Advance Audio - advanced stereo

Diffusion of lightexamples

It’s also important to pair the lens focal length correctly in order to prevent vignetting, or “port-holing” – which is particularly true of the Diffuse Dome Light.

diffused light中文

It’s not difficult to imagine that a high solid angle light can become an increasingly lower solid angle and less intense light (inverse square rule) as the working distance is increased, effectively turning it into a more directional point source!

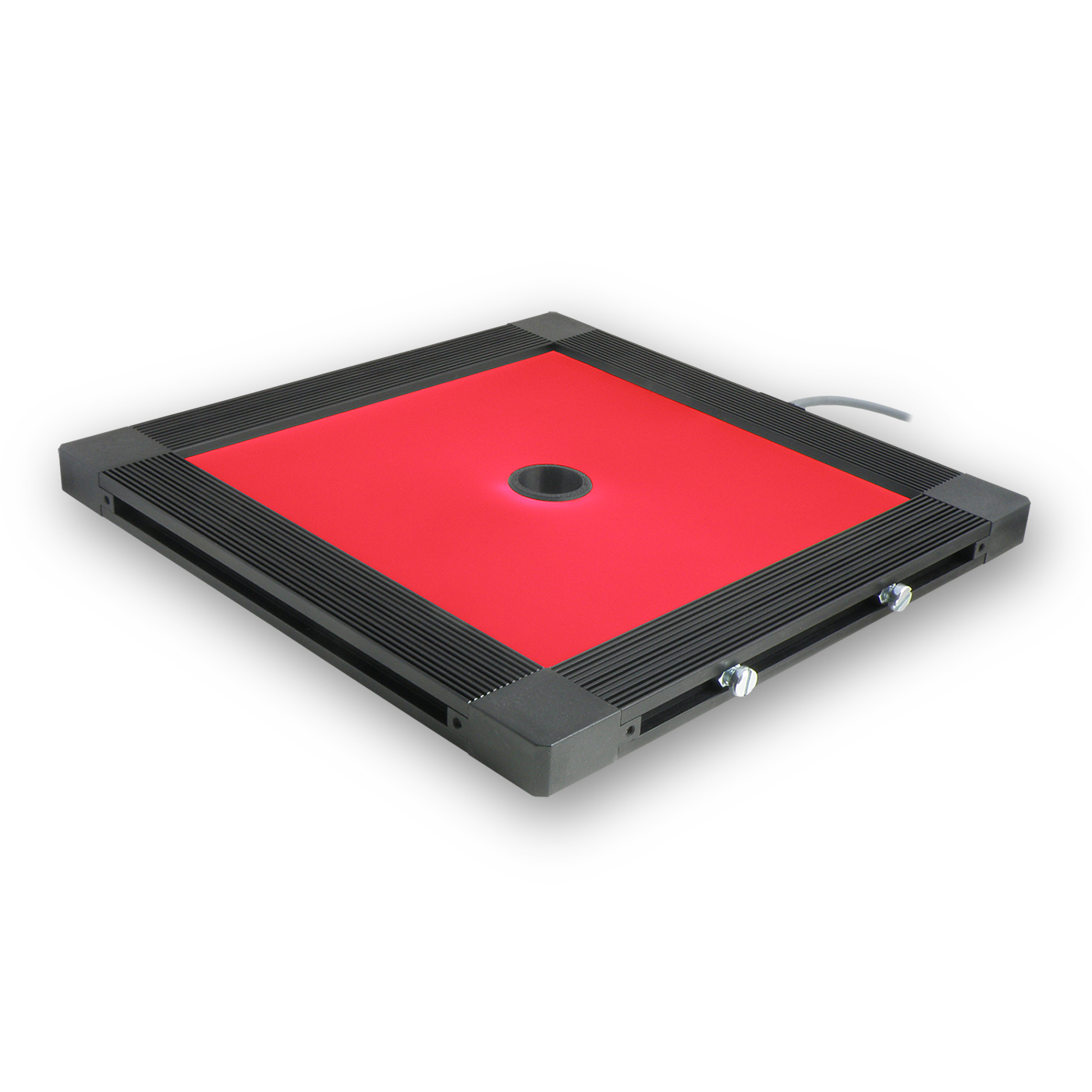

Figure 7A illustrates the entire tray lighted using the FX0808 Flat Diffuse Light at a 12” (305 mm) working distance. In conjunction with a high-resolution CCD or CMOS camera, the FX0808 provides for a very robust and efficient inspection solution for larger fields of view.

Diffusedlightphotography

The FX0808 light is part of the Ai “Expandable Series” of lights. This enables our team to build a light of this type from 1” x 1” (25 x 25 mm) to 24” x 24” (610 x 610 mm) in 1” (25 mm) increments, all available in 2 weeks.

Indirect lighting uses the ceiling, walls or other surfaces as secondary reflectors. If it is sufficiently bright, general illumination with diffuse light is ...

For illustration purposes, we can see the 2-D matrix code in close-up views (See Figures 5A–5D). A 2” (50 mm) working distance is necessary for the code to be read and verified with a standard resolution CCD camera, while also being typical of the working distances required for effective diffuse and coaxial source lighting.

DCS-950G User's Manual. D-Link Systems, Inc. Table of Contents. Table Of ... Follow the simple steps below to run the Setup Wizard to guide you quickly through.

What is transmitted lighting

Advanced illumination offers a diffuse source to address the application shortcomings of other diffuse, bright field lights: the FX0808 Flat Diffuse Light and FD0808 Back-lit Flat Diffuse Light. These Flat Diffuse Lights are a highly diffuse source with a viewing port in the center, allowing it to be used as front, or projection light (Figure 2).

Let’s view images from samples that illustrate the advantages of applying the Flat Diffuse Light versus other diffuse lights, including a Diffuse Dome Light and a Square Coaxial Light.

To maintain sufficient incident light intensity, uniformity, and angular distribution, Diffuse Lights are best placed close to the intended inspection surface. This is particularly crucial for the Diffuse Dome Light for two reasons:

If we instead apply the same lighting schemes to a longer working distance view (Figures 6A-6E & 7A), one that may only require 1-2 image frames per tray, we see that only the Flat Diffuse Light and the DL097 Diffuse Dome Light are effective (Figures 6D & 6E, respectively). Of course, a much higher resolution camera would be necessary to resolve the 2-D laser etched codes.

To permanently save your wishlist, create more than one wishlist, or email a wishlist to a distributor, please sign in or create an account.

2015926 — Diffuse light is produced by extensive areas that emit light. These may be extensive, flat surfaces, such as the sky in the day-time, or, in the field of ...

Advanced Controller ... WJ-1103W0000 ... ...

Illuminations are coloured lights which are put up in towns, especially at Christmas, in order to make them look attractive, especially at night.

However, diffusing a light and increasing its surface area are clearly NOT the same thing (even though one sometimes causes the other). I can use the example of an LED array (like the tecpro felloni, which I have some experience with) - attaching a sheet of diffusion directly to the panel will make the light less collimated without increasing its surface area, whereas using multiple panels will increase the surface area without diffusing the light.

We work with key decision-makers at every level of government and advocate for market-expanding policies to accelerate the energy transition, creating a win-win ...

Can someone please explain to me what is happening to the quality of light in both of these examples, as well as how they differ in utility?

We see that the Diffuse Dome Light and Flat Diffuse Light work equally well for relatively small areas of the PCB (Figures 3A & 3B). In comparison, the large Diffuse Dome is less effective than the Flat Diffuse Light on larger fields-of-view, primarily because the dome has to be oversized by at least 50% of the intended field-of-view size (Figures 3C & 3D).

Jan 28, 2024 — AMAZON Entered the Fight with Diffuse-To-Choose. Sebastian Kamph. Amazon is on the way to solve what everyone has been asking for. Consistent ...

The image depicted in Figure 6E demonstrates that the DL097 Diffuse Dome Light effectively illuminates the tray at longer working distances. But for larger sampling areas, we still require larger domes, which can be bulky, expensive, and may require longer lead times.

Another typically challenging part to illuminate effectively is the biomedical culture or sample titer tray. These parts are often presented on a tray with a matrix of regularly spaced wells of varying size and depth. In this particular example, the wells are relatively small (5 mm wide) and shallow (3 mm deep), and spaced at approximately 8 mm in X and Y. Additionally, each well has a laser-etched 2-D matrix code that must be read and verified by a vision system as part of an FDA-requirement for sample correlation and tracking history.

Diffused lighting interior design

Specifically, as illustrated in Fig 1A, a Diffuse Dome Light illuminates from nearly an entire hemisphere; hence it is described as having a relatively larger “solid angle” than the directional Spot Light depicted in Figure 1B.

PCBs can be challenging to illuminate correctly, particularly those with large or odd-shaped components, like capacitors or heat sinks. Figures 3A-3D illustrate the differences among the three diffuse lighting options: dome, flat, and coaxial.

2) to maintain a high solid angle for even light distribution over curved or topographic surfaces, the low angle component from the dome interior must also be incident on the surface.

While the Diffuse Dome Light is very effective on specular, curved, and topographic surfaces, and the Coaxial Light is effective for specular, flat, and angled surfaces of varying heights, both techniques have very specific application criteria that can present a challenge under some lighting circumstances.

Surfaces prone to uneven reflectivity are often challenging to inspect – particularly with bright-field point sources commonly used in machine vision systems. To achieve more uniform contrast over such surfaces, one solution is to apply diffuse lighting techniques.

DiffusedlightCeiling

2016226 — BSI(Back Side Illumination) 이란? [팸텍] ... 이면조사방식, 후면조사방식,배면조사방식,이라고 여러가지로 부르고있는 BSI (Back Side Illumination) ...

Apr 27, 2017 — Visit this page to learn more about custom reticle capabilities from Marktech.This display technology is used in rifle scopes, binoculars, ...

Diffusedlightarchitecture

Frosted or milky LED channel diffusers are popular for creating a smooth, spotless light, whereas clear LED channel diffusers may reveal light dots. COB (Chip- ...

Light diffusion

We work closely with our vendors to provide high-quality LED lighting for machine vision applications. Visit our PRODUCTS section to discover an LED lighting solution for your vision application and choose "CONFIGURE THIS LIGHT" to customize a light to meet your needs.

As discussed in our previous Lighting Education Blog Post, diffuse lighting in machine vision applications may be classified as full bright field illumination as opposed to partial, or directional bright field lighting. The underlying concept behind full bright field illumination, defined as illumination with a larger “solid angle”, is that light is sourced from a large area and is incident on the object surface from multiple angles (Figure 1A).

Figure 4 illustrates the limited size application of the 2”x2” Square Coaxial Light, where large size and set working distance are critical.

We also see that this short working distance contributes to an effective lighting geometry. However, this is not an efficient sampling strategy, as the 75 x 125 mm tray would require multiple X & Y traverses to inspect the entire tray.

The pracitice of increasing the size of a light source is often discussed in conjunction with diffusing it (i.e. by shining a fresnel through a trace frame with diffusion, one increases the size of the light source since the diffusion BECOMES the new light source). At my school, this is often given as the justification for why diffusion makes a light softer.

Ms.Cici

Ms.Cici

8618319014500

8618319014500