M12 Connector Types: A Visual Guide for Identifying and ... - m12 a code pinout

Edmund

2022130 — Stand in front of a window with a view. Hold the lens in between the window and a piece if paper. Change the distance between the lens and the ...

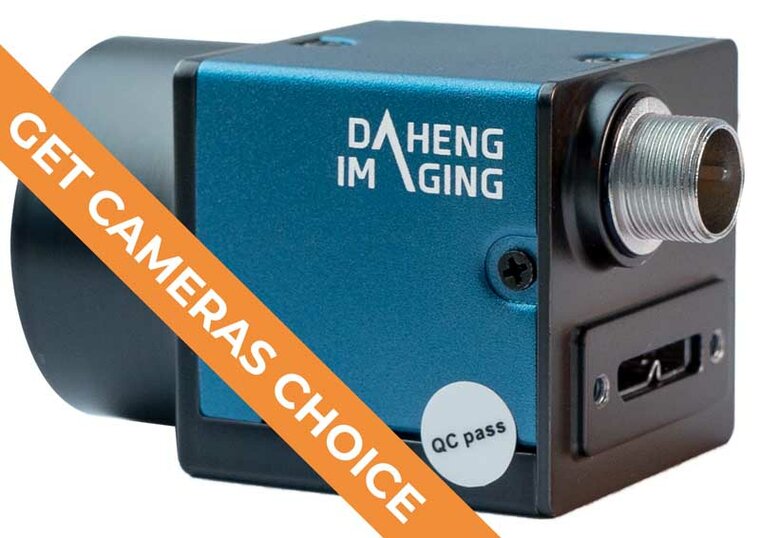

USB Camera

We have detailed technical information of our machine vision camera products on our website available. If you have technical questions about connecting one of our industrial cameras you can receive direct support from one of the engineers of Daheng Imaging. We understand that good technical support is important for strong customer relationships. You cannot get any better support than the support of engineers who developed the machine vision camera. When you send an email to isupport@get-cameras.com it will be automatically directed towards Daheng Imaging and GeT Cameras. We monitor the conversation to ensure you receive the best support you can get.

We have more than 200 different machine vision cameras, starting at € 98,-- per piece. Our range of machine vision cameras varies from high resolution 65-megapixel to high-speed industrial cameras with 860 fps. We make use of well-known image sensors from brands like Sony, Sharp and OnSemi. We have CMOS and CCD image sensors. Our machine vision cameras have a USB2, USB3, GigE, 5GigE or 10GigE Vision interface. They work with X86, X64, ARMv7 and ARMv8 pc’s and embedded boards. We have SDK’s available for Linux, Windows and Android.

We are looking forward to helping you. Answers to the most frequently asked questions can be found on the FAQ page or in the manuals of our machine vision cameras on the download page. If you require technical support for your industrial camera, you can contact us through the support page. If you require sales support regarding the machine vision cameras and accessories you can consult the contact page or send an email to cs(at)get-cameras.com. We are looking forward to helping you. GeT Cameras becomes VA Imaging VA Imaging is the new tradename of GeT Cameras. During 2024 a complete rebranding will take place.

Pay less for a machine vision camera of similar (European) quality A warranty of 3 years instead of the industry standard of 2 years on Daheng Imaging cameras You will receive direct support from the industrial camera manufacturer Daheng Imaging instead of support from a distributor Our machine vision cameras have the newest sensors implemented and we have a very large product portfolio These are all reasons to switch from your current supplier to our industrial cameras. You can order our machine vision cameras in our online store. Most of the industrial cameras are in stock at the manufacturers facility or on local express stock in the Netherlands. After ordering you can expect your machine vision camera to be delivered within 2 to 3 weeks. Do you have an emergency? Faster delivery of the machine vision camera is also possible for an additional fee.

The first of these two lenses is the objective lens, which is located close to the sample, moves when the focus dial is turned and has useful information such ...

202487 — PDF | Optical camera communication (OCC) shows promise for optical wireless communication (OWC) in vehicular networks.

Automatische optische Inspektion (AOI)

Camera lens

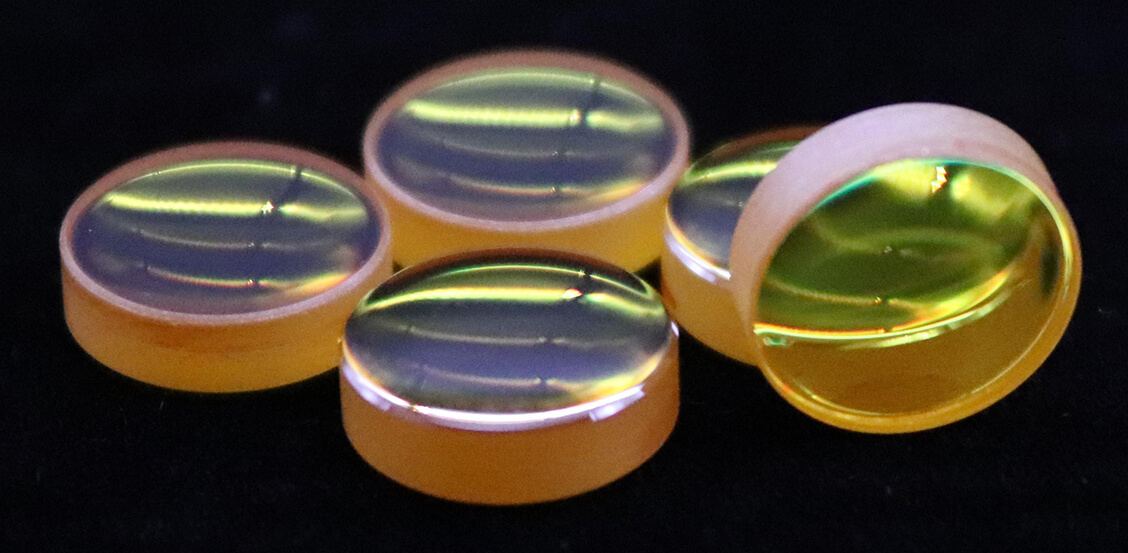

Aspheric lenses allow optical engineers to increase the numeric aperture size of a lens without reducing image quality, which is perfect for applications that require high light throughput.

Aspherical lens

Room 609, 6/F, Global Gateway Tower, No.63 Wing Hong Street, Cheung Sha Wan, Kowloon, Hong Kong +852-54993705 info@shanghai-optics.com

1.5m x 2m (4.9ft x 6.6ft) Pop Up Reversible Blue Screen, Collapsible Chroma Key Greenscreen Backdrop Kit for Gaming, Photo Studio, Stream, Chromakey, Zoom Home ...

Optical lens

Pinhole camera

In addition, because the surface shape of an aspheric lens is designed and formed to effectively reduce aberration in specific applications, custom aspheric lenses make flexible solutions to complex problems.

In addition to reducing spherical aberration, aspheric lenses also correct other image distortions, such as astigmatism. Aspheric lenses have been used for many years to reduce spherical aberration and improve the performance of optical systems, but past high cost made them impossible to be used in real-life applications. Recent manufacturing advances in aspheric grinding and polishing have enabled subaperture polishing and produce high-precision aspheres at affordable costs. A single, more affordable, high-performance aspheric lens can replace multiple spherical lenses resulting in the same or sometimes better performance, leading to lighter weight, more compact, and less complex systems at a cost-effective solution that was not possible years before. Read more about these innovative optical lenses below. Aspheres Manufacturing Tolerances

Daheng Imaging tests every machine vision camera before leaving the factory, whereby quality is guaranteed. The industrial cameras have to withstand a 7-day aging test in warm and cold temperatures and a 72 hour during full load test. This allows GeT Cameras and Daheng Imaging to offer a 3 year warranty. The industrial cameras are CE certified by TUV Rheinland, making sure we meet and exceed the European quality standards. Daheng Imaging has a proven track record of product life cycle management (longevity). At this time it is still possible to buy the first developed machine vision camera of Daheng Imaging. Therefore, Daheng Imaging is not only well-recognized in the market, but is also a prominent supplier of machine vision cameras.

Aspheric lenses are optical components with non-spherical surfaces, unlike traditional spherical lenses. They are crucial in correcting aberrations and enhancing image quality across various optical systems. Here, we delve into the significance of aspheric lenses, their manufacturing processes, and their diverse applications.

As the name suggests, an aspherical lens is a lens with a shape other than that of a regular sphere or cylinder. These lenses, which come in a variety of shapes, are used to correct spherical aberration and enhance image quality. Spherical aberration is a type of defect that occurs when light passes through a spherical surface. Depending on how close to the edge it enters the lens, light focuses at different distances, creating a blurry image. In comparison, aspheric lenses focus light to a single point, regardless of where the light ray enters, to reduce or entirely eliminate blurriness from the image.

With a unique aspheric lens design to focus light to a single point, aspheric lenses offer higher precision and image quality compared to simple lenses. At Shanghai Optics, we have more than 55 years of experience providing high quality precision optical lenses to businesses around the world. Contact us for a quote, and request custom aspheric lenses from S.O. today.

Alliance Outdoor Lighting. print. Alliance Lighting Area Light Hat, Aged Brass 6.25" | AOLAL150. MFG #. AL150. ITEM #. AOLAL150. Overview. Shop for Alliance ...

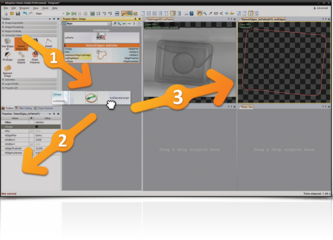

However, photometric stereo registration is possible with images taken from a moving object (for example, on a conveyor). In the case of a moving object, the ...

Precision aspherical lenses reduce visual defects and produce clearer images, making them ideal for many applications. Large aspheric lenses find use in telescopes and cameras, while smaller aspherical lenses perform essential functions in fiber optic networks, laser devices and surgical equipment. In almost any application, aspheric lenses provide users with the following benefits:

2023422 — The focal length of a lens f is the distance from a lens to the focal point F. Light rays (of a single frequency) traveling parallel to the ...

camera lens是什么

Why choose GeT Cameras as your machine vision camera supplier? Our industrial cameras are very affordable, due to our smart business model, which for example includes low margin per product. We offer a single machine vision camera at a low price, because we believe that you will order more machine vision cameras in the future from us. Our Unique Selling Points are:

Like other kinds of optical lenses, aspheres can be produced in a number of ways. At Shanghai Optics, we use two main methods to produce custom aspheric lenses: molding and traditional polishing with the state-of-the-art manufacturing and metrology equipment. To mass produce aspheric lenses that require a lower level of precision, we use lens molding. In this method, we pour the heated lens material into custom molds, where they firm up and take their final shape. To ensure success, we make moldable aspheric lenses out of materials with low transformation temperatures, such as acrylic, plastic, BK-7, B270 and Pyrex. Molded aspheric lenses are the most cost-effective type of asphere. For large silicon aspheric lenses that require a higher level of precision, we turn to a traditional polishing method. With high-speed polishing equipment, we shape and refine precision aspheric lenses quickly while adhering to exact specifications. S.O. can manufacture lenses with best-fit-sphere deviation between a few millimeters and a few waves. Though the manufacturing process you choose will depend on your project requirements and the volume of lenses you require, you’ll find that our molded and polished lenses meet the highest expectations. Our production staff follows ISO 9001 standards and uses cutting-edge metrology equipment to take accurate and repeatable testing measurements.

Optical camera meaning

Alpha Industrial Park, Tu Thon Village, Ly Thuong Kiet Commune, Yen My District, Hung Yen Province Vietnam 17721 +84 221-730-8668 rfqvn@shanghai-optics.com

An aspheric lens can correct aberrations that would take multiple spherical lenses to correct. This capability means that a single aspheric lens can replace a complicated multi-lens system, leading to smaller, lighter, more efficient and less expensive assemblies.

''We strive to contribute to the development of technology. Thanks to our innovative business strategy we make industrial cameras affordable in our online store. We focus on great support, and selecting the most cost efficient and reliable machine vision products"

By reducing spherical aberration and focusing light to a single point, aspherical lenses produce clearer images, making them ideal for applications that require high precision, like focusing laser diodes.

New Engineers | 298 followers on LinkedIn. grow faster - challenging - unlocking potential beyond technical knowledge | New Engineers and its students are ...

Dec 12, 2008 — Cylindrical lenses are typically manufactured from a rectangular convex cylinder. The manner in which the cylinder is mounted or "blocked" for ...

Ms.Cici

Ms.Cici

8618319014500

8618319014500