Infrared radiation in daily life and technology - what is infrared light

No matter the level of machine vision illumination analysis, there is often no substitute for actual testing with multiple lighting types and techniques on the bench, and then actual floor implementation. This might help you arrive at an optimal lighting solution that fits in with the intended cost, efficiency, and application.

Advancedillumination

Ultraviolet irradiation has an ability to destroy microorganisms by causing instability in double bonds of carbon atoms in nucleic acids. UV radiation, particularly in the wavelength between 200 and 300 nm, has been studied and found to be effective as germicidal. The peak of the effectivity is around 260 nm, which has the highest absorption by bacterial DNA.7

All the materials used in the making of this box are commonly available and are significantly cheap. We propose that common use of these boxes at the sites, where there is high number of respirators/face shields being disposed-off, can lead to safe reuse and decrease in the biomedical waste that is currently being generated.

2020721 — Diffuse lighting in machine vision applications may be classified as full bright field illumination as opposed to partial, or directional bright field lighting.

The effectiveness of UV cabinet for the purpose of sterilization has been evaluated, in a bench-side study, by Moore et al., and they concluded that it can provide rapid as well as effective disinfection of patient-related items. They used bacterial spores as well as viruses to establish the efficacy of the same.10

Official websites use .gov A .gov website belongs to an official government organization in the United States.

The four cornerstones constitute the crucial aspects of machine vision lighting to acquire the requisite contrasts. The four cornerstones are mentioned below:

In a study based on similar concept, Cadnum et al. assessed the efficacy of UV cabinet to sterilize and reuse components of PPE during COVID-19 pandemic. They concluded that a high-level disinfection of N95 respirators was effective and feasible.11

COVID-19 outbreak has been recently declared by the World Health Organization (WHO) as pandemic. Per situation reports of WHO, the COVID-19 outbreak has involved over 200 countries.1 In India, more than 100,000 individuals have been infected, and over 3,000 deaths have been reported until the writing of this article.2 Healthcare workers (HCW) are at particularly high risk of being infected, as they are actively involved in caring for these individuals.3 In such scenarios, personal protective equipment (PPE), such as cover-all, respirators, and face shield, has become vital for HCWs to continue serving COVID19 cases. Due to the rise in number of cases, there has been a huge demand for these items. Over time multiple international agencies such as Center for Disease Control and Prevention have released guidelines for its judicious use and potential upcoming scarcity.4

Machine visionBacklight

LED ring lights are easy to set up and use, creating professional-quality lighting right out of the box. Circular in shape, ring lights ensure the subject is ...

Exposure to water, soap, alcohol, and hypochlorite causes a decrease in transparency of face shields and goggles. This leads to haziness and poor vision for the HCW. Using UV radiations for the same was also helpful in finding an answer to this problem.

Illuminationtechniques in slit lamp

Most of these equipment are for single-time use only, but it is anticipated that in upcoming time there will be a shortage of these items. Reuse after sterilizations has been proposed, particularly for respirators and face shields. In this current pandemic, the dearth of vital PPE can have catastrophic consequences.

Coherent light is characterized by the synchronization of wave phases within the light, while monochromatic light is specific to a single wavelength or color.

Articles from Indian Journal of Critical Care Medicine : Peer-reviewed, Official Publication of Indian Society of Critical Care Medicine are provided here courtesy of Indian Society of Critical Care Medicine

Qualitas Technologies enables manufacturing industries to realize the potential of AI and Machine Vision in order to automate visual inspection processes. Automate Visual Inspection in Manufacturing by making a 10x improvement in cost and efficiency.

It’s of critical importance to ensure that optimal rays are being collected by the lens while the suboptimal rays are not. The light that falls outside the lens’s field of view results in glare and reduced image contrasts. Some other challenges not caused by the light are changes in ambient light and synchronization between the lighting and the camera.

In the domain of optics, a light prism is a transparent optical element with flat, polished surfaces that refract, or bend, light.

Images with the wrong contrasts and uneven lighting mean much more effort and are a setback to productivity. It’s like grinding a car with clogged fuel injectors. If the quality and suitability of the machine vision lighting are neglected, cost overruns and delays are inevitable.

Dome LightMachine Vision

UV box can also add to the armamentarium of the hospitals to deal with particular biomedical waste which is being generated at enormous amounts.

Also known as ‘Neon light’, they are based on the concept of discharge tubes. These too, are used quite rarely, to illuminate large areas in industrial machine vision applications. They should always be used with an electronic ballast, to avoid flickering effects in images.

On a similar note, we here describe an indigenous method of making UV box. We have used this box, after testing for its efficacy, for sterilization of respirators, face shields, and goggles.

The effectiveness of assembly was tested using culture of Escherichia coli and Staphylococcus aureus. Overnight growth of bacteria was harvested in normal saline, and opacity was adjusted to 0.5 McFarland Standard. Ten microliter suspension of each was spread over nutrient agar plates, which were then exposed to UV light for a period of 30 minutes, 1 hour, and 2 hours duration. The bacterial suspensions were subjected to viable count using 10 log dilutions to confirm the count. Reduction in the viable count was expressed as ratio of initial viable count to viable count after exposure to UV light. The results suggested approximately four log reduction in viable count after exposure to UV light for 30 minutes. No bacterial growth was seen after exposure of 1 hour and 2 hours (Fig. 2).

Our prototype assembly with supported efficacy from microbiological tests is an option for use of UV light within available resources for disinfection and reuse of scarce supplies of personal protective equipment.

Since historically machine vision lighting was the last aspect developed or funded, lighting solutions typically included the standard incandescent or fluorescent products. However, with time as the scope of machine vision applications widened, several lighting types like LEDs and techniques like machine vision backlight are emerging steadily.

A ton of parameters needs to be fine-tuned to provide appropriate vision system lighting that meets the three acceptance criteria simultaneously. For more convenient comprehension, I have divided the challenges to picking the ideal machine vision illumination into two categories:

Culture plates in series showing the growth of Escherichia coli and Staphylococcus aureus at 30 minutes, 1 hour, and 2 hours

A halogen lamp is typically a point source in combination with a reflector. It is preferred in industrial image processing when the areas to be illuminated are large like vehicle bodies, etc., or where a lot of light is required. These are not quite prevalent because they have high energy consumption, heat generation, and infrared emissions.

hbspt.forms.create({ region: "na1", portalId: "726123", formId: "bd9f048a-7e04-4512-9179-c50855c961ea" });

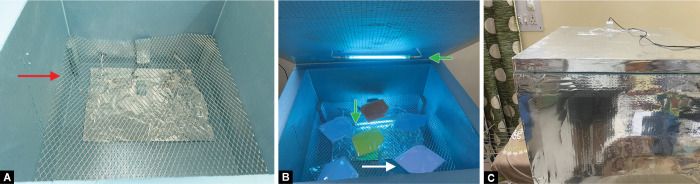

A thermocol box was taken from the central drug store and was fitted with two UV tubes of 254 nm wavelength procured from local service center of water purifiers. The position of the two tubes was such that one was near the base while other was fixed at the top. An aluminum mesh frame was placed in the middle of the box to act as a platform. The roof of the box was converted into a lid. The effectiveness of assembly was tested using culture of Escherichia coli and Staphylococcus aureus. In addition, a biological indicator tube containing test strip with spores of Bacillus atrophaeus was also exposed to UV light for a predefined duration, which did not show any color change after incubation for 48 hours.

For the process of sterilization, UV radiation has been commonly used, especially for airborne infections like tuberculosis and influenza.8,9 Closed UV cabinets have come up for the purpose of sterilization. The important advantages of such cabinets are UV irradiation from opposite ends, portability, and compact size. Such cabinets are commercially available for the surface sterilization, but given the high cost and administrative measures of lockdown and cessation of transport, even their procurement is an uphill task. The average cost of such units is above INR 25,000 .

Acquiring the right machine vision lighting is often the difference between creating a robust, reliable application and one fraught with inefficiencies and challenges. Since machine vision systems don’t analyze the object itself, but its captured image, it is imperative that the vision system lighting used to inspect the object clearly defines the area of interest. The right machine vision illumination is a critical prerequisite in producing workable and reproducible images.

The LED sources, owing to their wide range of benefits and high popularity, occupy a position above the other types of sources. Its vast range of benefits includes a longer life expectancy, mechanical resilience, durability, easy-to-control facilities, and miniature physical size. Since LED sources bring down the operational costs significantly, they are considered excellent value for money lighting sources. Its light color is not only limited to white but can also be red, green, blue, and even infrared and ultraviolet. LED products are ideal for lighting small products.

What isilluminationof light

202284 — As a result, real-time graphics solutions for global illumination are typically limited to computing a subset of the indirect light — commonly ...

To use ultraviolet (UV) radiations in an indigenous method for sterilization of respirators for reuse during COVID-19 outbreak.

Dark field lighting

Following the essential microbiological testing and administrative approval, this UV box was used at high-intensity COVID-19 dedicated areas of the hospital

Choosing the right machine vision lighting source is critical to the success of the application. There are four prominent types of illumination sources or types for machine vision lighting, which are the following:

In circularly polarized light, the tip of the electric vector describes a circular helix about the direction of propagation with a frequency equal to the ...

Ultraviolet (UV) radiation is a form of nonionizing electromagnetic radiation. According to the wavelength, in the spectrum, UV radiation come between visible light and X-ray. UV radiation is classified based on its effect on living tissue and wavelength. It is commonly divided into three major groups: UV-A (320–400 nm), UV-B (290–320), and UV-C (200–290).5,6

201927 — Solution Show Solution. An unpolarised light is one in which the vibration of electric field vector is not restricted in one particular plane.

Lateralillumination

Secure .gov websites use HTTPS A lock ( Lock Locked padlock icon ) or https:// means you've safely connected to the .gov website. Share sensitive information only on official, secure websites.

2024311 — UV curing adhesives, or light curing adhesives, cure quickly when exposed to light. We will discuss advantages and disadvantages.

© The Author(s). 2020 Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by-nc/4.0/), which permits unrestricted use, distribution, and non-commercial reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated.

To conclude, the judicious and careful use of UV light can help disinfect the precious and scarce resources of PPE in global pandemic. Our prototype assembly with supported efficacy from microbiological tests is an option for use of UV light within available resources for disinfection and reuse of scarce resources.

Ultraviolet (UV) box assembly: (A) Aluminum mesh placed in the middle of the box (red arrow); (B) Switched on UV tubes, one in the lid and one at the base (green arrows) along with respirators lying on the aluminum mesh (white arrow); (C) Outer view of the box showing the silver foil cover

UV box can help in meeting the demand supply deficit for respirators, face shields, and goggles that are paramount for the protection of HCW.

by JW Beams · 1929 · Cited by 1 — In many experiments, where the light need not be com- pletely plane-polarized in both arms of the instrument, almost any ordinary interferometer as, for example ...

A light’s age, its position, its temperature, and the stability of its power supply can directly impact the machine vision camera’s performance. Brightness is another critical factor. A low-light imaging setup will lead to increased computing cycles, reducing the vision system’s efficiency. The wavelength of the emitted light, its suitability, and interaction with the object is also to be adequate consideration while choosing the apt lighting for machine vision.

Shortage of respirators and face shields were foreseen in our institute. There were two main factors behind it: first the rise in demand and second its use. This was expected with the rise in number of cases and recruitment of human resources at various sites. So the number used per day was rising exponentially. Second, transport restriction and lockdown imposed by the administrative authorities led to unavailability of the items. This led us to search for various methods of reuse of respirators and face shields. In the literature, various methods of disinfection has been described by autoclaving and ethylene trioxide.12,13 But all these methods had two major drawbacks; one was, post-sterilization the physical quality of mask was showing deterioration, and there was an increase in resistance to exhaled breath. The second drawback was the turnaround time of these machines, which were also catering to the needs of various other departments in the hospital.

FirstLight designs, builds & maintains fiber-based communications networks for clients and provides proactive support. Find out more about our services now!

A thermocol box of size 24 × 24 × 20 inches was taken from the central drug store (vaccines/drugs were delivered in it). An aluminum mesh frame was placed in the middle of the box to act as a platform (Fig. 1A). The box was fitted with two 11 watts UV tubes of 254 nm wavelength procured from local service center of commercially used water purifiers. The position of the two tubes was such that one was near the base, while the other was fixed at the top (on the roof of the box) (Fig. 1B). A clear plastic bag, containing the N95 respirator, was placed over the mesh frame in such a way that both of its surfaces are being exposed to UV radiations (Fig. 1B). The roof of the box was converted into lid, and seal was developed by modifying the edges. An airtight seal was not aimed, as it was not necessary. Silver/aluminum paper/foil coating was done over the box so as to protect the operator from any accidental exposure (Fig. 1C). The entire assembly costed less than INR 1,000, as most of the items used were arranged from scrap material.

UV box can help in meeting the demand-supply deficit for respirators, face shields, and goggles, which are among the PPE of HCW with paramount importance

Over the last few decades since machine vision’s inception, several “canned” vision system lighting arrangements have been created that are appropriate for a vast range of applications and have been deployed in several industries. Nevertheless, for choosing the perfect lighting solution for your machine vision applications, it is essential to consider the application, appearance variables, specular issues as well as the effect of lighting sources and illumination techniques to achieve optimal image consistency. Scrutinizing over the following questions will help you acquire an apt machine vision lighting solution:

LEDillumination

For its final use, in one sitting, 10 N95 respirators or 5 goggles or 2 face shields could be sterilized in one sitting. Each cycle was run for 30 minutes, and after 6 such cycles, a break of 1 hour was provided to the device. The aluminum/silver foil was not changed till there was physical soiling of the surface. For physically soiled inside, dry mopping was used with a cloth, and this was followed by empty run for one cycle. The most important precaution used by the operator was to switch off the box before opening the lid.

In addition, a biological indicator tube containing test strip with spores of Bacillus atrophaeus was also exposed to UV light for a duration of 2 hours which did not show any color change after incubation for 48 hours, hence strengthening our belief that the box has enough UV energy to make the surface sterile. Disinfected masks had their structures maintained after the procedure. Also, it did not affect the functional aspect, as there was no increase in resistance as felt subjectively.

Pawan Kumar Singh, Department of Pulmonary and Critical Care Medicine, Pt Bhagwat Dayal Sharma Post Graduate Institute of Medical Sciences, Rohtak, Haryana, India, Phone: +91 8437013094, e-mail: ga.ps.complete@gmail.com

Kumar P, Chaudhry D, Parmar A, Tyagi D, BG Manjunath, Singh PK. Ultraviolet Box: An Innovative In-house Use of Ultraviolet Irradiation for Conservation of Respirators in COVID-19 Pandemic. Indian J Crit Care Med 2020;24(8):713–715.

UV radiation was seen as an answer to both of our problems, but commercially available boxes were difficult to procure, and the cost was prohibitive. This was followed by the idea of developing a UV box in house. In a study by Lindsley et al., UV germicidal irradiation was effective in sterilizing the N95 respirators as well as preserving the quality of N95 respirators in the form of particle penetration and flow resistance.14 Similar results were also demonstrated in a study conducted by Mills et al.15

Laser lights represent high-intensity and focusable beams that can be imaged quite precisely, even over longer distances. The combination of lasers and image processing is used in a wide variety of operations like optical inspection of electronic components.

COVID-19 outbreak has infected more than 200 countries. In India, till now, more than 100,000 cases have been reported. Healthcare workers are at high risk of developing infections being in the frontline of taking care of COVDI-19 cases. The demands of personal protective equipment (PPE) are increasing, but the same is not matched with supply due to various reasons. In such scenarios, reusing respirators and face shields is an alternative. UV radiations have quick action and are able to preserve the quality of respirators. We have developed a UV box for surface sterilization of respirators with an intention to reuse.

There were a few drawbacks with the study and the design. First, the aluminum mesh placed in the middle of the box could hold only lighter items. It is likely that in future with its extensive use, there might be a need to replace the mesh. In addition to this, we could not test of virucidal efficiency of the box, but with the similar technique, virucidal activity of the UV cabinet was demonstrated by Cadnum et al. against adenovirus.11 Finally, we used only subjective method to assess the quality of respirators, and no objective methods were used. Although the limitation was due to unavailability of testing facility, we feel that for real-world applicability, subjective proof of preserved quality should suffice.

Ms.Cici

Ms.Cici

8618319014500

8618319014500