU / PETGDiameter of filament: 1.75mmSupported language: EnglishFile transfer: USB/SD card

cr-30 3d printer

Equipped with the rolling conveyor-belt, it realizes continuous printing. No worries to print the infinite length model. High productivity, time-saving, and cost-efficient

The ocular lens is located at the top of the eyepiece tube where you position your eye during observation, while the objective lens is located closer to the sample. The ocular lens generally has a low magnification but works in combination with the objective lens to achieve greater magnification power. It magnifies the magnified image already captured by the objective lens. While the ocular lens focuses purely on magnification, the objective lens performs other functions, such as controlling the overall quality and clarity of the microscope image.

The unique 45 ° angle design offsets the limitations of the vertical nozzle structure. Equipped with a high-performance nozzle kit, it achieves continuous printing along the horizontal Z-axis

WOL3D offers 3D printer installation, training, and support with travel expenses covered by the client; services are governed by Indian law and include a 7-day post-installation warranty.

cr-30 belt

WOL3DCare+ offers complete protection for your 3D printers with priority support, damage coverage, and repairs. Keep your printing operations running smoothly year-round.

Need to make a payment? Use our secure online payment system to quickly and easily pay any amount. Click the "Pay Online" button to get started.

MXPLFLN-BD objective lenses add depth to the MPLFLN series for epi-illumination imaging by offering simultaneously improved numerical aperture and working distance.

3DPrintMill(CR-30) is a feature of infinite-length printing and bulk printing, thereby time-saving in printing and cost-efficient.

Terms Of Use | Privacy Notice | Cookies | Cookie Settings | About Us | Careers | Careers | Sitemap

Ms.Cici

Ms.Cici

8618319014500

8618319014500