Dino-Lite BL-ZW1 Polarized Backlight Stage - backlight bl

Experience a beautiful, intuitive interface designed for all devices. Our solution prioritizes user experience and accessibility, ensuring a seamless, integrated platform for all employees. Simple and intuitive.

Pulsarlogin

System interoperability with our robust API integrations. Our platform supports seamless integration with ERP, MES, and APS, offering two-way communication capabilities. Our middleware allows you to access and utilize individual services independently. No hard integrations!

Pulsarsocial listening

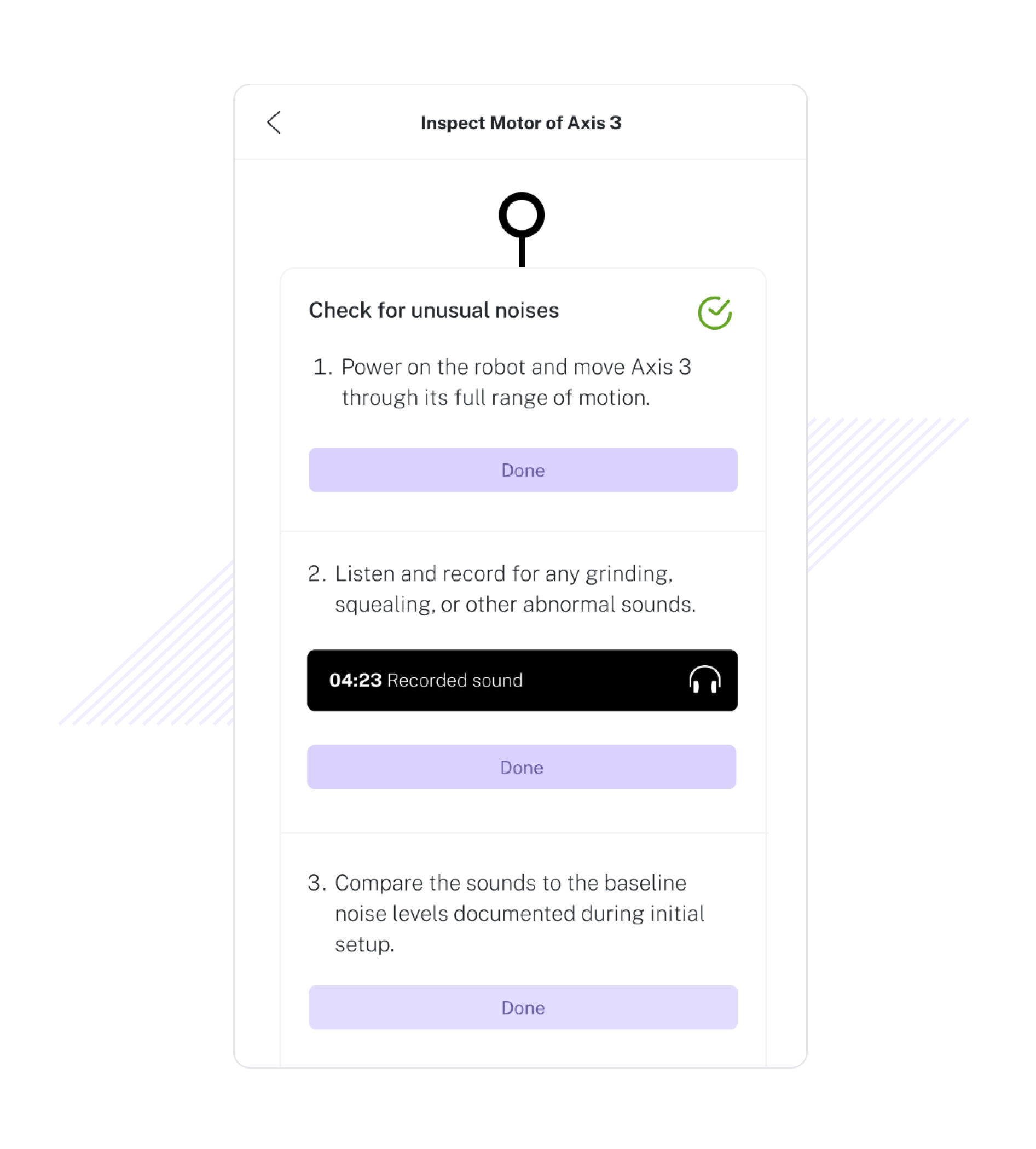

In today’s complex industrial environments, human errors—often resulting from fatigue, lack of motivation, or inexperience—can lead to significant operational challenges.We transform data from manuals, internal company processes into precise, step-by-step guides with AI generated in real time. These guides guide you through process, offering voice-guided support, add photos, spoken notes, and the ability to ask questions to experts. No more paperwork and mainly prevention of repeating errors due to lack of attention.

Explore all of our Pulsar maintenance solutions tailored to your factory. Our system is built with core and advanced features, configured to meet your specific needs. With these capabilities, we become the best digital version of your Head of Maintenance manager, transforming your processes and driving efficiency.

Pulsarpricing

Our system delivers real-time analytics from voice records, identifying machine issues and tracking who was involved and what actions were taken. It provides detailed reports on performance, along with a checklist of suggested improvements.

Enhance workforce management by retraining staff, identifying performance issues, and motivating employees with rewards. Our system enables the creation of custom maintenance plans tailored to individual skills and preferences, optimizing operational efficiency.

Upgrade your outdated maintenance ticketing systems to a modern, user-friendly interface that offers advanced features, lower licensing costs, and seamless AI integration. This ensures smarter, more efficient maintenance management.

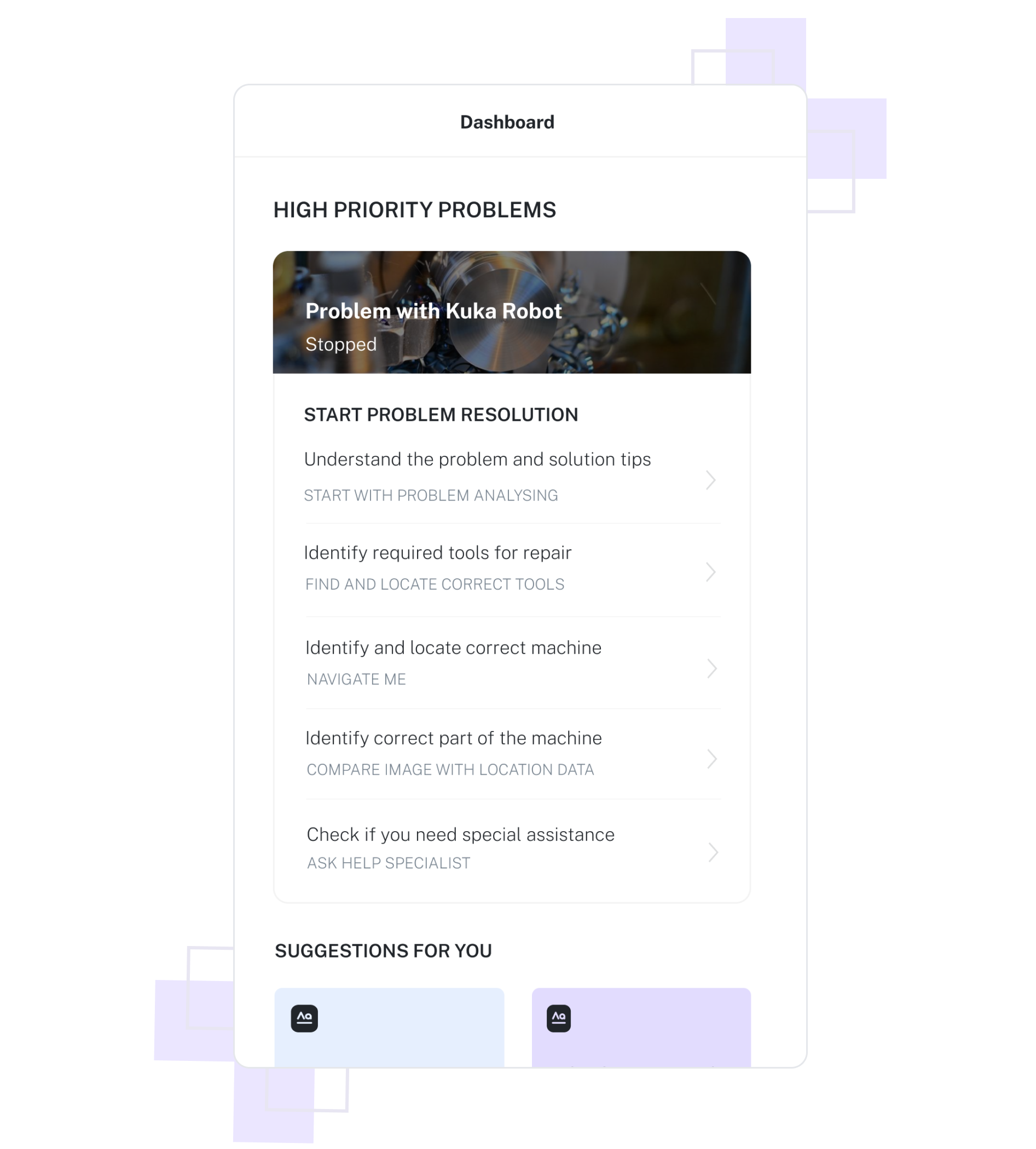

Optimize asset management with our solution that guides personnel directly to problematic machinery within the factory, assists in locating the necessary tools for immediate repairs, and verifies their position using photo-based map control to ensure accuracy and efficiency.

Pulsarplatform

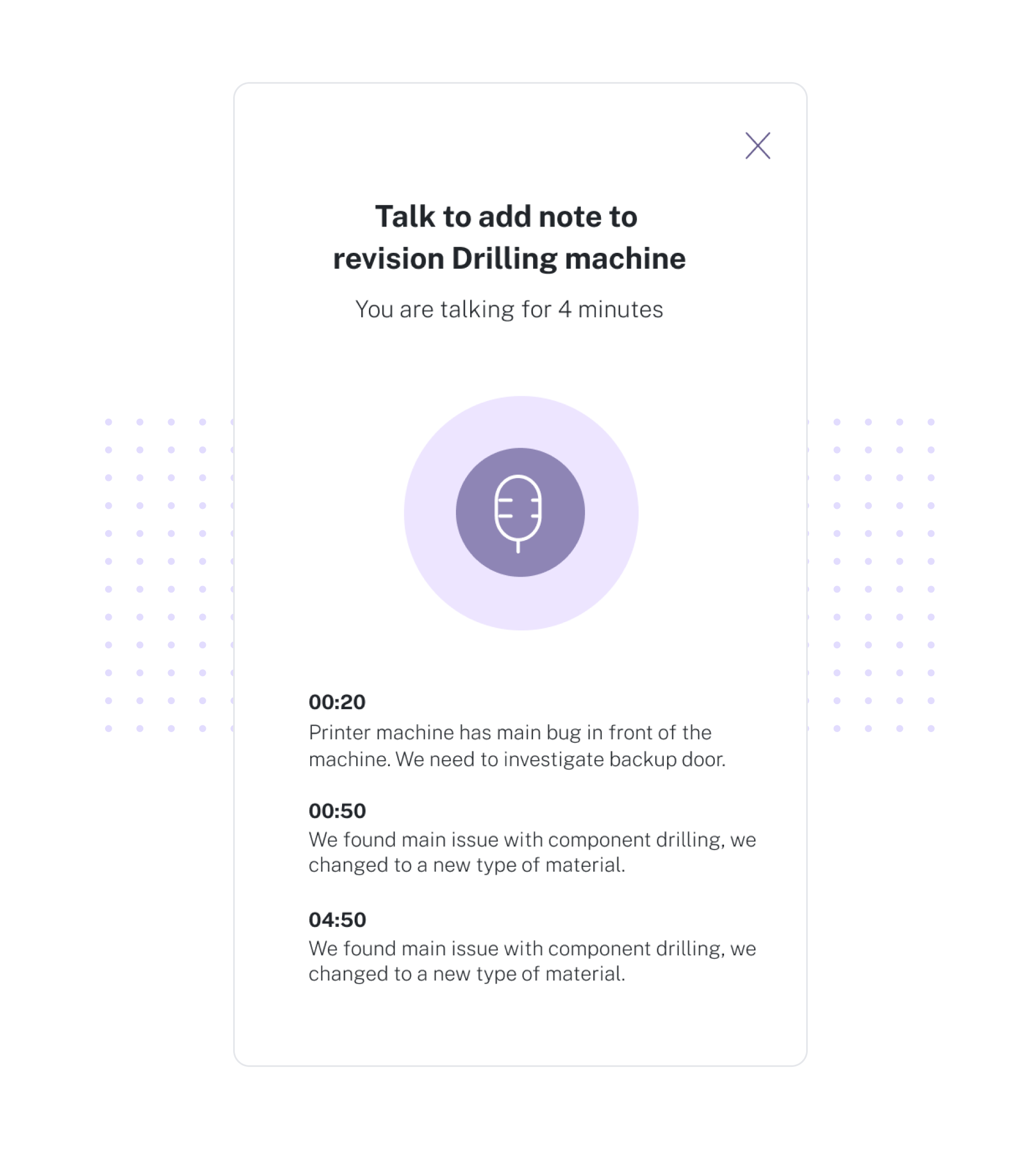

In many factories, crucial knowledge often resides solely with soon-to-retire experienced workers.Our solution bridges this gap through a voice assistant that allows experts to verbally share insights on operations, improvements, and practices. These are instantly shared factory-wide via notifications, enabling real-time training and feedback. This proactive approach preserves vital knowledge, ensures continuous learning, and enhances workplace efficiency. Data are updated real time, so you have always up-to-date information.

Predictive maintenance is often not feasible since machines rarely break, but prescriptive maintenance offering recommendations for optimal asset performance.

Elevate your maintenance management with our AI-powered shift summarization tool, designed exclusively for maintenance managers.At the end of each shift, it delivers comprehensive summaries of machine issues, safety incidents, and recommendations on what to focus on in the next shift. Voice or text to generate reports in any language. Custom questions provide deeper insights into specific concerns, while integration with other shift data ensures a complete overview for informed decision-making and smooth maintenance handovers.

HoloLens 2 AR/VR integration provides training and troubleshooting, enabling staff to perform complex tasks with precision. We also use it for interactive mapping of steps, automatically converting into guides without manual updates—bringing fun and life to your factory.

Unlock the full potential of your industrial systems with our AI maintenance solution, turning every data point into actionable insights. We believe that people who maintain, use or service machines will stay here even with machines innovations. Check below maintenance evolution to the future.

Streamline your maintenance knowledge by transforming all data—manuals, videos, spoken words—into a unified, computer-readable format. Automatic multilingual support and seamless data enhancement for optimal accessibility and consistency.

SoundOff LED Interior Dome Lights are designed with law enforcement in mind, to reduce officer targeting and improve officer safety. They are designed to cast a soft red glow which enables you to see inside your vehicle, yet still allows you to see what's going on outside. The red light allows officers the ability to see outside their vehicle, so no one can creep up and surprise them from the shadows. This Red LED light also prevents eye fatigue while providing officers with reliable interior lighting. These Dome Lights are surface mounts, which mean you don't have to cut out the headliner to install. The police vehicle model is compatible with the Dodge Charger, Ford Police Interceptor Sedan (Taurus based), and the Ford Police Interceptor Utility (Explorer based) only. The Universal Mount works for everything else.

CarLabsAI

Leveraging real-time data and analytics to monitor your factory health and optimize maintenance schedules. Increased collaboration and communication between teams.

Enhance maintenance with our AI Voice Assistant, designed for guided revisions and real-time communication between machines and staff, facilitating effective problem-solving and streamlined shift transitions.

PulsarIsentia

Optimize maintenance with our data-driven system that provides proactive recommendations and alerts for smooth operations. It recognizes patterns, predicts outcomes, and ensures compliance with sustainability standards to enhance equipment performance and longevity.

PulsarTRAC

Deploy our MVP within a month and see instant improvements, with 10x faster integration times. Our streamlined setup process allows you to quickly realize the benefits without the typical delays associated with long integration periods.

Summarizes key issues, incidents, and problems at the end of each shift related to maintenance, detailing who was involved, what was fixed, and health insights. It also provides recommendations for the next shift and allows custom questions for deeper insights.

Retaining critical knowledge from experienced workers leads to create digital repositories of maintenance procedures, best practices and guides.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

PulsarGroup

Before launching, we'll assess your company's readiness for AI integration, validate data sources, and begin with a focused area of maintenance. Together, we'll design an MVP package tailored to your needs, ensuring a smooth and effective AI deployment.Ideally, we would like to show you our demo with your employees directly in your factory. To see the power of the solution in action.

Our system automatically optimizes maintenance schedules and allocates resources based on needs, while seamlessly integrating workforce scheduling to ensure skilled technicians are assigned precisely when and where they are needed most.

Traditionally, resolving ad hoc issues or starting maintenance in a factory setting can be time-consuming, involving multiple notifications and operational halts.Our solution changing this process by providing instant problem identification through analysis of manuals and historical logs with AI. With voice-guided solutions and precise machine and tool location tracking, enable you to start maintenance or resolve issues swiftly, minimizing downtime and enhancing productivity. Immediatelly and without errors!

Maintenance inspections from AI-generated steps from manuals, voice-assisted guided revisions, photo data integration, and continual knowledge updates for streamlined operations and real-time knowledge enhancement.

Transform your factory operations with our intelligent system that provides a real-time overview of training and competencies from experienced workers, identifying skill gaps and optimal staff replacements instantly.Comprehensive problem logging differentiates between human and machine errors from voice records or machines, ensuring detailed reporting. Our solution also prepare shift handover documentation from all reported activities, issues, and resolutions for seamless transitions of informations between maintenance managers at the end of shift. Focused shift-related data in one place for enhanced worker safety.

Enhance teamwork and focus on people, together. Designed to foster a more connected and productive workplace, our solution empowers employees to work together effectively, driving innovation and improving satisfaction.

Ms.Cici

Ms.Cici

8618319014500

8618319014500