21mm Deep Impact Socket with Retaining Pin - 80mm Long - how long is 21mm

Ultraviolet ovendiy

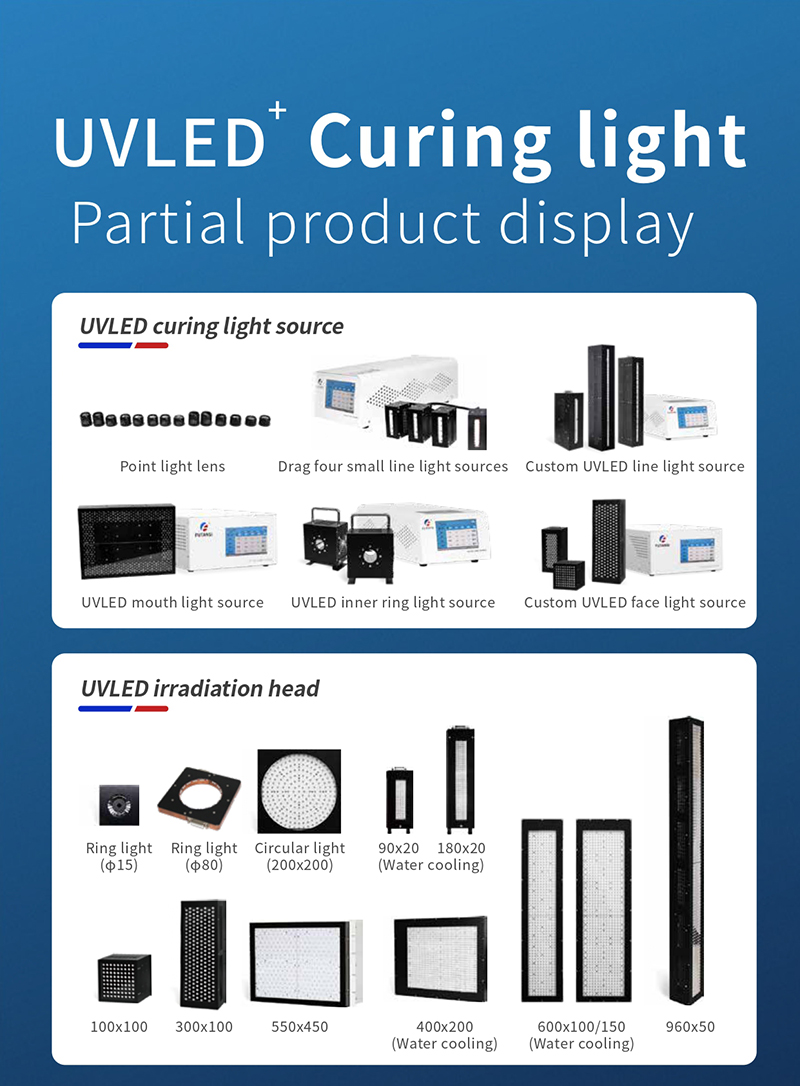

We support the download of relevant product manuals in PDF format, if you need special customized products, please contact our customer service by phone or email on the right

UVOvencooking

A UV LED curing oven is a device that uses ultraviolet (UV) light-emitting diodes (LEDs) range from 254nm-1000nm to cure or harden materials such as adhesives, coatings, and inks. Unlike traditional UV curing systems that use mercury vapor lamps, UV LED curing ovens offer several advantages, including energy efficiency, lower heat emission, and longer lifespan.

In summary, UV LED curing ovens provide a modern and efficient solution for various industries requiring precise and reliable curing processes.

The full form of LASER is Light Amplification by Stimulated Emission of Radiation. LASER is a type of electromagnetic machine that can emit light that is an Electromagnetic Radiation. Such lights are both coherent and very weak. They are produced by a method named as optical amplification.

Copyright 2023 — All rights reserved by Futansi (Shanghai) Electronic Technology Co., LTD | 沪ICP备17004081号-13 | 沪公网安备31011802005027号

Ultraviolet ovenprice

Ultraviolet ovenamazon

We support the download of relevant product manuals in PDF format, if you need special customized products, please contact our customer service by phone or email on the right

Albert Einstein was the first person to speak about the LASER process. The system was however completely developed in 1960 by Theodore H. Maiman. The LASER was based primarily on the concept given by Charles Hard Townes and Arthur Leonard Schawlow.

UV curingOven3D printing

The waves in between the mirrors are reflected back and forth. The length of the cavity is such that waves that are reflected reinforce each other. At the end of the cavity, with a partially reflective mirror, the electromagnetic waves emerge in harmony with one another. The laser output is a coherent, electric field. Both waves have the same phase and frequency in a coherent beam of electromagnetic energy.

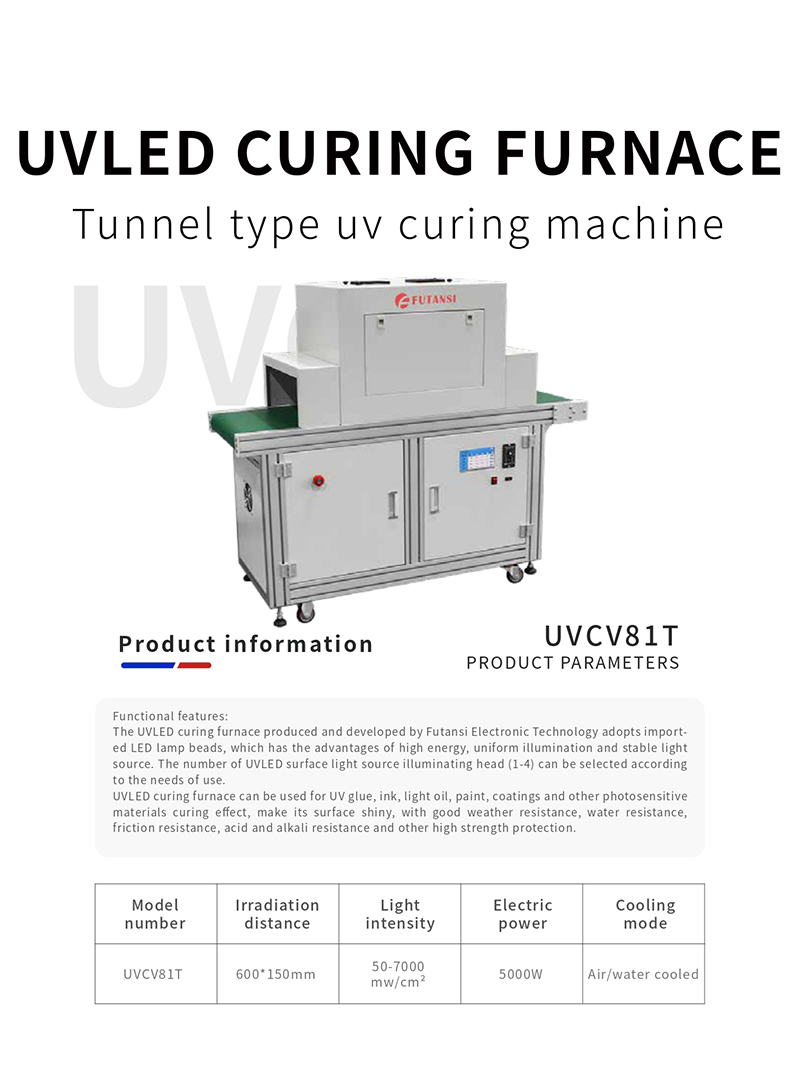

Futansi UV curing ovens can be used for UV glue, ink, varnish, paint, coating and other photosensitive materials curing role, so that its surface glossy and bright, with good weather resistance, water resistance, friction resistance, acid and alkali resistance and other high-intensity protection role. UV curing LED oven chamber application areas are wide, suitable for ink printing, industrial products fixed, specific applications can be referred to the following:

A simple laser consists of a chamber identified as the cavity that is built to reflect waves of visible, infrared or ultraviolet to reinforce one another. The cavity may either include liquids, solids or gases. The material selection in the cavity decides the output wavelength. Mirrors are located at either end of the cavity. One of the mirrors is fully reflective so that none of the light will pass into them. The other mirror is reflective in part, allowing 5 per cent of the light to pass through it. Energy is pumped into the cavity from an external source through a method known as pumping.

UV curing is a process widely employed in producing passive optical devices such as waveguides, lenses, and optical fibers. It involves the use of UV light to initiate a photochemical reaction in photosensitive materials, transforming them from a ...

UV curing adhesives emerge as an optimal solution for lens bonding owing to their rapid curing times and ability to forge strong, optically clear bonds. LED curing devices facilitate expedited assembly processes for manufacturers without compromis...

Ms.Cici

Ms.Cici

8618319014500

8618319014500