Led Diffuser - diffuse led light

The optional parameter `\alpha` is a derivative filter constant. The filter reduces the effect of measurement noise on the derivative term that can lead to controller output amplification of the noise.

PI or PID controller is best suited for non-integrating processes, meaning any process that eventually returns to the same output given the same set of inputs and disturbances. A P-only controller is best suited to integrating processes. Integral action is used to remove offset and can be thought of as an adjustable `u_{bias}`.

A PID (Proportional Integral Derivative) controller consists of three components that are adjusted based on the difference between a set point (SP) and a measured process variable (PV).

$$\frac{d u(t)}{dt} = \mathrm{KP}\,\color{red}{\frac{d e(t)}{dt}} + \mathrm{KI}\color{green}{e(t)} + \mathrm{KD} \color{blue}{\frac{d^2e(t)}{dt^2}}$$

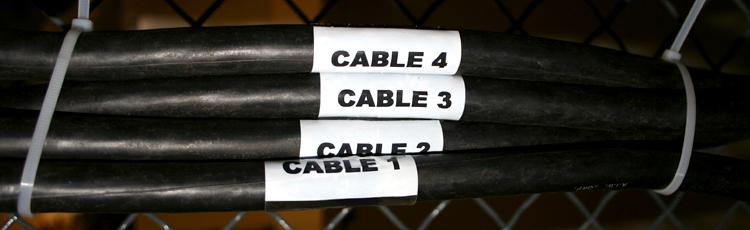

While color can rapidly provide some information, the amount of information is limited. For example, if a cable marker is blue, that might indicate that it's part of a specific subgroup of the local network. Printed text on the label, though, could identify which specific workstation uses that cable, which port on the server it should be connected to, as well as when the cable was installed. With information wiring, printed labels can be a necessity.

$$K_c = \frac{2 \zeta \tau_s}{K_p \left( \theta_p + \tau_c \right)} \quad \quad \tau_I = 2 \zeta \tau_s \quad \quad \tau_D=\frac{\tau_s}{2 \zeta}$$

$$u_k = u_{k-1} + \mathrm{KP} \, \left(e_k-e_{k-1}\right) + \mathrm{KI}\, e_k \Delta t - \mathrm{KD} \frac{PV_k-2 PV_{k-1} + PV_{k-2}}{\Delta t}$$

The derivative of the error is substituted with the derivative of the Process Variable (PV) to avoid derivative kick when there is a setpoint change. The value of the controller output `u(t)` is transferred as the system input. The KP, KI, and KD parameters from the Independent form can also be written in terms of controller gain `K_c`, integral reset time `\tau_I`, and derivative time constant `\tau_D`. All terms depend on a single controller gain `K_c` and this is known as the Dependent form of the PID equation.

In the United States, the following color codes are typically used for power wires in "branch circuits," the wiring between the last protective device (such as a circuit breaker) and the load (such as a tool or appliance).

Active vs passiveoutput

IMC tuning correlations are available for a range of model forms. With a second-order plus dead-time model there are 4 parameters `K_p`, `\tau_s`, `\zeta` and `\theta_p` adjusted to fit the model response to data.

$$u(t) = u_{bias} + K_c \, e(t) + \frac{K_c}{\tau_I}\int_0^t e(t)dt - K_c \tau_D \frac{d(PV)}{dt} - \alpha \tau_D \frac{du(t)}{dt}$$

A PID (Proportional-Integral-Derivative) controller is a control loop feedback mechanism widely used in industrial control systems and other applications requiring continuously modulated control. It is a type of control system that uses feedback to continuously adjust the output of a process or system to match a desired setpoint.

Where more detailed information is helpful (or even necessary), the DuraLabel line of label printers offer a simple and reliable way to print long-lasting markers and wire tags. Self-laminating wire wraps and heat-shrink tubes are available to create clean, professional labels for your project.

Controller outputdefinition

Most European countries follow a wire color code established by the International Electrotechnical Commission (IEC) for AC branch circuits. This standard was originally published as IEC 60446, but was merged into IEC 60445 in 2010.

Most narrow wires will be color-coded by the manufacturer, using insulation of different colors. When wires are larger than #6 AWG, they will typically be manufactured with black insulation. In these cases, color coding should be added during installation, using colored bands that wrap around the wire.

PIDcontrollerPython

PID controllers are widely used in a variety of applications, including temperature control, flow control, and motor control, due to the PID ability to provide stable and accurate control with relatively simple implementation. Below is an example with the Arduino-based Temperature Control Lab.

Although the "derivative" term implies `(de(t))/dt`, the derivative of the process variable `(d(PV))/dt` is used in practice to avoid a phenomena termed "derivative kick". Derivative kick occurs because the value of the error changes suddenly whenever the set point is adjusted. The derivative of a sudden jump in the error causes the derivative of the error to be instantaneously large and causes the controller output to saturate for one cycle at either an upper or lower bound. While this momentary jump isn't typically a problem for most systems, a sudden saturation of the controller output can put undue stress on the final control element or potentially disturb the process.

The output of a PID controller (u(t)) is calculated using the sum of the Proportional, Integral, and Derivative terms where KP, KI, and KD are constants that can be adjusted to fine-tune the performance of the controller.

Type B PID equation removes the setpoint from the derivative term to avoid derivative kick when there is a setpoint change because the error is discontinuous and leads to an impulse in the controller output (u).

Wiring used for telecommunications or computer network applications use a different approach for identifying data cables. The ANSI/TIA/EIA 606-A standard includes recommendations for marking telecommunications wires. This standard provides a consistent approach that can be applied to many different kinds of connections over time.

Note that older installations may use different color codes. In workplaces, it's a good idea to document the color code that is being followed. This way, work will be safer, and future maintenance will be easier.

Digital controllers are implemented with discrete sampling periods and a discrete form of the PID equation is needed to approximate the integral of the error and the derivative. This modification replaces the continuous form of the integral with a summation of the error and uses `\Delta t` as the time between sampling instances and `k` as the number of sampling instances. It also replaces the derivative with either a filtered version of the derivative or another method to approximate the instantaneous slope of the (PV).

$$u_k = u_{k-1} + \mathrm{KP} \, \left(e_k-e_{k-1}\right) + \mathrm{KI}\, e_k \Delta t + \mathrm{KD} \frac{e_k -2 e_{k-1} + e_{k-2}}{\Delta t}$$

PIDcontrollertransfer function

If the wiring system has one phase at a higher voltage than the others, using a "high-leg" connection, that phase's wires should be marked with orange. (This is required in NEC article 110.15.) However, these high-leg delta systems are uncommon with newer installations.

The most common tuning correlation for PID control is the IMC (Internal Model Control) rules. IMC is an extension of lambda tuning by accounting for time delay. The parameters `K_p`, `\tau_p`, and `\theta_p` are obtained by fitting dynamic input and output data to a first-order plus dead-time (FOPDT) model.

Plot the error, integral of error, and derivative of the PV for the following response. Show the value of the PID controller output and the contributions of each term to the overall output.

Integral (I) control: This component adjusts the output based on the accumulated error over time. It helps eliminate steady-state error and can improve the stability of the control system.

Wire markers should be visible during installation and normal maintenance of the wiring systems. When those labels use printed text, they should use high-contrast and durable print. Whatever marking system is used for the cables and wires in your facility, the markings should be durable enough to last as long as the wires themselves.

For higher-voltage cases, it becomes even more important to have a documented wire labeling system. More detailed labels can include information like circuit identification, or the appropriate disconnection point for lockout/tagout.

PIDcontroller

$$u_k = u_{bias} + K_c \, e_k + \frac{K_c}{\tau_I}\sum_{i=1}^{k} e_i\Delta t - K_c \tau_D \frac{PV_k-PV_{k-1}}{\Delta t}$$

Proportional (P) control: This component adjusts the output of the process based on the current error between the setpoint and the process variable (PV). The larger the error, the larger the correction applied.

$$K_c = \frac{1}{K_p}\frac{\tau_p+0.5\theta_p}{\left( \tau_c + 0.5\theta_p \right)} \quad \quad \tau_I = \tau_p + 0.5 \theta_p \quad \quad \tau_D = \frac{\tau_p\theta_p}{2\tau_p + \theta_p}$$

PDcontroller

Type C PID equation also removes the setpoint from the proporational term to avoid a similar impulse when there is a setpoint change. In velocity form, the proportional term uses the derivative of the error and eliminating sudden changes in the controller output is often desirable when there are setpoint changes.

Note that with moderate tuning and negligible dead-time `(\theta_p to 0 " and " \tau_c = 1.0 \tau_p)`, IMC reduces to simple tuning correlations that are easy to recall without a reference book.

Derivative (D) control: This component adjusts the output based on the rate of change of the error. It helps to dampen oscillations and improve the stability of the control system but is often omitted because PI control is sufficient. The derivative term can amplify measurement noise (random fluctuations) and cause excessive output changes. Filters are important to get a better estimate of the process variable rate of change.

Type B and Type C (preferred) are commonly used in industrial practice. The PID output is initialized to the starting manual controller output `u_0` when the controller is first initialized. If the controller output reaches an upper or lower actuator limit, then the output `u_k` is clipped to that limit. Changes in tuning parameters do not lead to a sudden jump in the controller output.

$$K_c = \frac{1}{K_p} \quad \quad \tau_I = \tau_p \quad \quad \tau_D = 0 \quad \quad \mathrm{Simple\,tuning\,correlations}$$

pd controller是什么

The `u_{bias}` term is a constant that is typically set to the value of `u(t)` when the controller is first switched from manual to automatic mode. This gives bumpless transfer if the error is zero when the controller is turned on. The three tuning values for a PID controller are the controller gain, `K_c`, the integral time constant `\tau_I`, and the derivative time constant `\tau_D`. The value of `K_c` is a multiplier on the proportional error and integral term and a higher value makes the controller more aggressive at responding to errors away from the set point. The integral time constant `\tau_I` (also known as integral reset time) must be positive and has units of time. As `\tau_I` gets smaller, the integral term is larger because `\tau_I` is in the denominator. Derivative time constant `\tau_D` also has units of time and must be positive. The set point (SP) is the target value and process variable (PV) is the measured value that may deviate from the desired value. The error from the set point is the difference between the SP and PV and is defined as `e(t) = SP - PV`.

$$u(t) = \mathrm{KP}\,\color{red}{e(t)} + \mathrm{KI}\color{green}{\int_0^t e(t)dt} + \mathrm{KD} \color{blue}{\frac{de(t)}{dt}}$$

In Canada, wire color coding standards are set by the Canadian Electric Code (CEC). The color code for AC power wiring is similar to the code used in the United States:

$$\frac{de(t)}{dt} = \frac{d\left(SP-PV\right)}{dt} = \frac{d\left(SP\right)}{dt} - \frac{d\left(PV\right)}{dt} = - \frac{d\left(PV\right)}{dt} $$

PIDcontrollerPDF

In discrete form, this leads to PID equation Type A, known as the textbook PID where k is a sample index and `e_k=SP_k-PV_k`.

The color codes used for wires can vary. In some areas, a color code is specified by law; other areas rely on common practice. Different codes are popular in different areas.

An alternative to the positional form shown above is the velocity form. This is commonly implemented in control systems such as Programmable Logic Controllers (PLCs) and Distributed Control Systems (DCSs) for industrial control. The advantage of the velocity form is that changes in the Proportional and Integral tuning parameters do not lead to sudden jumps in the controller output. The velocity form is obtained by differentiating the positional form.

An important feature of a controller with an integral term is to consider the case where the controller output `u(t)` saturates at an upper or lower bound for an extended period of time. This causes the integral term to accumulate to a large summation that causes the controller to stay at the saturation limit until the integral summation is reduced. Anti-reset windup is that the integral term does not accumulate if the controller output is saturated at an upper or lower limit.

There are many wire identification standards, and many of them rely on color codes. Not all electrical wiring color codes are the same, though, and some even contradict each other. Which standard should be used in your facility? It depends on your location, installation type, voltage, and other factors.

$$u_k = u_{k-1} - \mathrm{KP} \, \left(PV_k-PV_{k-1}\right) + \mathrm{KI}\, e_k \Delta t - \mathrm{KD} \frac{PV_k-2 PV_{k-1} + PV_{k-2}}{\Delta t}$$

Ms.Cici

Ms.Cici

8618319014500

8618319014500