InLine 2.0 Lighting - in line lighting

Sizing a heat sink to strip lights is a crucial step for the longevity and efficiency of the lighting system. Here are the steps to size the heat sink for strip lights:

Thermal resistance refers to the ability of the heat sink to dissipate heat away from the LED. If the thermal resistance is too high, heat will build up and cause the LED to overheat and fail prematurely.

I decided before taking any shots that I wanted maximum depth of field to keep all of the flower arrangement tack sharp. So I began by setting my aperture at f/16 at ISO64. With a few minutes of testing, I arrived at six seconds for the proper exposure time.

Yongnuo also offers the YN360W Light Wand which is daylight balanced only and also outputs 2,560 lumens of light. It sells for just $81.00.

Overall, LED heat sinks are specifically designed for LED lighting. It provides a way to keep LEDs running at their best while also keeping them from becoming too hot. They work by transferring the heat away from the LEDs. This allows them to be cooler and more efficient.

It’s vital to ensure that it is correctly sized to maximize the efficiency of an LED heat sink. Also, adequately constructed and suitably installed. Verify that the heat sink is large enough to withstand the heat generated by the LED device. If it is too small, it won’t dissipate heat effectively. Additionally, selecting a high-quality material with good thermal conductivity is a must. This will help to ensure optimal performance.

Most LED heat sinks are not waterproof. However, some LED lights are designed with waterproof heat sinks. So you can use them in damp environments. It is essential to check the specifications of the LED light to determine if it is designed for use in a waterproof environment.

I do encourage you to pay close attention to LEDs, even if you aren’t planning on owning any yet and if you are just starting out – I would encourage you to consider LEDs because of the simplicity of using them and the fact that it is much easier to learn the subtleties of lighting with continuous light then it is with a flash.

Hybrid LED heat sinks are thermal management devices. They combine traditional metal heat sink materials with additional elements- heat pipes, vapor chambers, or phase change materials. And the inclusion of these extra components improves the heat dissipation capability of LED lighting systems. A hybrid LED heat sink aims to efficiently remove heat generated by the LED chips, preventing thermal damage. They also improve the performance and longevity of the LED system.

For this first setup I placed a Smith Victor CooLED100 in a Photoflex Medium-sized softbox in front of and above the lovely Monae. I have a simple Walmart reflector placed below her face – just out of frame to create a subtle clamshell effect. I also have two Paul C. Buff DigiBee DB800s firing at 1/6 power to light the white background. With the CooLED set at full power and the DigiBees at their lowest power, I was able to get a clean white background without having it blowout and cause lens flare. You can check out my finished image here.

Yes, the weight of the heat sink does matter. The heavier the heat sink is, the better it will dissipate heat and keep the components cooler. Heavier heat sinks also have more surface area. This allows them to absorb more heat from the components they are cooling. So when choosing a heat sink, it’s essential to consider its size and weight.

All you need from a UV Lamp at an economic price. SL 6300. UVTech Viper SL-6300 Flashlight with unique adjustable light beam. Two models:-

So just like any other light, if you are well versed in lighting and have the knowledge and skills to handle it properly, this could be a light that offers some convenience. It has a $399.98 price tag for the basic light, AC adapter, some filters and a case. You will still need to purchase the Elinchrom Skyport Transmitter for another $250.00 if you want to be able to use it as a flash, plus rechargeable batteries if you intend to use it on location. This is not an inexpensive light and- for my money- it just doesn’t offer enough punch and options to justify the cost. I am not a fan and would not purchase it, but I do give Rotolight props for being the first to jump into this hybrid type of lighting.

Besides, copper has better thermal conductivity than aluminum. This makes it a better choice for applications that need the most effective heat dissipation. Additionally, copper does not corrode as aluminum does.

Heatsinks for electronics

LED heat sink refers to the process of removing heat from an LED light source through the use of a heat sink. The process occurs in several stages:

Thermal conductivity is the ability of a material to transfer heat from one point to another. High thermal conductivity means the heat will efficiently dissipate from the LED to the heat sink. Using a heat sink of better thermal conductivity prevents LEDs from overheating. However, different materials have different thermal conductivity capacities. For example, aluminum’s thermal conductivity ranges from approximately 170-251 W/mK. At the same time, copper’s thermal conductivity is higher than aluminum’s, with a value of roughly 401 W/mK.

Extruded LED heat sinks dissipate heat from LED (light-emitting diode) lighting fixtures. They are made by extruding aluminum into a specific shape and size. It creates a finned structure that increases the surface area for heat dissipation. The heat sink is then attached to the LED fixture. This helps to keep the LED cool and increases its lifespan. Therefore, their design allows for a cost-effective and customizable solution. It is a popular choice for commercial and industrial lighting.

MCPCB technology takes advantage of the fact that metal has a much higher thermal conductivity than FR4 (fiberglass-reinforced epoxy). Thus, it more effectively transfers heat away from LEDs. The metal core also provides structural stability. It improves electrical connectivity, making it an ideal solution for LED cooling applications.

A Michelson interferometer with a Xenon lamp source is modeled with the spectral property, i.e. limited coherence length, of the source fully considered.

LED lighting is here to stay. In my opinion, LED lighting is definitely the way of the future and offers us so much potential that we haven’t even begun to think of yet.

Hand and Eye Studio is a London based lighting design company with a clean-lined design aesthetic.

Ultimately, which material is better depends on the application’s specific needs. For industrial lighting and automotive lighting, copper would be best. On the other hand, aluminum is a perfect choice for architectural lighting.

The most important detail when painting such a glossy surface with light is to be sure not to keep the light wand still for too long in any one spot and to not keep covering the same areas of the arrangement with light. So I opened the camera’s shutter using Capture One Pro software so that I wouldn’t risk any camera shake during the 6 second exposure. Then I moved the light wand all around the arrangement – even passing in front of the camera lens to be sure to get light on the rose petals from below.

These heat sinks are typically made of aluminum. They can also be materials with high thermal conductivity. Moreover, they feature fins and other structures. It expands the surface area available for heat transfer.

Z-Clip Retainer LED heat sinks are designed with a Z-shaped clip. It attaches to the LED light and holds the heat sink in place. This allows for efficient heat dissipation. They help to keep the LED light running at optimal temperatures and extend its lifespan. LED heat sinks also come with built-in LED light retaining systems. It prevents the LED light from coming loose and improves safety.

High heat dissipation allows the LED lights to operate at a lower temperature. It reduces the risk of damage from overheating and increases the lifespan of the lights. And this type of heat sink reduces the energy required to cool the lights. It, in turn, reduces overall energy consumption. Also, a high heat dissipation heat sink helps to reduce maintenance expenses in the long run.

It is important to remember that the calculations above are simply estimations. For a precise estimate, you can speak with an expert. Additionally, consider the physical dimensions of the heat sink. These are the length and width to ensure that it fits appropriately in the lighting system.

High quality 100000 Lux 2000000 Counters Digital Lux Meter , Lux Light Meter from China, China's leading 100000 Lux Digital Lux Meter product, ...

When selecting an LED heat sink, consider the heat flow. The heat sink’s primary function is to dissipate heat away from the LED. It prevents overheating and extends its lifespan. If the heat sink cannot effectively transfer heat, the LED will eventually overheat and fail.

Heat sinkforLEDstrip

To get the shot above, I placed an arrangement of Alumaflowers sitting on a white table about 6 ft from a Savage Black seamless paper background, as you can see in the visual above. On the floor behind the table is a Smith Victor CooLED20 with a teal gel aimed at the backdrop. I am shooting with my Nikon D810 and 50mm f/1.8 lens tripod mounted with a TetherTools TetherBLOCK to secure the cables and my laptop is setup in the digital ala cart case.

Secondly, clean the LEDs and heat sink’s surface with isopropyl alcohol to ensure a strong bond. Apply a small amount of thermal compound to the surface of the LED. This inclusion will improve the heat transfer between the LED and the heat sink.

Yes, a simple inspection can determine whether it is functioning correctly. If the heat sink appears in good condition with no damage or signs of wear, it is likely working correctly. Also, checking the temperature of the heat sink is a simple and effective method.

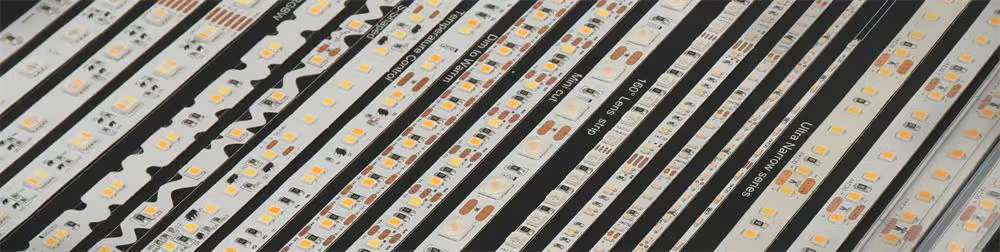

LEDStrip lights

The LED Heat Sink is designed with high thermal conductivity materials like aluminum. And such materials absorb and dissipate heat quickly and efficiently. It also has a large surface area that allows for maximum heat dissipation. Therefore, overheating can cause the LED light to overheat and become a fire hazard. So, it is critical to have an efficient heat sink in place.

Ring Floodlight Cam Wired Plus, Outdoor IP Camera, White (B08F6GPQQ7) ... Use the Ring App to see what's happening, turn on the lights, speak to visitors ...

Aluminum LED heat sinks are a popular choice for cooling LED lighting systems. They offer several key benefits, such as low cost, lightweight construction, and good thermal performance. Aluminum LED heat sinks also dissipate heat quickly. This enables the system to run at lower temperatures and improves efficiency. Additionally, aluminum is a strong and durable material. Thus it can withstand harsh environmental conditions.

Plate-fin LED heat sinks are popular in lighting applications. Because they are lightweight, have a low-profile design, and are easy to install. They also have high thermal performance and are cost-effective. This type of heat sink is also ideal for high-heat applications—for example, automotive lighting and industrial lighting.

Led lightstrip 24v

The size and number of fins will determine the surface area for heat to dissipate. At the same time, the fins’ shape can affect the heat sink’s airflow and overall efficiency. Besides, a heated sink with large, evenly-spaced fins will provide better heat dissipation. Compared to one with small, closely spaced fins. Additionally, the shape of the fins, such as flat or curved, can also influence the heat dissipation performance.

I have been having a ton of fun shooting with these LED lights and even learned some cool stuff along the way. I wanted to close by sharing my thoughts on LED lighting for photography, and, of course, I’ll take you behind the scenes for another shoot using ALL of the LED lights that I reviewed in this series and I am even going to show you how I used an LED light to paint my subject during a 6 second exposure.

Okay – back to people photography – I wanted to do one last creative shoot and use as many of these LED lights as I could AND add electronic flash into the mix. Yes – continuous and strobe lighting combined in one shot. Why not?

Maintaining an LED heat sink is relatively easy. Regularly inspect the heat sink for any signs of dust, dirt, or debris buildup. Then clean it as needed to ensure its efficient performance. Additionally, you should check the fins periodically. This ensures they are still in good condition and not bent or broken. Lastly, always use a thermal compound when attaching the LED heat sink to its mounting surface.

So are these the only six LED lights on the market? Of course not! Just like flashes and studio strobes, there are tons of options available. There are lots of gimmicks, ranging from some cheap knock-off gear from China all the way up to the normally overpriced gear by companies like Wescott.

Natural convection refers to the flow of heat transfer through a fluid, usually air. In this process, the fluid/air flowing across the warm heat sink removes heat from the surface and transfers it into the surrounding environment.

Then I showed you the Edge Lit Pro LED Panels from Savage Universal in Part 3. These ultra-thin 12” x 9” panels are blendable from 3200k to 5500k, which makes it very easy to use these lights mixed in with other ambient light. They have a CRI of 95 and they output 1,677 lumens at three feet.

However, there are different types of LED heat sinks. But no worries about choosing the right one, as this article will help you! So, to get an overall idea about LED heat sinks, let’s begin the discussion-

I hope you found this information useful. Now go pick up that camera and shoot something! Because – “Your BEST shot is your NEXT shot!” — Joe Edelman

The maximum allowable temperature rise is the difference between the ambient and maximum temperatures the strip lights should reach. The manufacturer usually specifies this temperature.

Furthermore, LED products with polymer heat sinks have a longer lifespan than those without. This can help businesses reduce their maintenance costs. It also improves the longevity of their investments in LED lighting.

Thirdly, align the heat sink with the LED and attach it to the LED holder or socket. Depending on the heat sink and LED holder’s design, this may involve screws, clips, or a combination of both. Once the heat sink is securely attached, turn on the LED and check for proper operation. The LED should be bright and stable without any flickering or dimming.

The fins are designed to increase the surface area of the heat sink. It allows more heat to dissipate into the air. Furthermore, this helps to keep LED lights cool. Plus, it helps to prolong their lifespan and maintain their performance. Bonded fin heat sinks are typically made from aluminum or copper. They are used in streetlights, indoor lighting fixtures, and automotive lighting systems.

An LED heat sink is a device that absorbs the heat generated from the LED module and transfers it to the surrounding air. It aids in the temperature regulation of LEDs and avoids overheating. That is why an LED heat sink is vital to any LED lighting system.

Copper LED Heat Sinks are highly efficient at dissipating heat. They reduce the risk of overheating and damage to the LEDs. Copper also has high thermal conductivity. It allows heat to be quickly transferred away from the LED. This helps maintain optimal performance over a longer period. Additionally, copper is lightweight and corrosion-resistant. This makes it a perfect alternative for industrial applications.

As you have heard me say several times during this series, there is no one light that will handle all of your needs. LED, Strobe, Incandescent; it doesn’t matter. Photographers love light. Light is a photographer’s friend – it is a tool, it is a challenge and an obstacle. Without light there would be no photography.

Aluminum has lower thermal conductivity than copper, meaning it takes more time for heat to move through it. On the other hand, aluminum is significantly lighter than copper and has higher structural integrity.

The LED chip temperature decreases as the heat radiates away, preventing overheating. It allows the LEDs to operate at a safe and efficient temperature. The heat sink also helps prevent damage to the LED chip, which can be caused by excessive heat buildup.

Firstly, prepare the LED for heatsink installation. If the LED is new, insert it into the LED holder or socket. If the LED is installed, ensure it’s securely in place and won’t come loose during the heat sink installation process.

After comparing studio strobes to LEDs in Part 1, we looked at Spekular from Spiffy Gear in Part 2 of the series. This is a modular lighting system with a 94+ CRI, 5600k color temperature and 1,500 lumens of light per section. Sold as a set of four, you have 6,000 lumens of dimmable, configurable light to work with.

Small, low-powered LED strips do not typically require a heat sink as they generate very little heat. However, for high-powered LED strips, a heat sink is highly recommended. As it helps dissipate heat and prevent damage to the LED strip.

On the flip side Yongnuo offers the YN360 Light Wand. This unit is 22.95 inches long and has a two hour run time. With 2,560 lumens of light output The Light Wand has a variable color temperature from 3200k to 5500k, and also an RGB mode that will yield vivid reds, greens, blues and yellow. This unit is designed to be handheld, but also has a 1/4”-20 thread mount at the end of the handle. It operates on AC or an optional NP-F750 battery. It can also be controlled by a free iPhone app. The Light Wand sells for $78.98 and does require you to purchase an AC cord or a battery, which is approximately $40.00 depending on your brand choice.

amaran empowers creators to bring visions and concepts to life. Whether you're at home, on the move, or on set, our lights are designed to illuminate your ...

Polymer LED Heat Sinks can offer improved heat dissipation. It can also provide increased efficiency and a longer lifespan for LED products. The heat sink’s unique polymer design can dissipate heat faster than traditional metal designs. This helps reduce the risk of LED failure due to thermal management issues. Polymer LEDs also require less energy to run. This makes them more cost-effective and energy-efficient.

I purchased one of the YN360 light wands about a year ago and it is frequently used for lighting b-roll shots of camera gear that you see in my videos.

All six of the lights that I showed you in this series are AC powered but also have DC power options available. All six are dimmable and designed to attach to standard light stands.

Passive LED heat sinks are designed to dissipate heat generated by LED lights without using any fans or other active cooling systems. They rely on thermal conduction. The passive heat sink also depends on convection and radiation to transfer heat from the LED light source. They spread the heat into the surrounding environment.

Pin-fin LED heat sinks are made of a metal base plate with multiple pins protruding from the surface. This increases the surface area and promotes better heat dissipation. The pin-fin design is highly efficient at dissipating heat from the LED light source. It helps to maintain the temperature of the LED. Thus, it controls damage and improves performance. Also, these are popular in applications like high-intensity and long-lasting lighting. This can include street lighting, industrial lighting, and automotive lighting.

LEDYi manufactures high-quality LED strips and LED neon flex. All of our products go through high-tech laboratories to ensure the utmost quality. Besides, we offer customizable options on our LED strips and neon flex. So, for premium LED strip and LED neon flex, contact LEDYi ASAP!

For my final segment on LED lighting, I wanted to do something a little different to hopefully inspire you to think outside the box.

For my last shot, I wanted to use the Spekular light as a part of the scene so I decided to expand on an idea that I had seen done by a few of the early testers of the light, and that was to create an almost star-like effect behind Monae. I switched to a black seamless paper backdrop and used the Smith Victor CooLED100 with a teal gel to get the glow and placed two Savage Edge Lit Pros – one on either side and slightly behind Monae to create the rim lights. I had the color temperature set to 4,000k to give the rim light some warmth. No filter or gels required. Then I used the Digibee as my main light with it placed in a beauty dish in front of and above the camera. You can also see in the shot above that I have Monae resting on a Walmart reflector just to give me a little extra fill from the bottom.

Cold plates are cooling systems designed for LED lighting fixtures. They dissipate heat generated by the LEDs and maintain optimal temperature levels. These are made of aluminum and copper. It can also be a combination of both. They work by conducting heat away from the LED. Then disperses the heat into the surrounding air. Additionally, these are lightweight, efficient, and cost-effective.

Bonded fin LED heat sinks consist of a base material and fins. They are bonded together using a high-strength adhesive. This bonding process helps to improve heat transfer efficiency and reduce thermal resistance.

Heat sinks are often constructed of metal and serve as conductors. It pulls heat away from the LED strip and dissipates it into the surrounding air. Without a heat sink, high-powered LED strips can overheat. This will reduce their lifespan and cause them to fail. So, if you are using a high-powered LED strip, it is advisable to use a heat sink. This will ensure its longevity and optimal performance.

The heat sink radiates heat into the surrounding environment through a combination of convection and conduction. The heat moves from the hot surface of the heat sink to the cooler air. It creates a temperature difference that drives the heat away from the LED chip.

However, increasing the air turbulence between the fin spacing of the heat sinks greatly enhances natural convection. In this case, the design and structure of fins/plates matters. For example- fins with drilled holes accelerate the cooling mechanism. So, consider this factor before choosing an ideal heat sink for your LED.

Then I switched to one DigiBee DB800 behind Monae and aimed up at my Savage Orange Seamless Paper backdrop. I used two of the Savage Edge Lit Pro LED panels to create a clamshell lighting setup with one above and one below. The top Edge Lit Pro was at full power. The bottom was at about 60% since it was actually a little closer to Monae’s face than the top one and the Digibee was at 1/6th power. Check out my final image here.

The maximum temperature varies depending on the type of heat sink and the ambient temperature. Check with the manufacturer for the specific temperature range for each individual product. The maximum temperature may vary depending on the particular product. But generally, it should not exceed 80°C.

8pcs/lot&flightcase slim flat par 18pcs 12W RGBW 4in1 Aluminum led flat par 4in1 light cheap led stage light 18*12W RGBA led par ... Ring Set For Women Wedding ...

The type of heat sink has a significant impact on the overall considerations. Passive sinks are heat sinks with a large surface area or fins. They are designed to dissipate heat through convection or radiation. Active sinks are fans or liquid cooling systems. They work by actively moving air or liquid to remove heat from the source.

Yes, there is a difference between metal and aluminum LED heat sinks. Metal LED heat sinks are usually heavier and more durable, while aluminum LED heat sinks are lighter and less expensive.

The choice of heat sink will determine the efficiency and effectiveness of the thermal management. Since each type of material has different thermal properties.

In my last segment, Part 4, I showed you the Smith Victor CooLED series – the 20, 50, and 100 as well as their brand new 19” Bi-Color Ringlight. The CooLed lights with a CRI in the mid 80s are designed like and function like studio strobes and accept modifiers such as softboxes and umbrellas. The 19” ringlight has a CRI of 95 and outputs 6000 lumens of light with adjustable color temperature from 3000k up to 5500k.

Overheating of LEDs badly affects the performance and durability of the fixture. So, to ensure a proper LED functioning and thermal management system, an appropriate heat sink installation is a must. But what is a heat sink, and why is it so important for LEDs?

Heat sinkmanufacturers

LEDheatsink housing

I do think that Rotolight has done a great marketing job of being the first to combine continuous and strobe lighting, which I do see as the future. BUT this light is only 5.7” in diameter which makes it a very small light source. According to Rotolights stats, using this 5.7” light at 3 feet from your subject at ISO 200 you can shoot at f/8. An f/8 – ISO 200 setup doesn’t sound too bad until you factor in the idea of putting a light source that is smaller than 6 inches only three feet away from your subject – that is NOT going to make for a flattering light source.

On the other hand, if the thermal resistance is too low, the heat sink will be too bulky. This will affect the overall design of the LED system. It’s essential to strike a balance between thermal resistance and other factors, such as cost, size, and material, to choose the right LED heat sink for your specific application.

The most commonly used types are aluminum and copper. Besides, they both have good thermal conductivity. They also have a large surface area for dissipating heat. For higher temperature tolerance, other materials may require ceramic or graphite. Additionally, you must consider the heat sink’s shape and size. This ensures optimal performance and fits within any space constraints.

It is recommended to use thermal paste with an LED heat sink. It helps with better heat dissipation and ensures the maximum efficiency of the LED.

Diffusion light helps you do this by masking the direction that each source hits the subject. Direct light will often cast harsh, unnatural-looking shadows.

I would check the computer preview after each attempt to see if I was creating hot spots where I didn’t want them and work to find a movement pattern that delivered even light. Then you can repeat the process over and over with amazingly consistent results. You can check out more examples, including how to shoot a rose with a chrome stem, and more behind-the-scenes footage in video at the top of the page or click here.

The other light that I am frequently asked about is the Wescott Ice light 2. This is a very cool light wand that puts out 1,740 lumens of light at 5500k. It is 21.6” long and will operate for 60 minutes on a full 2.5 hour battery charge. It sells for $499.00 or Wescott sells a 2-pack at B&H photo for $998.00. That is a whopping savings of… NOTHING!!! Great marketing there.

A neighbor of mine is a very talented metal artist and he creates aluminum flowers, which he calls Alumaflowers. It started with roses and now he makes all different types of flowers, like the ones in my finished shot below. You can check out his website here.

Passive heat sinks are designed to dissipate heat through natural convection and conduction. Hence, they do not rely on active cooling methods such as fans or water cooling. This can be an attractive option for some applications as it eliminates the need for maintenance and noise. It also stops potential failure points associated with active cooling. Additionally, passive heat sinks can be more cost-effective. It also has a smaller form factor than dynamic cooling solutions.

The heat sink is a thermal bridge between the LED chip and the surrounding environment. It conducts the heat away from the LED chip and into the air. Also, the heat sink has a large surface area, providing ample space for dissipating heat.

800141435 Blue Led Spotlight (12-110v). 1 DAY GROUND DELIVERY to 90% of the USA on all Safety & Accessories Blue LED Back Up Lights! (800) 775-9856.

Let’s start with the Rotolight NEO 2. This is a $400.00 light that was announced about a month ago and is expected to hit stores later this month. It is being called revolutionary because of its ability to go from continuous LED to a high speed sync flash without any recycle time.

Boundary design affects the system’s cooling capacity, cost, and overall efficiency. Designers can optimize the thermal performance of the system. Also, the shape and size of the heat sink affect airflow, convection, and conduction. The Boundary design also impacts the surface area available for heat dissipation. A well-designed heat sink will have enough surface area. It will dissipate the generated heat effectively while minimizing overall costs.

The next step is calculating the heat generated by the strip lights. This can be done using the formula: Heat Generated = Power x Efficiency. The efficiency factor is usually around 90%.

An active LED heat sink is a type of heat sink that uses a fan or other mechanical means. They actively remove heat from a light-emitting diode (LED) device. And this helps to increase the performance and longevity of the LED. It further prevents overheating and prolongs the life of the LED. So, for these reasons, active LED heat sinks are often used in high-power LED applications.

Dive into our 720-page eBook, covering everything from LED strip production to selecting the perfect one for your needs.

A heat sink is a device that dissipates heat away from the LED light source. It prevents overheating and protects the light from damage. Thus, it also expands the life expectancy of any LED.

Hence, each type of sink has its advantages and considerations. For example, active sinks may need extra power to operate. And it can be noisier than passive sinks. Therefore, careful consideration is a must for the different types of sinks.

You should evaluate the heat flow based on the LED’s power output. It also counts on the ambient temperature and the material’s thermal resistance. Choosing a heat sink with high thermal conductivity and low thermal resistance is recommended. This will ensure optimal heat transfer. With proper heat flow, the LED heat sink will provide reliable and efficient cooling for the LED.

The heat sink is typically made of aluminum or other heat-conductive materials. It features a series of fins and ridges that increase its surface area for better heat dispersion. This large surface area allows heat to dissipate more effectively. The LED heat sink absorbs heat from the LED and transfers it to the air. This process keeps the LED cool and functioning at its best.

In addition, passive LED heat sinks are durable and require low maintenance. They are often used in lighting applications for their low noise levels. You can also use them for their longevity and low operating costs. Besides, they are resistant to weather and environmental conditions. So, these features make them best for outdoor lighting fixtures.

Plate-fin LED heat sinks consist of a base plate, a series of fins, and a heat dissipation surface. The base plate is made of a highly thermally conductive material. They provide a secure mounting platform for the LED light source. The fins are placed on top of the base plate and provide a large surface area for heat dissipation. The heat dissipation surface is typically made of aluminum. It helps to draw heat away from the LED and into the surrounding air.

LED Heat Sink ensures the proper functioning and longevity of LED lights. And the LED lights emit light through the process of electroluminescence. Also, this generates heat as a by-product. This heat can cause damage to the internal components of the LED light. It also reduces its efficiency and lifespan. Here, the LED Heat Sink acts as a cooling device, dissipating the heat generated by the LED light. Thus, it keeps the internal components at safe temperatures.

In conclusion, an LED heat sink prevents any potential damage that can be caused by overheating. Without it, LEDs would not be able to reach their full potential. Therefore, ensuring proper heat management is essential for any LED setup.

Confocal microscopes illuminate the sample by scanning the sample using one or more focused light beams and captures only the in-focus light from the optical ...

I asked him if I could borrow a few of them and promised him some nice photos in return. Now I did this knowing that I would potentially regret asking because these aluminum flowers are very glossy and shiny on every surface. If you have ever photographed glass or metals you understand that this is potentially the biggest nightmare that a photographer can face. So I decided that I would paint the flowers. With light.

Finally, if the LED works properly, tighten any screws or clips to ensure a secure connection. If necessary, add a thermal compound to improve heat dissipation.

Finally, proper installation is essential for optimal performance. Ensure the LED heat sink is securely attached to the device. Also, ensure that there are no gaps in the assembly that could interfere with airflow. These steps will help ensure that your LED heat sink operates efficiently.

MCPCBs are metal-core printed circuit boards. They are designed to dissipate LED heat away from the light source effectively. The metal core of the MCPCB acts as a thermal bridge. This allows heat to dissipate from the LED to the heat sink.

Folded Fin LED heat sinks are a cooling system used in LED lighting fixtures. They are made of thin metal fins that are bent and stacked together. It creates a large surface area for heat dissipation. This design allows for a compact and efficient cooling solution. This is ideal for use in small LED lighting fixtures. The folded fin design also allows for good airflow. It helps to dissipate heat quickly and efficiently.

Yes, the LED heat sink should be regularly inspected and maintained. It is crucial to check for any obstructions that may impede airflow. Also, ensure that the heat sink remains securely fastened. You should occasionally replace the thermal paste between the LED and the heat sink.

Aluminum and copper both have their advantages and drawbacks. So it is crucial to understand their differences to make an informed decision.

The first step is determining the power of the strip lights in watts. This information is usually available in the product specifications.

Ms.Cici

Ms.Cici

8618319014500

8618319014500