Lighting - light vision

Both designs can, with the right front cover, produce excellent UGR performance. To compare different brands and models look at the UGR tables that are part of the photometric data that should be available from all reputable manufacturers.

LEDBacklight Panel Price

We use cookies to make our services work and collect analytics information. To accept or reject analytics cookies, turn on JavaScript in your browser settings and reload this page.

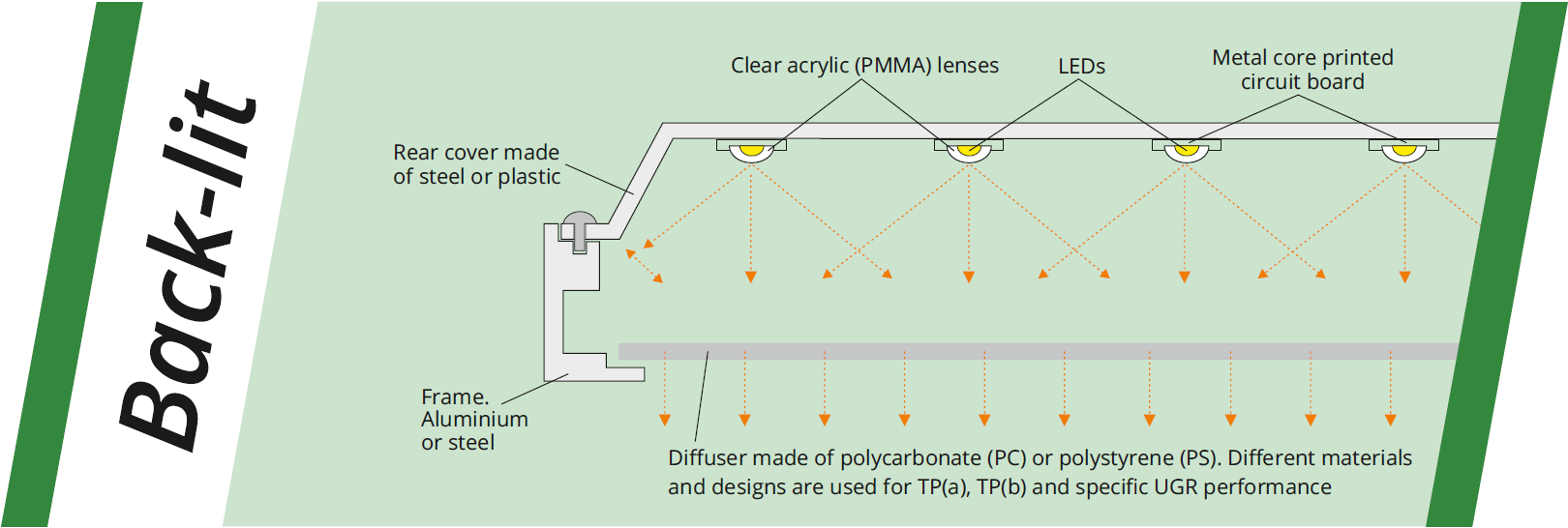

A back-lit LED panel is made of an array of LEDs fitted on a horizontal plate shining vertically down through a diffuser into the space to be illuminated. Back-lit panels are sometimes also known as direct-lit panels.

Backlit lightingphotography

The lighting market now accepts back-lit panels as readily as edge-lit panels. Here at NVC we have had both designs in our product range, but we have decided that edge-lit is marginally better. This is because the rear of the panel is the most convenient position for the driver and, because we offer 5 and 7 years warranties, we are keen that the driver should remain as cool as possible.

BacklightLED

In an effort to reduce the cost of edge-lit panels some manufacturers introduced cheaper materials and assembly processes that impacted on their quality. Principally, this involved the LGP. Polystyrene (PS) LGPs are now used by some manufacturers, but if UV stabilisers are not added these will yellow with age and the panel will become dull in the centre while the periphery remains bright. Also, PS has a lower light transmission % than PMMA.

An edge-lit LED panel is made of a row of LEDs attached to the frame (or circumference) of the panel, shining horizontally into a light-guide plate (LGP). The LGP directs the light downwards, through a diffuser into the space below. Edge-lit panels are sometimes also known as side-lit panels.

Because they have no LGP it is possible to make back-lit panels relatively cheaply. This leads some manufacturers to promote back-lit panels as a low-cost option.

Ms.Cici

Ms.Cici

8618319014500

8618319014500