Lightpath LED CPS推广 - lightpath led

Tungsten incandescent lightbulb

Many parallel rays hit a convex mirror, they reflect outwards and travel directly away from an imaginary focal point (F).

Tungsten lightbulb vsincandescent

After understanding the meaning of reflection, you must also understand its two imperative laws. Using these laws, the reflection of the incident ray on various surfaces like a plane mirror, water, metal surfaces, etc can be determined. For instance, if we consider a plane mirror, here are the laws of reflection:

4 — Find 30 different ways to say ILLUMINATION, along with antonyms, related words, and example sentences at Thesaurus.com.

The lights' magnification states how many times larger its lens makes an object appear as compared to the actual size. Diopter refers to the curve of the lens.

To begin with, the reflection of light occurs whenever a ray of light falls on a smooth polished surface and bounces back. In other words, the ray of light approaching any surface results in the reflection of the light. Further, the ray of light which falls on the surface is known as an Incident ray while the ray of light which gets reflected is called a Reflected ray. Also, if a perpendicular is to be drawn between the two rays on the reflecting surface, it is known as a Normal.

2024530 — UV light has enough energy to break apart DNA, which is why it's effective at killing viruses in the air (and why you should wear sunscreen at ...

The tungsten halogen lamp is similar to an inert gas-filled lamp, except it contains a small quantity of an active halogen gas such as Bromine. The inert gas suppresses the evaporation of the tungsten filament, while the halogen gas acts to reduce the amount of tungsten that plates the interior wall of the lamp. The halogen gas reacts with the tungsten that has evaporated, migrated outward, and been deposited on the lamp wall. When the lamp wall temperature is sufficient, the halogen reacts with the tungsten to form tungsten bromide, which is freed from the wall of the lamp and migrates back to the filament. The tungsten bromide compound reacts at the filament of the lamp where temperatures close to 2500˚C cause the tungsten and halogen to dissipate. The tungsten deposits on the filament and is freed to repeat the cycle again. Unfortunately the tungsten is not deposited in the same zone where the evaporation took place so the filament still becomes thinner and eventually fails. The tungsten filament of a halogen lamp has two purposes. One is to generate light, and the second is to generate the heat necessary to obtain a wall temperature exceeding 250˚C. These lamps have been designed to maintain this required wall temperature when operated at design voltage. A reduction of voltage exceeding 10% from the design voltage will probably result in the wall temperature falling below the required 250˚C. Tests reveal that in most cases this reduced operating condition is not detrimental to the operation of the lamp. By the time the wall temperature drops to a point where the halogen cycle ceases to function, the filament temperature has diminished to a point where the tungsten evaporation is negligible. If wall blackening is noticed, the operating voltage range at which this occurs should be avoided. Burning the lamp at design voltage for a short period of time can usually clean up lamp blackening due to temporary operation in such a voltage range. However, on rare occasions halogen lamps derated more than 10% could experience an adverse reaction of the corrosive halogen attacking the tungsten filament causing premature lamp failure. The light output of a tungsten halogen lamp is more stable than a non-halogen gas lamp due to the cleaning action of the halogen gas on the lamp envelope. This feature coupled with the high color temperature of the light and long-life make these lamps very desirable for many industrial and scientific applications. The restriction on duty cycle due to the requirement to maintain the envelope of the lamp at sufficient temperature to initiate the halogen cycle is a disadvantage. However, in continuous duty applications it is relatively easy to provide correct ventilation to ensure the proper operating temperature.

A spherical mirror, whose reflecting surface is curved inwards, that is, faces towards the centre of the sphere, is called a concave mirror. A concave mirror can be compared to the inside of the spoon. Concave mirrors are the reflecting objects that are used in reflecting telescopes.

A spherical mirror whose reflecting surface is curved outwards is called a convex mirror. A convex mirror can be compared to the outside of a balloon. A convex mirror is used as a rear-view mirror and for security purposes.

It is because light hits different particles in the atmosphere and it scatters in all directions. Since blue has a smaller wavelength than Red, it is scattered more than red. That is why the sky looks blue.

Regular Reflection can also be referred to as Specular Reflection and is simply understood by using a plane mirror. This mirror used for reflection of light is not the regular mirror we see around us, rather it is a glass which is heavily coated with a uniform layer of highly reflective material such as a powder. As it is coated, the surface reflects all the light which falls on it i.e., there is not much variation in both the angles of reflection at multiple points. Due to this minimal variation, we can say that all the haziness and the blurriness are completely gone.

Operating tungsten halogen lamps at voltages exceeding design voltage is not recommended as the lamps are normally designed to their maximum limits. Lamp seal temperatures must not exceed 350˚C or oxidation of the molybdenum ribbon will occur resulting in premature lamp failure. Tungsten Halogen Lamps are ideal light sources for spectrophotometers as they provide broadband spectral radiation ranging from the ultraviolet, through the visible and into the infrared out to five microns. Some radiation output can be obtained at 320 and 340 nanometers.

Your contact details will not be published. Required fields are marked *Name.* Email Save my name, email, and website in this browser for the next time I comment. Contact no.* Submit

The number of images varies as per the angle between two mirrors. If we decrease the angle, the number of images increases. The number of images becomes infinite when the angle between the two mirrors is zero i.e, they are parallel. Here is a formula to calculate the number of images for diffused reflection of light:

T Koma · 2022 · 3 — Deep ultraviolet light (UV) is useful for the disinfection of microorganisms, including bacteria and viruses. Although genome damage by UV ...

The Blue Sky is because light hits different particles in the atmosphere and it scatters in all directions. Since blue has a smaller wavelength than Red, it is scattered more than red. That is why the sky looks blue.

Incandescent light

This diagram allows the user to determine the dependence of Current, Mean Spherical Candela, and Life on the value of voltage applied to the lamp as a percentage of the design voltage for that lamp. Draw a horizontal line through the percent of design voltage to be used and read the value of the calculated parameters on the right side of the diagram.

Tungstenbulb vs LED

When light hits very small gas particles, water droplets or even dust particles, it scatters the light. The amount of scattering of the light depends on the wavelength of light and the size of the particle. Light on the sky is filled with all the colours of the rainbow i.e. VIBGYOR. So, the question is ‘Why is the Sky Blue?’

ILT offers a large selection of gas-filled lamps in a variety of sizes, bases, and gas types including T-1 3/4, G4-G10 bases, Bi-pin, wire lead, MR3 - MR11 reflector assembies, with gasses including Halogen, Xenon, Argon and Krypton

For both regular and diffused reflection of light, a single mirror is used while when we take two mirrors, a single source of light can be reflected multiple times. This type of reflection is only possible when the intensity of the light becomes so low that we cannot see it. Infinite images will be formed in multiple reflections, as each image is the result of another image.

Absorb ABV2, ABV2 features vertical sound absorbing panels made of felt-like polyester made from at least 40% post-consumer recycled PET bottles and are ...

Tungsten Halogen Lamps are similar in construction to conventional gas filled tungsten filament lamps except for a small trace of halogen (normally bromine) in the fill gas. The halogen gas reacts with the tungsten that has evaporated, migrated outward, and been deposited on the lamp wall. As the quartz envelope wall reaches a temperature of approximately 250C, the halogen reacts with the tungsten to form tungsten halide, which is freed from the wall of the lamp and migrates back to the filament. The halide compound reacts at the filament where temperatures approximating 2,500C cause the tungsten and halogen to dissociate. The tungsten deposits onto the colder portions of the filament, and the halogen is freed to continue the cycle. The filament of a Tungsten Halogen Lamp has two purposes. One is to generate light, and the second is to generate the heat necessary to obtain a wall temperature exceeding 250C. These lamps have been designed to maintain this required wall temperature when operated at design voltage. A reduction of voltage exceeding 10% from the design voltage will probably result in the wall temperature falling below the required 250C. Tests reveal that in most cases this reduced operating condition is not detrimental to the operation of the lamp. By the time the wall temperature drops to a point where the halogen cycle ceases to function, the filament temperature has diminished to a point where the tungsten evaporation is negligible. If wall blackening is noticed, the operating voltage range at which this occurs should be avoided. Burning the lamp at design voltage for a short period of time can usually clean up lamp blackening due to temporary operation in such a voltage range. However, on rare occasions tungsten halogen lamps de-rated by more than 10% could experience an adverse reaction of the corrosive halogen attacking the tungsten filament causing premature lamp failure. Operating Tungsten Halogen Lamps at voltages exceeding design voltage is not recommended as the lamps are normally designed to their maximum limits. Lamp seal temperatures must not exceed 350C or oxidation of the molybdenum ribbon will occur resulting in premature lamp failure.

To explore the meaning of diffused reflection, let us consider reflective surfaces other than mirrors. The common surfaces which can be used for diffusion of light are comparatively rough as they are made up of different material than glass and contain some marks, scratches, dust or dents. All these things hamper the quality and brightness of reflection. Thus, the comparison of both the angles of reflection on such rough surfaces is completely distorted. In diffused reflection, the incident ray falls on different points and gets reflected in an entirely different direction and hence, we see non-shiny objects.

Incident Ray= It is the ray that falls on the surface Reflected Ray= The ray which is reflected from the surface Normal = Perpendicular on the polished surface P= Point of reflection i= Angle of Incidence r= Angle of Reflection

201713 — Illumination is the act of lighting something. Enlightenment could be similar, but it's also a term used for the beginning of the modernity age, ...

Gas filled lamps produce light from an incandescent filament operated in an inert gas atmosphere. The addition of the inert gas suppresses the evaporation of the tungsten filament, which increases the lifetime of the lamp or allows higher temperature operation for the same life. The normal gases used are Nitrogen, Argon, Krypton and Xenon. The cost rises dramatically as the rarer gases are used, particularly for Xenon, due to their very low natural abundance. The advantage of the higher atomic weight gases is they suppress the evaporation of the tungsten filament more effectively than the lower weight gases. This allows the filament of gas filled lamps to be run at temperatures up to 3,200 degrees Kelvin and achieve reasonable life times. The light from these lamps has a high blue content giving the light a pure white appearance. Gas-filled lamps require more power to achieve the same filament temperature than vacuum lamps. The surrounding gas cools the filament while suppressing evaporation, and reducing the migration of evaporated tungsten to the wall of the lamp. The higher operating temperature of gas-filled lamps produces more light output per watt of input power, which justifies their use in critical applications.

Tungstenbulb photography

The phenomenon of bouncing back of light falling on an object in the same medium is known as a reflection of light. For example: We are not able to see anything on entering a dark room but once we switch on the lights, everything will be visible. Reflection of light is a popular topic in Physics, listed in the Optics chapter. Let’s explore more about this topic through this detailed blog. Ref

From the tiny MicroLED range to the massively powerful Sirius, we have an LED illuminator to suit any size of project.

The reflection of light occurs whenever a ray of light falls on a smooth polished surface and bounces back. In other words, the ray of light approaching any surface results in the reflection of the light. The refraction of light occurs when a ray of light moves from one medium to another and it changes its direction of travel.

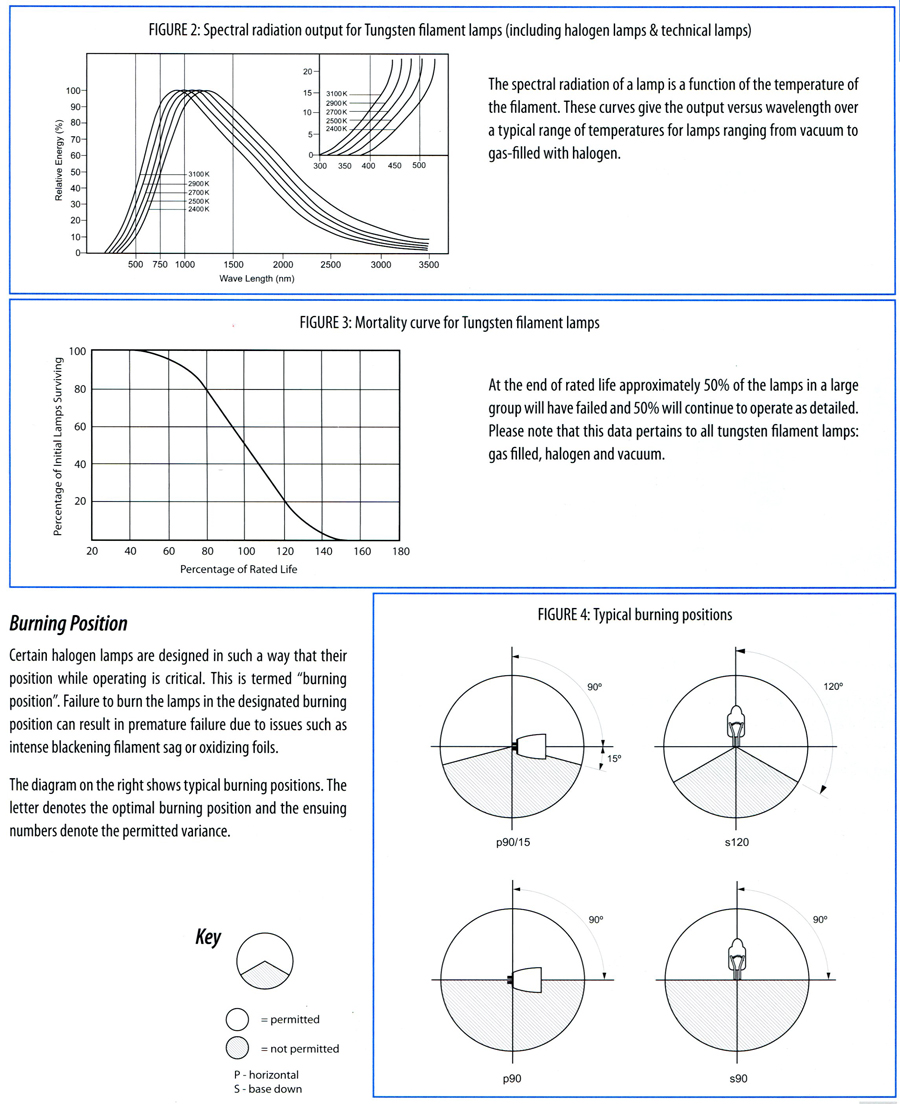

Lamp life expressed in hours is calculated at design voltage and under ideal laboratory conditions. Deviation from design voltage will result in decreased or increased values of lamp life. This deviation will also alter values of current consumption, brightness, and color temperature. These deviations should be used advantageously by the design engineer to enhance the technical lamp specifications for the specific application. Figure 1 is supplied to express percent variations in current, color temperature, and brightness when operating voltage differs from design voltage. Rated life as specified here is expressed in terms of hours. Rated life is calculated at design voltage, with alternating current, and under ideal laboratory conditions. In actual use, lifetime may be shortened as a result of hostile environments such as shock, vibration, and extreme temperatures. Life may be substantially increased, by selecting an operating voltage less than the design voltage. This decrease from design voltage will also result in a cooler filament providing increased resistance to shock and vibration. Because of slight variations in miniature lamp manufacturing and in the component parts it is impossible to have each individual lamp operate for exactly the life for which it was designed. Lamp life is rated as the average life of a large group of lamps.

Tungstenfilament

While exploring the basics of the reflection of light, it is also important to go through the different types of reflection. Whenever we change the basic elements or the form of basic elements involved in this phenomenon, the result also varies. Following are the main three types of reflection:

Below is technical and application information on ILT's Tungsten Halogen and Gas-Filled Lamps. Many of our lamps can be purchased right from our e-store. To speak with one of our lamp experts, inquire about a customized lamp, or to ask about a sample, contact us using the form here.

Thus, we hope that this blog has helped you understand the meaning, types and laws of reflection of light. Preparing for competitive exams like GRE, GMAT, IELTS or SAT? Sign up for an online demo session with our Leverage Edu career and we will assist in creating the right preparation strategy as well as providing you with the required study material and exam tips to ace your test successfully

202415 — Natural Sunlight as the Primary Source. At the heart of red and near-infrared light therapy lies the expansive spectrum of sunlight. The sun ...

Tungsten Halogen Lamps are ideal light sources for spectrophotometers as they provide broad band spectral radiation ranging from the ultraviolet, through the visible and into the infrared out to five microns. Some radiation output can be obtained at 320 and 340 nanometers. ILT Does NOT block UV radiation from our tungsten halogen lamps for this reason.

Description Precision spun .040 metal or phenolic baffle with deep grooved to reduce aperture glare and white flange. Non-reflected painted finish.

Custom Beam Light Collimated Lens. At the beam expander output, we work with a collimating lens to convert divergent light beams into parallel beams at the beam ...

The tungsten filament of a vacuum incandescent lamp is heated to temperatures where visible light is emitted by resistance heating. The filament acts as an electrical resistor, which dissipates power proportional to the voltage applied, times the current through the filament. When that power level is sufficient to raise the temperature to above 1000 degrees Kelvin, visible light is produced. As the power dissipated is increased, the amount of light increases and the peak wavelength of the light shifts to the blue. Typical vacuum lamps may have filament temperatures ranging from 1800 to 2700 degrees Kelvin. The light from the low temperature lamps appears reddish yellow while the high temperature lamps have a whiter appearance. The tungsten filament evaporates more rapidly as the temperature of the filament goes up. The evaporated tungsten particles tend to deposit on the glass envelope, causing over time, an increase in light output obstruction. Depending on the application, the light output obstruction could be high enough to end the useful life of the lamp. Eventually, the filament material will evaporate enough to cause the filament to break, completely ending the life of the lamp. Both of these effects are strongly dependent on the temperature of the filament, which is why long life vacuum lamps tend to be operated at the low end of the temperature range and the light has a yellowish appearance. The electrical resistance of the tungsten filament at room temperature is initially quite low. When electrical power is first applied to the lamp, a large inrush current causes rapid heating of the filament. The resistance of the filament rises to a value five to ten times the cold resistance, which causes the amount of current drawn by the lamp to stabilize and the lamp to emit a stable light output. Depending on the size of the filament, the in-rush period can be from tens of milliseconds to hundreds of milliseconds. This in-rush current requirement should be taken into account in the selection of the power source for a specific lamp application.

Ms.Cici

Ms.Cici

8618319014500

8618319014500