Core technology of machine vision inspection

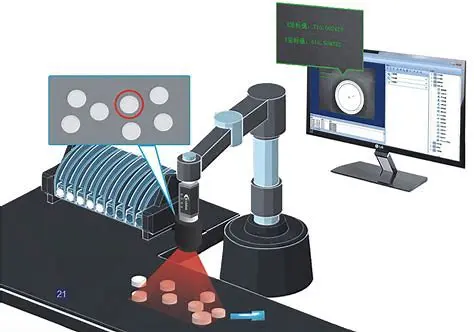

Machine Vision Inspection (MVI) uses computer vision technology to analyze and process images or videos to automatically detect, identify, and evaluate the features of target objects. It is widely used in industrial manufacturing, healthcare, agriculture, logistics, security, and other fields, replacing or assisting manual inspection tasks with high precision and efficiency.

Core Components

1. Hardware:

Image acquisition equipment: Industrial cameras, lenses, and light sources (such as LED ring lights and backlights).

Sensors: Used to trigger image acquisition or synchronize inspection processes.

Computing platforms: Industrial computers and embedded systems (such as GPU accelerators).

2. Software:

Image processing algorithms: Filtering, edge detection, binarization, and morphological operations.

Feature extraction and matching: Template matching, contour analysis, and keypoint detection (such as SIFT and ORB).

Machine learning/deep learning models: Used for complex defect classification (such as CNN, YOLO, and ResNet).

Control and decision-making systems: Trigger subsequent actions (such as sorting and alarms) based on inspection results.

Typical Application Scenarios

1. Industrial Manufacturing:

Defect Detection: Surface scratches, cracks, stains, etc.

Dimensional Measurement: Automated measurement of part geometric parameters (length, diameter, angle).

Assembly Verification: Checking for correct part installation (e.g., screw and label placement).

2. Medical:

Medical Image Analysis (e.g., lesion detection in X-rays and CT scans).

Pharmaceutical Packaging Integrity Inspection.

3. Agriculture and Food:

Fruit Sorting (color, size, defects).

Food Packaging Foreign Object Detection.

4. Logistics and Retail:

Barcode/QR Code Recognition.

Package Volume Measurement and Sorting.

Technical Advantages

1. High Efficiency: Processes hundreds to thousands of inspection objects per second.

2. High Precision: Micron-level measurement accuracy far exceeds manual visual inspection.

3. Consistency: Eliminates errors caused by fatigue or subjective judgment.

4. Cost Savings: Replaces repetitive manual labor in the long term.

Challenges and Difficulties

1. Complex environmental interference: Lighting variations, reflections, and background noise can affect image quality.

2. Small-sample learning: The scarcity of certain defect samples makes it difficult to train robust models.

3. Real-time requirements: High-speed production lines require low-latency processing (e.g., millisecond-level response).

4. Generalization: The model must adapt to product variations with different models and materials.

Development Trends

1. AI and Deep Learning:

Using Generative Adversarial Networks (GANs) to generate defect samples.

Self-supervised learning reduces reliance on labeled data.

2. 3D Visual Inspection:

Combining structured light and ToF (Time of Flight) cameras to achieve 3D defect detection.

3. Edge Computing:

Deploying lightweight models to embedded devices enables real-time edge detection.

4. Multimodal Fusion:

Combining data from multiple sensors, including vision, infrared, and X-ray, to improve detection accuracy.

Factors to Consider When Selecting a Machine Vision Inspection System

1. Inspection Requirements: Accuracy, speed, and target object type (size, material).

2. Environmental Conditions: Physical limitations such as lighting, temperature, and vibration.

3. Cost: Hardware (such as a high-resolution camera), software development, and maintenance costs.

4. Scalability: Support for future product iterations or the addition of new inspection features.

Machine vision inspection is gradually becoming a core technology in the field of intelligent manufacturing and automation. With the continuous advancement of algorithms and hardware, its application scenarios and reliability will continue to expand.

Ms.Cici

Ms.Cici

8618319014500

8618319014500