Illuminati - illuminati lighting

Belllighting

As the object characteristics of inspected part cannot or can only hardly be influenced, the object determines the illumination and the camera! The camera, in turn, defines the optics due to its working distance and mount, due to its data format and data rate it also determines the image acquisition card.

ArmadilloLIGHTING

Lighting plays a major role for industrial machine vision: Not the object itself, but only the visual image of the object is checked! It follows that only homogeneous lighting conditions result in a consistent image of the same inspection object. Fluctuating light conditions are therefore to be avoided at all costs!

VisionLight

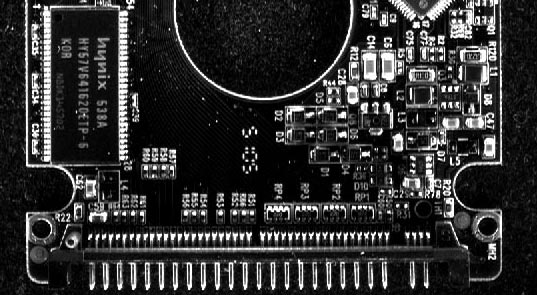

Direct frontlight illumination Surface partly very bright but overexposed, partly dark due to total reflection. Diffuse dom light illumination Surface smoothly illuminated due to homogeneous incident light. Dark field illumination Lateral edges are very bright. Scratches and dust are visible. Backlight illumination Part appears only as black silhouette. No surface information, contures ideal for measurement applications.

The key role plays the light with its interaction in a functional chain of illumination, test object, filter, lens and camera:

Only if it is possible to visualize the desired test characteristics or errors with enough contrast, these can then be evaluated with the image processing software. Usually the object is illuminated by an external light source. This principle sounds very trivial, but the practice reveals that it is one of the main difficulties of industrial machine vision to make the error in the object visible at all for the camera.

Ms.Cici

Ms.Cici

8618319014500

8618319014500