Luxury Illuminations - custom illuminations

Feb 20, 2022 — Diffused light is used for soft lighting and less harsh shadows. It is often more flattering on a subject. To visually understand diffusion and ...

This sealant stays clean and fresh. It's 100% waterproof and crack-proof, safe for granite and marble, and offers strong adhesion and flexibility for long- ...

lacquered & lit from behind. Painted full acrylic glass body with embedded LEDs. As with all of our products, we aim to create long-lasting stylish ...

The only LED lighting company in Miami and broward that offers lighting installation for commercial, architectural, LED strips, Wall Lights, LED Linear ...

Just another spot light? No, a LIFX SuperColor smart LED spot light. This is unlike any spotlight you've ever seen. Not only can it illuminate your ...

High speed, 100% automated inspection at the rate of several components per minuteAI & ML based deep learning tech that learns and adapts to a wide range of productsQuality Insights & manufacturing stats and at one placeEliminates Human Error and costs associated

With the high pace of growth in manufacturing, several supply chain issues arise, of which quality (and regulatory approval) of the products is the most critical. Many manufacturers – big & small – still use manual and semi-automated quality inspection processes, which acts as supply-chain bottleneck and huge quality threat

This solution inspects the fill-level and detects any foreign body in opaque containers. It utilizes Automated X-ray Inspection (AXI) to automatically inspect aspects which are otherwise hidden from view. Wherever large numbers of very similar items are produced according to a defined standard, our AXI based Opaque Bottle Inspection System proves to be invaluable tool to ensure quality and to improve yield in processing and manufacturing.

・Illuminated Magnifiers / Wide-view Illuminated Magnifiers / Energy-saving, LED Illuminated Magnifiers ・Interchangeable Lens System for Illuminated Magnifiers ・Multi (AR) Coated Interchangeable Lens System for Fatigue and Inspection Accuracy Improvement ・LED Inspection Lighting for Surface Scratches ・LED Inspection Loupe for Holes, Dents, and Interior / Stereoscopic Microscope / Loupe

Our solution utilizes a combination of machine vision and AI/ML algorithms along with robotics to help detect & eliminate products with skewed labels, label shift and improper variable data.

Thingularity is an engineering services & technology solutions company with core expertise in the Internet of Things, Industry 4.0, Embedded Systems, Cloud, and AI & ML.

Caps & Crowns InspectionAmpoule Inspection System & Vial Inspection SystemDimension CheckCosmetic CheckFill CheckCountingBottle Orientation SystemCaser – with 6 Axis / SCARA RobotCaser – Cartesian RobotUn-Caser – Cartesian Robot

M Sugimoto · 2021 · 8 — For calibration, a projector projects a series of structured light patterns in the device. The pinholes directionally decompose the structured ...

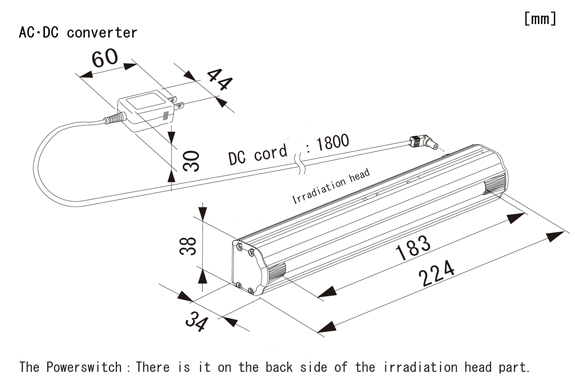

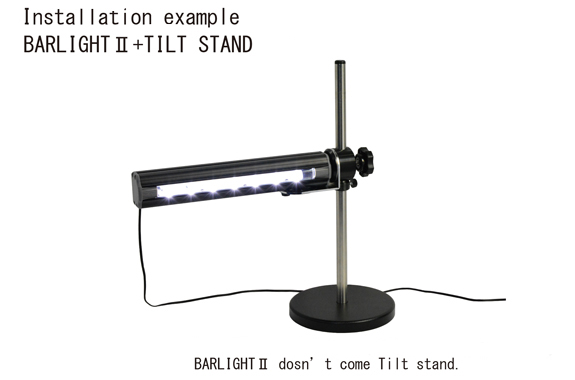

■Product features Barlight is a lighting equipment for inspection to easily detect defects with rough surfaces such as fine scratches, dust, and sink marks, by illuminating the object with planar light rays with a combination of bright LED and parallel arranged lens. By using the product in combination as an auxiliary light for optical equipment such as an illuminated magnifier, as well as any single use items, it is possible to improve the detection of defects. With the BARLIGHT 2, there is no adjustment function for the light intensity or the irradiation divergence angle of the light beam. Therefore, everything fixed. As an option, the “Tilt stand” is to fix a single product, the “Double tilt stand” for two products, the “Barlight Free-arm” for environments where more flexibility is necessary, and “Barlight grip” for holding the product with only one hand, are available.

NL-1029 Nirvana Lighting Ceiling Recessed Spot Light · WIPRO Garnet 3w Mini Led Spotlight, Round, WH/WW/BL/GR/RED · Spot LED Light in Uttarakhand, Warm White, 12 ...

【OTSUKA】 ・MAGNALIGHT ・Surflight series ・OLIGHT6 series ・OLIGHT5 series ・OLIGHT3L series ・OLIGHT3 6500K series ・OLIGHT3 series ・SKKL series ・ENVL6K series ・ENVL series ・LSK WIDE series ・LED-OSL/WiDE series ・OSL/WiDE series ・SKK series ・Boreloupe series ・Barlight series ・Modelight series ・o-scope/o-scope2 ・Toru-kun OTS-3 ・Interchangeable lens system ・Anti-reflection Coating Lens ・option loupe ・Circular fluorescent lamp tube FCL20EX-N/18

Label Inspection System: Container labels are key for a company’s branding and product information. Improperly applied labels spoil the aesthetics of the package, company credibility and product image.

Imperfect empty bottles and defects in them lead to stoppages in the filling line. By removing these defective bottles, higher efficiency in filling line can be achieved. Our solution utilizes a combination of machine vision and AI/ML algorithms along with robotics to helps detect imperfections like deformed bottles, cracks, chip-offs, and flaws in the mouth area, base and side wall in an automated fashion

・General Inspection ・Visual Inspection / Appearance Inspection / Appearance Visual Inspection / 100% Inspection / 100% Visual Inspection / Sampling Inspection ・Inspection for Surface Scratches / Inspection for Surface Dust ・Surface Irradiation Method / Diffused Reflection Method ・Burrs on Blind Hole / Visual Inspection for Foreign Article ・Burrs on Deep Groove / Scratches / Visual Inspection for Foreign Article

Machine Vision technology with latest image processing algorithms to identify visual defectsOptics & Lighting to ensure accurate image processing‘Good’ and ‘Bad’ or Other categories bifurcationReal Time Control and visibility of operation

May 3, 2013 — Harsh light gives darker shadows because of the contrast (the in comparison thing). There is a much larger contrast between light and dark areas ...

Labels also carries important variable data like manufacturing date, expiry date, batch number and other plant data to help tracking and tracing in the event of a customer complaint and for regulatory purposes. Improper labels can lead to consumer complaints, dissatisfaction and regulatory challenges.

Our automated Inspection solutions employ proprietary and industry-best approaches & components and provide the following benefits

・HOME ・Company Overview ー About Us └ Our Business └ Company Profile └ Our History ・Products ー OOTSUKA └ LUXO ・Downloadー Demo Unit └ Issuance of Certificate of Non-applicability └ Warranty Certificate ・Contact Us └Frequently Asked Questions

Nationwide Vision has ten eye care centers around the Scottsdale, Arizona area. Find an eye doctor near you & schedule an appointment today!

Missing Parts DetectionAssembly Integrity: Timing gear matchingValve Lock CheckMachining Defect Check (burs)Contact Area Verification with Matching GearGear Angle Measurements

Use our online form or Builder tool to design your own custom neon bar sign. You can choose your font, colors, and backing now!

The challenges posed by manual and semi-automated quality inspection cannot be overstated given the regulatory, financial & public relations implications of poor quality, especially for products like food, beverage, drugs, medical devices, auto components, electronics, etc. While companies are looking to fully automate their inspection processes, most existing solutions are very expensive, can not adapt to the range of products in the market and lack the flexibility required for different product lines.

Thingularity works with leading technology partners in the field of AI/ML & Vision based inspection solutions to offer affordable, fully-automated, and high-throughput solutions for the following industries applications

Ms.Cici

Ms.Cici

8618319014500

8618319014500