Compact Light Essential - compact light

The next level, Level 1, in the Decision Intelligence System “DIS” framework, comprises the specific applications or use cases of Digital Twins. Each use case addresses a business challenge or seizes an opportunity within the overarching value chain. These use cases are divided into eight universal categories consistently relevant across various industries, a focal point for XMPro’s solutions.

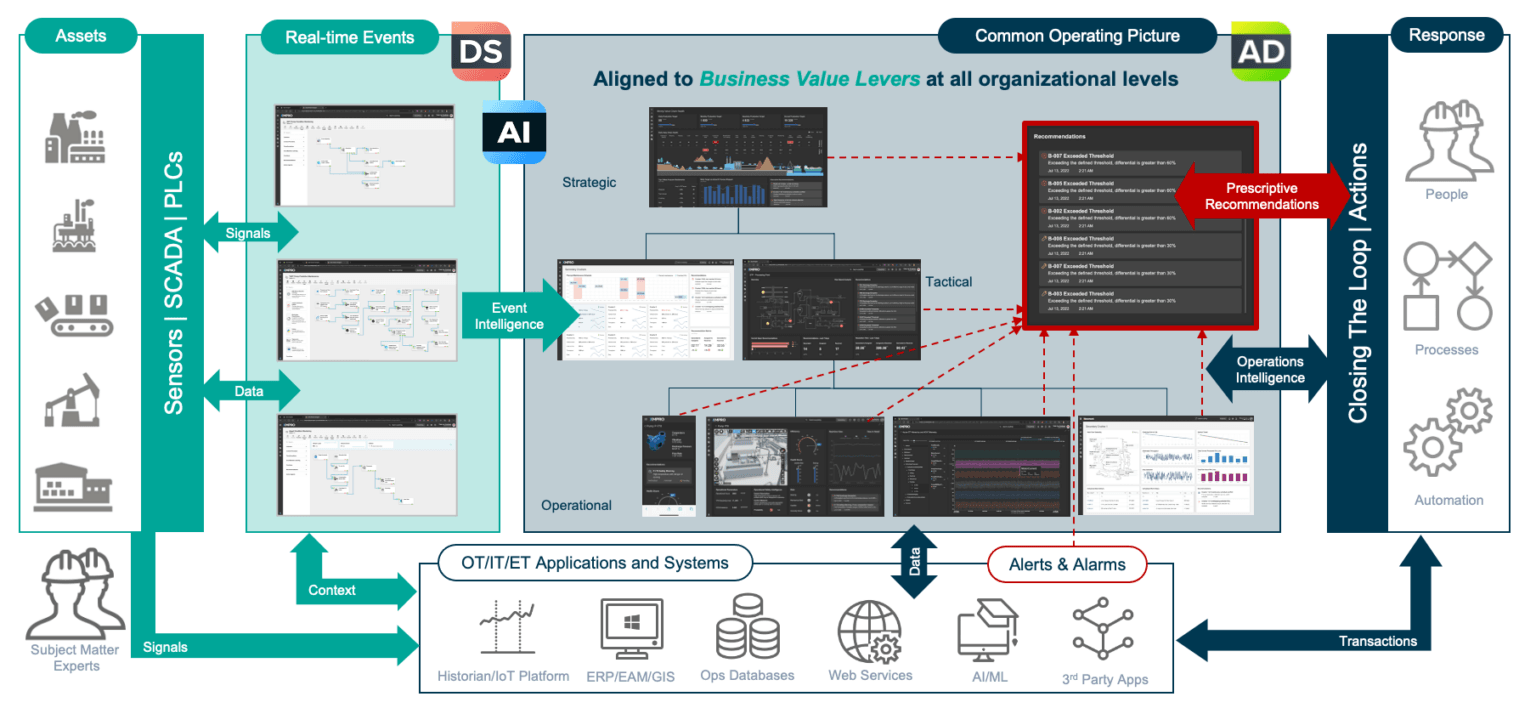

The digital twin architecture encapsulates three key models of decision enablement – decision support, augmentation, and automation, all under a robust umbrella, known as a Decision Intelligence System DIS. DIS revolutionizes business process automation by drawing parallels to how Distributed Control Systems (DCS) provide intelligence for automating plant or factory operations. Fueled by XMPro’s effective digital twin management tools, this framework offers diverse use cases across industries. It creates a network of distributed intelligence throughout the organization, responding dynamically to the changing business environment.

A Distributed Intelligence System “DIS” will serve as a robust and dynamic repository for managing a broad spectrum of digital rules and models. It will house essential elements of hyperautomation, including diverse rulesets, artificial intelligence models, and other emerging digital meta-models and artifacts.

A stereo microscope is special in that it produces a 3D image of the specimen. Learn more about these unique models, who invented them and how they work.

Moreover, DIS goes beyond connecting the dots between different operational levels. It builds an executive-level Common Operating Picture that reframes operational and tactical data through a strategic lens. This comprehensive view allows leadership to influence business process rules, seamlessly translating strategic planning into operational execution.

As we move into the future, the ambit of digital twins will extend beyond decision augmentation to decision automation. They will operate within a safe framework, making strategic decisions based on AI, analytics, and established business rules. This leap forward will enable ‘lights-out’ operations, driving an algorithmic business model.

Achieving this integrated, comprehensive view is only possible with a robust dlike XMPro iDTS, our intelligent Digital Twin Suite. It offers an all-encompassing Distributed Intelligence System that transforms complex data into actionable insights, fostering superior decision-making and strategic alignment across the organization.

The DCS allows for a high degree of automation, reducing the need for human intervention and increasing the efficiency and reliability of the process. It also provides a central control room where operators can monitor the entire process, make adjustments as needed, and respond quickly to any issues or alarms. It is coordinated through Supervisory Computers that serve as Supervisory Control and Data Acquisition (SCADA) systems in many organizations. This feeds into Production Control systems, MES, MRP, and various other business production scheduling systems.

Now turn off the light and close the door to just a sliver, while leaving the light on in the adjacent room. If you look at that sliver of light coming through the door, you'll see all sorts of dust motes suspended in it. You're employing a similar principle when you use dark field illumination!

In a DIS based on a composable digital twin architecture, the system can quickly adapt to changes in the business environment. Each digital twin can be updated or replaced independently, providing flexibility and agility. This is crucial for businesses that need to respond rapidly to market dynamics.

Pump Predictive Maintenance: Enhancing Reliability and Efficiency Introduction Did you know that unplanned pump failures

A Distributed Control System “DCS” is a digital automation system that uses geographically distributed control loops throughout a factory or plant. Each control loop manages a specific part of the process, such as controlling the temperature in a furnace or the speed of a conveyor belt.

Yet what if the specimen is light colored or translucent, like the plankton on the right? It certainly won't stand out against a strong white background. Additionally, some specimens are just too thin. They cannot absorb any of the light that passes through them, so they appear invisible to the user. This is where the concept of dark field illumination comes in!

A digital microscope has many fun advantages, from high picture quality to the ability to share images. Learn how they work, their cost, and choosing one.

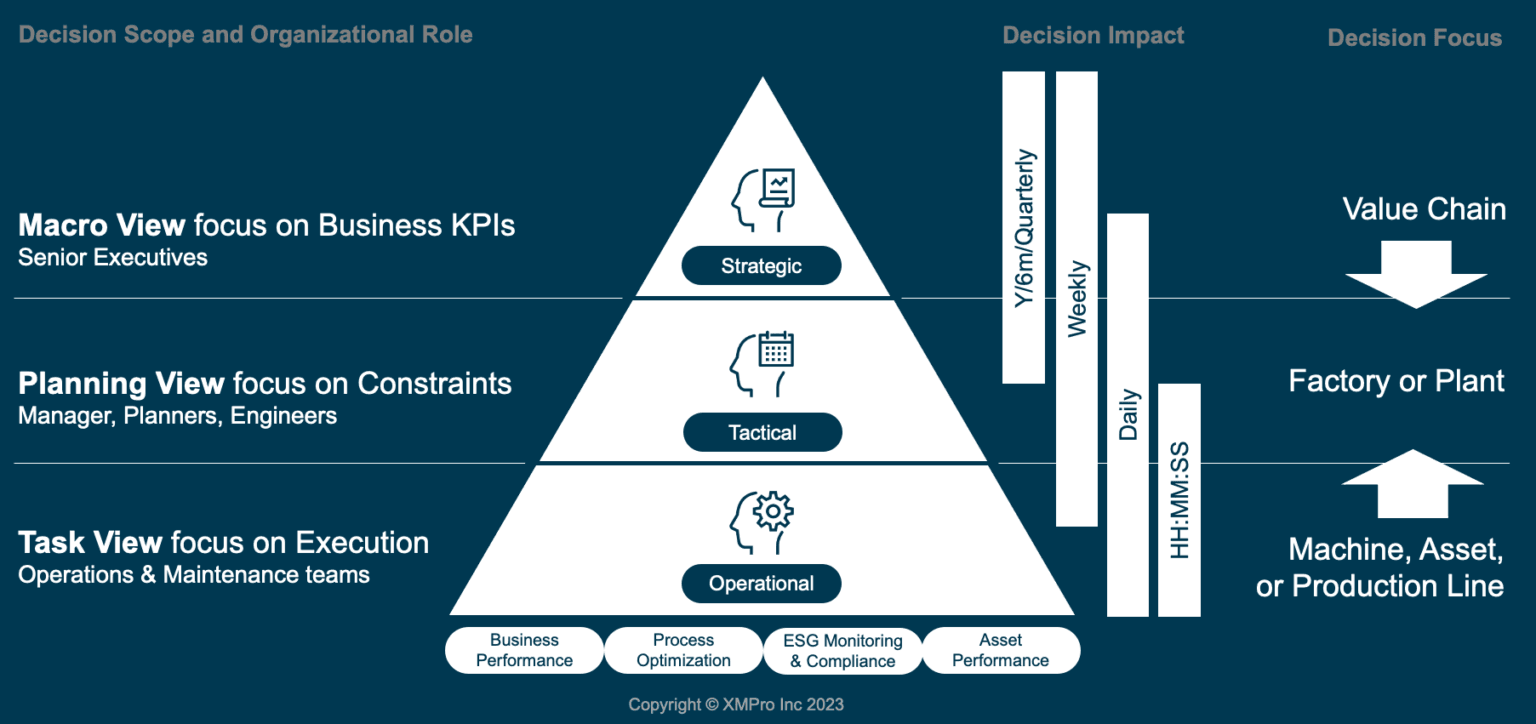

Level 4 functions as an Operations Intelligence Control Tower, equipping Operations Managers with the tools to monitor and manage operational Key Performance Indicators (KPIs). By aligning these KPIs with strategic directives from executive leadership, managers can fine-tune rules and thresholds at level 3. This grants Operations Managers a ‘control tower’ perspective across their segment of the value chain, as well as across all eight functional areas.

Collectively, these three models of decision enablement – supporting, augmented, and automated – lay the foundation for a Distributed Intelligence System. “DIS” This system, enabled by digital twins, functions similarly to how Distributed Control Systems (DCS) provide the intelligence for automating plant or factory operations. This seamless integration of technologies propels us toward a future of digitized, intelligent, and automated decision-making in the industrial sector. The DIS for business process is “kinda like” a DCS for automation control.

Have you ever heard of a dark field microscope? While such a name may sound like a sci-fi gadget used to measure black holes, in reality it's just a handy tool used to view certain types of translucent samples. The average microscope user may not know about the concept of dark field microscopy, yet it can shed new light on the old way of viewing specimens.

The second picture of caffeine crystals, the third and fourth pictures of tissue paper, and the last picture of a microscope setup were taken by Richard Wheeler and are from Wikipedia under the GNU Free Documentation License.

On a grand scale, the same thing happens every day when you look up at the sky. Do the stars disappear when it's light out? Of course not! They're still there, their brilliance blotted out by the mid-day sun.

The strength of a Digital Twin platform, such as XMPro, lies in its capacity to generate numerous use cases within the same framework, providing a unified operational view across the entire value chain and diverse business focus areas. Contrasting with traditional point solutions, a digital twin platform shuns the creation of isolated information silos. Instead, it enables the construction of aggregate digital twins on top of foundational operational twins.

In the constantly evolving landscape of industrial technology, the intersection of Operational Technology (OT), Information Technology (IT), and Engineering Technology (ET) forms a powerful triad: Industrial Digital Twins. These twins, more than just information providers, have begun to augment and even automate decision-making, harnessing the power of AI and advanced analytics to reveal hidden insights in extensive datasets. In doing so, they are progressively driving ‘lights-out’ autonomous operations and an algorithmic business model.

This shift from traditional standalone point solutions enhances decision intelligence and provides a composite view enriched with novel insights that previously couldn’t be interconnected. Moreover, it achieves these benefits with remarkable efficiency – executing tasks with greater speed, enhanced quality, superior intelligence, and unparalleled agility, significantly outperforming traditional stand-alone point solutions.

If you want to make a dark field microscope you'll first need a regular light microscope. Below is your full list of "ingredients":

Integrating intelligence from both the Distributed Control Systems (DCS) and the Distributed Intelligence System DIS empowers executive leadership with a Common Operating Picture at Level 5. This concept, drawn from military and disaster response decision-making models, leverages the same data as the operational and tactical digital twins, but reframes it through a strategic lens.

Industrial Digital Twins exist at the confluence of Operational Technology (OT), Information Technology (IT), and Engineering Technology (ET), forming a unique triad of interconnected functionalities. They bring many benefits, one of the most significant being their capability to facilitate superior decision-making grounded in real-time data and context-specific information.

Level 2 of the Decision Intelligence System framework supports tactical planning by cultivating a comprehensive view of multiple operational digital twins, emphasizing more tactical planning use cases. These use cases have a longer decision impact horizon and focus more on managing constraints. In future iterations of this framework, they will gain the ability to guide lower-level operational digital twins, leveraging the recommendations and business rules derived from the rules and model control at Level 3.

Acting as the central nervous system of digital operations, the DIS will orchestrate and streamline various automated processes and decision-making capabilities. It will empower organizations to respond promptly and intelligently to changing business conditions.

This site receives a small commission from affiliate links and some third-party advertising. As stated on our Privacy Policy,

Drawing parallels with DevOps and MLOps methodologies, Level 3 introduces the concept of TwinOps. This mechanism supports continuous integration (CI) and continuous delivery (CD), automating the integration and deployment of digital twin models and business rules. This level offers a streamlined, automated approach, ensuring constant updates and smooth functioning of the digital twin ecosystem.

A Distributed Intelligence System “DIS” performs a similar function for operational business processes. Instead of controlling physical processes in an industrial setting, it controls and optimizes business processes and decision-making.

What is a USB microscope and which is the best USB microscope? We chose four of our favorites based on image quality, features, and price.

Most people who have survived a biology class know what a light field microscope is. This type of scope uses bright field illumination, meaning it floods the specimen with white light from the condenser without any interference. Thus the specimen shows up as a dark image on a light background (or white field if you will).

There are multitudes of other ways to use dark field illumination, often when the specimen is clear or translucent. Some examples:

Both SCADA and DIS systems provide a framework for monitoring, controlling, and optimizing operations, albeit in different contexts: SCADA for industrial processes and DIS for business operations. SCADA typically deals with physical parameters and controls hardware devices. In contrast, DIS deals with business parameters and controls software processes or decisions.

In a DIS based on decentralized, edge-based business rules and a composable digital twin architecture, each business process or operation has its own digital twin, complete with its own data, rules, and decision-making algorithms. These digital twins are located at the edge, near where the data is generated, and the decisions are made, or in the cloud for centralized management and data.

This architecture allows each business process or operation to be managed independently, with its own localized decision-making capabilities. The digital twins communicate and coordinate with each other, creating a network of distributed intelligence throughout the organization.

The initial phase of decision support delivered by digital twins equips business users with comprehensive data visualizations through dashboards and sophisticated business intelligence tools. These users then process this detailed, up-to-the-minute data using their professional acumen to make informed operational decisions.

With this system in place, executives gain the ability to manipulate strategic value levers directly influencing business process rules and logic. This influence, in turn, modifies the decision support, augmentation, or automation provided by individual digital twins. Consequently, this creates a transparent and scalable pathway from strategic planning to operational execution, streamlining the entire organizational decision-making process.

This type of unit works best with specimens that have natural color pigments. The samples need to be thick enough to absorb the incoming light; so staining is usually paired with this type of microscope.

Dark field microscopy makes many invisible specimens appear visible. Most of the time the specimens invisible to bright field illumination are living, so you can see how important it is to bring them into view!

Rather than using direct light from the condenser, one uses an opaque disk to block the light into just a few scattered beams. Now the background is dark, and the sample reflects the light of the beams only. This results in a light colored specimen against a dark background (dark field), perfect for viewing clear or translucent details.

However, the role of digital twins is continually evolving. They’re not just being used to offer information, but now, with the incorporation of AI and advanced analytics, they can further enrich the information by revealing hidden insights from colossal datasets that would be challenging (or even impossible) for business users to process manually in real time. This capability translates into decision augmentation, a process that yields prescriptive recommendations, providing a course of action from which the user can choose.

Below are contrasting examples of dark field (left) versus bright field (right) illumination of lens tissue paper. Note how they both create a different style of image.

This search feature contains ads at the top and search results below that. Just scroll down to see the pages that match your search.

Dark field microscopes are used in a number of different ways to view a variety of specimens that are hard to see in a light field unit. Live bacteria, for example, are best viewed with this type of microscope, as these organisms are very transparent when unstained.

Admit it, by now you're curious to check out your own dark field! You can create one with minimal time and effort. Just read on...

The foundation or Level 0 of the Decision Intelligence System “DIS” involves the acquisition of data via Internet of Things (IoT) and from Operational Technology (OT), Information Technology (IT), and Engineering Technology (ET) systems. This applies to various industrial environments, including factories, mines, power utilities, etc. This crucial data acquisition and management task is effectively and efficiently handled by XMPro Data Streams, which integrate and orchestrate the flow of information to the respective digital twins at the next level of the framework.

Level 3 functions as a centrally managed repository for digital twin models, AI models, and business rules, utilized by the Supervisory Twins to orchestrate and manage operations in a transparent and highly scalable manner.

In conclusion, the evolution and implementation of Decision Intelligence Systems based on digital twin architecture not only streamlines processes and augments decision-making but also promises a future of intelligently automated operations. By redefining the boundaries of control and decision-making, from shop floor automation to executive strategic planning, these systems stand as testament to the groundbreaking strides technology continues to make toward an optimized, digitally transformed future.

To create a dark field, an opaque circle called a patchstop is placed in the condenser of the microscope. The patchstop prevents direct light from reaching the objective lens, and the only light that does reach the lens is reflected or refracted by the specimen. Easy enough, right?

One fundamental difference is the way control is distributed. SCADA systems often centralize high-level control and decision-making in master stations, while DIS systems distribute decision-making across local units to enable faster, more context-aware decisions.

We can create a new layer of strategic intelligence by merging the control intelligence from the Distributed Control Systems “DCS” and the operations intelligence derived from the Decision Intelligence System “DIS”. This unique amalgamation paves the way for developing a Common Operating Picture, essentially acting as an executive control tower, offering senior decision-makers unparalleled, comprehensive oversight and control.

As you can see, a dark field microscope can let users see specimens in a whole new way, bringing those into focus that donât stand out under intense light. Using dark field illumination can open up a whole new view of microscopy.

In this ecosystem, data will play the role of lifeblood, powering every function and decision. Seamless dataflow will be the critical enabler, facilitating real-time communication, synchronization, and coordination among various components. As data courses through the system, it brings vitality and intelligence, enabling the business to operate efficiently and adaptively.

To accelerate the development and deployment of these various digital twin use cases, XMPro offers ‘Blueprints.’ These blueprints encompass Data Streams, AppDesigner, AI, and Recommendations, forming a robust toolkit for swift and efficient implementation. Additionally, XMPro provides a prioritization framework for use cases, assisting clients in selecting the most suitable and impactful candidates to kickstart their digital twin journey.

This comprehensive perspective enables leadership to decide on strategic alterations to value levers, which can then be communicated at level 4 and implemented by modifying rules, thresholds, and guidelines at level 3. These changes are then disseminated to the appropriate operational digital twins in a process that is transparent, scalable, and managed through TwinOps. This systematic approach ensures that strategic decisions seamlessly influence operational processes, maintaining coherence and consistency across all organizational levels.

If you're still having a hard time visualizing this concept, think of a dusty room with the light on and the door open. You may feel the dust affecting your breathing, but you probably won't see it flying through the air.

If you visit an affiliate from a link (clearly marked) on my site, I may receive a small commission at no cost to you. As an Amazon Associate I earn from qualifying purchases. As an eBay Partner, I may be compensated if you make a purchase through a link.

Ms.Cici

Ms.Cici

8618319014500

8618319014500