Lisa, Bright and Dark (TV Movie 1973) - bright and dark

Machine vision inspection systemsprice

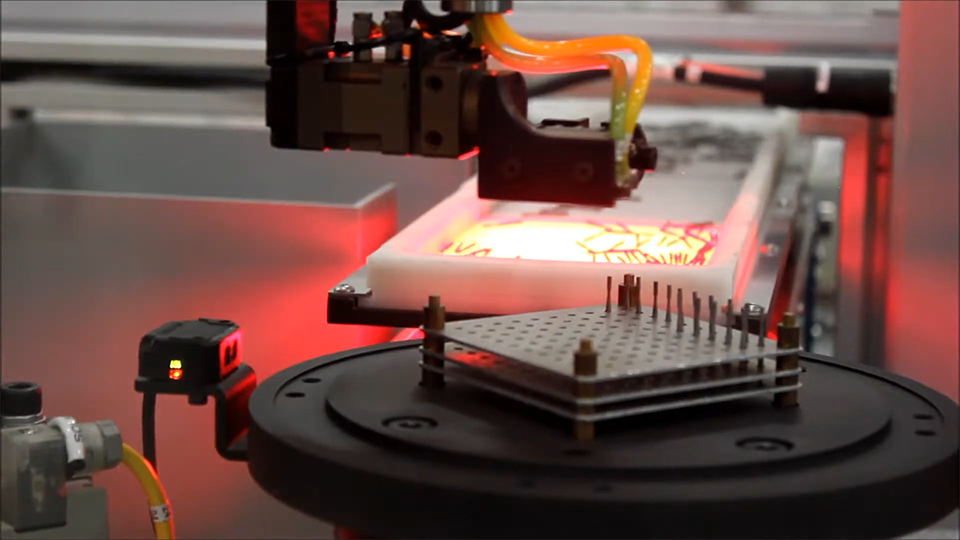

Machine vision uses a camera to create an image, then computer vision algorithms and tools process and interpret the image. It will then instruct other components in the system to act upon this data.

The integration of automation has become indispensable. Cobots, or collaborative robots, have emerged as a game-changer, particularly in material handling and process applications. These versatile machines work alongside human workers, enhancing efficiency, safety, and productivity. Read on to take a look at three key ways cobots are reshaping these sectors: vision inspection, dispensing, and palletizing.

Robotic vision inspection offers businesses a flexible and dependable solution for quality control issues by increasing productivity, eliminating quality slips and reducing rework. Robots can quickly and efficiently inspect every part produced, eliminating uncaught errors and incorrect orders.

The Common Data Model (CDM) is an abstract data model for scientific datasets. It merges the netCDF, OPeNDAP, and HDF5 data models to create a common API for many types of scientific data.

Vision systemsfor manufacturing

As a machine vision integrator, a Certified Vision Specialist has an expert level of experience and an in-depth technical understanding of machine vision applications, including the best components and technologies for your specific project needs.

Quality in manufacturing improves with robotic vision inspection because robots can inspect every part produced. Conventional, off-line quality inspection involves checking only a small percentage of parts.

Cameravision inspectionsystem

1D robotic vision inspection systems analyze a digital signal one line at a time instead of looking at an entire picture at once. 2D vision inspection systems most commonly include inspection cameras that either capture 2D snapshots or builds a 2D image line by line.

Geo-interface to Air, Land, Earth, Ocean NetCDF (GALEON) is a Unidata-led interoperability experiment within the OGC (Open Geospatial Consortium). The object of GALEON is to establish standards-based protocols through which other communities can access datasets provided via Unidata technologies. This approach allows Unidata to make data available to other groups (e.g., hydrology, societal impacts, hazards research, etc.) without supplying complete end-to-end support of analysis and display client applications as we do for our core user community. The OGC standardization effort is currently centered on making Unidata's netCDF technology an international data encoding standard in its own right.

Vision systemsfor qualityinspection

Unidata embarks on new projects to help make its data and tools available to a broader, more diverse audience. The following are a list of netCDF-related projects between the Unidata Program Center and external collaborators.

If you use netCDF and want to provide a DOI/citation, see How to Acknowledge Unidata.

3D robotic vision inspection systems involve multiple cameras or one or more laser displacement sensors. Multi-camera 3D vision in robotic guidance systems provides the robot with part orientation data. 3D laser-displacement applications can use just one sensor to provide 3D information for height mapping, volume measurement, and surface inspection.

Bestmachine vision inspection systems

KEYENCEvisionSystem Price

Remtec is your qualified source for robotic vision inspection system integration. Our extensive experience includes expertise in the area of 3D Line Scanning. We are a Certified Vision Specialist for FANUC, a Cognex Certified System Integrator, and an industry leader in robotic vision and inspection technology across other platforms.

Automotive manufacturing, consumer product manufacturing, aerospace manufacturing and general industry have all benefited from industrial robotic vision inspection projects.

NetCDF is widely used and has a number of contributors ensuring its continued development.

Note: Much netCDF support is about installing on new combinations of platforms, compilers, and settings. If we don't have the platform or compiler required to reproduce the problem, we may not be able to provide much help.

Lighting in robotic machine vision applications plays a pivotal role in capturing an accurate and reliable image. Read more to consider the challenges posed by lighting in robotic machine vision applications and explore strategies to overcome them.

Vision inspectionsystem manufacturers

Our comprehensive services meet all project needs, from system design and development to installation and training. Contact us to discuss your project!

Problems with process inefficiencies, product quality, and uncaught errors cost businesses greatly in terms of lost productivity, missed delivery deadlines, and incorrect orders.

Machine vision inspection systemspdf

Machine vision technology uses digital sensors integrated into industrial cameras equipped with specially designed optics for capturing images. Keep reading for examples of machine vision in manufacturing.

Robotic vision inspection systems have become increasingly powerful and flexible, allowing inspection tasks to be integrated into robotic work cells. Robotic inspection systems offer substantial cost savings over traditional labor intensive inspection solutions.

NetCDF (Network Common Data Form) is a set of software libraries and machine-independent data formats that support the creation, access, and sharing of array-oriented scientific data. It is also a community standard for sharing scientific data. The Unidata Program Center supports and maintains netCDF programming interfaces for C, C++, Java, and Fortran. Programming interfaces are also available for Python, IDL, MATLAB, R, Ruby, and Perl.

A netCDF fact sheet provides a brief overview of the netCDF package and supported languages and platforms.

These losses result in lower profits and even damage to the reputation of a business. Thorough quality control procedures can only go so far, and staffing qualified personnel to inspect products and processes can be costly.

Remtec assists both new and experienced robot users with stand-alone or integrated robotic vision inspection systems. We have worked on a wide range of industrial robotic vision inspection projects in industries such as automotive manufacturing, consumer product manufacturing, aerospace manufacturing, and general industry.

Ms.Cici

Ms.Cici

8618319014500

8618319014500