300 years of the light microscope - icroscope

VIETNAM:Alpha Industrial Park, Tu ThonVillage, Yen My District, HungYen Province 17721+84 221-730-8668sales-vn@avantierinc.com

Idlccoating

Fiber Optic Illuminator: These illuminators employ fiber optic cables to direct light onto the specimen, offering flexibility and directional control. This is often used for specialized applications requiring focused illumination.

UmicoreCoatingServices

Mar 31, 2023 — Roll pitch and yaw, and how they translate into vestibular coordinates.

The thin films used in high-power laser systems exhibit their performance in three main aspects. Firstly, the films possess excellent spectral characteristics. Secondly, the lenses exhibit remarkable resistance to laser-induced damage. Thirdly, there is a requirement for effective control of wavefront distortion before and after coating the lenses.

Jan 26, 2024 — The term cylinder in an eyeglass prescription speaks directly to astigmatism. It refers to the lens power needed to correct the irregular shape ...

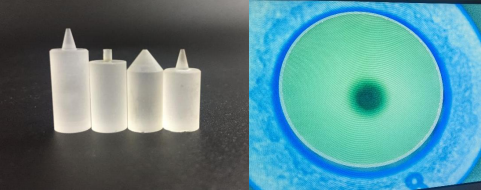

Fiber optic end caps are a flagship product of the company. Inspection under a 40x microscope reveals no defects or blemishes, with a cleanliness level surpassing the U.S. military standard of 10-5. They can withstand laser power of up to 15,000 watts. The image below shows the typical shape and exterior appearance of an end cap(Figure 10).

by SJ Sheldon · 1982 · Cited by 538 — A theoretical model for the laser-induced thermal lens effect in weakly absorbing media is derived. The model predicts the intensity variation in the far field ...

Transmitted Illumination: This classic setup uses a light source positioned below the stage. The light shines upwards through the specimen, allowing us to observe transparent or translucent specimens. This is the most common illumination method for observing stained slides or living cells.

Count on GEARWRENCH to get the job done with our innovative tools. Get the GEARWRENCH 3/8" Drive 6 Point Mid Length Metric Socket 8mm.

Reflected Illumination (Epi-illumination): Used for opaque or thick specimens, reflected illumination directs light onto the specimen from above, allowing the viewer to see the reflected light. This technique is ideal for examining metals, rocks, or insects.

Gas lasers such as He-Ne, CO2 & Argon-Ion are useful for generating high quality beams with long coherence lengths.

The microscope, a powerful tool for exploring the unseen, relies on a complex interplay of components to reveal the intricate details of the microscopic world. One of the most crucial elements is the illuminator, the source of light that illuminates the specimen and makes it visible.

IR coatingglass

When infrared radiation propagates through the Earth’s atmosphere, it is influenced by various substances within the atmosphere, resulting in a decrease in the ability of light to penetrate. This phenomenon is known as atmospheric attenuation or atmospheric extinction. The impact of atmospheric extinction on infrared radiation is wavelength-dependent, showing distinct selectivity across different wavelengths. There are three wavelength intervals within the infrared spectrum that exhibit high transmittance through the atmosphere, commonly referred to as “atmospheric windows”(Figure 1). These intervals are: the near-infrared range of 1 to 3 μm, the mid-infrared range of 3 to 5 μm, and the far-infrared range of 8 to 14 μm. As a result, the target wavelengths for infrared thin films typically fall within these three wavelength ranges.Infrared imaging in different spectral bands exhibits variations in imaging mechanisms. Long-wave and mid-wave infrared imaging primarily relies on the thermal radiation emitted by objects at room temperature. On the other hand, short-wave infrared imaging predominantly utilizes the short-wave infrared radiation that is commonly present in the environment and is reflected by objects at room temperature. These distinctions determine the spectral characteristics of thin films across different wavelength ranges.

When light is incident at an inclined angle, the film layers unavoidably introduce a polarization effect. For most practical applications, this phenomenon leads to a degradation in system performance that must be eliminated or minimized. Depolarization of optical thin films is a challenging problem in thin film design. For the most commonly used long-pass and short-pass filters, our company has developed a versatile design approach to address this issue (Figure 8 and Figure 9) .

For high-damage-threshold thin films, our company employs metallic hafnium as the coating material. In view of the unique properties of hafnium films, we have independently developed thin film spectral optimization algorithms and stress calculation tools. The resultant products effectively fulfill the aforementioned three conditions.

Ir coatingvs infrared

Apr 13, 2023 — While hyperspectral data provides a higher spectral resolution, multispectral data shines in spatial detail. The choice between the two should ...

Thin-film polarizers are created by depositing a dielectric interference coating on the surface of a flat substrate. At a certain angle of incidence (often the Brewster angle), this design separates s-polarized light and p-polarized light, typically reflecting s-polarized light while allowing p-polarized light to transmit. A key parameter for assessing polarizer performance is extinction ratio, which is the ratio of p-polarized light transmittance to s-polarized light transmittance.

Hdarcoating

A Bandpass Filter is the type of filter allows light signals to pass through within a specific wavelength range while blocking light signals outside this range on both sides. The passband of a narrowband filter is relatively narrow, typically less than 5% of the center wavelength value. The manufacturing process for these filters is usually more complex and often involves optical thickness control for process management. Therefore, when the center wavelength is shorter, the preparation method becomes particularly crucial.

by X Li · 2021 · Cited by 6 — For spectral techniques, one of the most critical parameters is spatial resolution. The spatial resolution of nanosecond laser-induced breakdown ...

These polarizers are commonly used as alternatives to Glan-Taylor prisms and polarizing beam splitters (polarizing cubes). They offer advantages such as a large aperture, low loss, and flexible system design.

The illuminator, often overlooked, is a vital component of the microscope, playing a crucial role in revealing the hidden beauty and intricate details of the microscopic world. By understanding the function and optimization of illuminators, we can enhance our microscopic observations and unlock the secrets of the unseen.

by L Mutter · 2007 · Cited by 127 — DSTMS crystals exhibit a very large nonlinear activity with a nonlinear optical coefficient d111=214±20 pm∕V. Phase-matching curves determined from our optical ...

Jun 15, 2021 — Rummaging through in-laws' old family negatives, I found 40 x 40 mm ones. I found a likely match on Wikipedia's film formats page: 127, ...

Anti reflectivecoatingspray

It’s important to note that due to the cone angle effect in most spectrometers and differences in the spectral characteristics of polarizing elements during inclined testing, different instruments might yield significantly varied polarized spectra. Our company has improved measurement methods and equipment, resulting in notable enhancements in the accuracy of polarizer and wide-angle spectral measurements

Microscope illumination plays a central role in revealing the intricacies of the microscopic world. The light source illuminates the specimen, allowing the light to pass through or reflect off it. This light then travels through the objective lens, which magnifies the image before it reaches the eyepiece, where we observe it.

But what exactly does an illuminator do, and how does it contribute to our microscopic observations? Let's delve into the fascinating world of microscope illumination.

Company ARO corp is a leading concavo convex lens factory that also makes Caf2 cylindrical lens focal length glass used for manufacturing of lenses. The optimal ...

Ms.Cici

Ms.Cici

8618319014500

8618319014500