AGE 145 - g 145

After doing that, I try the XYZ calibration again - now it drives to the top, comes down, and walks through the calibration point search.

In the end as a last-gasp, clutching at straws hope, I flashed the latest Mk3 firmware onto my Mk3S. On reboot it informed me that the model had changed and that I had MK3 firmware with MK3S hardware but other than that all seemed ok. The XYZ calibration worked first time without a problem. A Z-axis calibration also worked without issue. At that point I reflashed it with the correct MK3S firmware and the calibration settings stayed intact. After that I did the usual bed levelling and first layer calibrations for both sheets and all was well. It's been working fine since.

Could you please clarify this for me—are the terms float glass, flat glass, plate glass and sheet glass used somewhat interchangeably?

Glass.com is a participant in the Amazon Services LLC Associates Program, an affiliate program designed to provide a means for sites to earn advertising fees by advertising and linking to shop.glass.com

I have a question I need answered. How can you tell the difference between float glass and non-float glass, plate glass and non-plate glass?

Thanks for the question Stewart. No, typically mirror glass is not made with a different tolerance for flatness than standard glass.

Thank you for making contact with the Glass Detective with your questions regarding what I will refer to as “glass nomenclature”. By the way, Glass.com has a Glass Dictionary which you may want to take a look at after we have tried to address your questions with this response. Please be aware that not everyone will be in total agreement with my answers, but I feel that for what you want to know, we are going to end up on solid ground. Let’s call this a brief overview so we don’t offend too many of our “expert” friends. One last thing—I am going to answer your questions not in the order in which you presented them but in an order that I think will be clearer and more helpful. Here we go!

I believe it's hardcoded for the printer to not exceed 210mm travel. If you hit it prior to getting to the top of the Z-axis, just turn off the printer, turn it back on, and drive it up until both left and right touch the top. This is to make sure they are at the same height.

Plate glassvs floatglass

I hope this information/explanation is of some value to you and I again thank you for contacting the Glass.com Glass Detective.

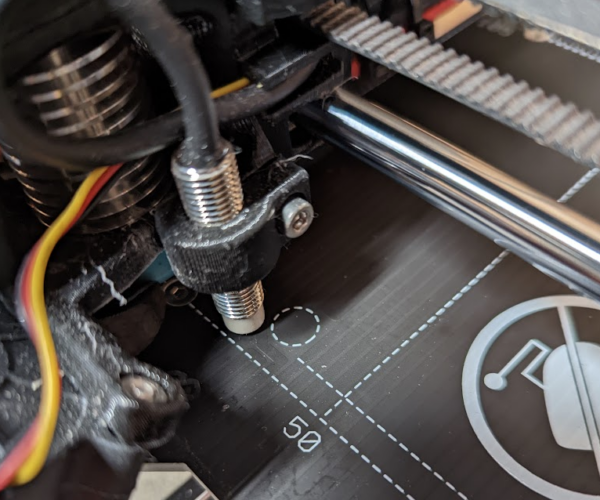

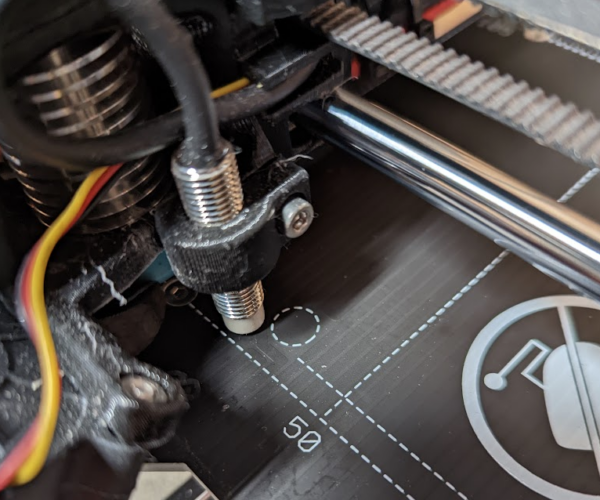

Has this been addressed? I just updated the firmware on my MK3S for the first time in quite a while (probably two years) and I'm getting the same error, along with the pinda not lining up with the circle on the hotbed. I tried loading MK3 firmware to calibrate, but still getting the same issue. If I auto home however, the pinda lines up correctly with the circle.

I had this problem on my MK3S about a year ago after I did swapped the hot end and re-ran calibration to make sure all was still good. Like you calibration started, the z axis went to the top until it hit the stops and missed a few steps, then scrolled all the way down until the nozzle was just above the bare bed, and the PINDA triggered whereupon it immediately stopped with the 'Check Axes' error. . The PINDA also seemed to be misaligned with the marks on the bed as per your experience. The display also showed Z=5.0?. When I used the settings menu to move the z axis back up it got to Z=210 and stopped, but now the top of the axis screws was approx 6mm below the end stop. When I drove it down again using the menu the nozzle would hit the bed at Z=4.0. It's like the firmware missed the first 5mm of travel before it started counting the distance.

Plate glassfor sale

Hi Emica, Thanks for the question! Yes, it’s typically okay to have the mid-pane as floated glass as long as it’s clear and not tinted.

Please note, this article may contain links to Amazon products. As an Amazon Associate, Glass.com earns commissions from qualifying purchases.

Plate glasswindow

3. I found that my case is X-endstop not working properly. When i press it, it change from zero (0) to one (1) and stay there more than 1 second. and some case it appear to be one (1) even before i press the endstop.

hope it helps most of you. I stuck for this issue more than 1 months.. and eventually managed to solved it. write me email @ [email protected] if you need me show you the broken piece (X-endstop) and how i solve it via videocall.

Hi, When you have a triple glazing, is it okay to have the mid-pane as floated glass while the outter panes are thermally toughened?

You can also simply press the reset button to get the same effect. Yes, to avoid damaging itself, the printer prevents downward movement and limits upward distance until it learns its position. When you run out of upward movement, resetting or rebooting "zeros" its dead reckoning and you get another 210 mm upward motion available.

I think it's a good idea to lubricate the machine as well, but why does the build instructions insist heavily on not needing to do an initial lubrication since the bearings have already been lubricated? I just finished my build and I'm having issues with XYZ calibration that I am working through.

Why is there no link to see a page about sheet glass but there is for the other types? I am trying to find out in more detail about how sheet glass was/is made for a report I am writing. Or could you refer me to some other source?

Plate Glassprice

Copyright © 2024 Glass.com Inc. All Rights Reserved. No reproduction without expressed written permission. Questions? Contact info@glass.com

Thank you! Lubricating the z axis rods, per these instructions allowed me to get past a stubborn "check the axes an run again" error during the xyz calibration of my mk3s:

I recently had cause to re-work the extruder and I faced exactly the same problems. Again I spent an evening trying everything I could to no avail so I flashed it with the MK3. The calibration with the wrong firmware worked fine. Flashed back to the MK3S firmware and all was well. To my mind there's clearly something odd, and there's clearly some differences between the calibration routines in the MK3 and MK3S firmwares. Either way it might be worth giving this strange workaround a go if you have the same issue

What isplate glassused for

Glass.com attempts to provide accurate information but cannot be held liable for any information provided or omitted. You should always work with a licensed, insured and reputable glass shop that can assess your specific needs and local building codes and offer professional services. Never attempt to cut, install, or otherwise work with glass yourself. All content is provided on an informational basis only.

Which is better. I have for large windows 80×92 in my great room. Trouble is evidently they are two panes and moisture has shown up between them. When I replace them I want to do it right. Please give me your advice for replacement.

4. I change the endstop and run the endstop test to make sure it run as it should be. Press and it show (1) and release it show (0) instantly.

Update: chatted with Prusa support, and resetting the pinda adjustment fixed it. The Z axis wasn't going all the way up to the top before performing the XYZ calibration, and adjusting the pinda must have fixed that.

Check out @joantabb's reply on this post: https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-assembly-and-first-prints-troubleshooting/pinda-is-out-of-align-and-z-calibration-issue/#post-159789

Plate glassvs temperedglass

Lyle Hill has been in the glass and metal industry for more than 40 years. In this time he has managed glass retail, contract glazing, mirror, architectural window, window film, and automotive glass businesses throughout America. He obtained an MBA from IIT with a focus on Technology and Engineering Management. Hill is also a columnist for glass industry trade magazines and often called the “face” of the glass industry. He has also authored books including “The Broken Tomato and Other Business Parables,” which is available through Amazon. Find out more about Lyle on Linkedin.

If you didn't grease the bearings before installing them, you might want to try adding a few drops of machine oil to the rods and work the oil into the bearings. Seems sticky bearings also causes the XYZ cal to fail.

I just tried doing “Calibrate Z” only, and that drove Z all the way to the top, then back down, but at that point I also noted that the PINDA was not over the calibration points on the bed - a bit left and front of them.

I spent many hours on chat with Prusa support over the next few days. We tried factory resets, lubricating the rods, swapping out the PINDA, beta firmware and old firmware. I even rebuilt the extruder axis completely, all the time sending pics and videos to support just to make sure it was good. We couldn't figure out anything and no-one at Prusa support could work out what was wrong.

Hi Dallas, I think you’ll find this blog helpful in answering your question: https://info.glass.com/whats-the-best-replacement-glass-for-a-condo-window/

Hi Daryl, Float glass has what is known as a “tin side”. The tin side is the side of the glass that was “floated” over the bed of molten tin as it flowed out of the oven. There are devices which can indicate which side of a piece of glass was the tin side during the float process. Non-float produced plate glass does not have a tin side because it was not floated over tin. Non-float glass is ground/polished on both sides. Feel free to give us a call if you’d like to discuss further.

Glass.com is a participant in the Amazon Services LLC Associates Program, an affiliate program designed to provide a means for sites to earn advertising fees by advertising and linking to shop.glass.com

Plate glassInsurance

If you didn't grease the bearings before installing them, you might want to try adding a few drops of machine oil to the rods and work the oil into the bearings. Seems sticky bearings also causes the XYZ cal to fail.

I noted when it proved for Z top it stopped at 210mm. It then comes down, stops at z=5.0 and gives the error. I’ve tested PINDA probe. It’s reading correctly. It’s about 1mm above extruder tip. It is triggered.

Plate glassnear me

Is a mirror made with a greater tolerance for flatness than standard glass. This is a big debate for the 3D printing community

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

All said - the fact the initial attempt to "adjust" Z at the top stops was failing due to the 210 limit is a clue. It's been long enough I can't recall what the order is when running the setup wizard. If a user does the cal manually, but out of some "proper" order, I wonder if that isn't part of the problem here.

Has this been addressed? I just updated the firmware on my MK3S for the first time in quite a while (probably two years) and I'm getting the same error, along with the pinda not lining up with the circle on the hotbed. I tried loading MK3 firmware to calibrate, but still getting the same issue. If I auto home however, the pinda lines up correctly with the circle.

Ms.Cici

Ms.Cici

8618319014500

8618319014500