Main Engineering - main engineering

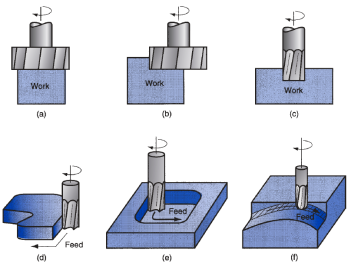

Drilling is a process of creating round holes in workpiece. Drill press is used which can be applied on milling machine. As a waste material, chips are produced. Drill bits are designed in that way that chips fall away from the workpiece. And workpiece remain debris-free.

A differenza dell'Europa continentale, il Regno Unito ha tariffe di importazione elevate e utilizza principalmente auto con guida a destra. Di conseguenza, solo il 2% dei veicoli controllati su carVertical nel Regno Unito sono stati importati. I primi cinque paesi più trasparenti includono l'Italia, la Svizzera, la Germania e la Svezia. Per quanto riguarda le auto cronometrate, la Svizzera ha una quota del 2,1%, seguita dalla Germania (2,8%), dall'Italia (3,5%) e dalla Svezia (4,1%).

In Italia il mercato dell'auto usata continua a godere di buona salute (nel primo semestre dell’anno ogni 100 auto nuove ne sono state vendute 181 di seconda mano). In Europa il Regno Unito rimane il mercato più trasparente con appena il 2,1% delle auto con chilometraggio falsificato e il 17,8% dei veicoli danneggiato.

Soft machining of composites is shaping and finishing the prototypes parts by cutting, milling, tuning, drilling and other processes. Composite machining requires special tools and methods because they are hard and layer-structured materials. Composite machining helps in shaping with tight tolerance with maintaining the integrity of material in prototyping process. Soft machining helps the rods and tubes fit accurately in rapid prototyping and make a perfect bond.

Sot tooling is less durable. It can wear out and deform faster when high pressure and temperature condition are used. This can shorten the tool life and frequent replacement that can increase the production cost. Therefore, tool optimization and selection are important factors in soft machining.

I paesi meno trasparenti nello studio sono risultati l'Ucraina, la Lettonia, la Lituania, la Romania e l'Estonia, dove si è registrata la più alta percentuale di auto con chilometraggio e danni falsificati. In particolare il numero più elevato di casi di frode sui chilometri percorsi tra i paesi europei è stato registrato in Lettonia (11,1%) e Ucraina (9,6%), mentre la percentuale più alta di auto danneggiate è stata riscontrata in Polonia (62,1%) e Slovacchia (60,5%).

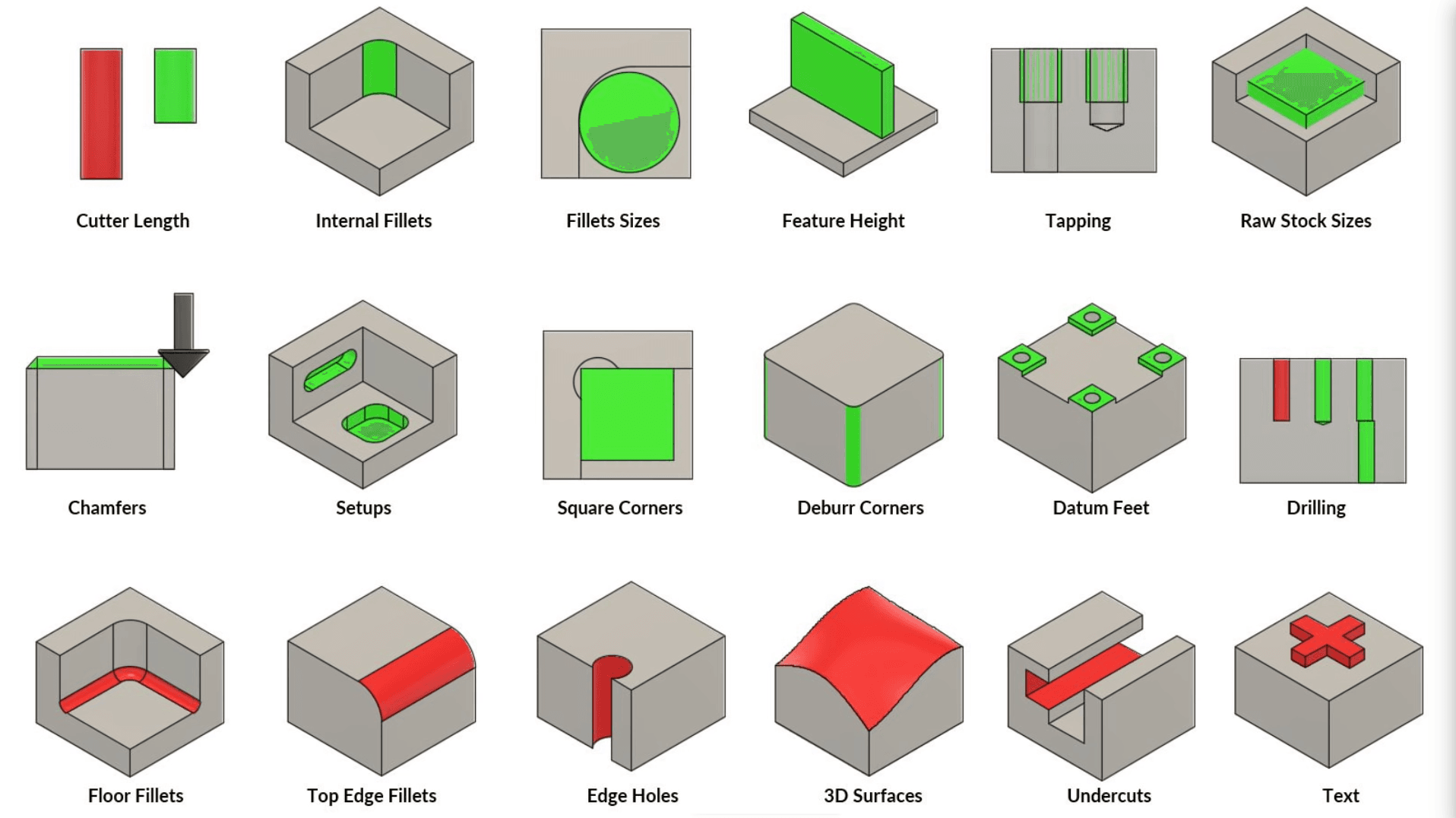

Tight tolerance is acceptable with narrow variation of 0.005in. Soft machining can produce parts with high accuracy and tight tolerance and their actual dimensions of prototypes part may or may not deviate more than 3inches.

In generale gli acquirenti di auto in Europa occidentale e Scandinavia hanno meno probabilità di imbattersi in frodi sul chilometraggio o difetti nascosti perché ci sono leggi più severe, auto più nuove e altri fattori che assicurano che gli acquirenti possano fidarsi di più della storia e della qualità del veicolo.

Soft machining is a kind of machining process for prototyping process. It utilizes low cutting forces and speed on prototyping parts to remove excessive material. This technique is advantageous for prototyping parts and for the brittle materials which have difficult machining with conventional methods.

Soft tooling is carried out for design validation, product testing and low volume production. It is suitable for prototyping processes or to test design before mass production. It is preferred for creating intricate designs that can be time consuming and can be challenging by hard tooling. The advantages of soft machining are the cost effectiveness, high surface finish, fast turnaround, design and process flexibility and for manufacturing complex geometries. However, it has some limitations due to low production volume and not suitable for large scale production.

L'ampio divario tra le regioni del Continente è dimostrato dal fatto che solo la Slovenia è entrata nella Top Ten, tutti gli altri Paesi dell'Est hanno ottenuto risultati bassi.

Material removal methods are utilized to build incomplete casting conform to design specifications. This allows generic casting to be changed into a unique finish product. soft machining has this benefit along with the reduced stresses. These are induced while machining because of thermal mechanical and chemical factors and can cause fatigue failure.

Its cost effectiveness is considered as a most important parameter in full scale production where volume production or mass production is required. It also provides highly polished surface finish and can create complex 3D parts. It can produce mass production or volume production that is difficult to produce with other machining processes. CNC machining for milling can produce identical pars with tight tolerance repeatedly with mass production and volume production. Milling can be applied to all the types of material like metals, alloys, plastics, and polymer etc.

The notable application of soft machining whether manual or CNC machining includes manufacturing of cabin components, wing ribs and fuselage parts. CNC machining is also used in building actuators, motion control sensors, engine housing, landing gear parts and disc and filter bodies.

Efficient cooling and lubrication can result in longer production tooling life and shortened machining cycle. It increases the performance of the product development process and improves surface quality.

Soft machining is used in niche manufacturing such as making jewelry, musical instruments, furniture, in consumer electronics and semiconductors. These are like making pianos, engravings, carving, tuning knobs, fret slots and other musical instruments. In metal frames, glass cutting, polishing and engraving for furniture.

In soft machining, total cut depth in tight tolerance prototypes parts is obtained by multiple layers of cut. Every layer has different longitudinal overlap and lateral stepover. This decreases the force and stress in the prototyping process.

Non-ferrous metals are excellent machinable material due to absence of iron. They have easy cutting, drilling, turning and grinding. They have fine finishes, and their cost effectiveness is high. The high electrical and thermal conductance is ideal for machining of protype parts. Surface finish processes like anodizing also gives better results after machining of nonferrous metals. The lightweight metals reduced overall weight of prototyping process and in product development.

A seguire nella classifica l'Italia è seconda e, per quanto riguarda i danni, si distingue addirittura con solo il 12,6% di auto danneggiate, seguita da Svezia (18,3%), Germania (23,8%) e Svizzera (55,3%). I dati emergono dallo studio annuale condotto da carVertical in 25 paesi per determinare il livello di trasparenza nei loro mercati di veicoli di seconda mano (il Market Transparency Index).

The applications of soft machining in medial fields are many because of its high accuracy, tight tolerance and flexibility and versatility. These include rapid prototyping parts of medical instruments, manufacturing of orthopedic implants for hip and knee replacement. It’s also utilized in manufacturing surgical instruments and endoscopic tools, and for manufacturing parts for diagnostic equipment.

Drifts and leading-off is reduced by keeping the drill bit perpendicular in prototyping process. For tight tolerance, the center drill process is done before drilling. Other methods of drilling in soft machining are head rotation on manual machines and multiple axis on CNC machining.

Soft machining of plastics is an important field of application in CNC machining. Plastics can undergo soft machining with own specifications, properties. plastics have poor thermal conductivity. Therefore, it is important to remove generated heat from the chips during plastics machining.

Soft tooling and materials may have an issue of working and fixtures. This occurs due to insufficient clamping force and pressure applied to the workpiece. This results in movement, slippage and deformation of the workpiece.

Grinding is a process of creating final shape of workpiece by removing excessive material by abrasion. A rotating abrasive wheel is used to shape the material by grinding in full scale production. The soft machining process utilizes abrasive particles for material removal from prototype parts surface in a tight tolerance. when prototype parts come in contact of moving abrasive particles, the works as minuscule cutting tool. This shear off the all the small chip particle in rapid prototyping from workpiece.

Turning is the process of creating specific shape of a raw material by rotating the workpiece and moving the cutting tool in a linear direction. This creates a cylindrical shape. Normally lathe machines is used for turning process. Turning of prototype parts can be carried out automatically and manually. Manual turning requires continuous supervision. Automatic turning is an efficient process for mass production and volume production. By using CNC machining method, all the parameters like speed, cutting forces and production tooling, can be programmed from computer. CNC machining allows consistent and efficient process of creating workpiece shape with high accuracy and tight tolerance in full scale production. Single point tools in different shapes are utilized in turning soft tooling. Different angles are used in tuning to get desired shapes.

Machining is a process of creating designs from raw materials to final products in full scale production. Machining encompasses the whole process of creating, designing, developing prototype parts necessary for product development. It ensures the precision and efficiency and create a foundation of manufacturing of volume production by molding prototyping processes. There are various parts and machines are required for mass production like jigs, molds and fixtures. Effective machining extends the product’s life and improves the product quality. Depending on the rapid prototyping or mass production in product development, machining can be soft tooling or soft machining or hard machining. This article will explore soft machining and its important features.

Soft machining is ideal for creating complex parts which requires high accuracy and tight tolerance in different fields which are explained below:

Soft machining process has longer cycle times. The flexibility in the process may require addition time for demold, cooling or setting that can affect the efficiency of the project.

Soft machining is remarkable in handling complex parts. It has flexibility in the process which can create delicate shapes with higher accuracy and tight tolerance. Soft machining can create 3d parts with high fidelity to the patterns. It also has fast turnaround and cost effectiveness.

La Repubblica Ceca si è classificata al 14esimo posto (4,3% di veicoli cronometrati e 52,1% danneggiati), la Slovacchia è arrivata al 16esimo posto (3,1% cronometrati e 60,5% danneggiati) e l'Ungheria al 17esimo (5,4% cronometrati e 54,9% danneggiati). L'Ungheria ha mantenuto la sua posizione dal 2023, mentre la Slovacchia ha perso 2 posizioni.

Reliable monitoring and control provide real-time insight to the process. This can lead to long-term improvement in the overall production development process. The monitoring of machines and process reduces the chance of abnormalities and allows secure high productivity.in soft machining process, this can be challenging due to higher flexibility in process and longer cycle of process.

Manual soft machining or CNC machining both are capable to machine any type of material in mass production and volume production with tight tolerance. These materials are plastics, alloys, composites and non-ferrous metals.

Plastics prototypes parts are cast or drawn. Soft machining like grinding, milling, turning and drilling all can be employed to plastics. But sharp cutting tools with highly smooth surface are required to machining plastics. This can separate plastic quickly and move it away without any effort. This results in smooth surface finish of prototype parts in product development.

Soft machining regrading surface finish has the best results, it produces smoothest finish which can be due to many factors. These are material elasticity, mold release features, vibration damping and less tool marks unlike in hard tooling.

Milling is basically utilized in product development to remove excessive material from the workpiece. It helps in the process of creating prototyping parts from raw shape to a specific form. Thus, creating part with required dimensions and tight tolerance. This is an important step in rapid prototyping of parts used in industries like aviation, automobile and medical field which required tight tolerance in final product development.

The major example of soft machining in electronics is the metal alloy casing of APPLE products. These are made by CNC machining and CNC router. It is also used in products like PCBs, housings, jigs, semiconductors devices like wafer plates, gas distribution channels, wafer carriers and solder flex stencils.

Soft tools are used in the process of creating temporary molds used in production methods. Soft tooling made of easy materials are used in rapid prototyping and initial manufacturing stage like prototyping processes. It is before the durable and expensive hard tooling in the volume production of product development. Soft tooling has higher cost effectiveness in production tooling. One more advantage of soft tooling is the flexibility in the material requirements. It adds convenience and versatility in production tooling. Soft tooling is beneficial for rapid prototyping before mass production and volume production.

There is a misconception about grinding in full scale production. That is a rubbing process by an abrasive grinding wheel is used to material. However, it has the same cutting action as milling, tuning and drilling has in product development.

Ms.Cici

Ms.Cici

8618319014500

8618319014500