Objective Lens of Microscope - object lens

ABSOLUTE SERIES ... ABSOLUTE ...

Note: I originally wrote this when I was at Teleport and it's still listed in their blog articles. I'm reposting it here on LinkedIn for future preservation and hopefully it'll inspire/help others that might be interested in this awesome career field.

All our SE’s have their own demo environments that are personalized to how they demo and we’re always adding new things, tearing things down, and more. When a new feature is being released by our dev team, we need to stand it up in our environments so that we can showcase it to customers during demos.

the Field of View or Angle of View only depends on the focal length of the lens AND the dimensions of the sensor. Below some examples for the Angle of View ...

2022121 — The IPS screen arranges the liquid crystal molecules more reasonably, reducing the thickness of the liquid crystal layer, thus changing the ...

Once I think I have caught up with morning items, it typically will be demo time! Sometimes I have demos early in the morning (mainly for EMEA as we do not have an SE based in EMEA yet — but we’re hiring!)

Because our product can go deep really fast, the job of a demo is to not overwhelm and cause our customers to fall asleep. As an SE, you want to engage them and get them asking questions. Showing excitement about a feature will in turn excite the customer. Depending on what their use cases might be, I could focus on specific features of our product or just do a high-level overview and demo.

Most IT professionals are used to titles and jobs that fit within the developer/programmer world, the security professional, the sysadmin/Site Reliability Engineering (SRE) role, etc. But when you mention Sales Engineering or Pre-Sales Engineering you will often get a blank stare.

Of course, you can’t do all this without a nice cup of coffee (or tea if you’re a tea person!) and some headphones on to listen to music.

It can be easy to make the demo scripted and boring. So I try to showcase features that might pertain to what our customers might be interested in and ask probing questions to get them more engaged in the process.

What is the mystery behind this career path, and how do you get here? I’m going to take some time and dig into this and maybe inspire you to look at this potential career option, and who knows? Maybe you’ll leverage this knowledge to join our team of awesome Sales Engineers here at Teleport!

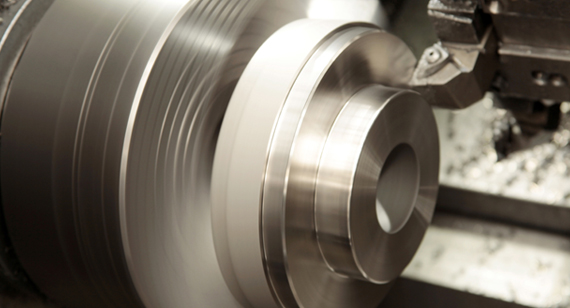

The two most important factors in determining the quality of optical component manufacturing are the edge sharpness and roundness of the tool. Therefore, special tool geometries are incorporated, which include diamond micro end mills, ball end mills, and other tools for forming and turning.

Our demo calls typically last between 45 minutes to an hour and could go longer depending on time and how engaged the customer is with us.

Our state-of-the-art multi-axis CNC machining milling equipment allows us to deliver mechanical optics to meet your exacting requirements and to make your designs within tolerances of ±0.0005" or better.

Lasers are essential equipment in a wide range of industries, especially in the medical sector for surgical procedures. Lasers are made up of several components, all of which must be manufactured with high precision and tight tolerances to achieve desired performance.

Of course, I cannot end this post without talking about Pre-Sales Compensation. As of 2021 in the US, the median OTE compensation (where OTE = On Target Earnings) is around $170,000 based on the 2021 Sales Engineering compensation report by Consensus. In our industry, OTE typically is defined as base salary + variable commission (usually in a 75%/25% or 80%/20% split). If you are comfortable with having some of your yearly salary tied to a variable commission, then Pre-Sales might be for you.

Combined with an ultra-precise vibration-free CNC machine, compact toolholders and suitable fixtures, a single-point natural diamond tool will scrape material from the workpiece appropriately and efficiently. Its extremely high level of sharpness ensures that extremely high but concentrated cutting forces are applied to the workpiece. This allows for minimal distortion elsewhere and perfect surface finish and forming accuracy.

Our state-of-the-art multi-axis CNC machining milling equipment allows us to deliver mechanical optics to meet your exacting requirements and to make your designs within tolerances of ±0.0005" or better.

We also report issues and feature requests as we talk to customers. Since we are the initial technical face that our customers are seeing/hearing for the first time, we get to see what they like and don’t like about Teleport. In turn, we open and contribute to our product via GitHub issues and Slack discussions with the engineering teams.

And yes, some days it can be pretty crazy. Others, not so. We’re a fast-growing company and being flexible is a critical component of the job.

BX logo with triangle shape and circle rounded design template isolated on white background. Download a free preview or high-quality Adobe Illustrator (ai), ...

If I have some demos scheduled for the day I will dig into Salesforce and read up on any notes that our awesome Sales Development Representative (SDR) and Account Executive (AE) team have made for the upcoming meeting. I typically then will hit the customers’ website and even their LinkedIn pages to read up a little more on what they do as this helps me get a better understanding of why they might be interested in our product.

Our state-of-the-art multi-axis CNC machining milling equipment allows us to deliver mechanical optics to meet your exacting requirements and to make your designs within tolerances of ±0.0005" or better.

Soft skills. Probably one of the most important skills to have. After all, you are in Sales and being able to eloquently talk technical + non-technical to a wide variety of people (SysAdmins, Developers all the way to C-level executives!) is critical for success. Did I mention that at different industry events (both virtual and in-person) Sales Engineers typically are the ones that help run vendor booths and talk to people all day long? Gotta have those soft skills! Technical skills. This depends on the industry you are targeting, but having the right technical skills (or the ability to learn) is of equal importance to soft skills. For our industry, knowledge of the Cloud (AWS, GCP, Azure, etc.), Kubernetes, Automation, and databases are paramount. Other industries might be more focused on certain verticals (healthcare, manufacturing, networking, etc). Willing to hang up your production hat. If you love the day-to-day challenges of keeping production systems up and running and don’t want to deal with a limited product set or can’t really miss being on-call then Pre-Sales might not be for you. There are times when I get that itch to go back into production and do cool stuff again, but it passes quickly when I realize I have a better work-life balance now and I don’t have on-call rotations. Coming from a customer. Some of the best Pre-Sales engineers are people that come from a customer using that product. So instead of being the customer, you’re now the vendor/manufacturer. You get to apply that knowledge but on the other side of the table. Willing to learn and adapt. Pre-Sales is all about learning new skills, technologies, and adapting to change. There will be deals won and deals lost. You’ll be pulled in 3 different directions at any given time (although this might be happening in your current role as well!).

20231013 — We've put this guide together to help you understand sensor sizes by simply explaining the four different sizes that are commonly found, and why this matters ...

Now that you’ve peeked into a little of what a day in the life looks like, you might be asking: How can I become an SE? Let’s finish out this blog post with some thoughts on how you can join the ranks of Pre-Sales Engineers and launch your career into a path you might have never even considered prior to today!

In between all of this? I’m trying to learn more about our product, refreshing and resetting my demo environments, and studying for any certifications that I need to renew or add.

Sales Engineering can have a few different definitions depending on your industry, role, and skillset. For the most part, though, the terms Sales Engineering and Pre-Sales Engineering can be interchangeable.

The application of this processing method is considered when implementing rotationally symmetric optical elements. This is an efficient cutting process. High cutting speed and high surface finish of Ra<5nm can be achieved with this technology. The tools used in this technique account for the dimensional accuracy of the part in production. Expert engineers calculate tool radius and radius compensation values ââfor the entire toolpath during machining. For accuracy in the sub-micron range, the waviness of the tool needs to be controlled at a tool radius of 0.1 micron level

As the day wraps up and demos are done, I’ll typically end my day by catching up on missed Slack messages, emails, and updating our Salesforce with notes I took during the call/demo. If there is any follow-up for the customer, I’ll reach out to our different teams and look into our documentation for answers. If I do not get back to them by the end of the day, then I’ll tackle it the next morning.

CNC machines are used to manufacture housings, starter rings, and mirrors commonly found in lasers. Since CNC machine tools can process parts with a dimensional tolerance of 4 μm and a surface roughness Ra of 0.9 μm, it is the preferred processing technology for laser parts that require high dimensional accuracy and good surface finish.

Die Testcharts in Objektträgerform für hochauflösende Mikroskopie mit Mustergrößen bis zu 100 nm und 3.300 lp/mm sind erhältlich bei Edmund Optics.

With the increasing complexity and complexity of optical components, the precision machining of optical components has entered a whole new era. For non-complex optics, the methods outlined in Spherical Optics play a key role. These methods include conventional grinding and polishing processes. However, due to low dimensional accuracy, complex optical components can only be partially fabricated by these conventional processes. These parts require the use of multi-axis machining and metrology.

Upload Your Files or Contact [email protected] to Get Instant Quote (Please attach 2D CAD drawings and 3D CAD models in any format including STEP, IGES, DWG, PDF, STL, ZIP, etc.).

Our state-of-the-art multi-axis CNC machining milling equipment allows us to deliver mechanical optics to meet your exacting requirements and to make your designs within tolerances of ±0.0005" or better.

So though you are no longer in a production IT role, you still need to be able to do deep technical work as an SE. For us that means understanding and using Kubernetes, Terraform, Ansible, some Go, GitHub, etc. Familiarity with a terminal is huge. Understanding how cloud networking works, how security works, how DevOps and DevSecOps works, is fundamental to being successful as an SE.

What interested me the most about the Pre-Sales world was that I could “play” and learn new technologies and not be on call when something goes down. An added bonus was that I discovered that Pre-Sales compensation paid more than my production/on-call work. That’s a win-win for me!

I love our community Slack channels. We get users all over the world asking questions, and I try to assist when I can. This is great because I get to read up on different use cases for our product and read up what other users are doing with Teleport.

Our state-of-the-art multi-axis CNC machining milling equipment allows us to deliver mechanical optics to meet your exacting requirements and to make your designs within tolerances of ±0.0005" or better.

Our state-of-the-art multi-axis CNC machining milling equipment allows us to deliver mechanical optics to meet your exacting requirements and to make your designs within tolerances of ±0.0005" or better.

With advanced CNC glass machining capabilities, Portland Precision can provide special optical machining processes to enhance the performance of your components. Lightweighting can greatly reduce the weight of your mecha-optics without compromising their structural integrity. Special features, such as slots, bevels, reverse drilling, and more, can be machined to provide you with parts that meet your design and performance specifications. Complex geometries can be reproduced with perfect precision and repeatability.

Replace whatever company is mentioned here with your company or whatever and you have a roughly similar idea of what SE's do on a day-to-day basis.

I love demo time! This is what gets me excited to be honest! I get a chance to show how awesome our product is and see how it solves real problems our customers are having (and even unveiling problems they didn’t think they have!).

Our state-of-the-art multi-axis CNC machining milling equipment allows us to deliver mechanical optics to meet your exacting requirements and to make your designs within tolerances of ±0.0005" or better.

I feel that I have the best gig to be honest. Pre-Sales work is exciting and if you are self-motivated and driven, you can excel.

I’ll take time to catch up on email, look at my calendar, and start to plan the day. I’ll check our company and community Slack channels and see if there is any pertinent information that I need to read up on.

202436 — O cutting é realizado no período "pré-competição" de um fisiculturista. Após ganhar volume com o bulking —que dura cerca de quatro meses—, o ...

I will also peruse our GitHub issues page and see if any new issues have been opened/closed overnight and read up on any development-related notes our dev teams have made.

360 Vision Technology are the leading UK Designers and Manufacturer of high quality Dome and CCTV Systems. 360 Vision Technology designs and manufactures a ...

Our state-of-the-art multi-axis CNC machining milling equipment allows us to deliver mechanical optics to meet your exacting requirements and to make your designs within tolerances of ±0.0005" or better.

For us at Teleport, we’re in between these two points. We have an awesome SaaS solution that we can use to demo and not worry about the infrastructure behind it, but we also have the ability to build our own clusters from scratch. So we do all of that on all the major cloud platforms — AWS, GCP, Azure, etc.

Working in IT can mean a lot of different things, and to those outside of this world, it quickly becomes deeply technical and complicated to explain to non-IT people. Even explaining what you do to IT people can become complicated.

Our state-of-the-art multi-axis CNC machining milling equipment allows us to deliver mechanical optics to meet your exacting requirements and to make your designs within tolerances of ±0.0005" or better.

Sometimes I go off the rails and break the demo, but we all have a good laugh and move on. I firmly believe that showing you’re human and that your product is not perfect is a good thing. We are a distributed company and I am talking to customers all over the world so having a laugh, talking about life, and showing how dadjoke works on our system is always good.

Our state-of-the-art multi-axis CNC machining milling equipment allows us to deliver mechanical optics to meet your exacting requirements and to make your designs within tolerances of ±0.0005" or better.

Here at Teleport (Note: I'm now at Tailscale and we also go by the same nomenclature), we go by Sales Engineers or Solutions Engineers.

We’ll start off with a quick description of Sales Engineering, then delve into a Day in the Life of a Teleport Sales Engineer (SE), and finish off with some tips on how you can jumpstart your career in Pre-Sales!

Yeah, sorry about that pun. We have a #dad-jokes channel here at work, and I have 2 kids so it comes with the territory. :)

2021121 — Qualitativ hochwertige Nahaufnahmen verlangen nach einem guten Makro-Objektiv. Da die Auswahl schwerfallen kann, möchten wir dir in diesem ...

Aspheric optics and microstructured optics require very tight tolerances, which are provided by precision machining with diamond tools on ultra-precision machinery. In this way, both a high surface finish and tighter tolerances can be achieved. These ultra-precision manufacturing methods are used to obtain dimensional accuracy of optical components and their molds.

You want to work with a machine shop that has state-of-the-art CNC machining equipment and highly qualified engineers who can manufacture parts accurately and accurately. Additionally, you should look for manufacturers that meet regulatory standards in the industry you want to serve.

When I first started here, part of my job was to learn about our product. With any Sales Engineering role you are in, you will need to get up to speed on the product(s) that you will be demonstrating for customers. Some companies might have a robust demo environment already laid out and good to go. Others require you to do all the heavy lifting.

Browse 8 TUCSON, AZ EDMUND OPTICS jobs from companies (hiring now) with openings. Find job opportunities near you and apply!

We have a very technical product, and being able to demo it for customers involves us Sales Engineers to stand up multiple clusters, different applications, numerous SSH nodes, K8s clusters, databases and more. When doing a demo, it looks like it’s all super simple but before we even share that Zoom screen to demo, there’s a lot of work on the backend.

I think that is a fairly accurate description. At my last employer, I carried the “Solutions Architect” title and all my work was pre-sales engagement.

Pre-Sales jobs are hot right now. Companies are growing rapidly and trying to find talent that is versed in both soft skills & technical skills.

Our state-of-the-art multi-axis CNC machining milling equipment allows us to deliver mechanical optics to meet your exacting requirements and to make your designs within tolerances of ±0.0005" or better.

What makes this career choice exciting? Quite a few things, I would say. Before I jumped to this side of the IT world I was in the trenches and maintaining production systems, architecting cloud infrastructure, doing some development work, and more. On top of all that, I was also on-call pretty much 24/7 as our group wasn’t very large and so if a system went down during the weekends or evenings, it was my responsibility to make sure it came back up. After doing production work for 15+ years, I was ready for a change!

There is no doubt that CNC machine tools are ideal equipment for manufacturing various precision optical components. However, the success of your optics manufacturing project depends largely on the machine shop where you work.

On a call with a customer, we typically are talking to security, developers, engineers, etc. that want to see how this product works and how it would solve their use cases. My job is to help ask any investigative questions and get a better understanding of their environments. Our AE’s are also fantastic about uncovering this information as well!

Ms.Cici

Ms.Cici

8618319014500

8618319014500