mpy-cross-v6 - m p y

Given the extensive history of the mirror, let’s hone in a few key periods in the evolution of the fragile object, and explore how that evolution parallels with humans’ sense of self.

Ancient copper mirrors were created by the people of Mesopotamia in 4000 BC, and later in ancient Egypt in 3000 BC. Archaeologists discovered polished stone mirrors from Central and South America dating back to 2,000 BC.

The performance advantage of CMOS imagers over CCDs for machine vision merits a brief explanation. For machine vision, the key parameters are speed and noise. CMOS and CCD imagers differ in the way that signals are converted from signal charge to an analog signal and finally to a digital signal. In CMOS area and line scan imagers, the front end of this data path is massively parallel. This allows each amplifier to have low bandwidth. By the time the signal reaches the data path bottleneck, which is normally the interface between the imager and the off-chip circuitry, CMOS data are firmly in the digital domain. In contrast, high speed CCDs have a large number of parallel fast output channels, but not as massively parallel as high speed CMOS imagers. Hence, each CCD amplifier has higher bandwidth, which results in higher noise. Consequently, high speed CMOS imagers can be designed to have much lower noise than high speed CCDs.

The Delta Machine Vision System DMV Series was developed to meet the demands for industrial automation applications on the production line, such as stain ...

During the Bronze Age (3300-1200 BC), more cultures around the world began crafting mirrors out of bronze, silver, copper, and other metals. One particular group, the Kerma people of Nubia, were particularly skilled at mirror manufacturing.

Bronze mirror manufacturing emerged in China around 2000 BC, and the Qijia culture can be credited with creating some of the earliest bronze and copper mirrors.

CCDs combine signal charges, while CMOS TDIs can combine either voltage or charge signals. The charge summing operation can be noiseless, but CMOS voltage summing cannot. When a CMOS voltage-domain TDI has more than a certain number of rows, the noise from the summing operation adds up to the point that it becomes impossible to match a charge-domain TDI. The tradeoff is in speed and cost. CCD TDI provides great sensitivity but eventually reaches a speed limit. CMOS has speed advantages, but charge-domain CMOS TDI is more difficult and costly to design and manufacture. For lower numbers of row summing, voltage-domain TDI summing can provide cost-effective high performance, but for the most challenging (highest speed, lowest light) applications, charge-domain CMOS TDI (like that found in Teledyne's Linea HS cameras) delivers the highest performance.

But Kelleher later adds that looking in the mirror, especially for women, became a survival technique as more women got their hands on them. “In reality, a woman [looking] in the mirror is practicing. She’s seeing herself how men see her, how society sees her. She’s assessing her value and figuring out how to enhance her worth, her power.”

Low noise CMOS imagers may not have the NIR, UV, or TDI integrating advantages of a CCD. Consequently, because the signal can be much weaker, even when the read noise is comparable to what an EMCCD can achieve, an EMCCD solution may still be better overall.

Electron multiplication CCDs (EMCCDs) are CCDs with structures to multiply the signal charge packet in a manner that limits the noise added during the multiplication process. This results in a net signal-to-noise ratio (SNR) gain. In applications where the signal is so faint that it is barely above the imager noise floor, EMCCDs can detect previously indiscernible signals.

Both types of imagers convert light into electric charge and process it into electronic signals. In a CCD sensor, every pixel's charge is transferred through a very limited number of output nodes (often just one) to be converted to voltage, buffered, and sent off-chip as an analog signal. All of the pixel can be devoted to light capture, and the output's uniformity (a key factor in image quality) is high. In a CMOS sensor, each pixel has its own charge-to-voltage conversion, and the sensor often also includes amplifiers, noise-correction, and digitization circuits, so that the chip outputs digital bits. These other functions increase the design complexity and reduce the area available for light capture. With each pixel doing its own conversion, uniformity is lower, but it is also massively parallel, allowing high total bandwidth for high speed.

During the late Industrial Revolution, the ribbon machine helped mirror makers produce glass panes in large quantities. In France, the Saint-Gobain factory became particularly important as a manufacturer of modern-day glass mirrors.

WORKING DISTANCE- distance between the objective lens and the slide. FIELD OF VIEW- area you can see through the microscope.

Goof rings are essential accessories for our recessed pot light products. Get a quote or find more information here.

Of course, the silvered-glass mirror as we know it today isn’t thousands of years old – it dates back to Germany about 200 years ago (more on this below). But antique mirrors have existed for much longer. According to a 2006 issue of the journal Optometry and Vision Science, it was about 8,000 years ago that the first mirrors were manufactured in what’s now Turkey. These antique mirrors were made of ground and polished obsidian, also called volcanic glass.

That same year, ceramist Jen Dwyer created Rococo-style mirrors and combined them with antique symbols, pairings which the artist says are meant to represent patriarchy.

Alongside the emergence of the mirror as an object and piece of art, its wide variety of materials over the centuries, and its more recent mass production techniques, we wonder how exactly the ancient mirror’s purpose evolved over time. Furthermore, we wonder how the mirror led to a transformation and discovery in terms of our own perception of ourselves. The answer to both lies in the region and culture in which mirrors were created.

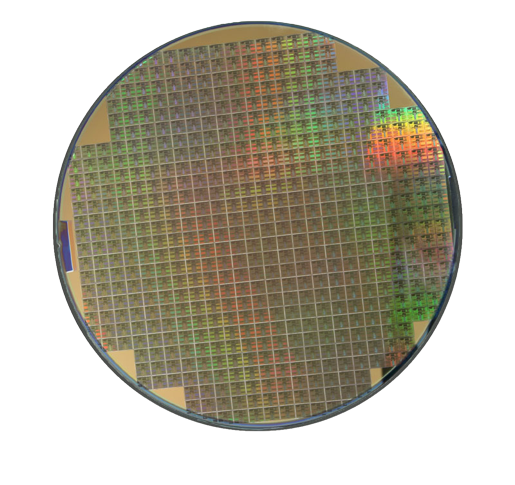

CCDs and CMOS imagers were both invented in the late 1960s and 1970s (DALSA founder Dr. Savvas Chamberlain was a pioneer in developing both technologies). CCD became dominant, primarily because they gave far superior images with the fabrication technology available. CMOS image sensors required more uniformity and smaller features than silicon wafer foundries could deliver at the time. Not until the 1990s did lithography develop to the point that designers could begin making a case for CMOS imagers again. Renewed interest in CMOS was based on expectations of lowered power consumption, camera-on-a-chip integration, and lowered fabrication costs from the reuse of mainstream logic and memory device fabrication. Achieving these benefits in practice while simultaneously delivering high image quality has taken far more time, money, and process adaptation than original projections suggested, but CMOS imagers have joined CCDs as mainstream, mature technology.

Secondly, volume matters. Although the cost to develop a new CMOS imager is higher, CMOS imagers that can leverage from larger economies of scale will have lower unit cost. With high volumes, a low unit cost can be financially more important than a low development cost.

Led Lighting Jobs in Dubai ; Design Manager - Lighting. Client of 8 Recruitment. 4 - 8 Years · Posted 30+ days ago ; Sales Consultant (Lighting). EROS ELECTRICALS ...

As Kelleher writes, “We’ve all felt fascinated by the image of our own selves, captured in silver or water or glass. The way we look matters, whether we want it to or not: It alters our job and mating prospects, contributes to our quality of life. We value different human bodies differently, and the ugly truth is that the ones that fit the prevailing culture’s definition of beautiful are evaluated at a higher worth. There’s both a power and a survival necessity in seeing yourself the way the world sees you.” That new purpose for mirrors that emerged ridded the mirror of its fascinating, magical, spiritual meanings and made it a bit more mundane (and ugly).

CMOS image sensorPDF

More recently, a mirror made by the famous Parisian designer Line Vautrin surprisingly sold for €127,000 at a French TV auction in June 2021.

To image in the near infrared (700 to 1000nm), imagers need to have a thicker photon absorption region. This is because infrared photons are absorbed deeper than visible photons in silicon.

Much has been written about the relative advantages of CMOS versus CCD imagers. It seems that the debate has continued on for as long as most people can remember with no definitive conclusion in sight. It is not surprising that a definitive answer is elusive, since the topic is not static. Technologies and markets evolve, affecting not only what is technically feasible, but also what is commercially viable. Imager applications are varied, with different and changing requirements. Some applications are best served by CMOS imagers, some by CCDs. In this article, we will attempt to add some clarity to the discussion by examining the different situations, explaining some of the lesser known technical trade-offs, and introducing cost considerations into the picture.

by UDC Bischof · Cited by 3 — Da geteil- ter Hauptspeicher und damit einhergehende Anforderungen an die Koheränz der. Speicher und Caches kompliziert zu implementieren sind, haben solche ...

Have you ever looked in the mirror and asked yourself, “Where did mirrors come from, anyway?” Perhaps not regularly, but it does turn out that mirrors have a fascinating history that extends back thousands of years, far beyond antique mirrors.

Beleuchtung| KJK Modellbau ... 36mm ECO-Scheinwerfer mit Linse, 8W, T-FUSE Art.Nr.: SPOT36F-080-WE Großer und günstiger Scheinwerfer im Kunststoffgehäuse. Sehr ...

Active pixelsensor

Venetian mirrors soon became the optimal choice for royalty, who decorated their lavish palaces with them. The Countess de Fiesque reportedly traded a whole wheat farm for a Venetian mirror, and considered that a good bargain. But by the end of the 17th century, French workshops had discovered the secret to the Venetian technique, and started to mass produce them. Industrializing the process made mirrors more affordable to all.

Join the weekly In Good Taste newsletter for artistic insight, collector’s tips, art history, style guides and the opportunity to own the art and collectibles you love.

With the promise of lower power consumption and higher integration for smaller components, CMOS designers focused efforts on imagers for mobile phones, the highest volume image sensor application in the world. An enormous amount of investment was made to develop and fine tune CMOS imagers and the fabrication processes that manufacture them. As a result of this investment, we witnessed great improvements in image quality, even as pixel sizes shrank. Therefore, in the case of high volume consumer area and line scan imagers, based on almost every performance parameter imaginable, CMOS imagers outperform CCDs.

Early antique mirrors made of glass were crafted by blowing a glass bubble, and cutting off a small circular section of about 10-20 cm in diameter to create a concave or convex surface, often coated with molten lead (often with imperfections that distorted the image!) But because glass mirrors were poorer in quality, small in size, and higher in cost, solid-metal mirrors like those made of steel remained most widely in use through the late 19th century.

First, leverage is key. At the risk of stating the obvious, imagers that are already on the market will cost much less than a full custom imager, regardless of whether it is a CMOS or a CCD imager. If customization is necessary, unless the change is minor, it is generally cheaper to develop a custom CCD than it is to develop a custom CMOS imager. CMOS imager development is generally more expensive because CMOS uses more expensive deep submicron masks. There is also much more circuitry to design in a CMOS device. As a result, even in applications where a custom CMOS imager clearly has better performance, the value proposition can still favor a custom CCD.

Pliny the Elder claimed that artisans in Sidon (modern-day Lebanon) produced glass mirrors during this period, coating them with gold leaf or lead. Glass, after all, was much more reflective than previously used metals. However, this claim hasn’t been supported by archaeological evidence. Our findings can only confirm that glass mirrors were used as far back as the third century AD.

Common metal mirrors remained the norm throughout Greco-Roman antiquity, and through the Middle Ages in Europe. But they often tarnished, required polishing, and bronze and stone mirrors particularly had low reflectivity. Such defects demanded a new mirror material: glass.

Spanning worldwide literature and mythology, science, art, and culture, below are a few key meanings behind the mirror that may have led to a newfound perception of the self, self-loathing or self-loving, or to magical or religious beliefs.

CMOS sensorSamsung

Flat dome lighting » Inspection of low-reflective surfaces ✓ ➤ Go to product!

Today, the meaning of mirrors, suggests Kelleher, is changing. For one, it’s an object that embraces and supports the art and power of makeup. YouTubers and Instagram influencers of today are using mirrors to apply makeup, not just to conceal their imperfections, but also to sustain them with a career.

CMOS image sensorbook

CCD (charge coupled device) and CMOS (complementary metal oxide semiconductor) image sensors are two different technologies for capturing images digitally. Each has unique strengths and weaknesses giving advantages in different applications.

Since ultraviolet photons are absorbed very close to the silicon surface, UV imagers must not have polysilicon, nitride or thick oxide layers that impede the absorption of UV photons. Modern UV imagers are hence backside thinned, most with only a very thin layer of AR coating on top of the silicon imaging surface.

CMOS area and line scan imagers outperform CCDs in most visible imaging applications. TDI CCDs, used for high speed, low light level applications, outperform CMOS TDIs. The need to image in the NIR can make CCDs a better choice for some area and line scan applications. To image in the UV, the surface treatment after backside thinning is key, as is the global shutter requirement. The need for very low noise introduces new constraints, with CMOS generally still outperforming CCDs at high readout speeds. The price-performance trade-off can favor either CCD or CMOS imagers, depending on leverage, volume, and supply security.

Aside from area and line scan imagers, there is another important type of imager. Time delay and integration (TDI) imagers are commonly used in machine vision and remote sensing and operate much like line scan imagers, except that a TDI has many, often hundreds, of lines. As the image of the object moves past each line, each line captures a snapshot of the object. TDIs are most useful when signals are very weak, since the multiple snapshots of the object are added together to create a stronger signal.

Third, supply security is important. It is very costly to be left with a product that is designed around an imager that is discontinued. In spite of a better value proposition, it may be wiser to choose the company which is best able to produce the imager – CMOS or CCD – long term.

UV response and backside thinning are achievable in all line scan imagers, but not all area imagers. No global shutter area CCD can be backside thinned. The situation is better in CMOS area imagers, though still not without trade-offs. CMOS area imagers with rolling shutter can be backside thinned. Conventional CMOS global shutter area imagers have storage nodes in each pixel that need to be shielded when thinned, but only if these UV sensitive imagers will also be imaging in the visible. In backside thinned area imagers, it is not possible to effectively shield part of the pixel from incident illumination, without severely degrading the imager’s fill factor (the ratio of the light sensitive area to the total pixel area). There are other types of CMOS global shutter area imagers that do not have light sensitive storage nodes, but have higher noise, lower full well, rolling shutter, or a combination of these.

Although backside thinning is now ubiquitous in mobile imagers, UV response is not. To achieve stable UV response, the imager surface requires specialty surface treatment, regardless of whether the imager is CMOS or CCD. Many backside thinned imagers developed for visible imaging have thick oxide layers that can discolor and absorb UV after extended UV exposure. Some backside thinned imagers have imaging surfaces that are passivated by a highly doped boron layer that extends too deep into the silicon epi, causing a large fraction of UV photogenerated electrons to be lost to recombination.

Experts believe the first mirrors used by humans were not objects, but pools of dark, still water. In order to reflect well, mirrors must have flat surfaces, and a surface roughness that’s smaller than the wavelength of the light reflecting in them.

What isCMOS sensor

The silvered-glass mirror, the type of mirror commonly found across the world today, was invented by German chemist Justus von Liebig in 1835. His process involved applying a thin layer of metallic silver to one side of a clear glass pane. Liebig’s silvering process was adapted for mass manufacturing, and led to even wider availability of mirrors to all.

Knight Optical offers a range of stock and custom precision Fresnel Lenses made from PMMA Acrylic in two grade for fast global delivery ...

Was ist eine LED-Beleuchtung für RC Autos? Die LED-Beleuchtung für RC Autos besteht aus kleinen, energieeffizienten Leuchtdioden (LEDs), die in speziellen Kits ...

Most CMOS imager fabrication processes are tuned for high volume applications that only image in the visible. These imagers are not very sensitive to the near infrared (NIR). In fact, they are engineered to be as insensitive as possible in the NIR. Increasing the substrate thickness (or more accurately, the epitaxial or epi layer thickness) to improve the infrared sensitivity will degrade the ability of the imager to resolve spatial features, if the thicker epi layer is not coupled with higher pixel bias voltages or a lower epi doping levels. Changing the voltage or epi doping will affect the operation of the CMOS analog and digital circuits.

Today, many types of antique mirrors remain in demand by collectors. One antique mirror of provenance that recently sold for a record price at auction in March 2021 is Karl Lagerfield’s Paris studio mirror. The antique gold mirror was made back in 1948 by French ironworker Gilbert Poillerat, and sold for $238,000 at a Bonham’s sale.

Compared to CMOS, EMCCDs are most advantageous when the imager does not need to image at high speed. Higher speed operation increases the read noise in CCDs. Hence, even with the SNR improvement from the EMCCD, the difference between an EMCCD and a CMOS imager may not be much, especially when compared to scientific CMOS imagers that are specifically designed to have very low read noise. High speed EMCCDs also dissipate significantly more power than conventional imagers.

Eventually, glass mirrors did become more widely used in the Middle Ages, thanks to advancements in glassmaking across France, Germany, and Italy (Venice). By the 11th century, Moorish Spain was also producing quality glass mirrors.

IsCMOS sensorfull frame

CMOS image sensor

The famed Greek philosopher Socrates urged young people to look at themselves in mirrors. If they were beautiful, they would become worthy of that beauty. If they were ugly, they would learn how to hide their disgrace. On the contrary, the Greek story of Narcissus warns of the consequences of becoming too in love with oneself, detailing the events of the god who too often stared at his own reflection in water.

Choosing the correct imager for an application has never been a simple task. Varied applications have varied requirements. These requirements impose constraints that affect performance and price. With these complexities at play, it is not surprising that it is impossible to make a general statement about CMOS versus CCD imagers that applies to all applications.

CCDs that are specifically designed to be highly sensitive in the near infrared are much more sensitive than CMOS imagers.

Bar lights are a versatile illumination that can be utilised in many lighting conditions. wenglor bar lights are a linear array of LEDs with ...

CCDs can be fabricated with thicker epi layers while preserving their ability to resolve fine spatial features. In some near infrared CCDs, the epi is more than 100 microns thick, compared to the 5 to 10 micron thick epi in most CMOS imagers. The CCD pixel bias and epi concentration also has to be modified for thicker epi, but the effect on CCD circuits is much easier to manage than in CMOS.

During the Roman Empire, silver mirrors were still widely used, even by maidservants. Glass mirrors were first mentioned in books during the first century AD, when Roman author Pliny the Elder included them in his encyclopedia, Natural History, but before they were commonly used. This literary mention paralleled the discovery of soda-lime glass and glass-blowing.

cmos imagesensor是什么

So far, we have focused on the performance differences between CMOS and CCD imagers. It would be naive to assume that business decisions are based on performance trade-offs alone. What matters more to many business decision-makers is value, or the performance received for the price paid.

In machine vision, area and line scan imagers rode on the coattails of the enormous mobile phone imager investment to displace CCDs. For most machine vision area and line scan imagers, CCDs are also a technology of the past.

Fire-gilding developed at the start of the European Renaissance, resulting in an even and very reflective tin coating (tin amalgam) to be used for glass mirrors. The molten-lead method that predated this new technique had produced more thermal show to the glass. In the 16th century, Venice became the center of using fire-gilding for mirror production, and it remained the leader in this technique for another century.

“The very first mirrors most probably were quiet pools of water and rock or clay containers of water,” claims vision scientist Dr. Jay Enoch. But by around 6,000 BC, the people of Anatolia (modern-day Turkey) used polished stone, including obsidian, to manufacture mirrors.

Elsewhere, mirrors are being used as subjects in contemporary art to take on new, or spotlight old, meanings. Portuguese artist Joana Vasconcelos, for example, created a 17-foot-tall sculpture of a carnival mask from baroque-style mirrors. I’ll Be Your Mirror (2018) is confrontational, and is meant to remind viewers of “how little information a mirror actually provides.” Mirrors are juxtaposed with a mask to show that mirrors, like masks, “only reveal what the wearer wants to reveal.”

As Katy Kelleher, author of The Ugly History of Beautiful Things, writes, “…no matter what they’re made of, mirrors are objects of mystery, obsession, and fear. They’re simple yet complex. They’ve been used for purposes both sacred and profane. We love them, yet we’re loath to admit it.”

Ms.Cici

Ms.Cici

8618319014500

8618319014500