3.5 Polarization of Light – Analytical Methods in Geosciences - polarization of the light

The way in which the diffraction angle λβ behaves when light composed of different wavelengths is directed at a grating is an important point when considering the separation of light into its components. If the incident angle α is regarded as a constant, differentiating both sides of equation (2) with respect to λ gives the following:

Shop Spacer for women at La Senza. Browse our collection of bras, panties, lingerie and more.

What isdiffraction gratingin Physics

It supports almost all parallel interface image sensors and many MIPI camera sensors, including both global and rolling shutter sensors. The USB cameras adopt ...

USAF 1951 Chart. One way to test your own lenses is with the USAF 1951 lens testing chart. The best way to do this is to download a high resolution file of the ...

Diffraction gratingPDF

We use optional cookies to review analytics that help us to improve our website experience. By clicking accept, you are giving consent for us to do this. You can find out more and manage cookies in our privacy policy.

A diffraction grating is an optical element that divides(disperses) light composed of lots of different wavelengths(e.g., white light) into light components by wavelength. The simplest type of grating is one with a large number of evenly spaced parallel slits. When white light enters the grating, the light components are diffracted at angles that are determined by the respective wavelengths(diffraction). Picking out diffracted (reinforced) light makes it possible to select the required light component. In short, for parallel beams that enter neighboring slits as shown in Fig. 1, light is reinforced when the optical path difference is a multiple of the wavelength. The light from all the slits is reinforced in the same way to produce "diffracted light."

Welcome to UQG Optics! It looks like you are visiting from the US. Select your preferred currency below to see appropriate pricing. Contact us for additional support or to discuss specific requirements.

Reflection grating

As shown in Fig.1-1 and Fig.1-2, α is the angle between the incident light and the normal to the grating (the incident angle) and à is the angle between the diffracted light and the normal to the grating (the diffraction angle), then, they satisfy the following relationship: as shown in Fig.1-1, in case of transmission grating

Diffraction gratingformula

Dec 17, 2023 — They are like the eyes of the microscope. Additionally, these lenses gather light from the specimen (the tiny thing you want to see) and magnify ...

Diffraction grating reflectionequation

Where necessary, tougher AR coatings in the form of diamond-like carbon (DLC) are available. The most basic form of AR coating is created by using a thin film ...

Welcome to UQG Optics! It looks like you are visiting from outside the UK. Select your preferred currency below to see appropriate pricing. Contact us for additional support or to discuss specific requirements.

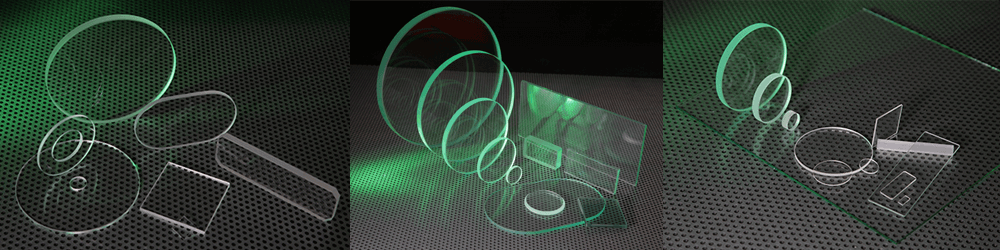

The materials used in our Technical Glasses include borosilicate, float glasses, low iron glass, ceramic glasses and toughened glass. As these are sheet glasses they are produced in large sizes and a range of standard thicknesses.

Diffraction gratingexperiment

Light of this type is termed non-polarized. In addition, there exist several states of elliptically polarized light that lie between linear and non-polarized ...

The largest independent ophthalmic lens manufacturer in the world. Younger Optics is a privately held company with a tradition dating back to 1955. And that ...

Good quality surfaces can nonetheless be achieved without optical polishing of the glass, which is a more cost-effective solution when precision surfaces are not required and where tolerances may be relaxed.

d : Spacing between the slits (the grating period) N : Number of slits per mm (the groove density, equal to the reciprocal of the grating period) m : Order of diffraction (m = 0, ± 1, ± 2,...) λ : Wavelength It can be seen from this relationship that all components of light corresponding to m = 0 (zero-order light) are radiated in a straight line and so it is not possible to separate the wavelengths with this order. It can also be seen that for m â 0 the diffraction angle à is different for each wavelength. This is why gratings can be used to separate white light into its constituent wavelengths. The diffraction angle à also varies with the groove density N and the incident angle α. One point requiring consideration is that, depending on the groove density N, it may not be possible to obtain diffracted light. For example, if the incident angle α = 30° and the groove density N = 2400 grooves/mm, applying the equation to first-order light (i.e., m = +1) with a wavelength λ of 700nm gives sin à = 1.18, then diffracted light cannot be obtained in this case.

Diffraction gratingpattern

Here, dβ/dλ is called the "angular dispersion" and can be used to obtain the change in diffraction angle dβcorresponding to a change in wavelength dλ. Multiplying both sides of equation (3) by the focal distance Æ for the optical systems gives the following:

Technical Glasses are generally used in scientific and pharmaceuticals laboratory applications, in optoelectronics and in consumer products technology. Specific applications include touch screens, display panels, cover glasses, safety windows, 3D printers, instrument windows, wafers, substrates, view ports, coverslips and microscope slides.

by RS Sirohi · 2020 · Cited by 5 — When a beam from an incoherent source is to be collimated, an aperture of diameter 2a 2 a is placed at the front focal point of the collimating ...

Diffraction grating reflectionformula

Here, D is called the "reciprocal linear dispersion" and represents the difference in wavelength per unit length on the surface of the exit slit in the optical system. Multiplying D by the slit width gives an indication of the wavelength resolution.

Jan 9, 2024 — Objective lenses are crucial to a microscope's performance as they affect the quality of the formed image. Evident offers more than 200 ...

Glasses may be produced using different manufacturing processes to achieve a wide range of compositional ranges and finishes and can be polished, etched, ground, AR coated, laminated, toughened and screen printed.

Jun 1, 2022 — Most images sensors are either charge-coupled devices (CCD) or complementary metal-oxide semiconductor (CMOS) arrays. These sensors operate ...

Ms.Cici

Ms.Cici

8618319014500

8618319014500