Advanced Healthcare Distributors, LLC and Apex International ... - advanced distributors

Flatlens Glasses

There are many other potential uses: mass-produced cameras for quality control in factories, light-weight optics for virtual-reality headsets, even contact lenses. "We can make these on soft materials," Prof Capasso assured the BBC.

Probably! We stock over 3 million contact lenses in our distribution centers and aim to despatch over 95% of orders on a same day basis. For more information click here.

Flatlens camera

Mass production is the key to managing costs, which is why Prof Capasso sees cell-phone cameras as an obvious target. Most of their other components, including the camera's detector, are already made with chip technology. Extending that to include the lens would be natural, he argues.

If you would like further information please contact our customer support team who will be happy to help or you can help yourself by searching our user friendly Help Pages.

Or to get a different focus, engineers could change the size, spacing and orientation of the pillars. It simply means doing the computer calculations and dialling the results into the new design.

Just 2mm across and far thinner than a human hair, the tiny device can magnify nanoscale objects and gives a sharper focus than top-end microscope lenses.

Flatlens sunglasses

Flatlens vs curved lens

And with ease. Electronics manufacturers making microprocessors and memory chips routinely craft components far smaller than the pillars in the flat lenses. Yet a memory chip containing billions of components may cost just a few pounds.

Computer calculations are needed to find the exact pattern which will replicate the focussing effect of a conventional lens.

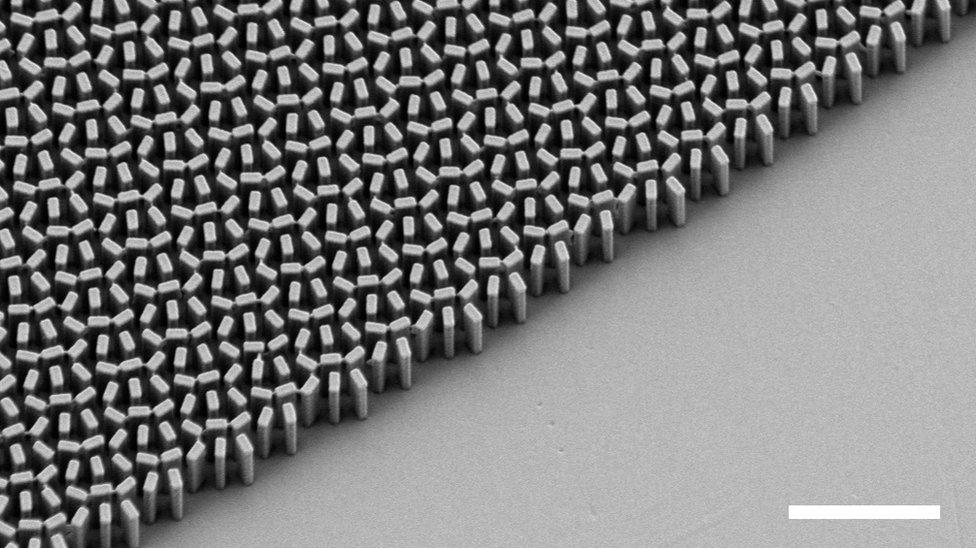

Singly, each pillar interacts strongly with light. Their combined effect is to slice up a light beam and remould it as the rays pass through the array (see video below).

Optical FlatPrice

The lens is quite unlike the curved disks of glass familiar from cameras and binoculars. Instead, it is made of a thin layer of transparent quartz coated in millions of tiny pillars, each just tens of nanometres across and hundreds high.

We are an online retailer specialising in contact lenses plus solutions and accessories and have been online since 1996 and selling cheap contact lenses direct to customers since 2002. In that time we have despatched over 4 million orders and we take pride in the fact that over 90% of orders are from existing, satisfied customers. We literally started from our spare room and grew from there and still proudly independent (one of the few).

The team has previously worked with silicon, which functions well in the infrared. Other materials could be used to make ultraviolet lenses.

The precise character of the lens depends on the layout and composition of the pillars. Paint-whitener - titanium dioxide - is used to make the pillars, because it is transparent and interacts strongly with visible light. It is also cheap.

Flatlens examples

"The quality of our images is actually better than with a state-of-the-art objective lens. I think it is no exaggeration to say that this is potentially revolutionary."

Optical flatmeasurement

Light passing through the "metalens" is focussed by the array of nanostructures on its surface (video: Capasso Lab/Harvard)

The prototypes lenses are 2mm across, but only because of the limitations of the Harvard manufacturing equipment. In principle, the method could scale to any size, Prof Capasso said.

Optical flatinterferometer

Being online means that customers can also order what they want, when they want, 24 hours a day. Our huge stock (over four million contact lenses!) results in you getting your contact lenses fast - the order is generally posted within 24 hours, in a letterbox friendly package (where possible) delivered to an address of your choosing - not just home, as is often the case with online ordering.

"But our lenses, being planar, can be fabricated in the same foundries that make computer chips. So all of a sudden the factories that make integrated circuits can make our lenses."

"The conventional fabrication of shaped lenses depends on moulding and essentially goes back to 19th Century technology.

The advantage, Prof Capasso said, is that these "metalenses" avoid shortfalls - called aberrations - that are inherent in traditional glass optics.

"In my opinion, this technology will be game-changing," said Federico Capasso of Harvard University, the senior author of a report on the new lens which appears in the journal Science, external.

Those comparisons were made against top-end lenses used in research microscopes, designed to achieve absolute maximum magnification. The focal spot of the flat lens was typically 30% sharper than its competition, meaning that in a lab setting, finer details can be revealed.

The team is already working on beating the performance of its first prototypes. Watch this space, they say - if possible, with a pair of metalenses.

In order to find the best daily contact lenses we looked at the technical specifications - the water content, availability of a UV block, oxygen transmission, wetting properties and material. On the prescription side, we looked at the powers that are available and overall size, and fitting characteristics. Not least we looked at the consumer experience - what was the customer feedback on the daily lenses and of course, the price. So here we go with our review and some final recommendations...

Ms.Cici

Ms.Cici

8618319014500

8618319014500