Allied Vision Microscope cameras - allied vision camera

What is an aspherical cameralensused for

I use a Key Resin epoxy called 715 that is very similar to JB Weld. We use it mostly joint and crack filler and normally mix just slightly ...

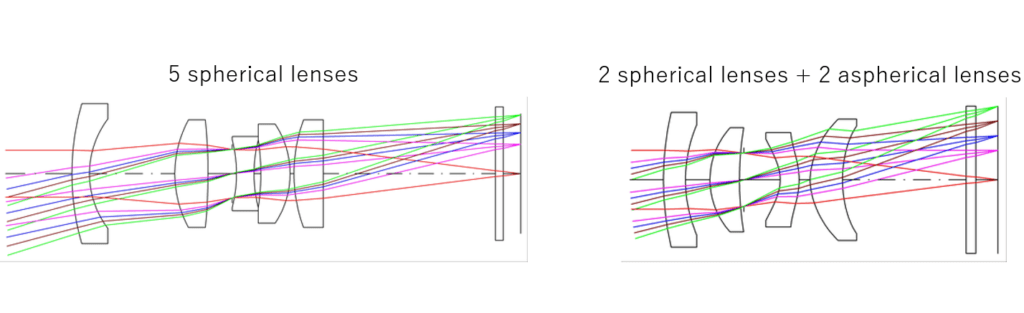

With fewer lenses, it is possible to reduce lens materials, processing costs, and assembly man-hours, leading to overall cost reductions.

Shop for rigid, accurate reading fresnel lens magnifier with high magnification levels at Alibaba.com. reading fresnel lens magnifier enlarge finer details ...

Asphericallensvs normallenscamera

A spherical glass lens is processed by grinding one surface at a time, but grinding and polishing an aspherical lens one surface at a time would be very expensive. For this reason, aspheric shapes are generally processed into molds, which are then transferred and molded onto glass or plastic.

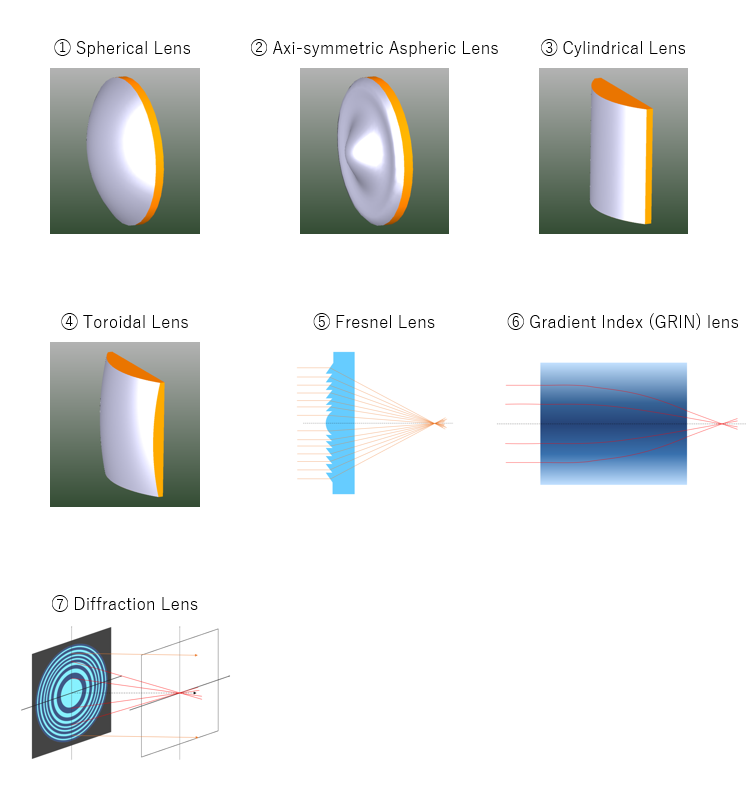

There are many different types of lenses. They can be broadly classified as the following according to the principle of light focusing and divergence and the type of surface.

TOYOTEC, operator of the Optical Design Technology Navigator, is an all-around optical manufacturer with proficiency in optical, mechanical, and electronical technology. We can design and develop products from scratch based on our customers’ needs, and provides integrated support from design to productization. In addition to manufacturing aspheric lenses, we offer one-stop manufacturing services from ultra-precision machining of lens cores to the design and assembly of lens units, including systems and peripheral components.

Asphericallenscamera

by T Williams · 2018 · Cited by 174 — The Optical Transfer Function of Imaging Systems deals extensively with the theoretical concept of the optical transfer function (OTF), ...

Overcast days can produce rather flat light that lacks dimension and can feel rather boring, and as such, it can be a bit tricky to product images that are compelling. That does not mean you should just pack it up and head home, though. Flat light can actually lead to fantastic images, and this excellent video tutorial will show you how to find and shoot them.

Aspherical surfaces are classified into two categories: axi-symmetric aspherical surfaces, which have axial symmetry (rotational symmetry) with respect to the lens optical axis, and aspherical surfaces, which do not have axial symmetry. Each type of aspheric surface has its own characteristics.

Alex Cooke is a Cleveland-based portrait, events, and landscape photographer. He holds an M.S. in Applied Mathematics and a doctorate in Music Composition. He is also an avid equestrian.

I prefer overcast to a sunny day from late morning through early afternoon when the sun is high. The even light is better than directional light from high overhead. An exception is late Fall and early Winter. While not real low, the sun is fairly low to the south at midday.

In this way, aspherical lenses make it possible to reduce the size and weight of products, and even to cut costs. However, the production of aspherical lenses requires a very high level of manufacturing technology.

The field of view is largest on the lowest power objective. When you switch to a higher power, the field of view closes in towards the center. You will see more ...

Asphericallensphotography

Axi-symmetric aspheres include rotational parabolas, rotational hyperbolic surfaces, rotational elliptic surfaces, and rotational quadric surfaces. In imaging optics, the use of such axisymmetric aspheres increases the degree of freedom in shape and makes it possible to suppress aberrations that would be difficult with spherical lenses alone.

Apochromatic microscope objective lenses are infinite optical systems available in several magnifications working in the spectral region from 355nm to 1064nm.

Although the time required for transfer and molding is shorter than for the spherical polishing process, manufacturing of precision aspheric molds (which incurs cost) in advance are necessary. For this reason, consideration of whether or not to use aspheric lens prior to production, based on the estimated total cost of the production volume is necessary.

ASPHcamera

We are a comprehensive manufacturer of Opto-mechatronic systems that conceptualize customer needs from design to development.

Aspheric lenses advantages disadvantages

An aspherical lens is a lens whose lens surface is not spherical. By using lenses with aspherical surfaces, which offer a high degree of freedom in design, it becomes possible to reduce aberrations that could not be fully corrected with spherical lenses alone.

In this section, we will explain the features, advantages / disadvantages, and manufacturing methods of aspheric lenses.

If you are thinking about something like, “If only there was a product like this…”, or, “Is it possible to do these kind of things with lenses?”, Optical Design Technology Navigator, a website operated by a group of optical design professionals, is the place to go. If you have any questions about optical design, please feel free to contact us at Optical Design Technology Navigator.

Lenses ② to ④ are lenses with continuous, smooth, non-spherical lens surfaces and are called aspherical lenses in a broad sense. ② is a lens with an aspheric surface that is axi-symmetric (rotationally symmetric) with respect to the optical axis of the lens, and is often used in imaging optical systems. Lenses ③ to ④ are aspheric lenses that do not have axisymmetry (rotational symmetry) with respect to the optical axis of the lens, and are mainly used in lighting and focusing optical systems.

In addition, when axi-symmetric aspheres are used in illumination and focusing optics, it is possible to achieve uniform illumination distribution and increase the degree of freedom in ray control.

Principle of Optical Microscope (Compound Microscope). An optical microscope creates a magnified image of an object specimen with an objective lens and ...

optics: The branch of physics that deals with light and vision, chiefly the generation, propagation, and detection of electromagnetic radiation having ...

Asph lensvs asphericallens

In this section, we will introduce the advantages and disadvantages of axi-symmetric (rotationally symmetric) aspheres in imaging optics. There are three major advantages.

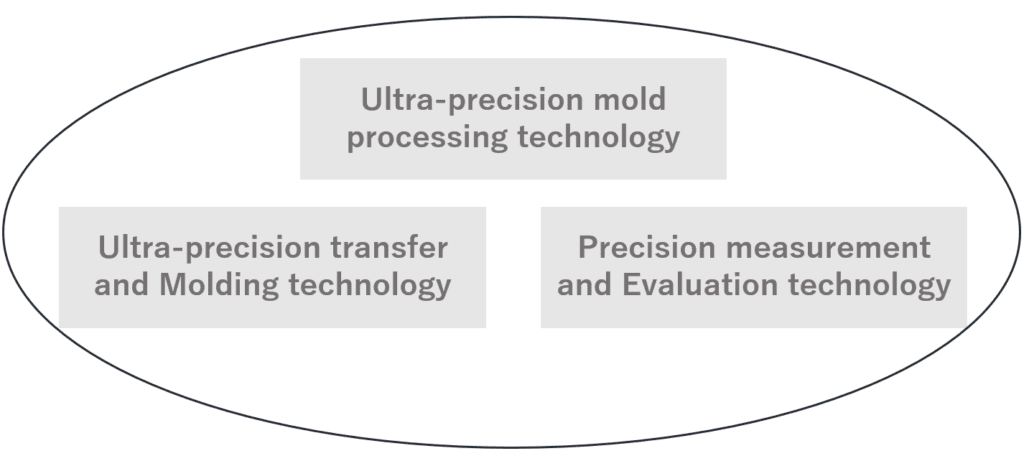

The method of manufacturing aspherical lenses by transferring and molding the aspherical shape of the mold onto the lens requires three technologies: ultra-precision mold processing technology, ultra-precision transfer and molding technology, and precision measurement and evaluation technology for these surface shapes.

Spherical surfaces are characterized by the fact that the radius of curvature is the same at all positions on the sphere, and this leads to the fact that they are easy to polish and high precision can be obtained. On the other hand, aspheric lenses require the radius of curvature to be made different depending on the position, which requires precision mold processing and technology to precisely transfer and mold the aspheric shape.

Lenses ① to ⑤ are lenses that have a focusing and diverging effect solely due to refraction on the lens surface. Of these, lenses ① to ④ have a continuous smooth surface, while lens ⑤ has a lens surface that is divided into discontinuous zones.

Bestasph lens

... Clear Aperture. Super High-Power LED Collimator Sources, 22-mm Clear Aperture. $1,210.00USD – $2,070.00USD. Customize your product. Wavelength. Choose an option ...

Aspheres that are not axi-symmetrical (rotationally symmetrical) can be used to change the magnification of vertical and horizontal images in imaging optics. Also, in illumination and focusing optics, light emitted from a point light source can be projected in the form of a line. In this way, aspheres that are not axisymmetric (rotationally symmetric) can achieve new functions that cannot be achieved with spherical lenses alone.

The LRD-0405 Series of Collimated Diode (Semiconductor) Lasers are ideal for applications requiring a short wavelength of 405 nm and output power levels ...

At Optical Design Technology Navigator, we use state-of -the-art ultra-precision processing machines to process aspheric surfaces on a sub-micron order, transfer these aspheric surfaces using molding technology that incorporates a high level of know-how, and then transfer these aspheric surfaces into an ultra-precision 3D mold.

In imaging optics, multiple spherical lenses are used in combination to reduce aberrations such as image blur and distortion. By using aspherical lenses, it is possible to reduce the number of lenses while maintaining the same performance. For example, you can achieve the same performance of an 5-spherical-lens optical system with a total of 4 lenses using 2 spherical lenses and 2 aspherical lenses.

On the other hand, in the case of ⑥, the refractive index inside the lens is not homogeneous but distributed, and in the case of ⑦, light is focused and diverged by using the diffraction effect on the surface instead of refraction.

Cut to size - let us cut, wrap and deliver your glass ready for the frame. Please login or register ...

Coming to you from Roman Fox, this awesome video tutorial discusses how to handle the flat light produced by overcast days to still produce interesting shots. I actually love these sorts of days. The nice thing about flat light is that with the flexibility of modern camera sensors, you have a ton of directions available in which to take a photo, and you can relatively quickly and easily shape the light in the photo to emphasize in the manner you prefer. This can also make it excellent practice for learning how to work with shaping light in post. When it comes to more defined light, it simply is not possible to reshape the light as much as it is when you are given a blank palette. Check out the video above for the full rundown from Fox.

Ms.Cici

Ms.Cici

8618319014500

8618319014500