Parabolic mirror : a complete guide - parabolic reflector mirror

Manufacturers can produce off-axis parabolic mirrors in several ways. One method involves using a rotating furnace to form the mirrors from a molten base material. A simpler way is to cut and shape the off-axis paraboloids from metal blanks. At Shanghai Optics, we use the latter method to produce high-quality standard and custom OAP mirrors quickly.

Off-axis parabolic mirrors are designed to eliminate this problem. These mirrors are sections of a parent paraboloid that are taken from a point other than the center axis. Depending on how far away from the axis the section originates, an off-axis parabolic mirror may feature a large or a small angle. But since these mirrors focus light to offset points, outside the collection area, there is no issue with receiver shadowing. This makes off-axis parabolic mirrors the optic of choice for long-range and precision instrumentation. The unrestricted access these mirrors give to the system’s focal point also leads to compact system designs.

Cognex

Machine vision is the ability of a computer to see the environment. For example, a video camera runs with analog-to-digital conversion and digital screen processing. The image data is then sent to a computer or robot controller.

A parabolic mirror is a reflector in the shape of a circular paraboloid. Typically made of a highly reflective material such as aluminum, a standard parabolic mirror will center on the vertex of the paraboloid. This is the point where the curvature is greatest, and where the paraboloid is symmetrically divided by its axis. Parabolic mirrors are effective at collecting collimating light and focusing this light to a point, but the receiver will often cast s shadow on the paraboloid’s vertex. This blocks a significant part of the mirror from reflecting light, resulting in substantial signal loss.

When selecting the right machine vision camera, you have to consider several factors. Initially, it is essential to ensure the camera you’ve chosen is suitable for the application you are looking for. For instance, a camera used for robot guidance won’t have the same characteristics as the one used for production control. The choice of any feature will depend on both your budget and your application.

Industrialmachine vision

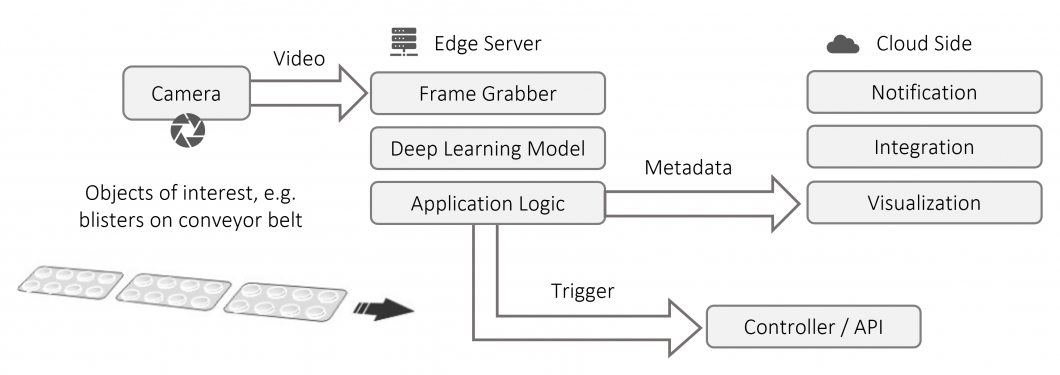

Edge Intelligence, or Edge AI, is the next big trend, moving machine learning for image recognition from the cloud to physical edge devices connected to the cameras. This is relevant for the future of machine vision applications since advances in edge computing (on-device processing) make it possible to apply deep learning capabilities in traditional computer vision tasks. For example, deep learning machine vision is useful for camera inspection systems and vision systems for quality control.

Machine vision systems are embedded components that use data extorted from online images to automatically guide manufacturing and production operations, such as go/no testing and quality control processes. These systems can also play a role in inspection operations and automated assembly verification. They can do so using their capabilities to direct material handling equipment to position products or materials required in a particular process.

While using OAPs it is also important to remember that the orientation matters. If a collimated beam is incident upon the off axis mirror from an off-axis focal angle, it will not produce a diffraction limited image. If a spherical wave enters on axis, it won’t produce a collimated beam either.

Machine vision cameras are used in various industries, including pharmaceuticals, industrial manufacturing, semiconductors, food and beverages, electronics, automotive, and packaging and printing. Moreover, it has a lot of applications in pattern recognition, location analysis, and inspection with cameras.

康耐视

The major components of an intelligent camera system are lighting, sensors, communications systems, lenses, and vision processing systems. The camera sensor converts the light into an online digital image. It is then sent to the processor for analysis.

Machine Vision can enhance the diagnostic abilities of radiologists. It can precisely detect diseases and anomalies within medical images. It can also quickly and accurately analyze vast datasets, such as MRI or CT scans helping medical professionals to make critical decisions about patient treatment plans and care. This has opened up new avenues for early disease detection and customized medicines.

For example, computer vision can process images or videos online, along with images from motion detectors, infrared sensors, or other sources. The next megatrend is Edge AI, moving computer vision from the cloud to the edge, close to the sensor gathering data. Machine vision is a sub-class of computer vision.

Request a quote online today or contact an S.O. representative to learn more about our custom off-axis parabolic mirrors and other optical manufacturing capabilities.

Cognex 3d

Computer vision and machine vision are overlapping technologies. An intelligent system needs a computer and a particular software tool to function, while computer vision doesn’t need to be linked to a machine.

Shanghai Optics manufactures off axis parabolic metal mirrors in curvatures of 15°, 30°, 45°, and 60° off-Axis options. Our standard mirrors are manufactured from high quality aluminum, and come in diameters between 2.5 and 10 inches. Our mirrors are hand polished to an accuracy of 1/20 lambda RMS.

A machine vision system uses a sensor in the robot to see and identify a physical entity using a computer. Various industrial processes, including recognition of optical characters, material inspection, currency recognition, object recognition, pattern recognition, and electronic component analysis, use this system.

The flat back of each of our OAP mirrors is equipped with three threaded holes for mounting. Typically an adaptor plate will be placed between the OAP back surface and a kinematic mirror mount.

An off axis parabolic mirror is an optical device which transforms plane waves into spherical waves and spherical waves into plane waves. This makes it useful for collimating light from a point source as well as focusing collimated light to a point. It does this with high accuracy, and is not dependent on wavelength. Shanghai Optics high quality off-axis parabolic mirrors can be used in broadband UV, visible, and IR applications.

Human eyes can sense the range of electromagnetic (EM) wavelengths from 390 to 770 nm. However, video cameras are responsive to wavelengths much broader than this, with some machine vision systems operating at X-ray, infrared, or ultraviolet (UV) wavelengths. Machine vision supports a computer’s ability to see.

Our OAP metal mirrors are used in spectrometers, interferometers, astronomical optical instruments, spectrum analyzers, and in beam expanders and beam collimators. They can be used in sequence to create a relay system, since with multiple mirrors you can switch between focal plane and pupil plane of your system without degradation in image quality.

Cognex insight

The machine vision algorithms can analyze vast agricultural fields to identify areas that are affected by pests or diseases in real time with the help of aerial drones. This would help the farmers target interventions precisely where needed, reducing the application of blanket pesticides and minimizing the environmental impact.

The purpose of the system in location applications is to find the physical entity and detect its position and orientation. In an inspection application, a system validates certain features, including the presence or absence of the correct label on a bottle or chocolates in a box. In identification applications, the purpose of a vision system is to read different codes and alphanumeric characteristics.

Off axis parabolic mirrors should only be used at infinite conjugates. They can produce a perfectly collimated beam from a spherical wave, or diffraction limited imaging when focusing a collimated beam, but when they’re used at finite conjugates the image quality will be abysmal.

VisionPro

Machine vision systems are designed to find defects in manufactured products, assess their dimensional precision, and ensure component integrity. These systems depend on advanced image processing algorithms and HD cameras to analyze products in real-time, ensuring that they stick to stringent quality standards. Such applications reduce production costs, minimize waste, and improve product quality.

Cognex scanner

We are also able to provide off-axis parabolic mirrors in custom sizes and coatings upon request, so you can find an OAP mirror to meet your exact project requirements.

One of the easiest ways to understand a computer vision system is to consider it the eyes of a machine. This system improves quality, efficiency, and operations.

Machine vision plays an important role in transforming autonomous vehicles. A multitude of sensors, including cameras, are used by vehicles to perceive their surroundings, interpret road signs, recognize pedestrians, and navigate safely. The Machine Vision algorithms process the data from the sensors thereby enabling autonomous vehicles to make quick decisions, avoid collisions, and enhance transportation systems. With advancements, these vehicles can also reduce accidents and congestion, reshaping the future of mobility.

Viso Suite is the leading end to end computer vision infrastructure to build, deploy, and scale AI vision dramatically faster and better.

Machine vision cameras are based on sensors with special optics to capture images, process, evaluate, and measure different characteristics through hardware and computer software for precise decision-making. If engineered with the correct optics and resolution, a machine vision camera can detect small object details almost invisible to the human eye.

Since off axis mirrors are not rotationally symmetric, rotation must be restricted around the optical axis. We recommend using a precision machined mount since alignment of the other six degrees of freedom is very sensitive.

About us: Viso.ai provides the leading end-to-end Infrastructure for Computer Vision Applications. The Viso Suite platform enables industry leaders to build, deploy, and scale high-performance computer vision applications. Get a demo for your company.

Let’s see how these discrete elements work together when evaluating a product in a manufacturing operation — which is a typical example of an automated system in practice.

These systems have a wide range of applications in different industries that can automate time-consuming, repetitive jobs that would otherwise be tiring to a human operator. The use of such systems allows for the examination of products or components in a process. It results in higher yields, increased quality, low defect rates, reduced costs, and higher consistency of process results.

Our optical engineers are available to provide off-axis parabolic mirror consulting and can help you design and produce a mirror that best matches your application. Feel free to contact us with a request for a quote, or for more information on custom options.

Computervision

Understanding the anatomy and capabilities of systems can help guarantee that an application is suitable for camera-based systems. In reality, a camera can capture whatever a human eye can see, and deciphering and reporting the data can be a little daunting. However, with the help of a vendor knowledgeable in the systems, lighting, and techniques, we can save a significant amount of time in the long run.

Off Axis Parabolic Mirror for Every ApplicationAn off axis parabolic mirror is an optical device which transforms plane waves into spherical waves and spherical waves into plane waves. This makes it useful for collimating light from a point source as well as focusing collimated light to a point. It does this with high accuracy, and is not dependent on wavelength. Shanghai Optics high quality off-axis parabolic mirrors can be used in broadband UV, visible, and IR applications.Understanding Parabolic MirrorsA parabolic mirror is a reflector in the shape of a circular paraboloid. Typically made of a highly reflective material such as aluminum, a standard parabolic mirror will center on the vertex of the paraboloid. This is the point where the curvature is greatest, and where the paraboloid is symmetrically divided by its axis. Parabolic mirrors are effective at collecting collimating light and focusing this light to a point, but the receiver will often cast s shadow on the paraboloid’s vertex. This blocks a significant part of the mirror from reflecting light, resulting in substantial signal loss.Off-axis parabolic mirrors are designed to eliminate this problem. These mirrors are sections of a parent paraboloid that are taken from a point other than the center axis. Depending on how far away from the axis the section originates, an off-axis parabolic mirror may feature a large or a small angle. But since these mirrors focus light to offset points, outside the collection area, there is no issue with receiver shadowing. This makes off-axis parabolic mirrors the optic of choice for long-range and precision instrumentation. The unrestricted access these mirrors give to the system’s focal point also leads to compact system designs.Applications of Off-Axis Parabolic MirrorsOur OAP metal mirrors are used in spectrometers, interferometers, astronomical optical instruments, spectrum analyzers, and in beam expanders and beam collimators. They can be used in sequence to create a relay system, since with multiple mirrors you can switch between focal plane and pupil plane of your system without degradation in image quality.Limitations of an Off Axis Parabolic MirrorOff axis parabolic mirrors should only be used at infinite conjugates. They can produce a perfectly collimated beam from a spherical wave, or diffraction limited imaging when focusing a collimated beam, but when they’re used at finite conjugates the image quality will be abysmal.While using OAPs it is also important to remember that the orientation matters. If a collimated beam is incident upon the off axis mirror from an off-axis focal angle, it will not produce a diffraction limited image. If a spherical wave enters on axis, it won’t produce a collimated beam either.How Are Off-Axis Parabolic Mirrors Produced?Manufacturers can produce off-axis parabolic mirrors in several ways. One method involves using a rotating furnace to form the mirrors from a molten base material. A simpler way is to cut and shape the off-axis paraboloids from metal blanks. At Shanghai Optics, we use the latter method to produce high-quality standard and custom OAP mirrors quickly.To provide the best results, we hand-polish our parabolic mirrors from large aluminum blanks and finish them to an accuracy of 1/20 lambda RMS. Our standard mirrors come in diameters between 2.5 and 10 inches and curvatures 15, 30, 45 and 60 degrees off-axis. We also provide off-axis parabolic mirrors in custom sizes and coatings upon request, so you can find an OAP mirror to meet your exact project requirements.

Mounting Your Off Axis Parabolic MirrorThe flat back of each of our OAP mirrors is equipped with three threaded holes for mounting. Typically an adaptor plate will be placed between the OAP back surface and a kinematic mirror mount.Since off axis mirrors are not rotationally symmetric, rotation must be restricted around the optical axis. We recommend using a precision machined mount since alignment of the other six degrees of freedom is very sensitive.Alignment of an OAPTo align your off axis parabolic mirror to collimate a spherical wave, follow these steps:Check that the incoming beam is at an appropriate height and is propagating parallel to your reference surface.Adjust the height of your mount so that the center of the mirror will match the center of the incident light.Position the center of your mirror a one focal length distance(that is, reflected focal length) from the origin of the sphericalMatch the angle of your mirror to the reflection angle designed into your optical system.Use a shear plate interferometer to check collimation. This is a four step process, in which you first check collimation in one plane, adjust as necessary, then check collimation in the orthogonal plane, and after adjusting, go back to the first plane again and readjust. Each plane will have to be checked at least twice, perhaps more, as the adjustments are not decoupledAs a last step, check that the output beam is parallel to the reference surface.Specifications of Off-Axis Parabolic Mirrors from S.O.Shanghai Optics manufactures off axis parabolic metal mirrors in curvatures of 15°, 30°, 45°, and 60° off-Axis options. Our standard mirrors are manufactured from high quality aluminum, and come in diameters between 2.5 and 10 inches. Our mirrors are hand polished to an accuracy of 1/20 lambda RMS.We are also able to provide off-axis parabolic mirrors in custom sizes and coatings upon request, so you can find an OAP mirror to meet your exact project requirements.Possible coatings include:Enhanced aluminum coating with 99 % reflectivity (for visible spectrum)9% dielectric coating for laser use (for visible spectrum)UV aluminum/MgF2 coating for laser use (near infrared region)Ion plated protected silver coating (for NIR, up to 2 um)Protected gold coating (for 750 nm to far infrared applications).Our optical engineers are available to provide off-axis parabolic mirror consulting and can help you design and produce a mirror that best matches your application. Feel free to contact us with a request for a quote, or for more information on custom options.Request a quote online today or contact an S.O. representative to learn more about our custom off-axis parabolic mirrors and other optical manufacturing capabilities.Learn More

If you want to learn more about how Deep Learning brought great advances in the field of Computer Vision, I recommend you to check out the following articles.

Machine vision systems include distinct elements or may be combined into a single unit, such as a smart camera that combines the functions of the discrete components into a single package. Irrespective of whether it is using a distinct or integrated system, the efficiency of the intelligent system also depends on the nature of the parts getting analyzed. The more effective the orientation or placement of the component is, the better the system’s performance.

To provide the best results, we hand-polish our parabolic mirrors from large aluminum blanks and finish them to an accuracy of 1/20 lambda RMS. Our standard mirrors come in diameters between 2.5 and 10 inches and curvatures 15, 30, 45 and 60 degrees off-axis. We also provide off-axis parabolic mirrors in custom sizes and coatings upon request, so you can find an OAP mirror to meet your exact project requirements.

Machine vision systems, also called vision inspection systems or automated vision systems, include many parts commonly found in most systems. Even though each of these parts has its function, they have a particular role in an intelligent system when working together.

Ms.Cici

Ms.Cici

8618319014500

8618319014500