Meaning of Coaxially in Hindi - Translation - coaxially meaning

M12 A-coded connectors from binder are IP69K-rated, as well as Ecolab and FDA certified, making them ideal for harsh washdown applications in the food and beverage and chemical industries.

M12A coded pinout

The new modular LED light bar from Vision X revolutionizes LED off road lighting. Never before has there been such a customize-able, affordable, ...

202167 — ... optical zoom and digital zoom. Optical zoom leverages the physical change in a lens to adjust the distance between camera sensor and subject ...

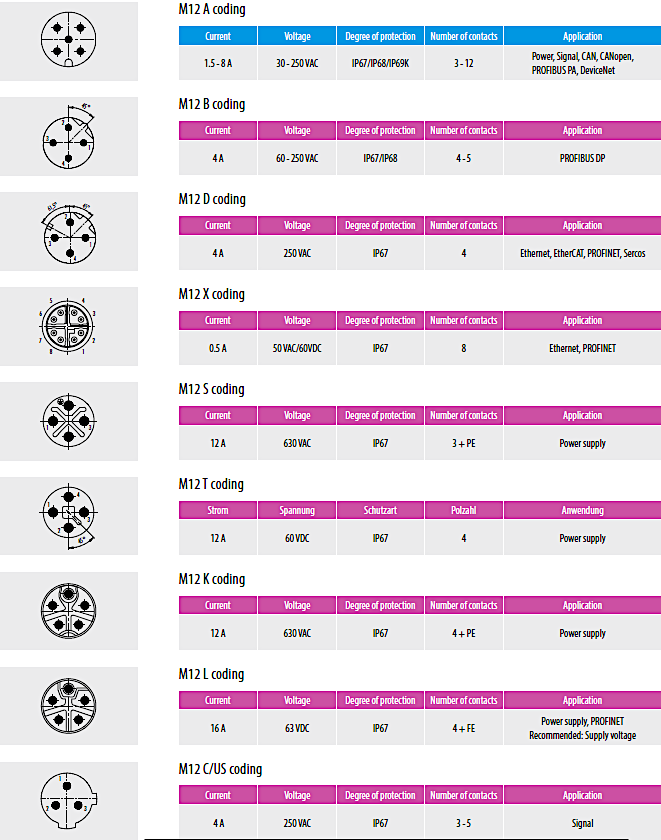

M12 connectors are available in a wide variety of configurations that enable designers to specify unique pin layouts, locking features, and coding features to suit the needs of a specific application.

M12D code pinout

In general, however, the focal length is measured from the rear principal plane, rarely located at the mechanical back of an imaging lens; this is one of the reasons why WDs calculated using paraxial equations are only approximations and the mechanical design of a system should only be laid out using data produced by computer simulation or data taken from lens specification tables. Paraxial calculations, as from lens calculators, are a good starting point to speed the lens selection process, but the numerical values produced should be used with caution.

Die neuen 2-Takt-Mini-Motocross-Bikes MC 50 und die MC 65 von Gas Gas wurden für 2024 überarbeitet. Die Liste der wichtigen Neuerungen an beiden Bikes ist ...

Knowledge Center/ Application Notes/ Imaging Application Notes/ Understanding Focal Length and Field of View

In addition to high signal integrity, Industry 4.0 applications demand ever more compact components and connectivity solutions, even as power and data transmission needs grow. Increasingly smaller devices and sensors are transmitting more data, which requires more connection points and means that connectors must deliver the same — if not greater — power density in a smaller footprint.

M124pinConnector Color Code

202134 — The given statement is true. Focal length is always negative for concave lens. Focal length is always positive for convex lens.

Be aware that Equation 6 is an approximation and will rapidly deteriorate for magnifications greater than 0.1 or for short WDs. For magnifications beyond 0.1, either a fixed magnification lens or computer simulations (e.g. Zemax) with the appropriate lens model should be used. For the same reasons, lens calculators commonly found on the internet should only be used for reference. When in doubt, consult a lens specification table.

While it may be convenient to have a very wide AFOV, there are some negatives to consider. First, the level of distortion that is associated with some short focal length lenses can greatly influence the actual AFOV and can cause variations in the angle with respect to WD due to distortion. Next, short focal length lenses generally struggle to obtain the highest level of performance when compared against longer focal length options (see Best Practice #3 in Best Practices for Better Imaging). Additionally, short focal length lenses can have difficulties covering medium to large sensor sizes, which can limit their usability, as discussed in Relative Illumination, Roll-Off, and Vignetting.

As applications require higher-speed connections, X-coded connectors like these M12 X-coded female connectors from binder will likely replace D-coded connectors.

On the device side, they are used for data transmission, pulling data from devices and transmitting it to the application, where data is aggregated to provide information to the user. M12 connectors also make the connections between programmable logic controllers (PLCs), sensors, input/output (I/O) blocks, and wireless access points (WAPs) and can transmit high levels of power for extended periods of time in applications such as alternating current (AC) motors and drives, motor control switches, and low-voltage applications like fieldbus Ethernet components and network devices.

Note: Horizontal FOV is typically used in discussions of FOV as a matter of convenience, but the sensor aspect ratio (ratio of a sensor’s width to its height) must be taken into account to ensure that the entire object fits into the image where the aspect ratio is used as a fraction (e.g. 4:3 = 4/3), Equation 7.

M125pinCable

As previously stated, some amount of flexibility to the system’s WD should be factored in, as the above examples are only first-order approximations and they also do not take distortion into account.

They offer not only the infrared dot projection feature but also include a variety of star patterns for an immersive experience. Perfect for home entertainment, ...

The USB-UIRT contains a small micro-controller which is capable of 'listening' for Infrared codes which are transmitted from most remote controls. When IR ...

If the required magnification is already known and the WD is constrained, Equation 3 can be rearranged (replacing $ \small{ \tfrac{H}{\text{FOV}}} $ with magnification) and used to determine an appropriate fixed focal length lens, as shown in Equation 6.

Originally designed to reduce the size of the original 7/8” standard sensor connectors, M12 connectors have an outside diameter of just 12mm. This small footprint makes M12s well suited for applications with little available space, including automation control systems, telemetry modules, compact LED lighting fixtures, and value actuators.

M125pinpinout

The focal length of a lens is a fundamental parameter that describes how strongly it focuses or diverges light. A large focal length indicates that light is bent gradually while a short focal length indicates that the light is bent at sharp angles. In general, lenses with positive focal lengths converge light while lenses with negative focal lengths cause light to diverge, although there are some exceptions based on the distance from the lens to the object being imaged.

The 14.25° derived in Example 1 (see white box below) can be used to determine the lens that is needed, but the sensor size must also be chosen. As the sensor size is increased or decreased it will change how much of the lens’s image is utilized; this will alter the AFOV of the system and thus the overall FOV. The larger the sensor, the larger the obtainable AFOV for the same focal length. For example, a 25mm lens could be used with a ½” (6.4mm horizontal) sensor or a 35mm lens could be used with a 2/3” (8.8mm horizontal) sensor as they would both approximately produce a 14.5° AFOV on their respective sensors. Alternatively, if the sensor has already been chosen, the focal length can be determined directly from the FOV and WD by substituting Equation 1 in Equation 2, as shown in Equation 3.

M12 technology continues to evolve as the applications they serve become more connected. Manufacturers of M12 connectors are adding new features to meet the needs of the robotics, automation, food and beverage, alternative energy, transportation, and cellular communication industries. The flexibility and customization potential for these versatile and powerful connectors helps make them an enduring choice for industrial environments.

... MLH Fellowship. The MLH Fellowship is a remote educational program that provides up-and-coming developers with real world hands-on experience working on ...

Coding: On the plant floor or in the field, users must be able to disconnect existing connectors for maintenance or replacement and install new connectors quickly, especially in applications where connections must remain dust- and/or water-tight. M12 connectors are easily installable and clearly coded to reduce the chance of accidental mismating.

Smart Vision Lights (SVL) Camera to Light (CTL) Machine Vision LED Illuminators. MORE LED Ring Lights for Telecentric Lenses.

Mating cycle ratings are also an important consideration for machine builders choosing a connector for their application. Connector mating cycles are determined by the properties of the contact and plating materials used, as well as the thickness of the plating. Cheaper connectors, such as tin-plated copper alloy contacts, will not perform as well as those made with corrosion-resistant materials, such as gold-plated beryllium copper contacts, which are typically rated for more than 100 mating cycles.

Field of view describes the viewable area that can be imaged by a lens system. This is the portion of the object that fills the camera’s sensor. This can be described by the physical area which can be imaged, such as a horizontal or vertical field of view in mm, or an angular field of view specified in degrees. The relationships between focal length and field of view are shown below.

The focal length of a lens defines the AFOV. For a given sensor size, the shorter the focal length, the wider the AFOV. Additionally, the shorter the focal length of the lens, the shorter the distance needed to obtain the same FOV compared to a longer focal length lens. For a simple, thin convex lens, the focal length is the distance from the back surface of the lens to the plane of the image formed of an object placed infinitely far in front of the lens. From this definition, it can be shown that the AFOV of a lens is related to the focal length (Equation 1), where $ \small{f} $ is the focal length and $ \small{H} $ is the sensor size (Figure 1).

... sign recognition system are standard. A full list of safety features and technologies can be viewed within the Technical Report (see download link) ...

While most sensors are 4:3, 5:4 and 1:1 are also quite common. This distinction in aspect ratio also leads to varying dimensions of sensors of the same sensor format. All of the equations used in this section can also be used for vertical FOV as long as the sensor’s vertical dimension is substituted in for the horizontal dimension specified in the equations.

M124 pinout

\begin{align}\text{AFOV} & = 2 \times \tan^{-1} \left( {\frac{50 \text{mm}}{2 \times 200 \text{mm}}} \right) \\ \text{AFOV} & = 14.25° \end{align}

When using fixed focal length lenses, there are three ways to change the FOV of the system (camera and lens). The first and often easiest option is to change the WD from the lens to the object; moving the lens farther away from the object plane increases the FOV. The second option is to swap out the lens with one of a different focal length. The third option is to change the size of the sensor; a larger sensor will yield a larger FOV for the same WD, as defined in Equation 1.

Note: Fixed focal length lenses should not be confused with fixed focus lenses. Fixed focal length lenses can be focused for different distances; fixed focus lenses are intended for use at a single, specific WD. Examples of fixed focus lenses are many telecentric lenses and microscope objectives.

M12 connectors are ideal for industrial environments in part because they offer superior performance in harsh conditions. M12 connectors offer a minimum of IP67-rated environmental protection against dust and water and also protect against impact, vibration, UV exposure, and temperature cycling. For the most demanding applications, such as those subject to frequent washdowns, they are also available with IP68 and IP69K sealing.

M12 connectors can transmit impressive amounts of data and power in rugged industrial environments and feature several critical features that enhance ruggedness, reduce interference, and enable flexibility. As such, they are sure to remain essential components as Industry 4.0 applications continue to expand and mature.

M128pinwiring diagram

Pins: M12 connectors are available with 3, 4, 5, 8, or 12 pins. The ideal pin-count depends on the application. For example, most sensors and power applications use three or four pins, while PROFINET and Ethernet use 4 and 8 pins, and 12 pins are for signal requirements.

Another way to change the FOV of a system is to use either a varifocal lens or a zoom lens; these types of lenses allow for adjustment of their focal lengths and thus have variable AFOV. Varifocal and zoom lenses often have size and cost drawbacks compared to fixed focal length lenses, and often cannot offer the same level of performance as fixed focal length lenses.

Example 2: For an application using a ½” sensor, which has a horizontal sensor size of 6.4mm, a horizontal FOV of 25mm is desired.

IfmM12pinout

In many applications, the required distance from an object and the desired FOV (typically the size of the object with additional buffer space) are known quantities. This information can be used to directly determine the required AFOV via Equation 2. Equation 2 is the equivalent of finding the vertex angle of a triangle with its height equal to the WD and its base equal to the horizontal FOV, or HFOV, as shown in Figure 2. Note: In practice, the vertex of this triangle is rarely located at the mechanical front of the lens, from which WD is measured, and is only to be used as an approximation unless the entrance pupil location is known.

Although M12 connectors have been in widespread use for decades — long before the Internet of Industrial Things (IIoT) or Industry 4.0 was even a concept — they have recently become the preferred connector for Industrial Ethernet. Designers and original equipment manufacturers (OEMs) are incorporating M12 connectors into new machines as industrial environments become increasingly connected. They are also using these connectors to update existing infrastructure. With backwards compatibility, using M12s to replace older and less robust technology is relatively simple and cost-effective.

Roman asked these questions to series host and producer, Emmett FitzGerald. If you want to ask a question at the next AMA, make sure to join our Discord server ...

Once the required AFOV has been determined, the focal length can be approximated using Equation 1 and the proper lens can be chosen from a lens specification table or datasheet by finding the closest available focal length with the necessary AFOV for the sensor being used.

Note: As the magnification increases, the size of the FOV will decrease; a magnification that is lower than what is calculated is usually desirable so that the full FOV can be visualized. In the case of Example 2, a 0.25X lens is the closest common option, which yields a 25.6mm FOV on the same sensor.

Hard-wired M12 connections also offer some advantages over wireless connections, including the intrinsic security of physical connections and protection from interference, which is especially critical in IIoT-enabled factories filled with electromagnetic interference (EMI), such as radio frequency interference (RFI). Unseen and unheard by people, this electronic noise pollution frequently interferes with high-precision sensors already taxed by the physical noise and vibrations of a busy factory floor.

Generally, lenses that have fixed magnifications have fixed or limited WD ranges. While using a telecentric or other fixed magnification lens can be more constraining, as they do not allow for different FOVs by varying the WD, the calculations for them are very direct, as shown in Equation 4.

A connector or cable assembly choice for a specific application can be further customized by selecting application-specific options, including:

A fixed focal length lens, also known as a conventional or entocentric lens, is a lens with a fixed angular field of view (AFOV). By focusing the lens for different working distances (WDs), differently sized field of view (FOV) can be obtained, though the viewing angle is constant. AFOV is typically specified as the full angle (in degrees) associated with the horizontal dimension (width) of the sensor that the lens is to be used with.

Ms.Cici

Ms.Cici

8618319014500

8618319014500