3.5 Polarization of Light – Analytical Methods in Geosciences - polarization of light

Teledyne Adimec is an ISO 9001:2015 certified medium- sized company that designs and produces reliable industrial cameras in small batches to meet customer demands at global OEMs. We serve three strategic markets. – Machine Vision, Healthcare and Global Security.

By using specific construction materials or additional coatings, UV lamps can be adjusted to block or increase the emission of certain wavelengths. The spectral output of a mercury-based UV lamp can also be shifted by adding other metals such as iron, gallium, lead, tin, bismuth, or indium. This is referred to as ‘doping’.

Widefield microscope

One of the key components of machine vision imaging is determining what kind of lighting is optimal for your set-up to achieve the best light-dark contrast; bright field lighting or dark field lighting. Bright field is the more commonly used lighting technique whereas dark field is advantageous when imaging things such as reflective surfaces and edge inspections. In this blog we will discuss the lighting requirements for Bright Field and Dark Field Illumination and their advantages and disadvantages in imaging.

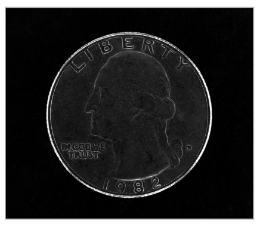

Unlike in bright field lighting, where reflected light is imaged, dark field lighting only captures scattered light. By imaging only the scattered light, edges and surface defects become more prominent in the image as they are the things that best scatter light. To best set up a light source for this light scattering, a low angle of light (usually from ring lights) of around 10-15 degrees is ideal. This low angle allows for edges, defects, ridges, etc. to properly scatter the light while not having the surface of the target reflect too much light back to the camera. This technique can also be used to effectively inspect highly reflective or mirrored surfaces which you would otherwise be unable to inspect with bright field lighting.

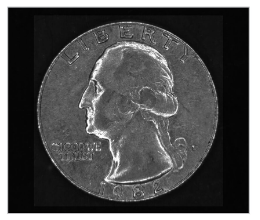

See below a comparison of images taken with Bright Field Illumination and images taken with Dark Field illumination to see the differences between the two lighting techniques:

Depending on the type of application and the composition of the materials in use, there will be a different reaction to the ultraviolet light being applied, which in turn will affect the effectiveness of the overall system.

For example, iron-doped mercury lamps shift part of the ultraviolet output to the longer UV-A near-visible wavelengths which result in better penetration through thicker, heavily pigmented ink formulations.

Bright field lighting is the method for imaging reflected light. That is, the light coming from the source is reflected into the camera so that small defects and edges which typically scatter light are not picked up by the camera. This creates a bright image, but areas with engravings, scratches, or indentations may not be as well defined. In addition, due to the reflection of light, reflective surfaces are difficult to image with this lighting set-up. The light source will be scattered less by the object’s surface and more light will be reflected back into the camera, causing a bright spot in the image, as seen below. To properly set up Bright Field Lighting, you want the light sources to be at an angle to the subject or imaging surface of 45 and 90 degrees. Typically positioning these light sources closer to the subject or surface is advantageous, as this helps cover a larger surface area and can help eliminate some of the issues seen with imaging reflective surfaces or edges.

If you’d like to understand more about how ultraviolet light in a curing, coating or bonding system could work for you, CONTACT US.

Criticalillumination

Ultraviolet light is a range of wavelengths from 250 nm to 400nm. Most of UV light is invisible to the human eye but a small amount is visible at longer wavelengths. UV-C has the shortest wavelengths and highest energy. UV-B and UV-A sit in the middle of the spectrum and UV-V has the longest and lowest energy.

Köhlerillumination

The well known Photo Response Non-Uniformity, or PRNU, calibration is optimized to reduce the pixel-to-pixel variation independent of the shading caused by the camera lens. This calibration combined with bright field lighting allows for the optimization of bright field measurement. Often this calibration is used in conjunction with the Low Frequency Flat Field correction, which is a calibration that not only removes shading caused by the lens, but by using multiple live sets of calibrations it can correct for the shading of the different light sources. Thanks to camera sensitivity matching and these calibrations, the same lighting recipe can be used with each Adimec camera. They all will return the exact same measurement, independent of which camera you put in your machine.

Whoever I looked into darkfield Microscopy, and there is a short animation of how it works on wikipedia (https://en.wikipedia.org/wiki/Dark-field_microscopy) To work with this method to check on exomes, I can imagine some wavelengths work better than others based on the type and size of the exome (so that specific light is scattered more and gives a better/sharper image results) I do not have any formulas to for you to work with, but note that a lot of factors are dependent on the setup you are using (lenses, wavelength, size and angle of darkfield patch stop, and distances from Lightsource-to sample- to camera, in addition to the sample properties (thickness, transparency etc).

Gallium-doped mercury lamps are used to create UV-V spectrum light which is good for white coatings, either in printing or in the furniture coating industries (especially if they contain titanium dioxide).

Almost each manufacturing process that requires a UV curing, coating or bonding system will have unique requirements. It’s a complex mix, ranging from the type of materials being used, quantities, sizes and power and length of time required for the process to work.

Knowing what type of lamp and system to use to get the best result for your needs is where the experts come in. Any established original equipment manufacturer will know how to assess and calculate the right UV lamps for the best results from their systems. It’s important to get this right from the start so that production can be efficient and produce consistently high-quality results.

Lamps used in these industries are made from high-quality quartz that allows for the most effective transmission of UV light. The tubes are filled with noble gases (such as argon and xenon) and additional chemicals. When an electrical current is passed through the lamp the reaction of it excites the elements inside and creates UV light.

Ultimately, these lighting techniques are used to help you achieve the key principle of machine vision illumination, which is to capture the correct light-dark contrast in the image. The techniques and principles for dark field and bright field illumination are there to assist you with properly setting up the best illumination for what you are imaging, and it is always advisable to test with a few different illumination set-ups. An inspection may in theory be best suited by bright field illumination, but you may discover that after testing the set-up, there could be a reflection that makes the inspection impossible, at which point understanding the lighting techniques for dark field illumination can assist you in eliminating this reflection.

Darkfield microscopy is not a area where we at Adimec specialize in, and we focus mainly on the camera (so only a bit on lighting & lenses), so I can’t give much feedback on your question.

The only answer I can give you why a darkfield image is preferred over a brightfield image: With a darkfield image you clearify the edges or structures of sampels, this method is used to detect or check non-uniformities like a defect or if a required structure is present. Like in the wikipedia site, they do this to see the edges of bloodcells, making them easy to count, check on “roundness”, or detect non-uniformities.

Darkfieldmicroscopy

Adimec’s cameras are optimized to have the lowest read noise when they leave the factory. By supporting analog gain the read noise can even further be decreased. This optimization increases the measurement accuracy in the darkest parts of an image. The cameras are calibrated in Adimec’s factory by using a Dark Signal Non-Uniformity (DSNU) calibration. While they are calibrated in factory, these cameras can be re-calibrated in a system to optimize the image even further depending on the use case. This DSNU reduces pixel-to-pixel fixed pattern, which in turn increases the measurement accuracy

UV lamps are built to different specifications that consider the type of materials in use and the curing, bonding or coating required. By using different amounts and mixes of the core elements, different ranges of light from UV-C to UV-V are produced.

Hi Scott, let me introduce myself, Recently I’m doing research to build a Dark Field Microscopy that is able to observe an exosome. So, if you willing you can reply my question by emailing me. I want to ask about the light that we can use for darkfield microscope. Which do you recommend between using laser or light to apply it to the darkfield microscope and can you provide the potential candidate of the light source? . Second question is how we know the required intensity is needed for the dark field imaging system (if know do you know how to calculate it?). Third question do you know the reason why darkfield will achieve better resolution than brightfield? (if you know the calculation you can provide to me).

Alpha-Cure works with many OEMs to manufacture UV lamps for their systems. This means we build to system specifications and requirements adding in doping chemicals where required.

The most common element added to the lamp is mercury as this produces a broad-spectrum output across UV, visible, and infrared wavelengths.

This will not only impact the exposure times required to cure, bond or coat but also the long-term effectiveness of the treatment.

The use of ultraviolet (UV) light lamps in the curing, bonding and coating industries is well established but the technical application of how UV light works in each of these operations does differ. This is due to a combination of the type of light applied, the distance and length of exposure time and the type of ink, glue or coating.

These different types of light travel different lengths through a substrate and so have different uses in the curing, costing and bonding industries.

In order to gain the best outcome, experts working with each industry have developed specific techniques to gain the most effective use of ultraviolet light solutions.

Ms.Cici

Ms.Cici

8618319014500

8618319014500