18KW 20 Gauge Soft Wire 0.79mm (0.031 Inches) - 0.79 in to mm

This website uses functional, analytical and tracking cookies (and similar technologies), placed by ourselves and third parties, in order to measure the use of, optimise and further develop our website, as well as for (personalised) advertising purposes and to monitor and analyse your internet behavior. Click on 'Change settings' to read our cookies statement and choose the cookies you want to accept.

Holographicdiffuser

Sydor Optics manufactures IR windows utilizing a range of infrared materials suited for the NIR, SWIR, MWIR and LWIR spectrums ranging from 0.75µm to 15µm for applications including thermal imaging, mineral & gas detection and monitoring and other forward-looking infrared (FLIR) imaging applications.

Counterbores, steps, slots, holes, bevels, chamfers, notches and more. Sydor Optics has the experience and tools to produce accurate and consistent mechanical alterations to meet your custom designs and specifications.

RotatingdiffuserThorlabs

Precision mechanical alterations for your custom optical designs and specifications. CNC capabilities include lightweighting, drilling, coring, edging, beveling, 3D contouring, and more.

Damage caused by misuse or abusive use, negligence, accidents, commercial use and/or changes to the product made by the end consumer is explicitly excluded from this warranty.

RotatingdiffuserOptics

Sydor Optics utilizes various techniques that for the “lightweighting” of optics through design patterns to achieve optimal performance for your product requirements. We take into consideration manufacturing concepts that will maintain the strength and integrity required of the component, while reducing the overall weight.

When it comes to fabricating custom optical components, Sydor Optics uses state-of-the-art CNC machines and leading experts to handle even the most intricate optical designs, specifications, and demands.

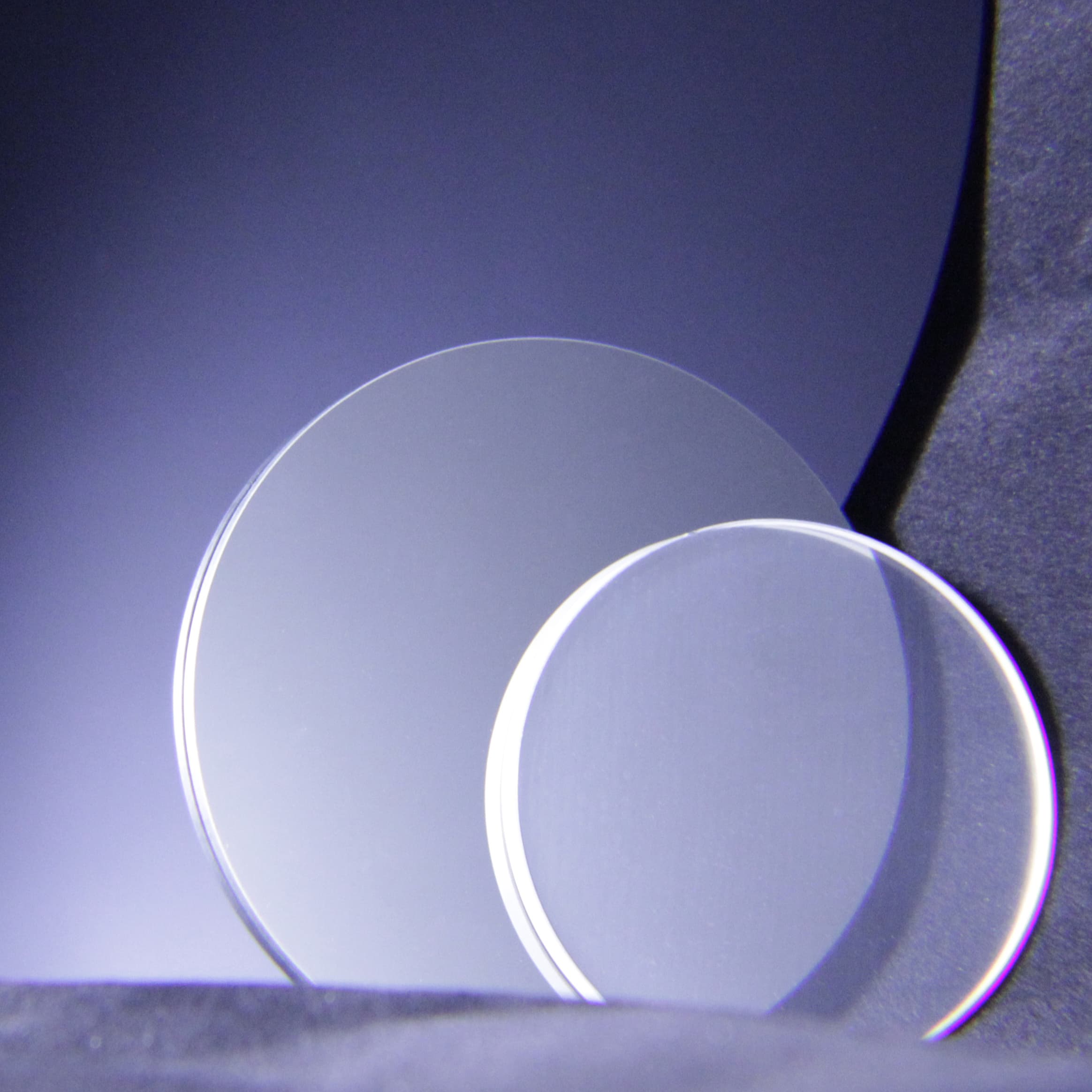

Reflect and transmit any combinations of wavelengths with precision plate beamsplitters. UV, VIS, or IR, Polarized or Unpolarized, 10:90 – 90:10 Reflection:Transmission(R:T).

Optical Diffuserfilm

Best practices suggest that when coating or setting up an optical component, it’s best to use a witness sample, also called a “test piece,” to ensure that the actual part will match your specific coating specifications and your application.

Opticaldiffusers in makeup

Sydor Optics has a vast array of CNC glass machining equipment, including the Haas VF-3SSYT, VF-3, VF-2, Mini-mill and Mini-Mill2, and Fanuc Robodrill. Regardless of the machine used, every job adheres to the same quality standards to meet your glass CNC machining needs and precise specifications.

Optical diffusereye cream

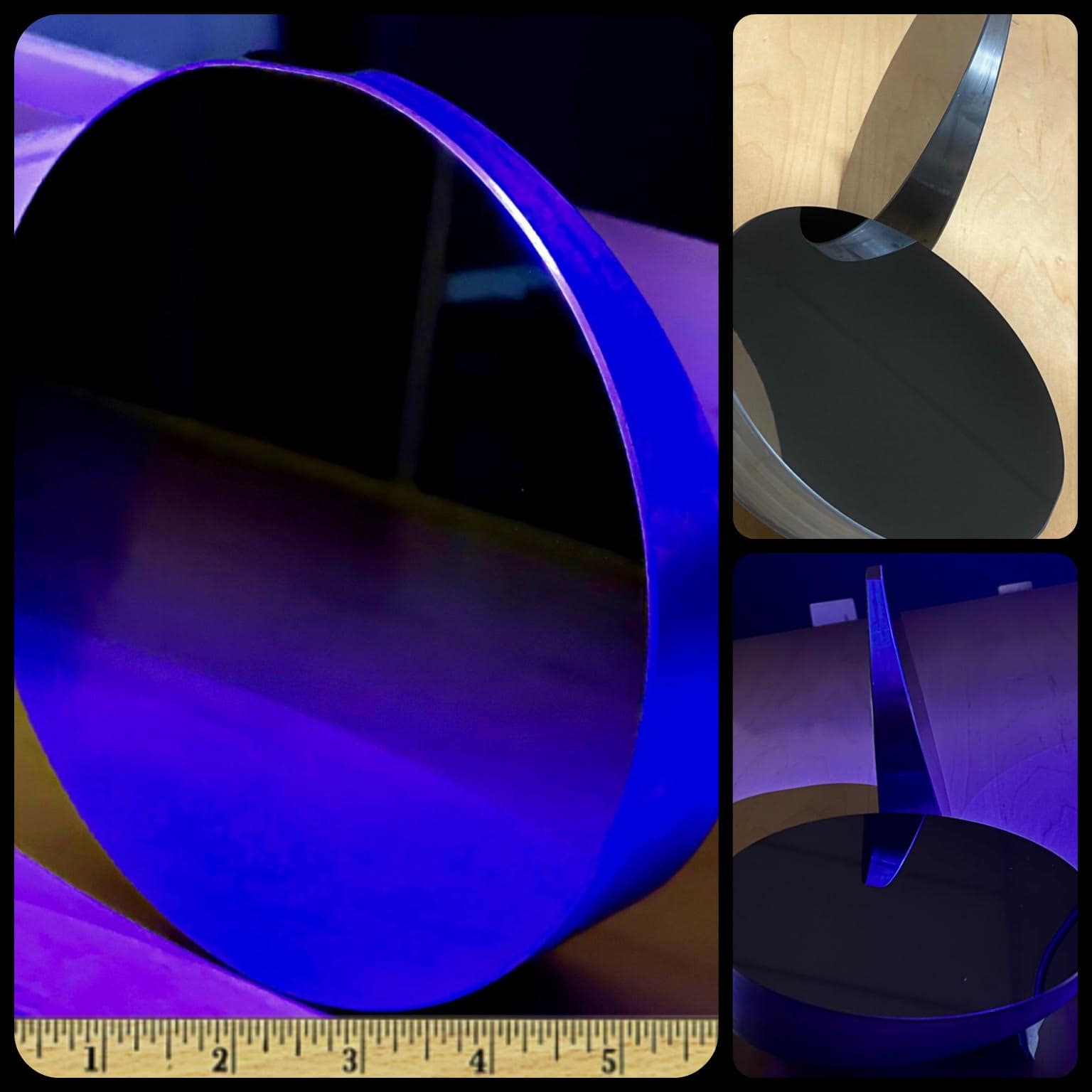

Aside from standard size glass wafers such as 100mm, 150mm, 200mm and 300mm, Sydor Optics can provide custom wafers with diameters up to 450mm and thin wafers with thicknesses down to 0.1mm.

Optical wedges with ± 10 arc seconds of wedge angle tolerance. Superior craftsmanship made to your specifications in a variety of shapes, sizes, and materials.

With the aid of the latest CAD / CAM software systems combined with cutting-edge equipment and expert CNC machine operators, Sydor Optics has the ability to manufacture the most complex geometries and tightest tolerances.

Your product has a warranty that protects against defects in the material and the finishing of the product in accordance with it's maintenance and usage instructions. See more details.

Ms.Cici

Ms.Cici

8618319014500

8618319014500